Aeration tyre

A technology for pneumatic tires and tires, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc. It can solve problems such as the deterioration of bump resistance to partial wear, achieve white noise, improve performance, The effect of reducing the suction noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

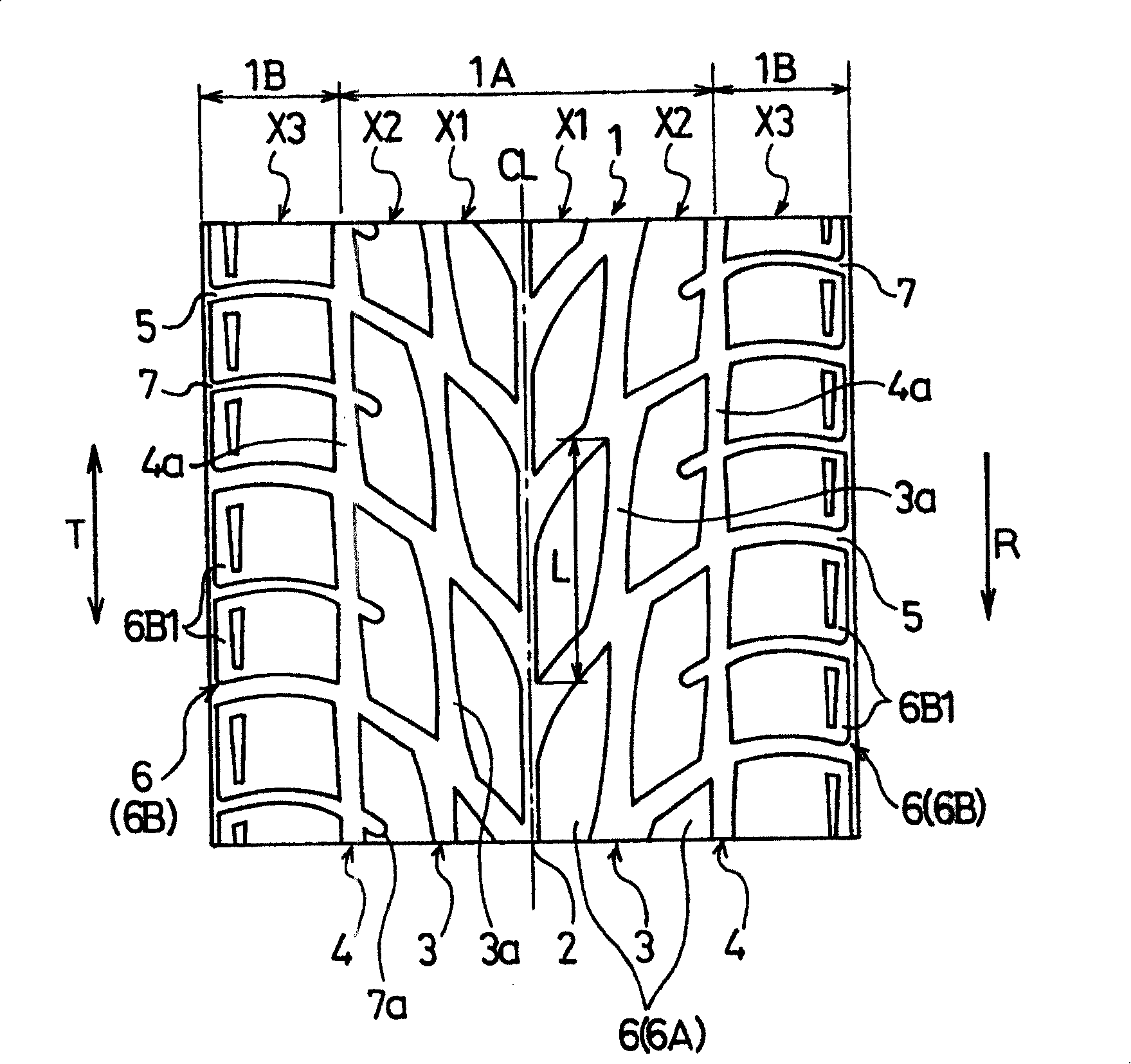

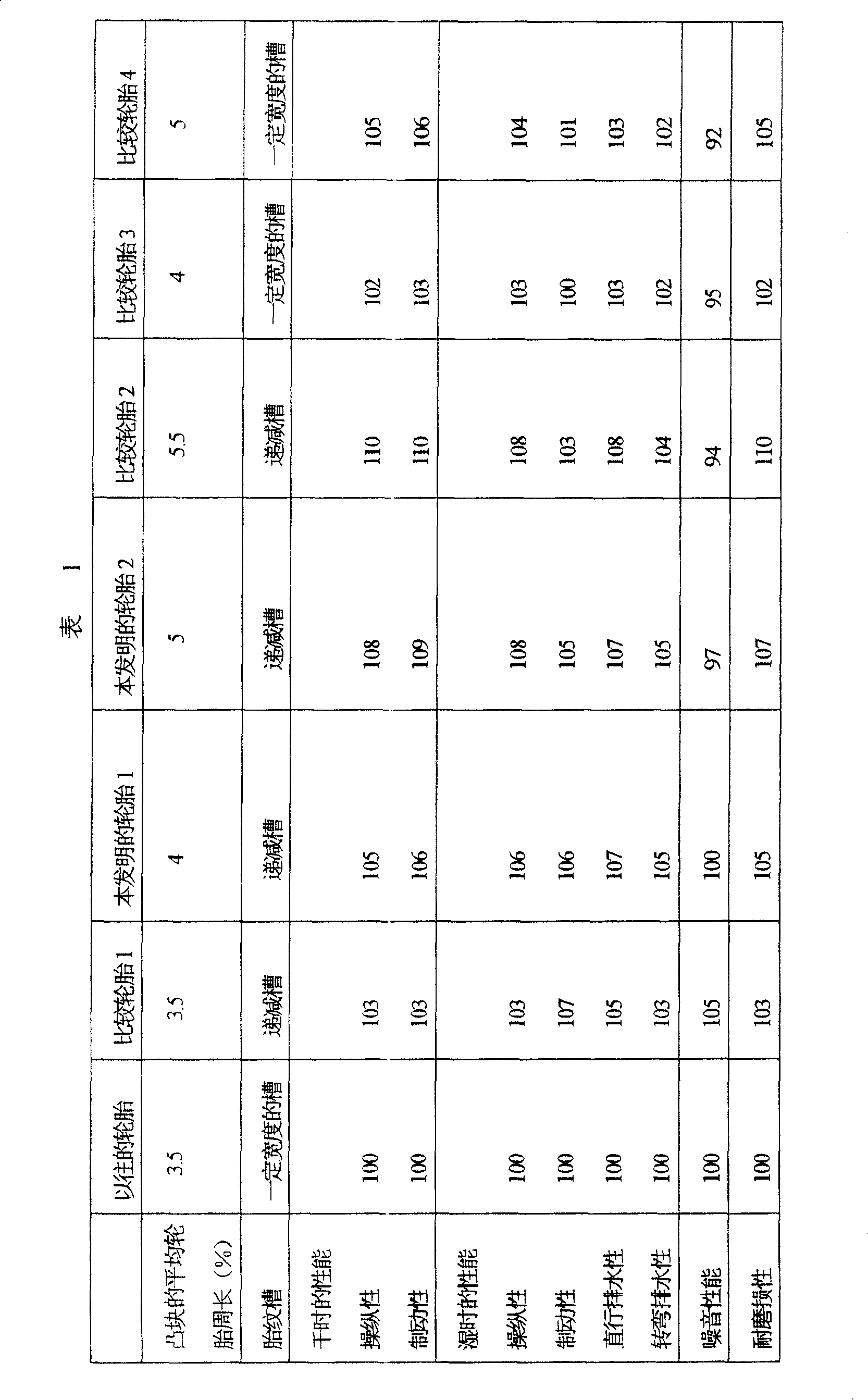

[0036] The size of all the tires used is 225 / 45ZR17, and the structures are manufactured respectively as listed in Table 1. figure 1 Invention tire 1-2, comparative tire 1-4 and the conventional tire with the average tire circumference length of the center bump and sipes shown, and the conventional tire in which the The extended linear main grooves and the sipes extending in the tire width direction form a block pattern.

[0037] In Tire 1-2 of the present invention and Comparative Tire 1-4, the groove width of the narrow grooves was 3 mm, and the groove area ratio was 33%. In addition, the average tire circumferential length of the bumps in the conventional tire is 3.5% of the tire circumferential length on the tire center line, and the groove area ratio is 33%.

[0038] Each of the test tires was assembled on a rim with a rim size of 17×7 1 / 2JJ, the air pressure reached 220kPa, and then assembled on a vehicle with a displacement of 2500cc. Time performance, noise performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com