Patents

Literature

39results about How to "Reduce suction noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

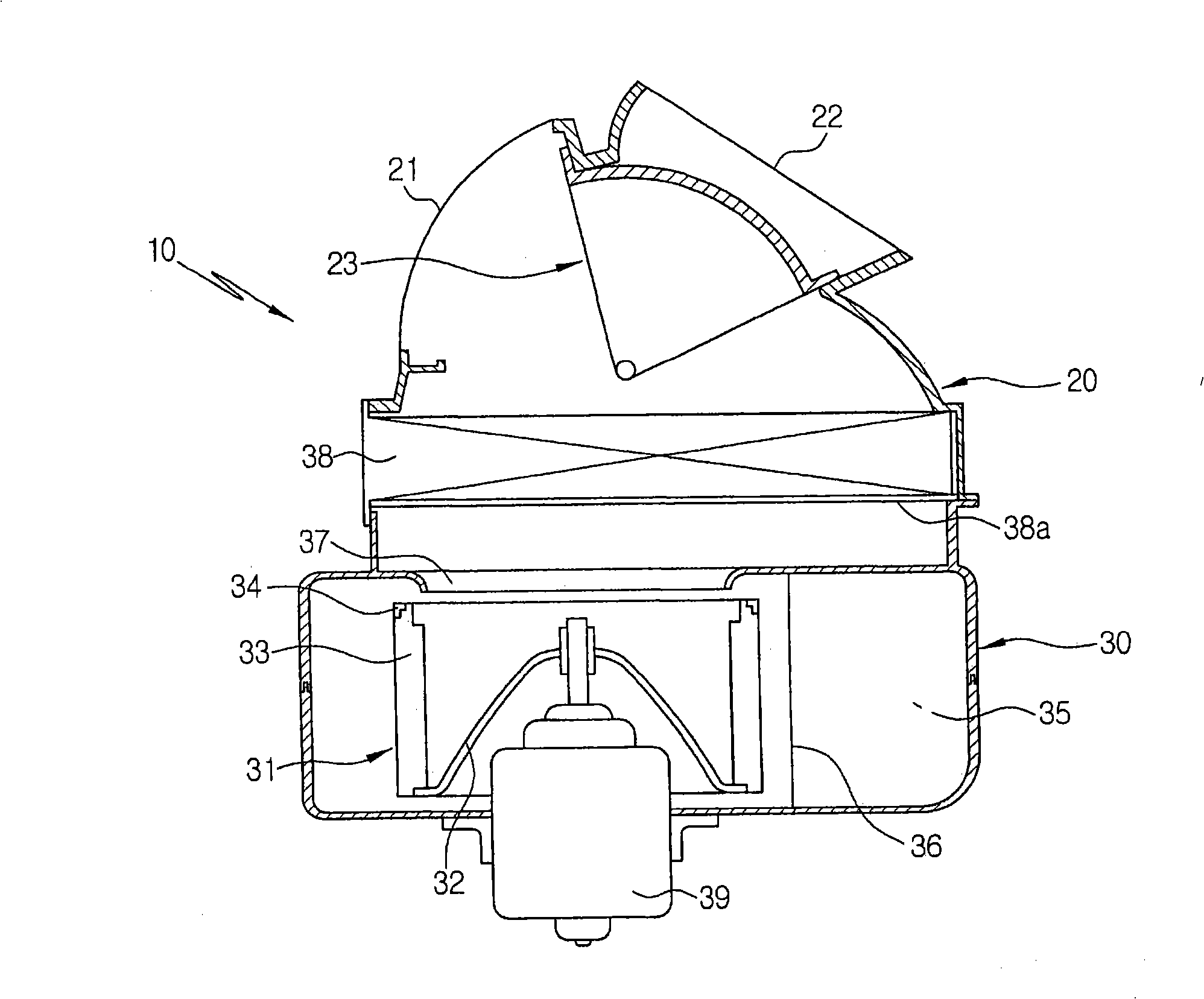

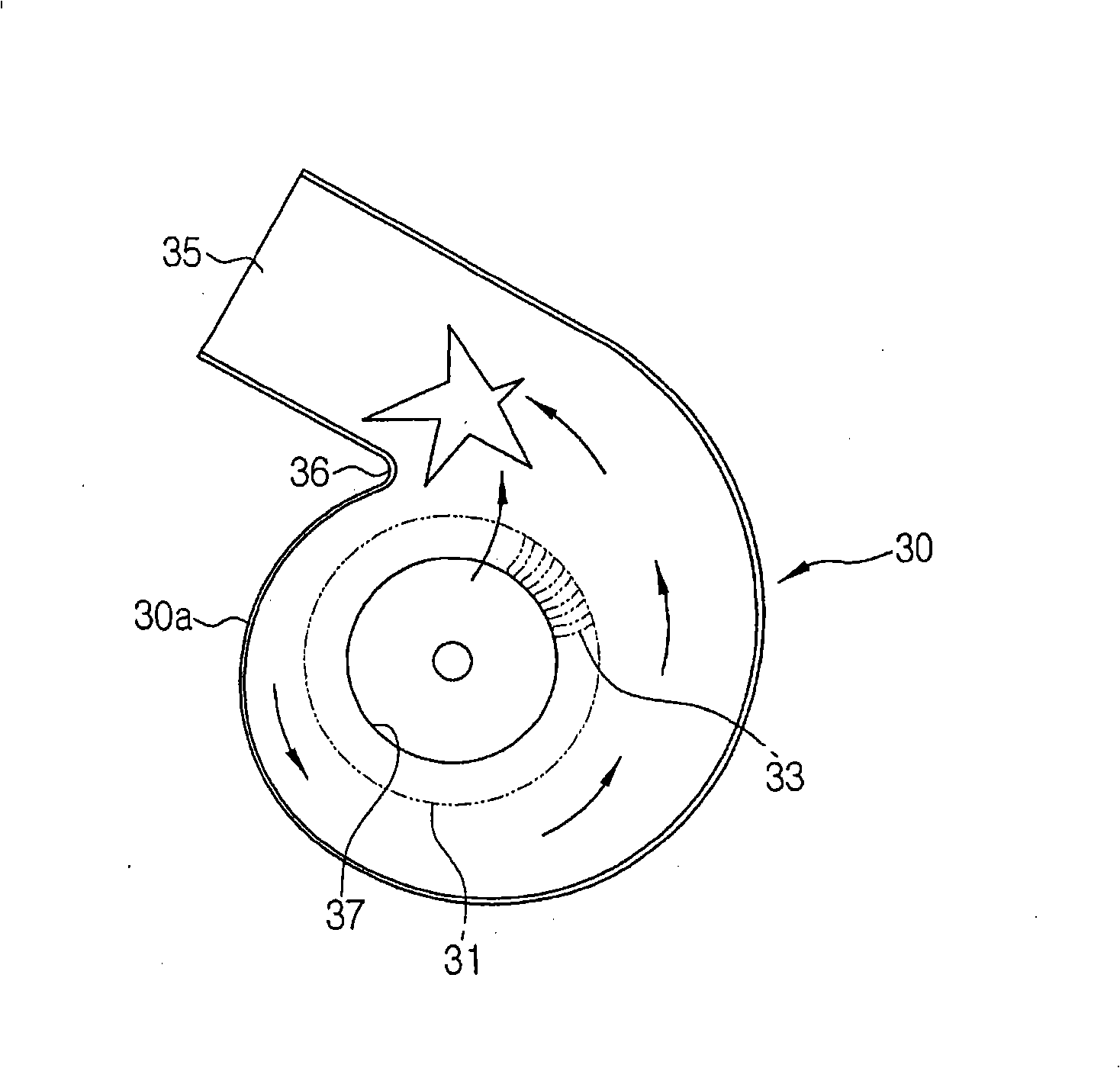

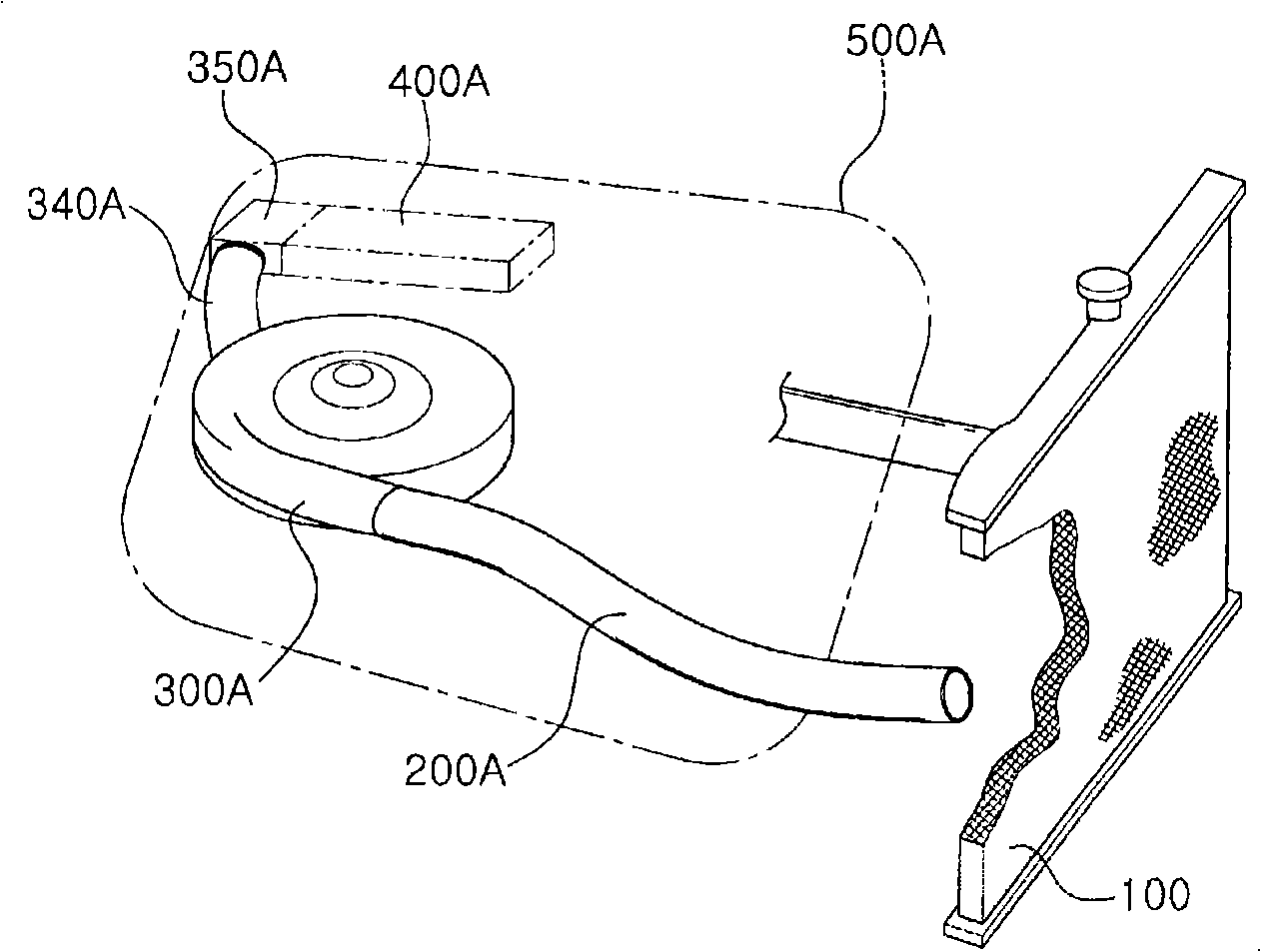

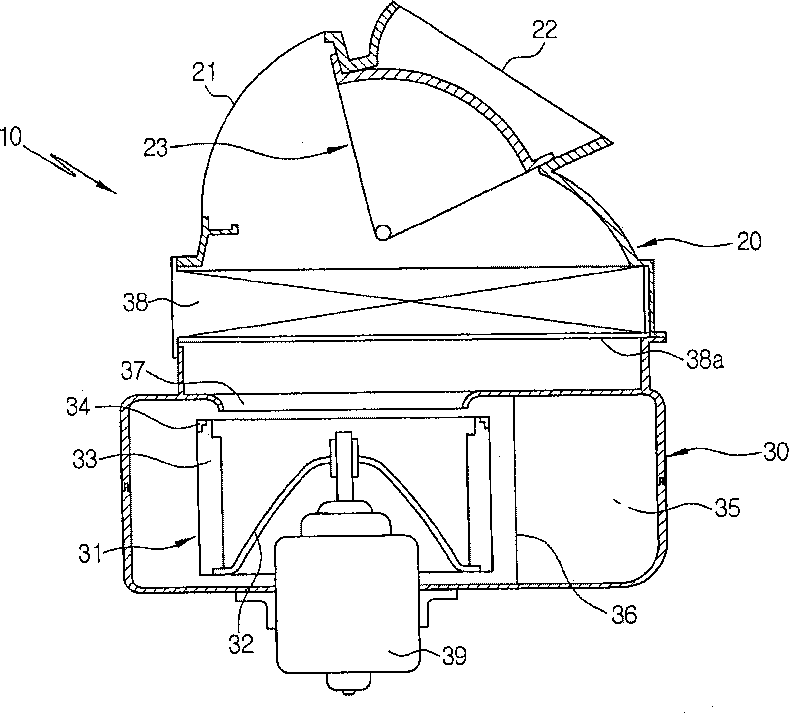

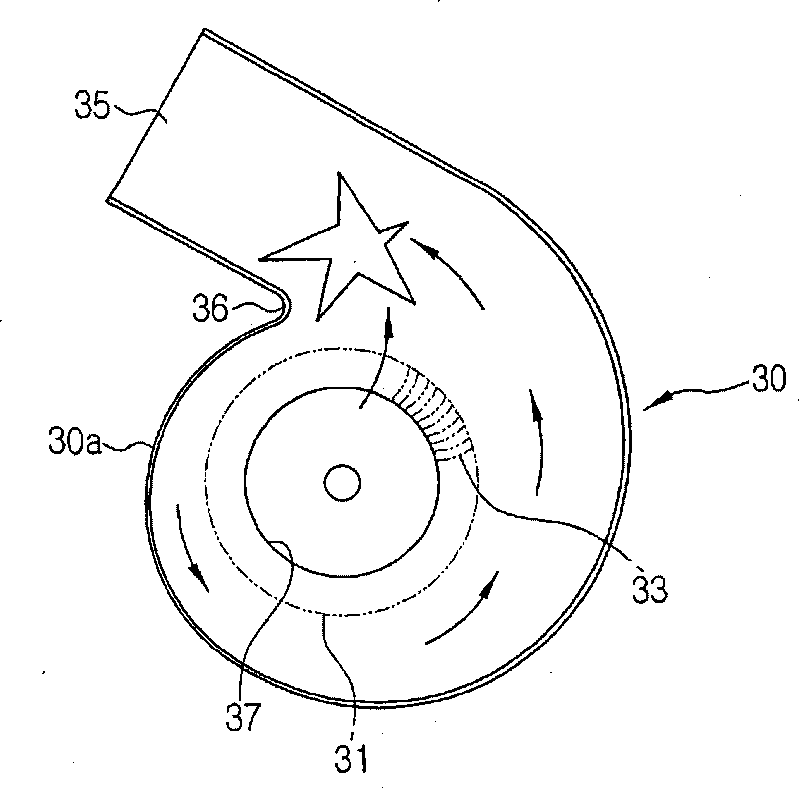

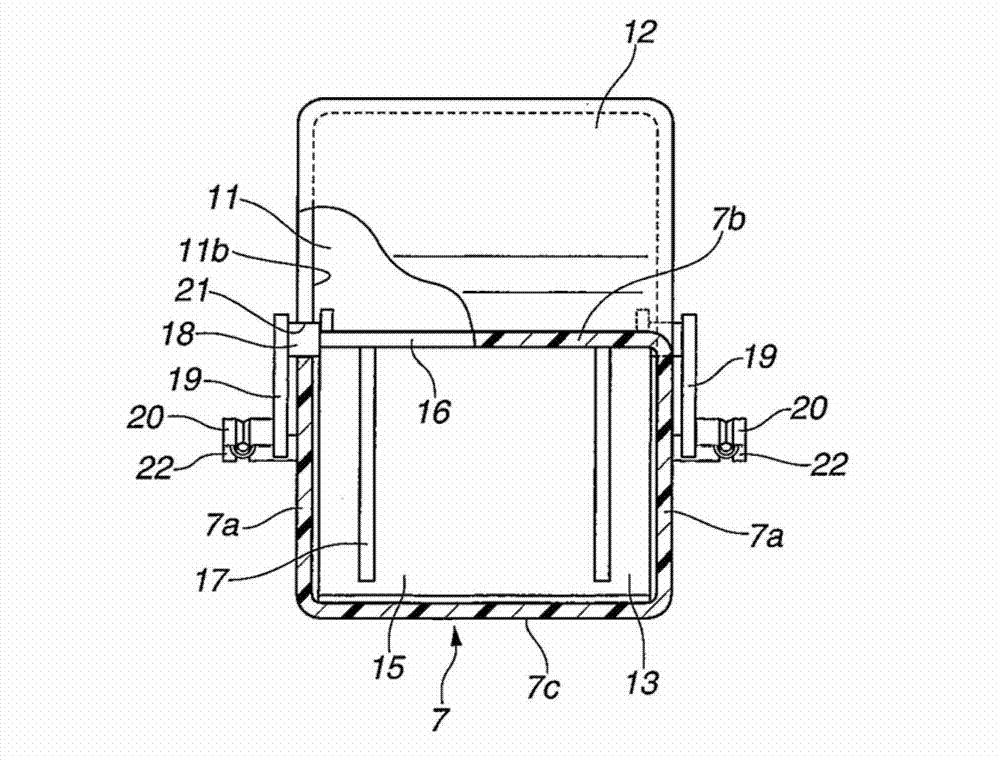

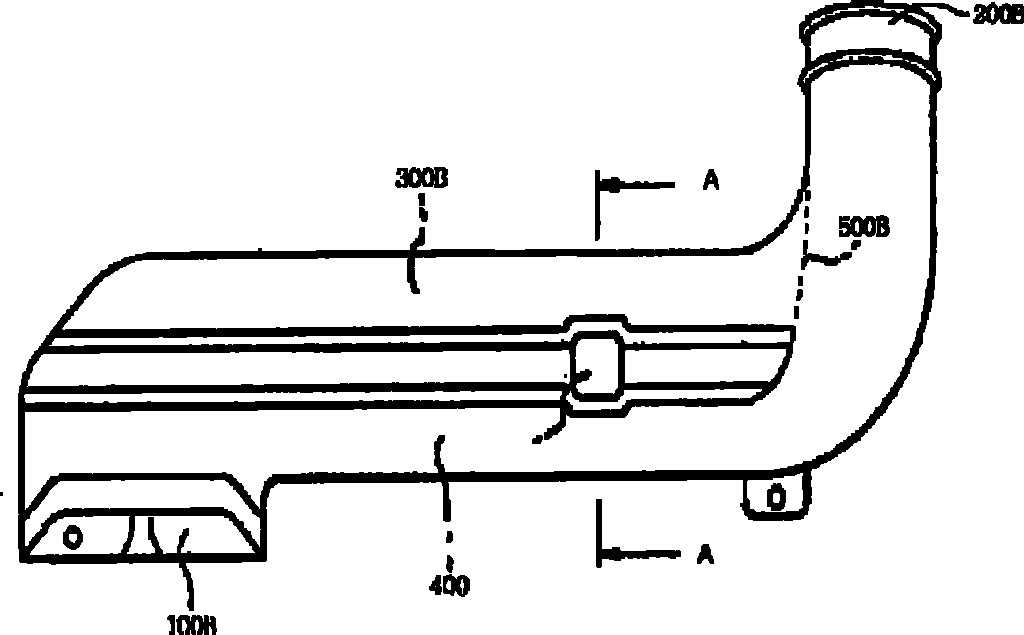

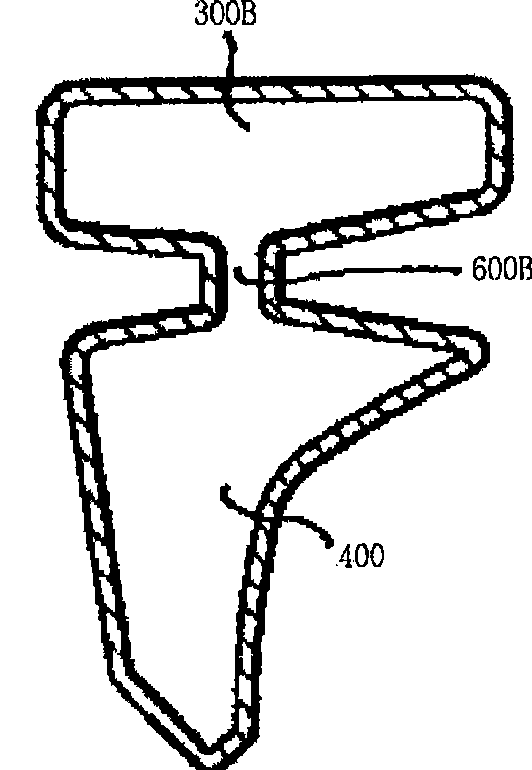

Blower for vehicles

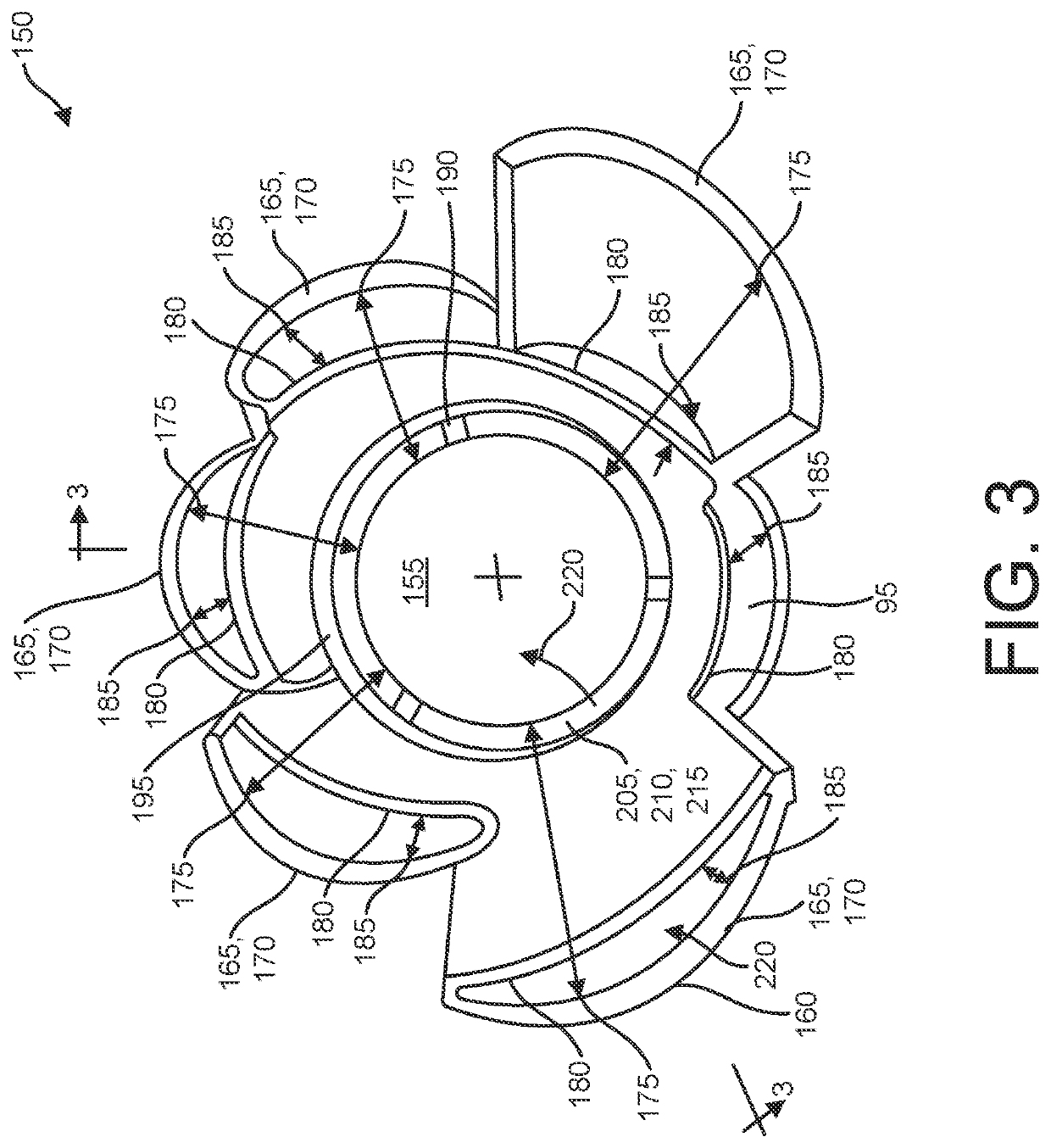

ActiveUS20080253879A1Reduce suction noiseAvoid deformationPump componentsWind motor controlAir filterInjection moulding

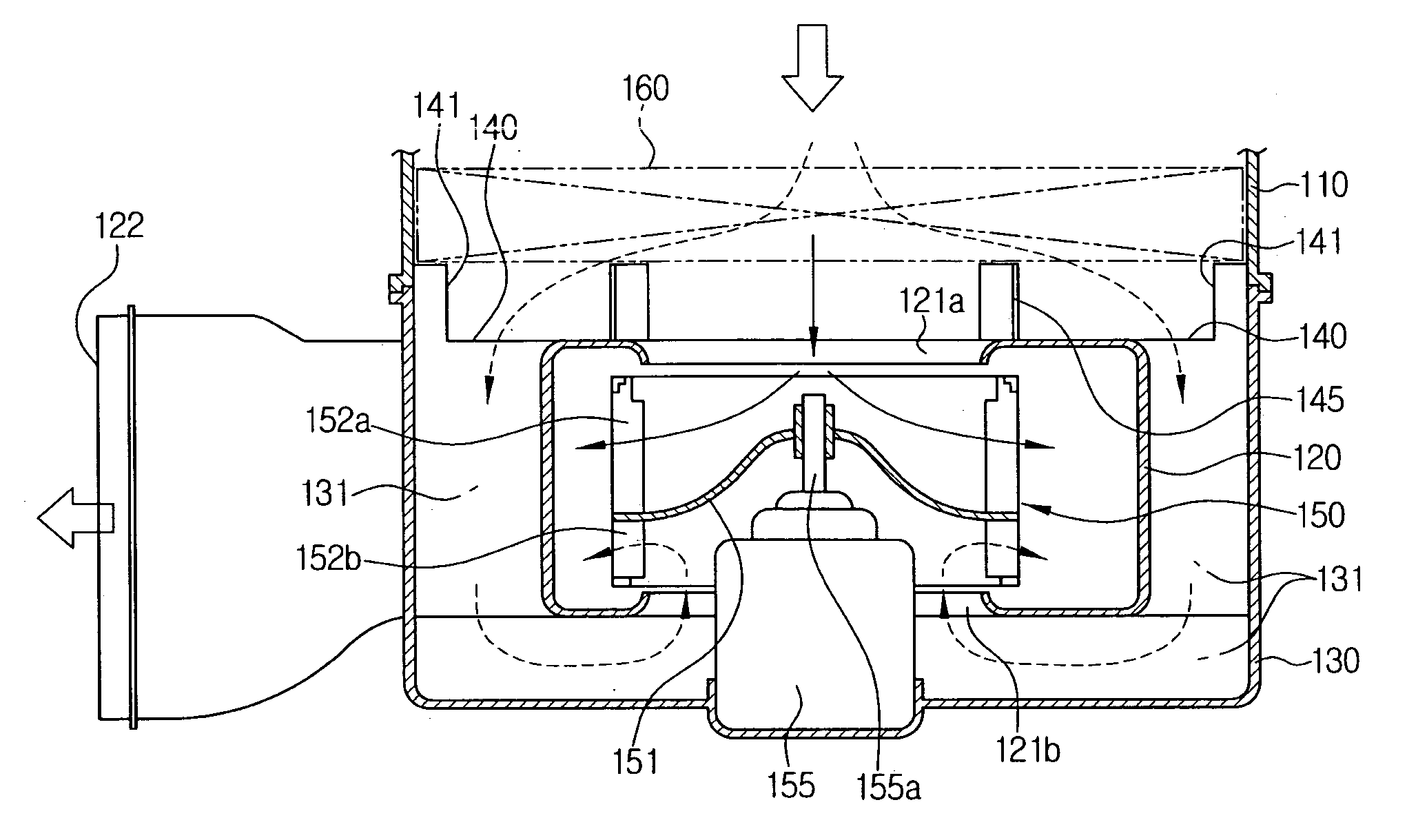

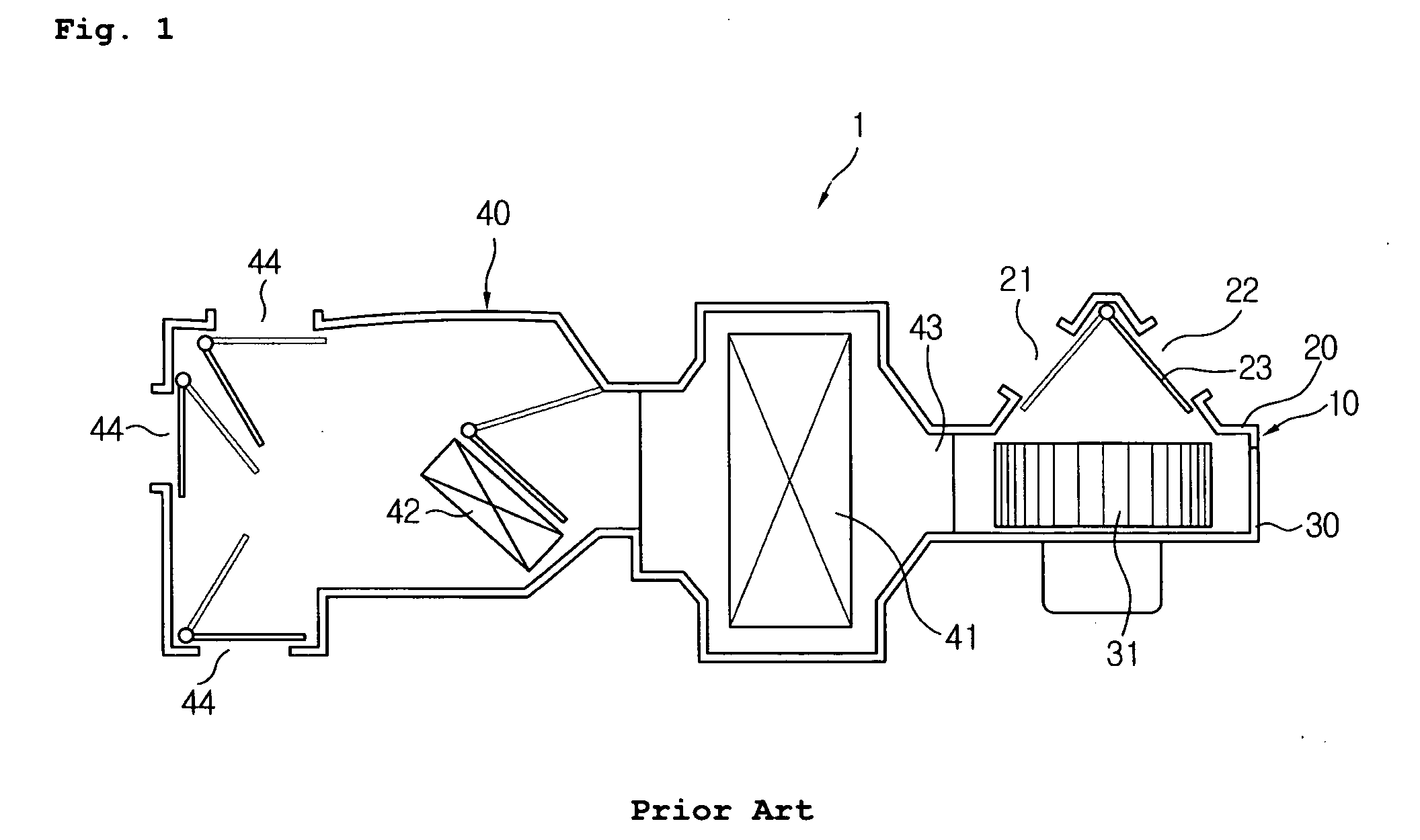

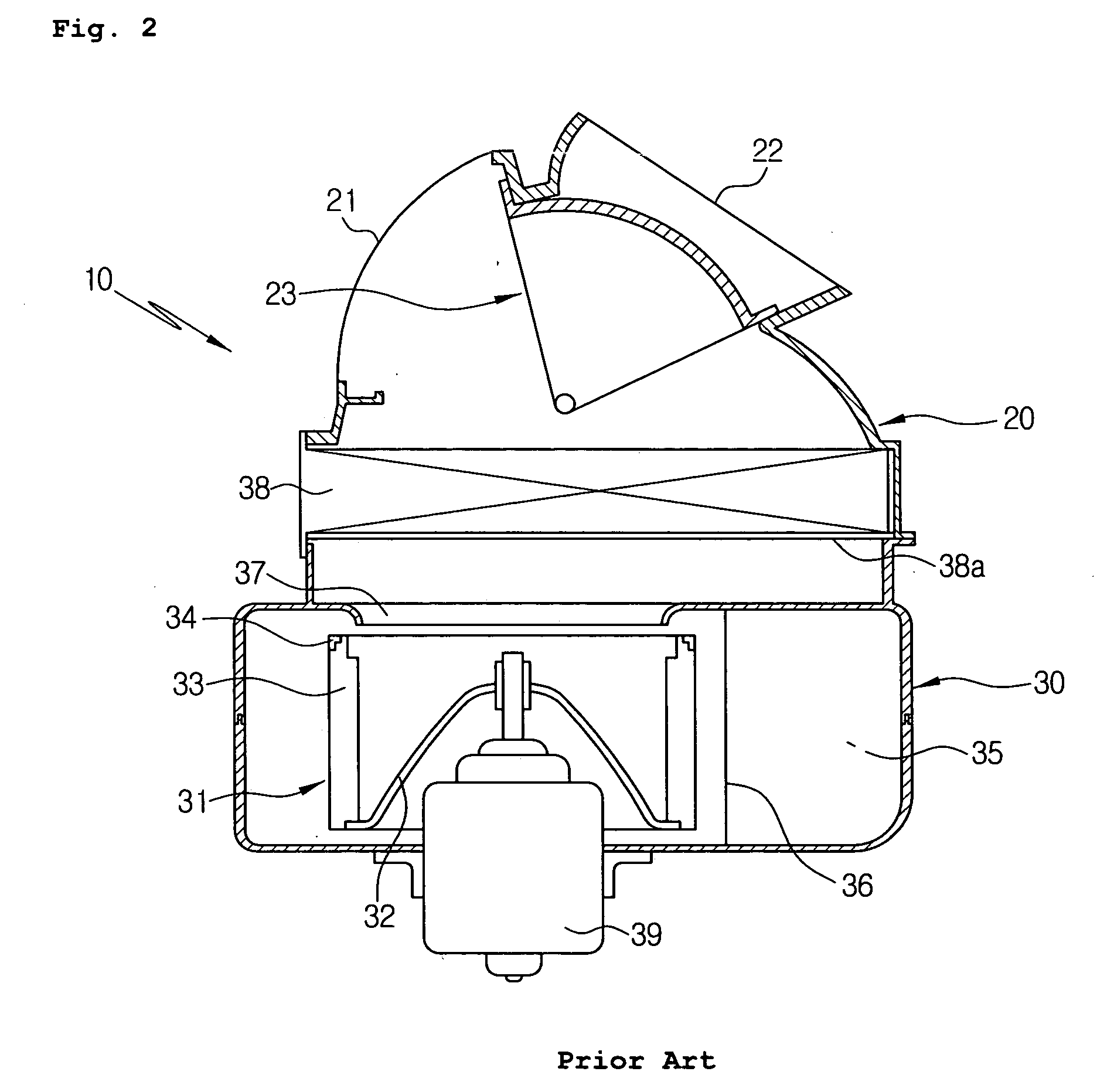

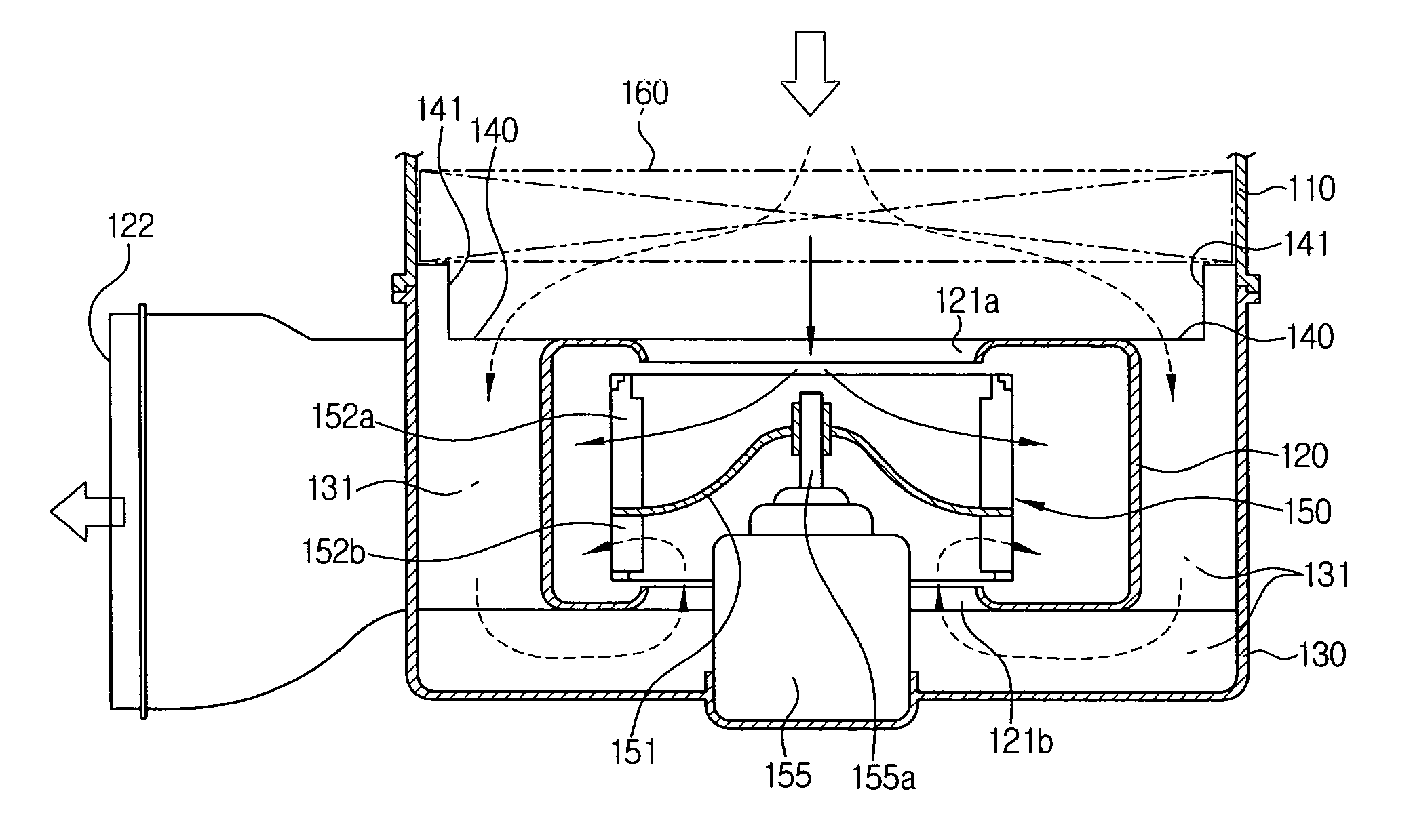

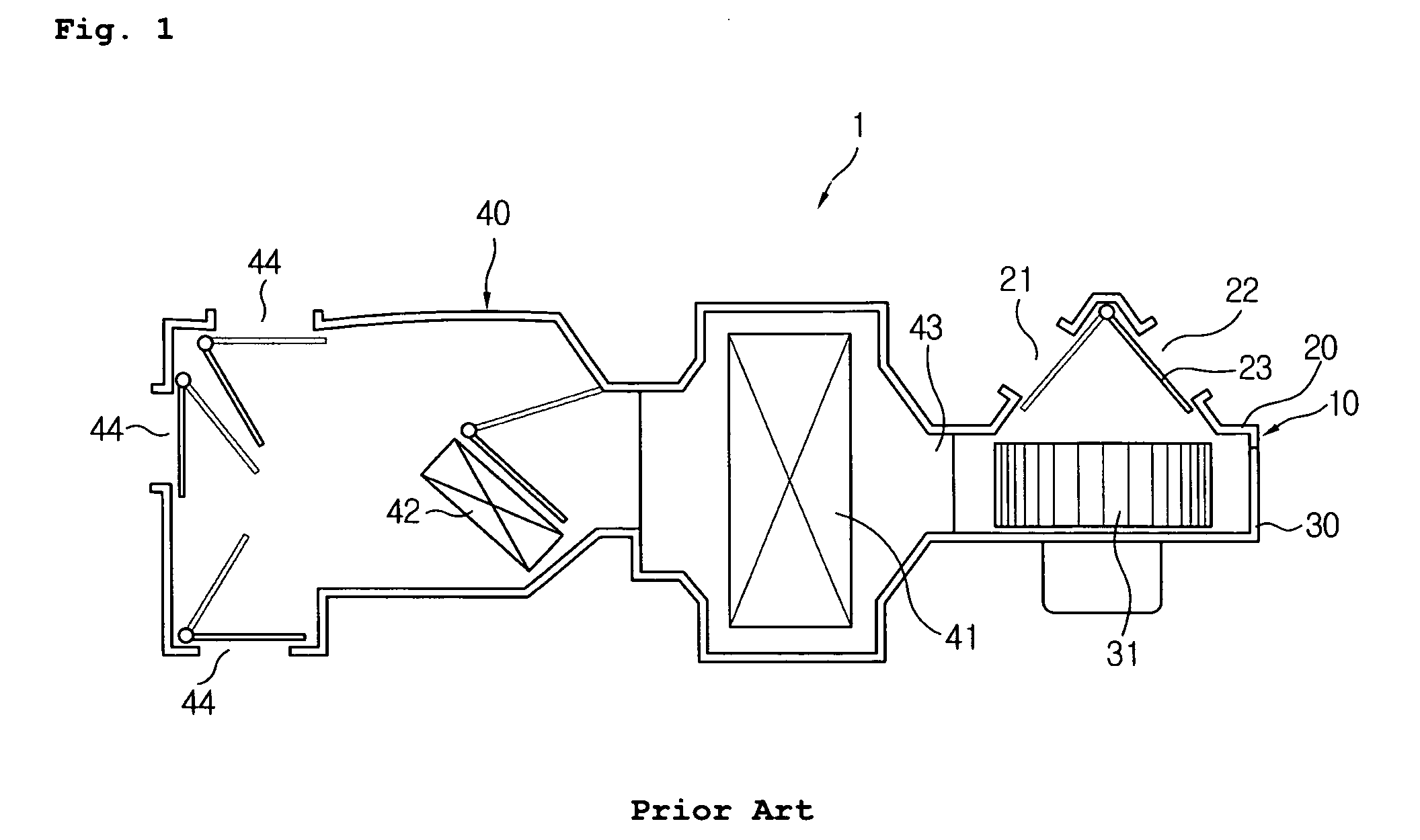

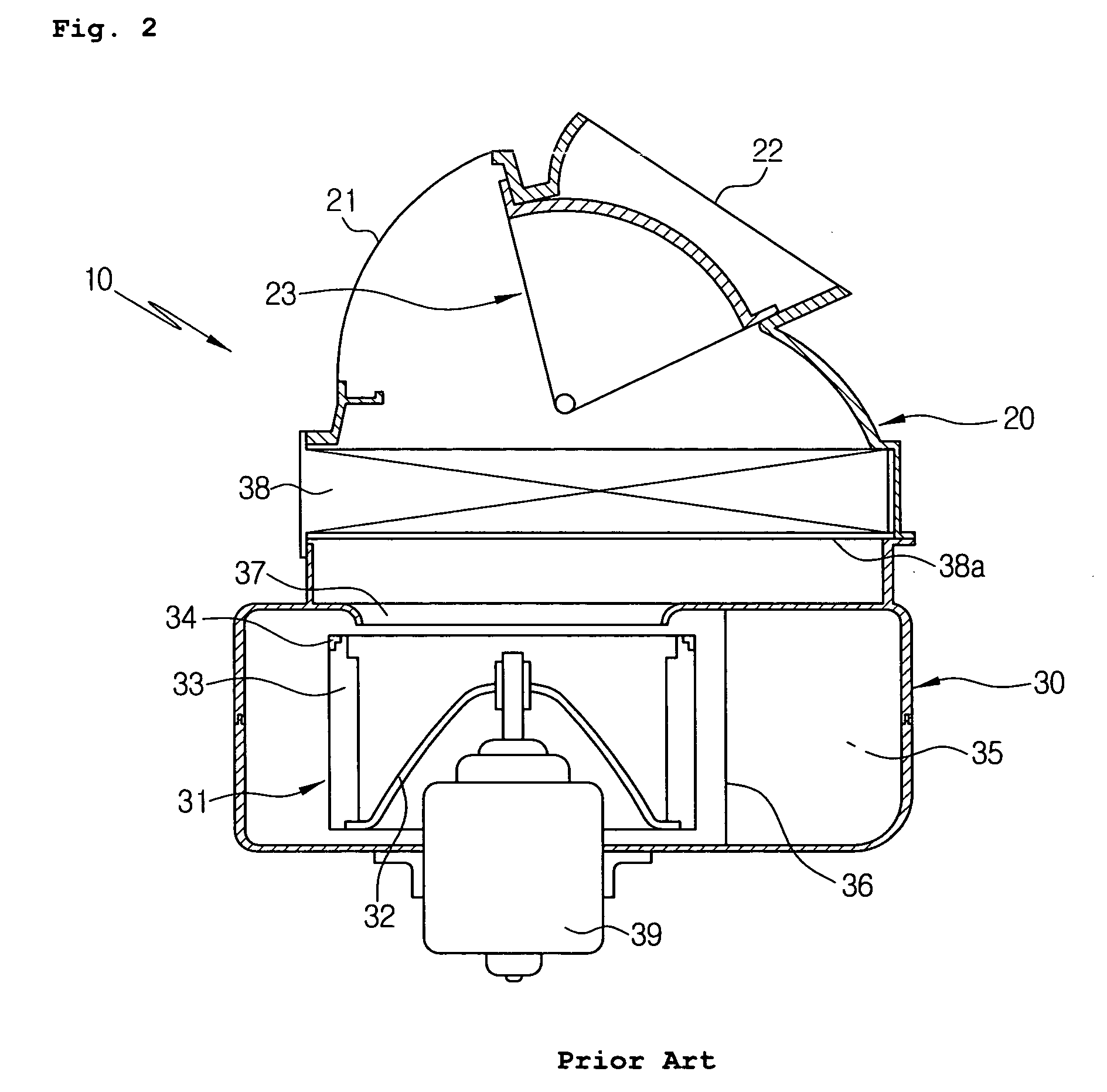

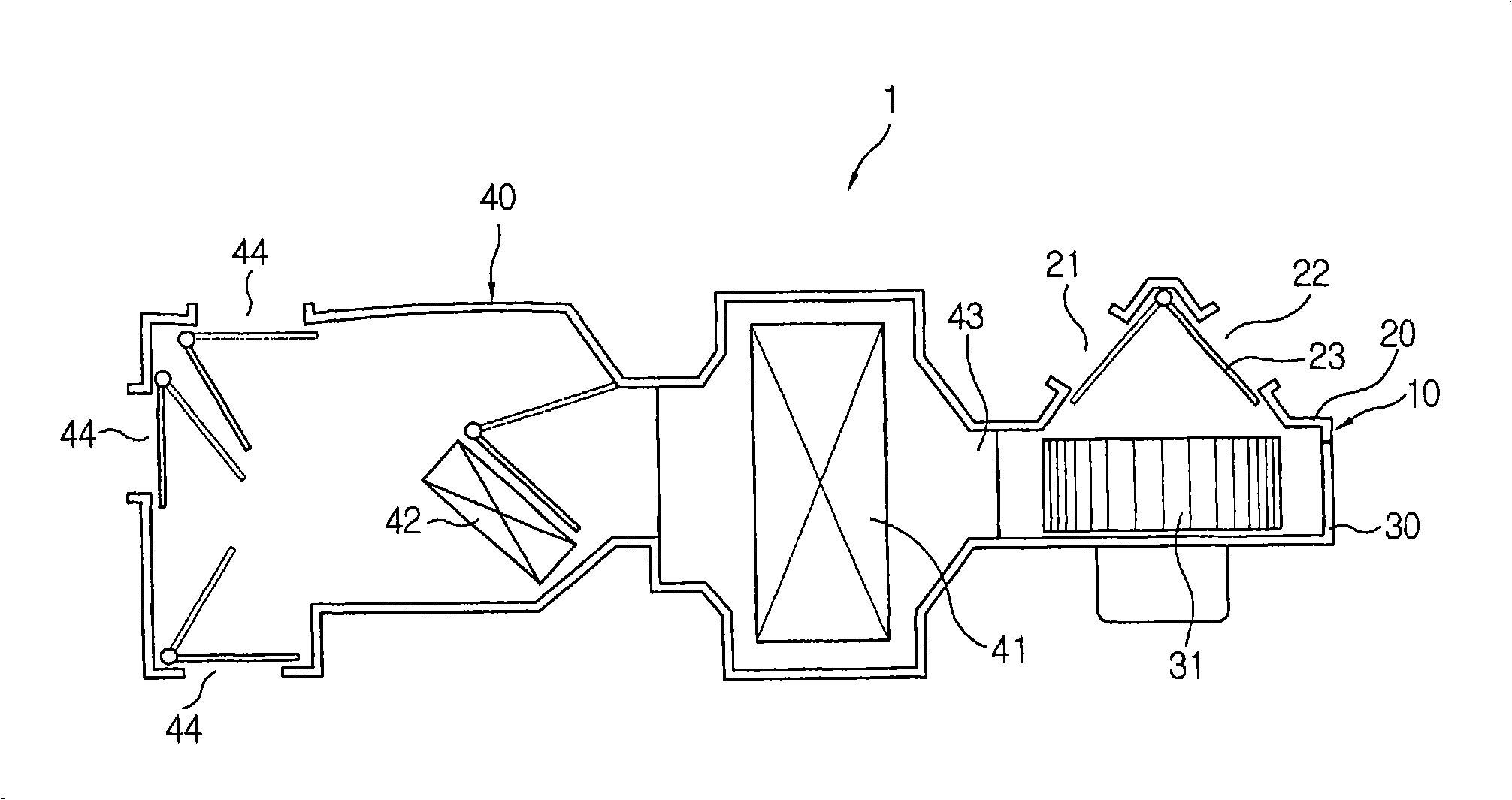

The present invention relates to a blower for vehicles, which includes guide walls formed on a bypass passageway formed between a scroll case and an outer case to send the indoor air and the outdoor air to a lower suction opening of the scroll case, thereby reducing suction noise by guiding a uniform flow of air introduced into the lower suction opening, preventing deformation of the outer case, and preventing a droop of the air filter by supporting a lower portion of an air filter when an intake duct injection-molded in a vertically parted mold is applied thereto.

Owner:HANON SYST

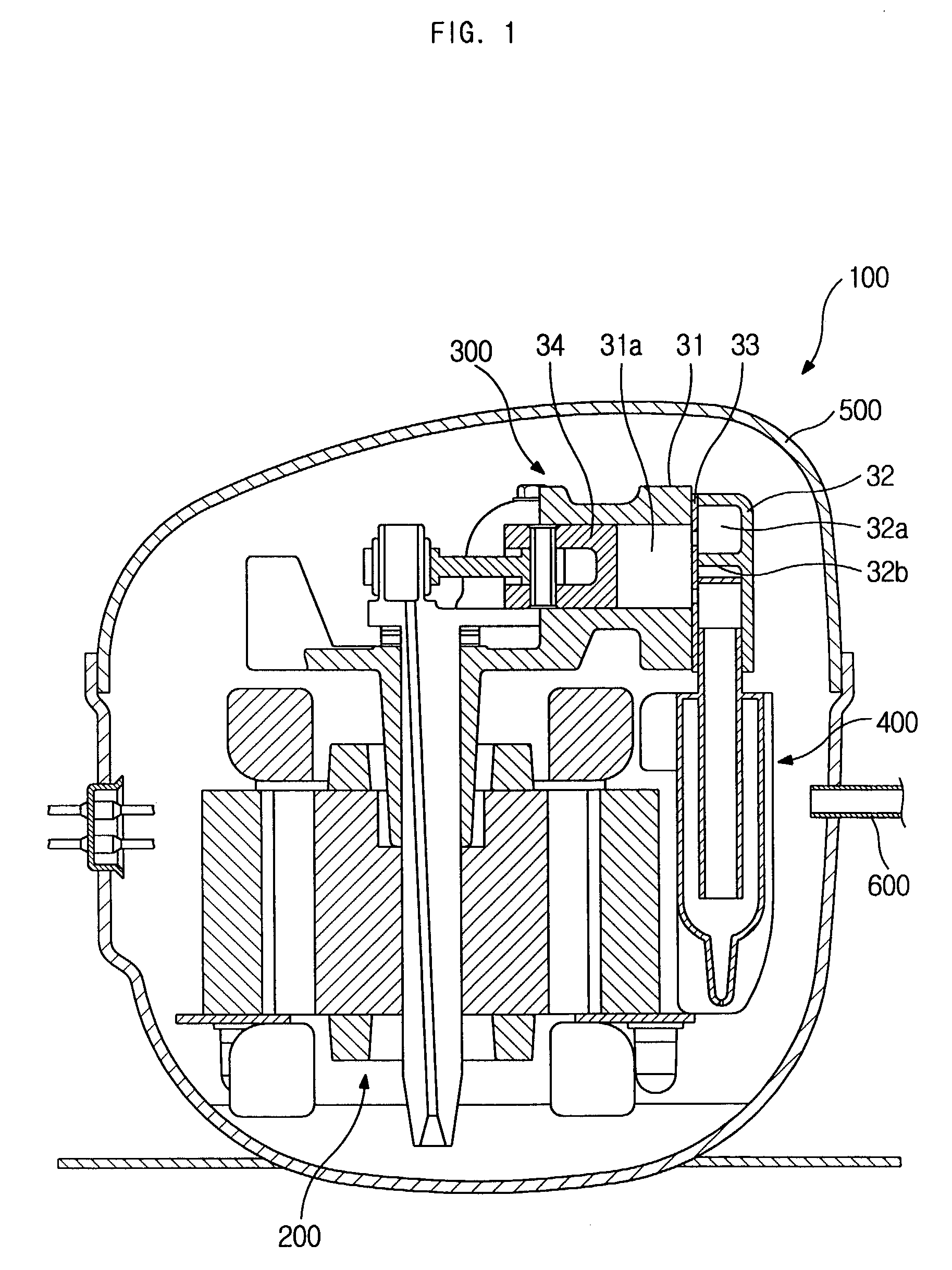

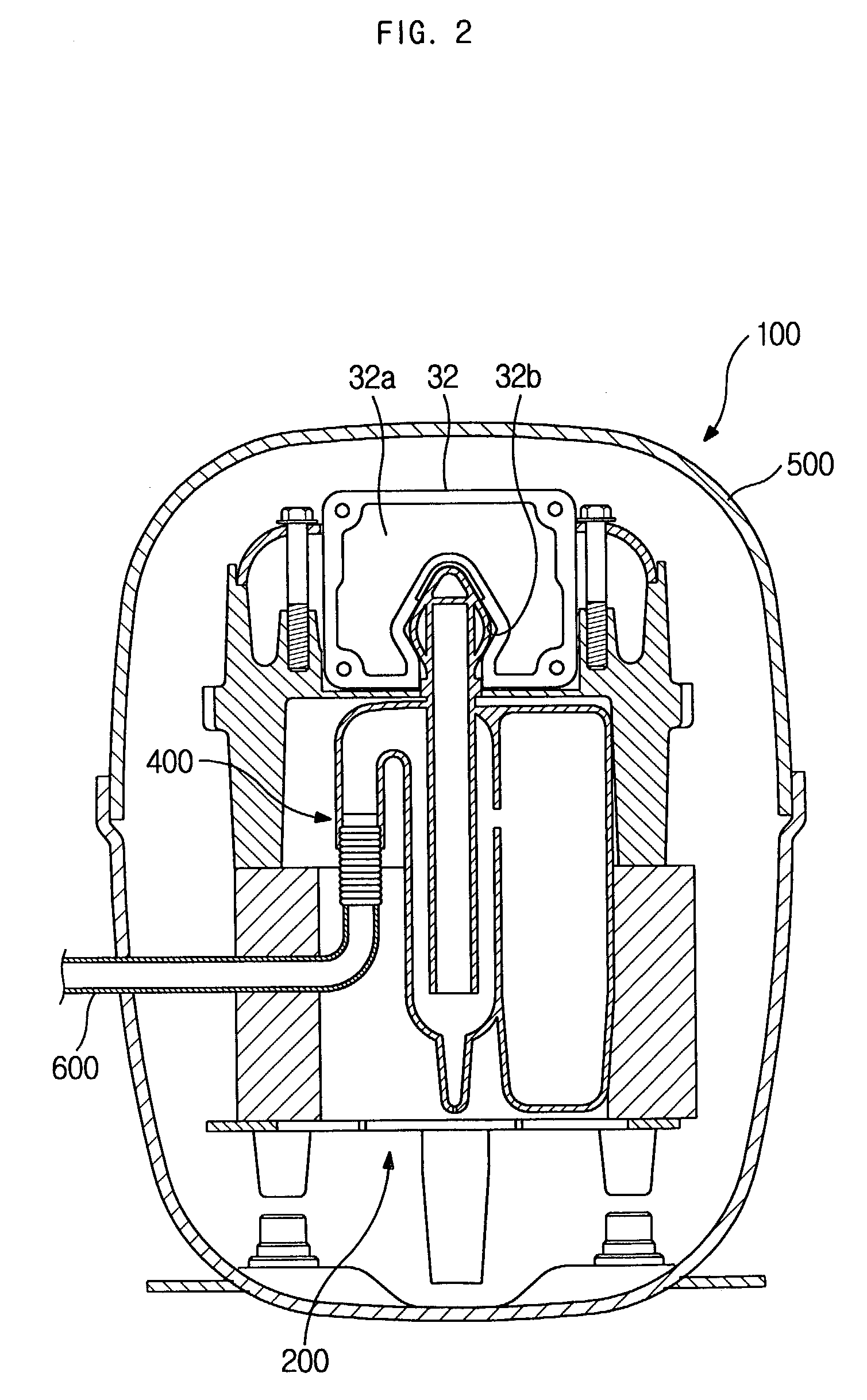

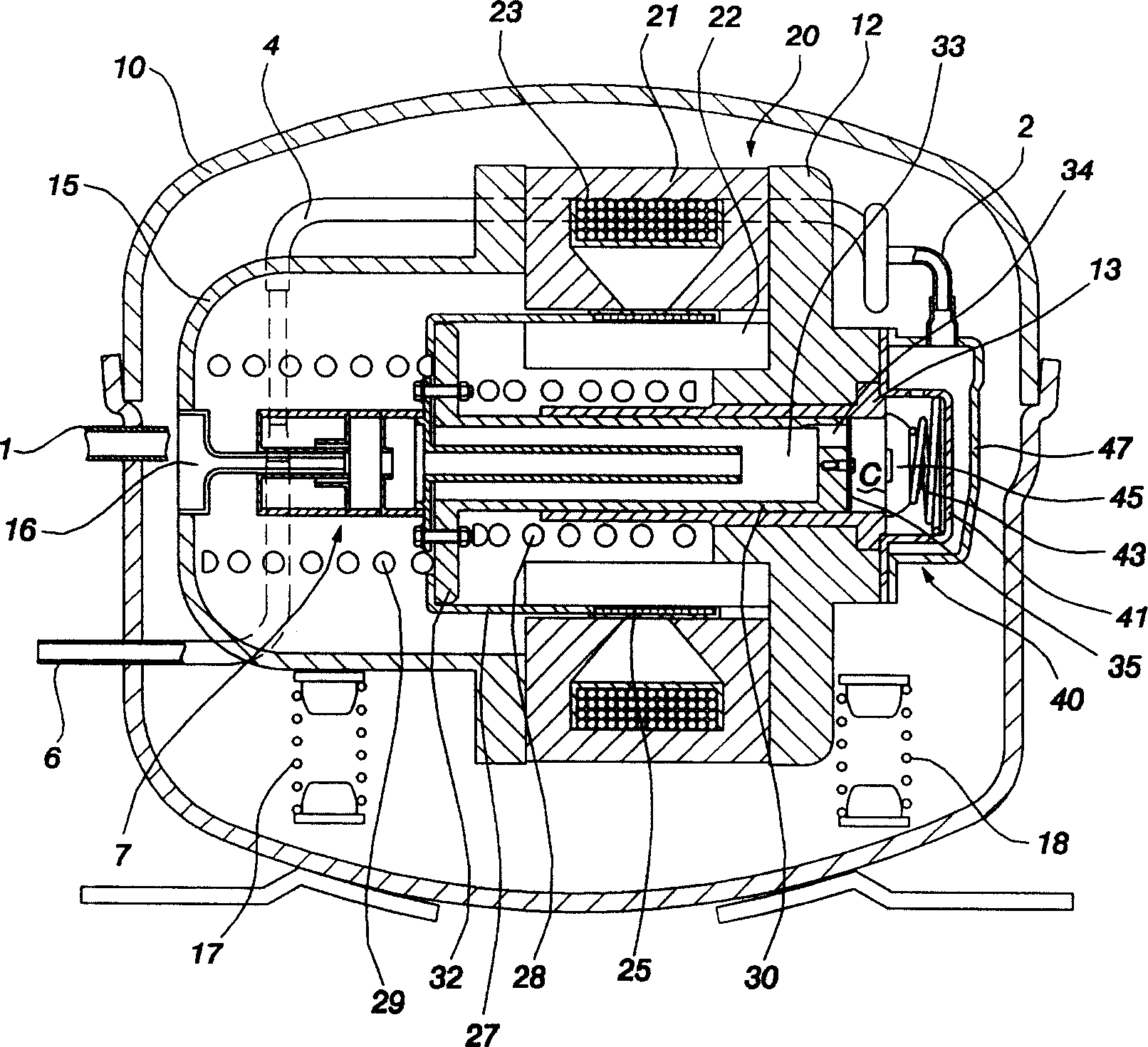

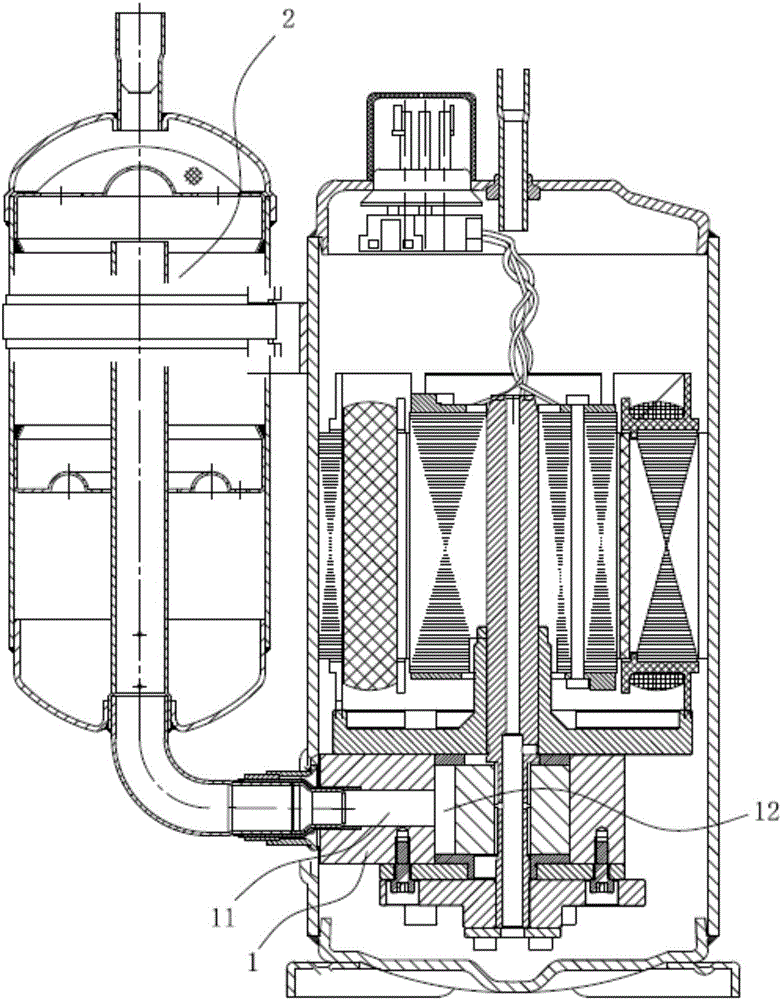

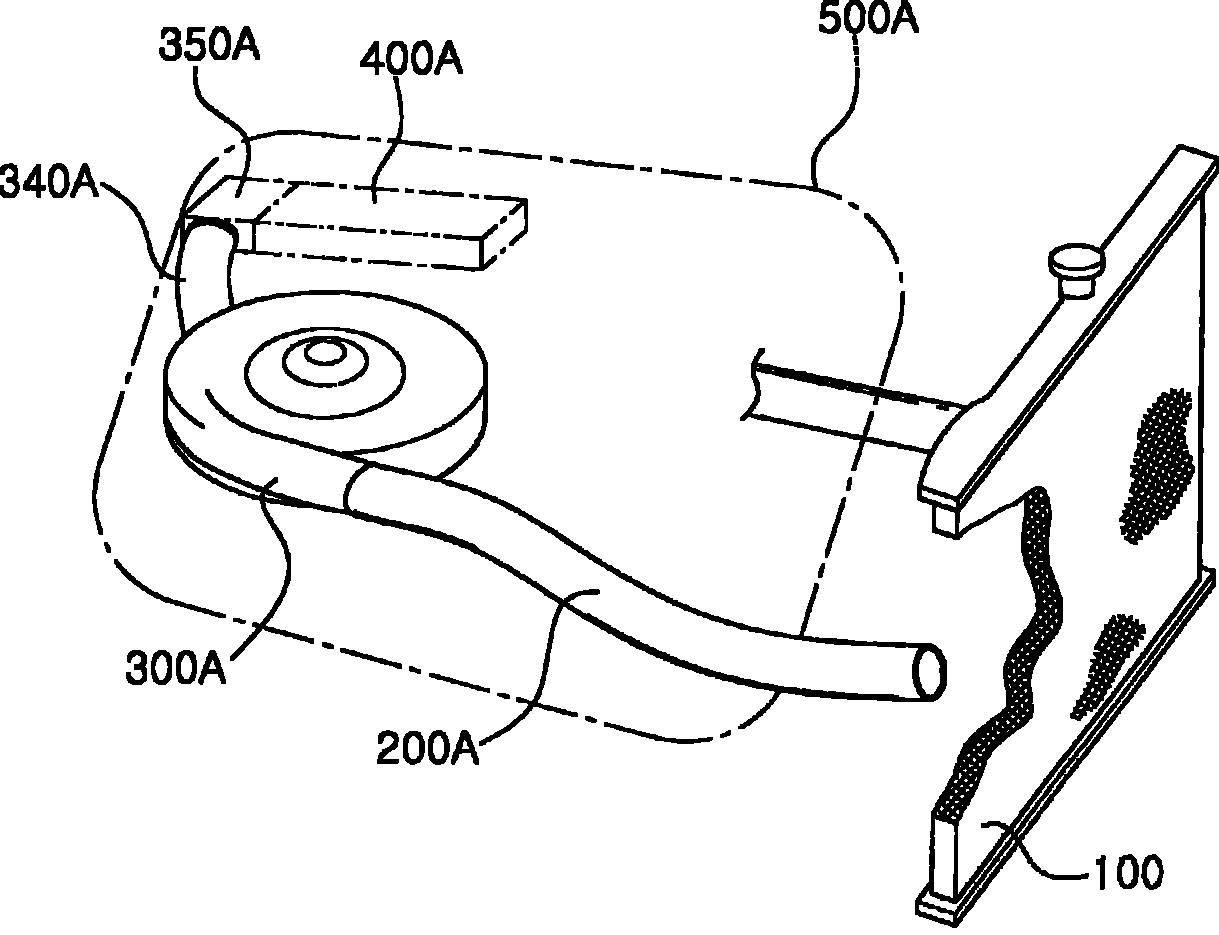

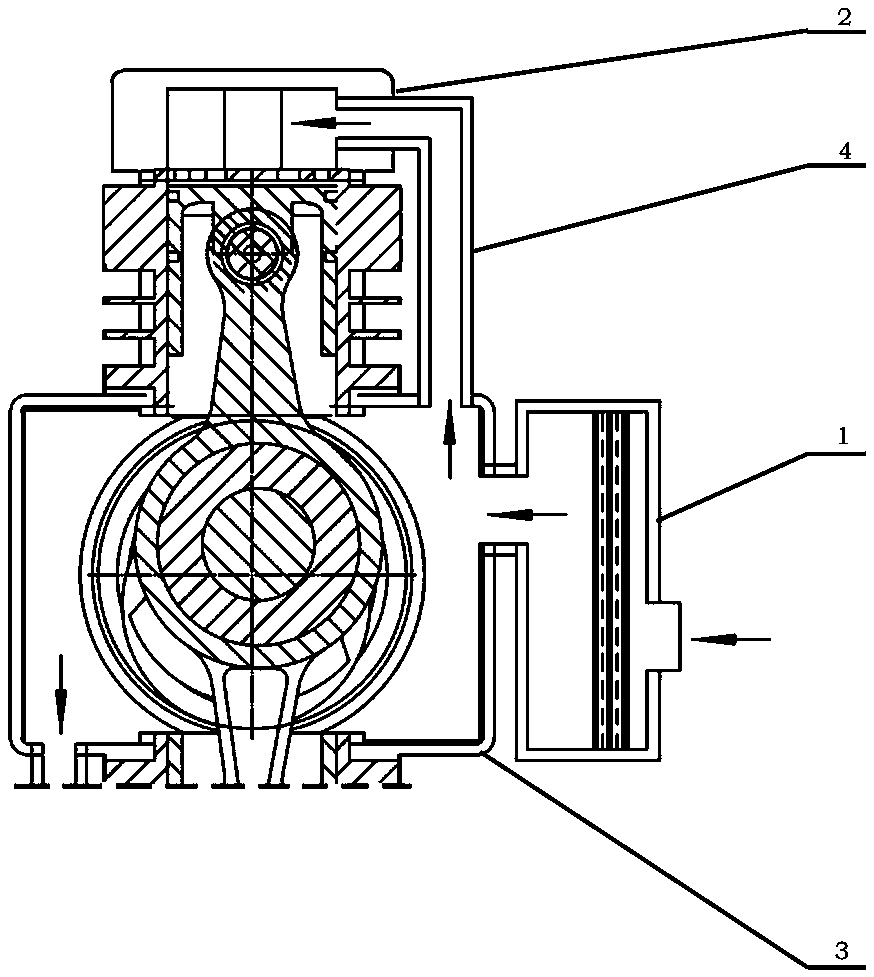

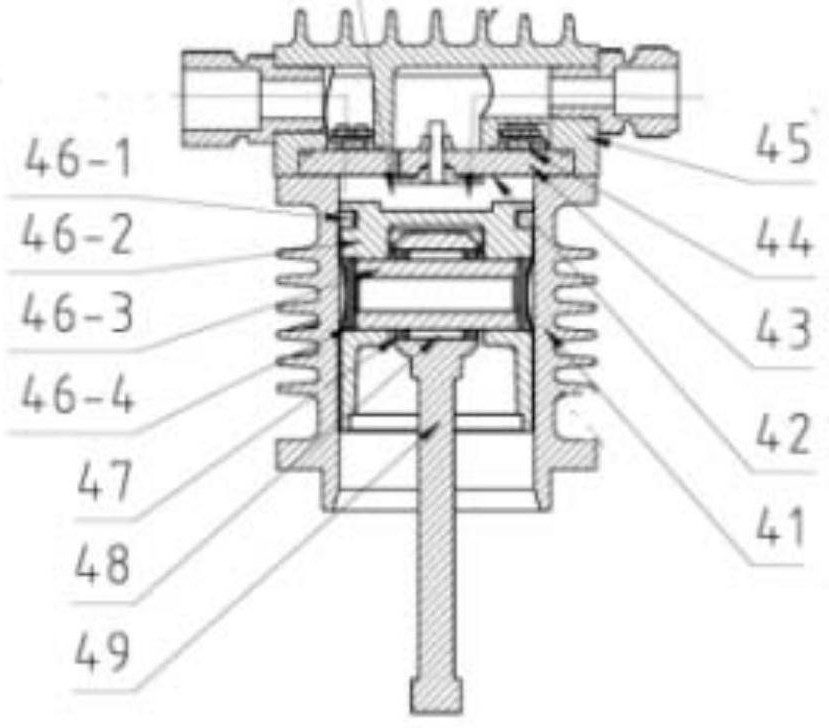

Suction muffler for compressors, compressor with the suction muffler, and apparatus having refrigerant circulation circuit including the compressor

InactiveUS7052247B2Maximize amount of refrigerantReduce suction noisePositive displacement pump componentsCombustion-air/fuel-air treatmentEngineeringRefrigerant

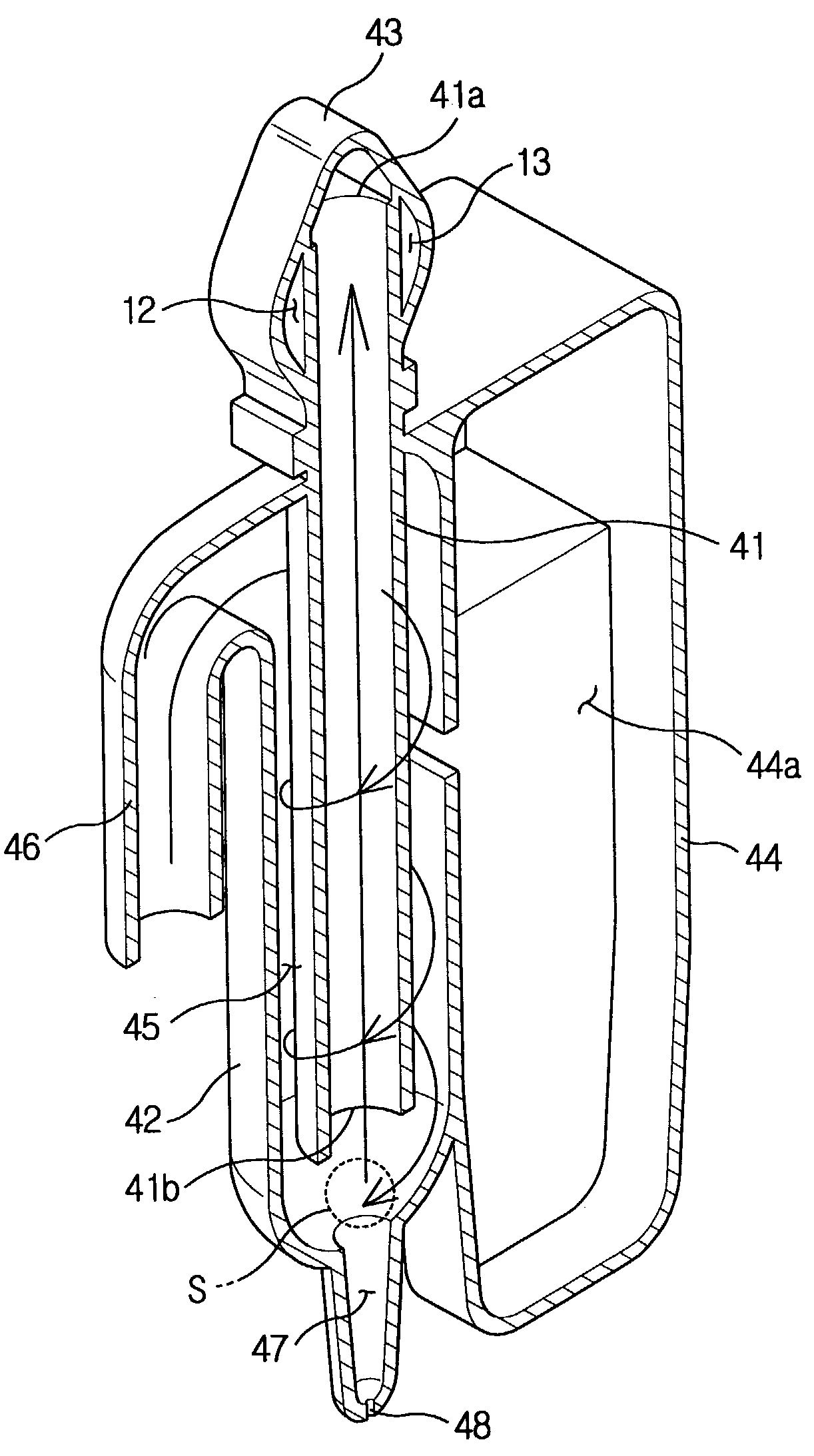

Disclosed herein are a suction muffler for compressors, a compressor with the suction muffler, and an apparatus having a refrigerant circulation circuit including the compressor. The present invention allows an amount of a refrigerant sucked into a compression chamber to be maximized, and allows suction noise generated during a suction stroke to be minimized. The suction muffler includes a refrigerant channel, and an outer casing. The refrigerant channel communicates at an inlet thereof with a suction pipe which guides a refrigerant to a compressor, and controllably communicates at an outlet thereof with a compression chamber in which the refrigerant is compressed. The outer casing has a structure to convert a flowing motion of the refrigerant into a spiral flowing motion while the refrigerant flows from the suction pipe to the inlet. At least one resonance chamber is formed around an outlet of the refrigerant channel. The compressor having the suction muffler includes at least one insulating space to prevent a heat transfer between the refrigerant inside a refrigerant intake chamber and the refrigerant inside a refrigerant discharge chamber. Further, the compressor is applied to an apparatus having a refrigerant circulation circuit. The present invention increases compression efficiency of the compressor, and considerably reduces suction noise.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

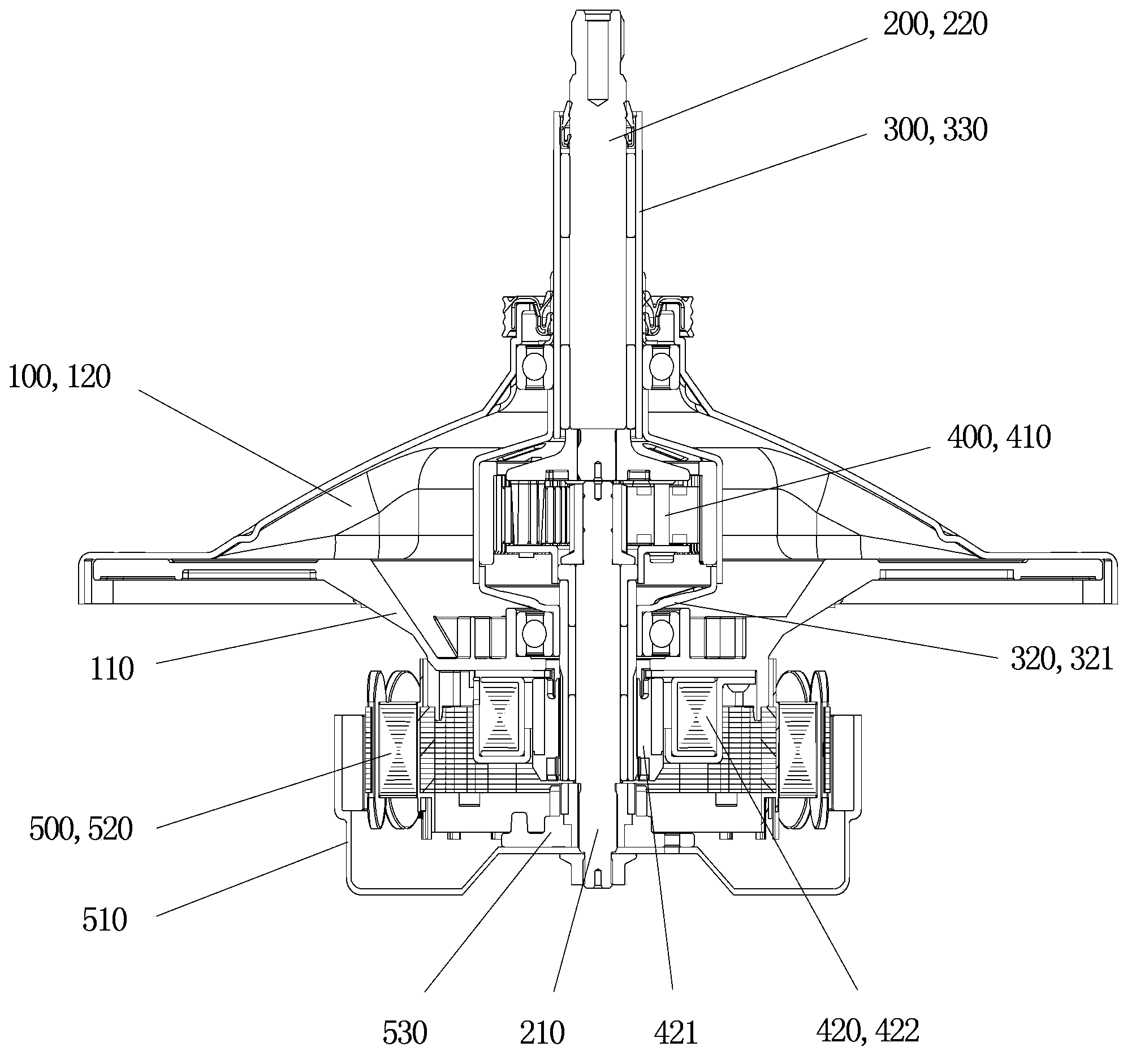

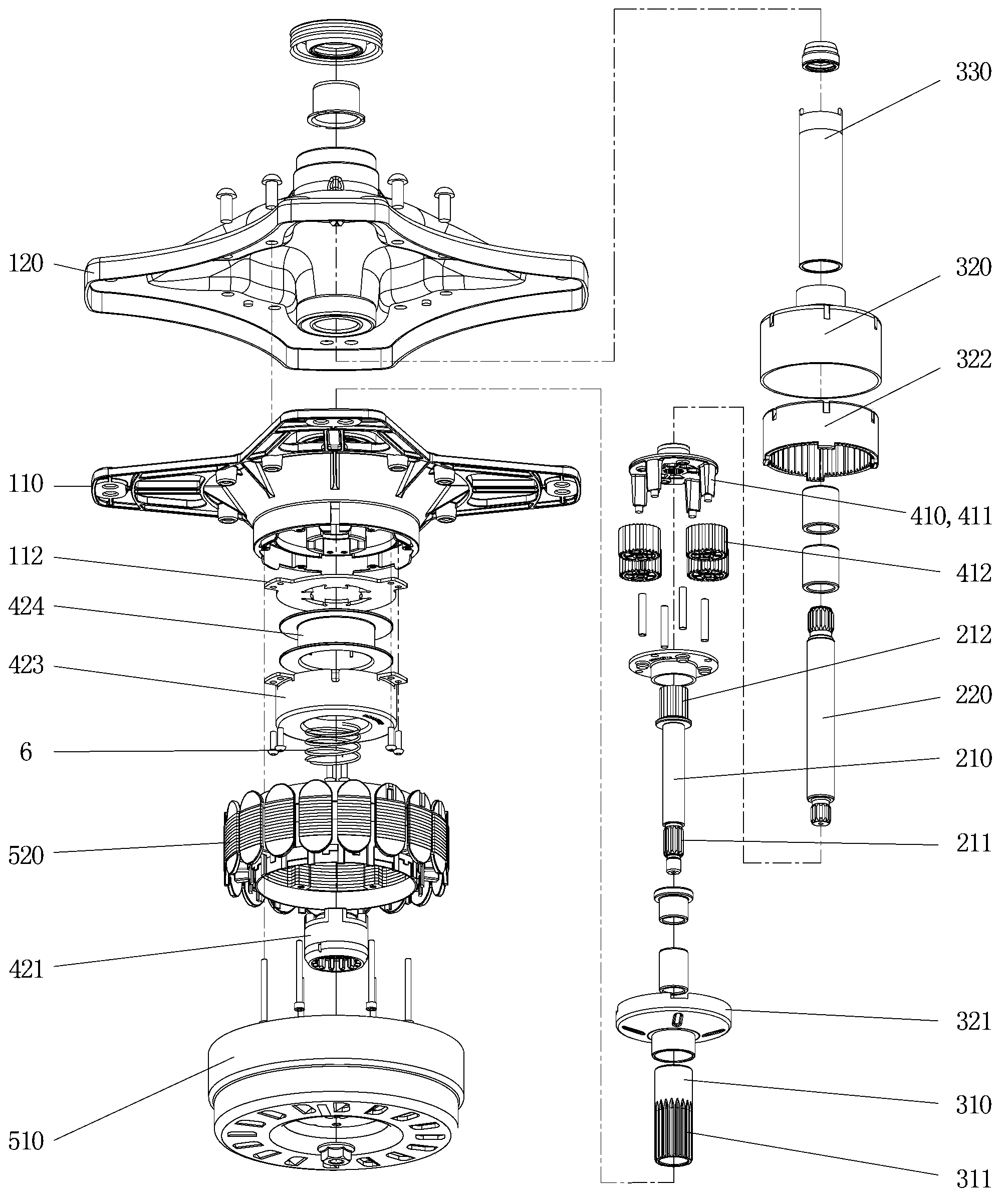

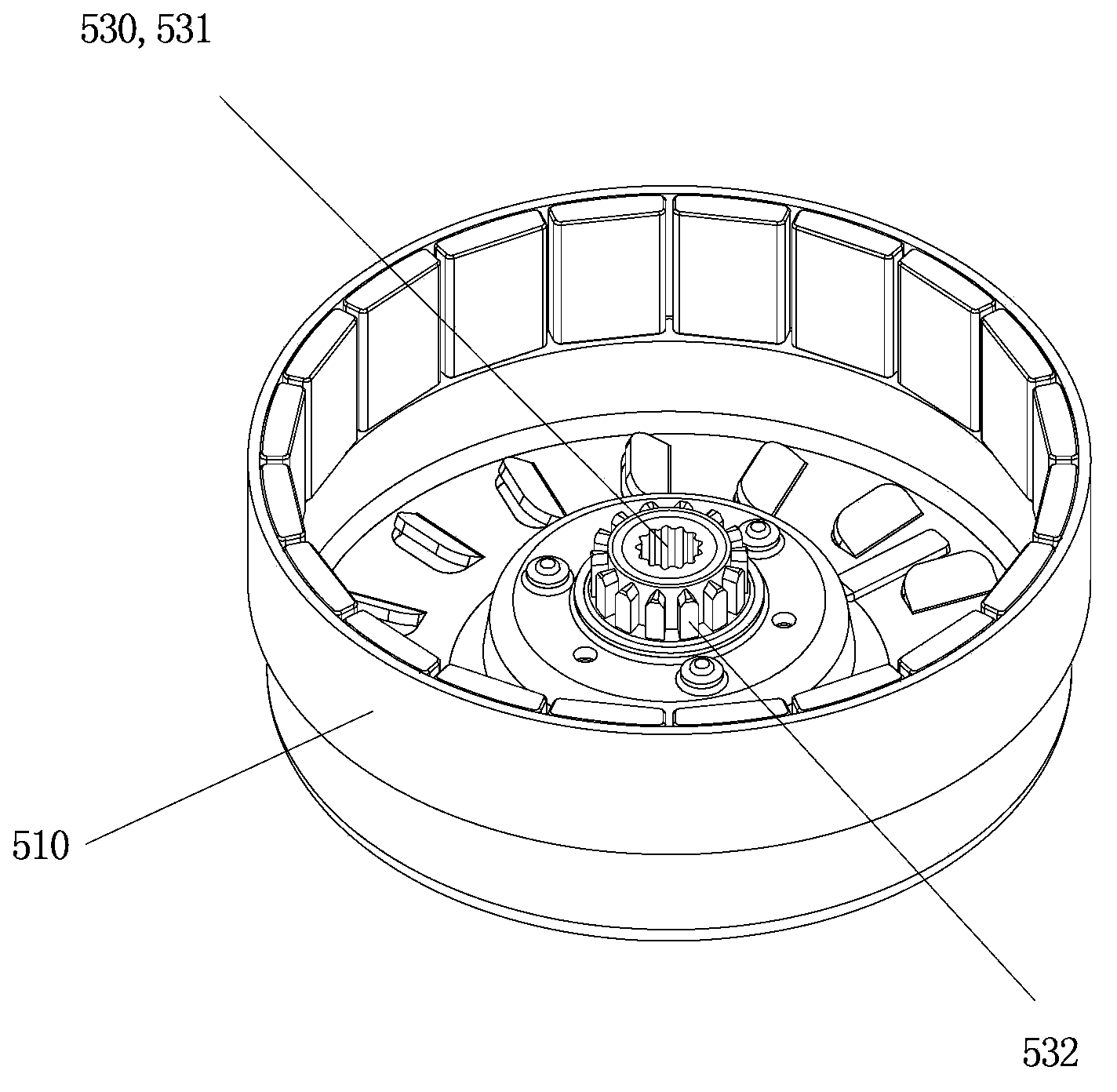

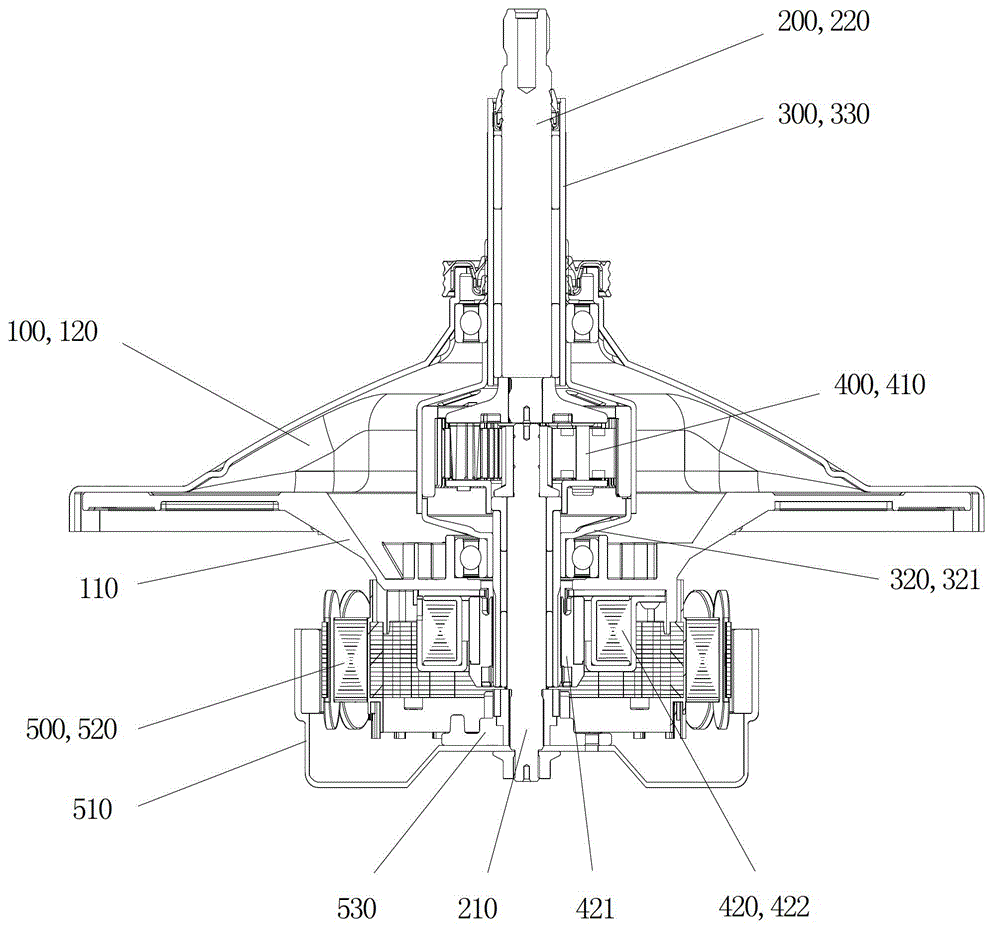

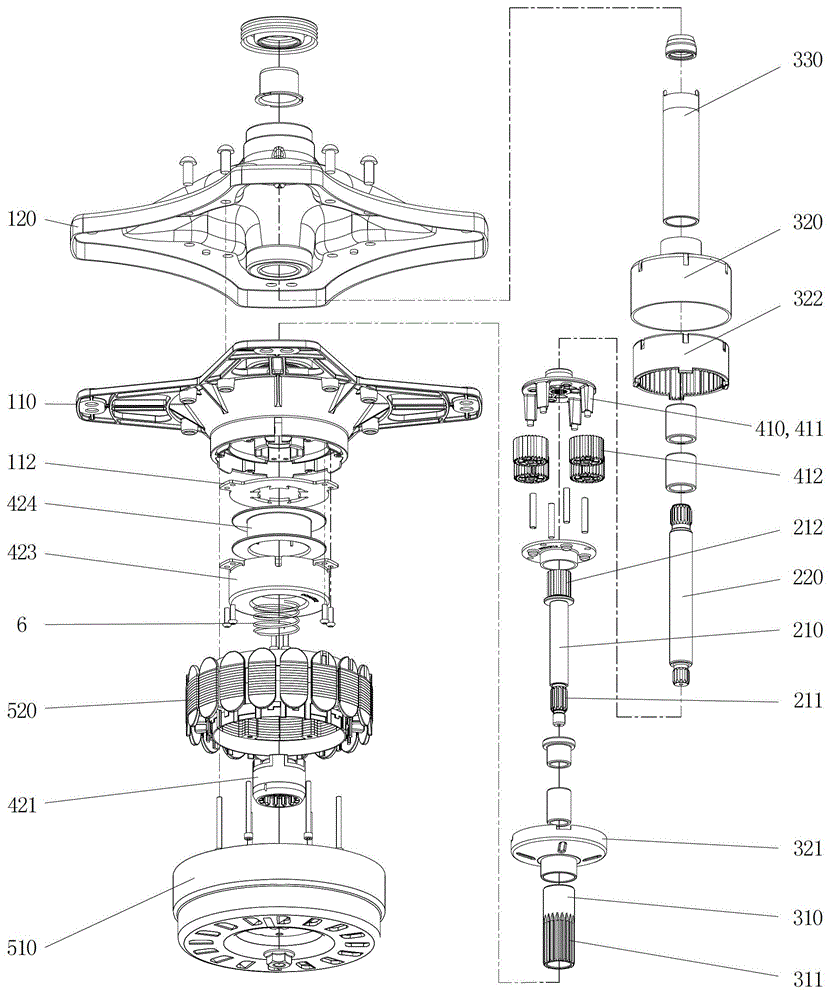

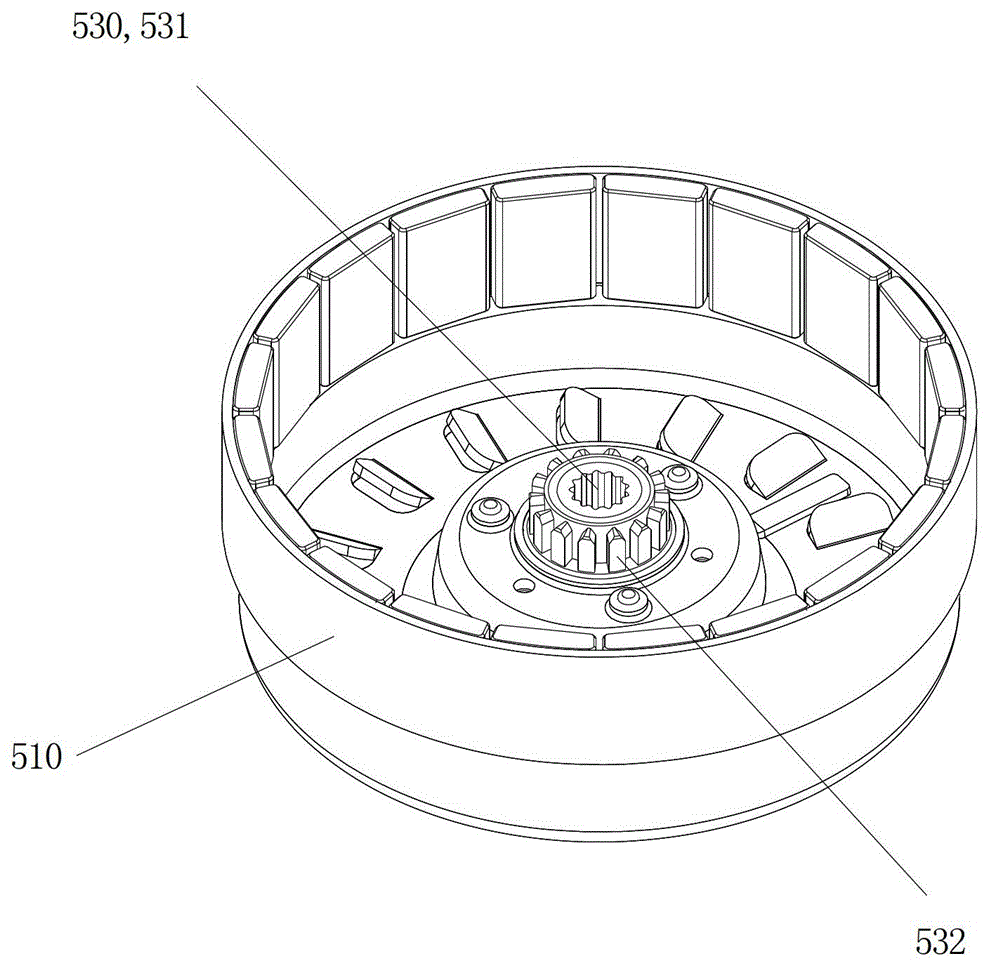

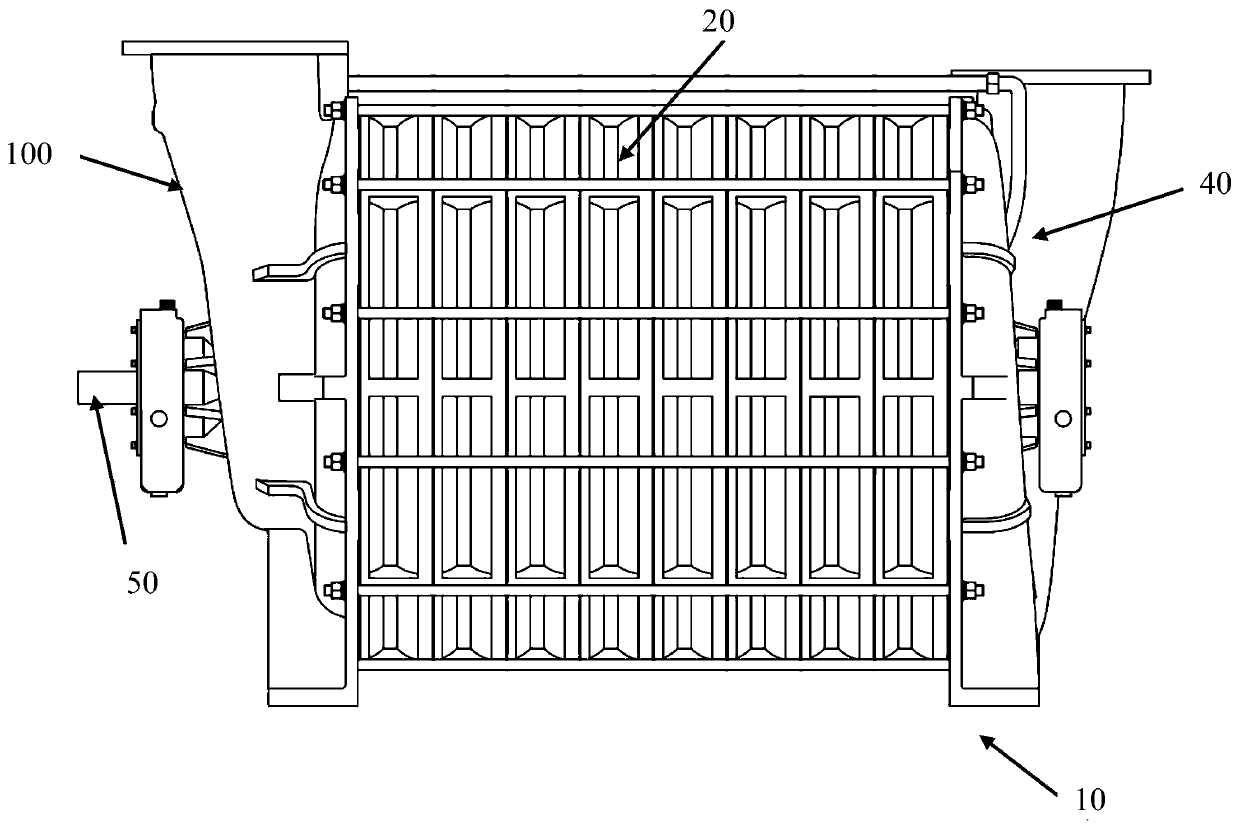

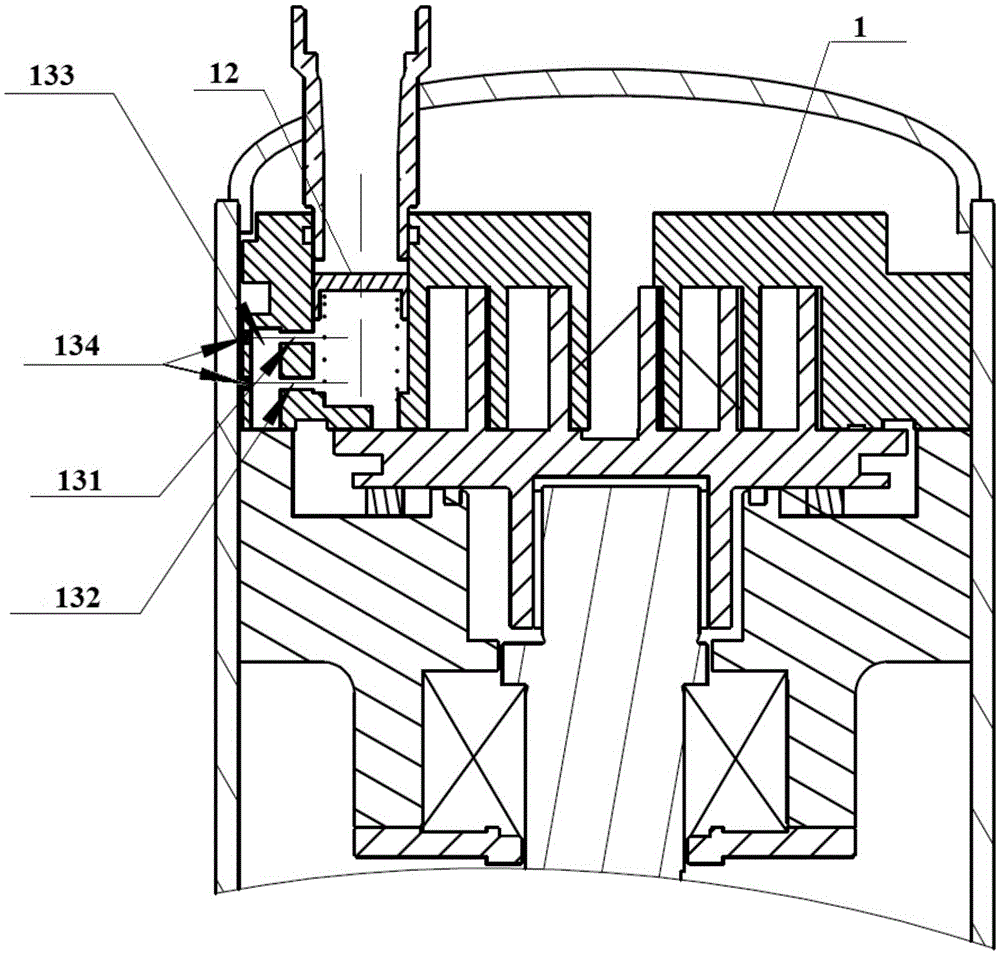

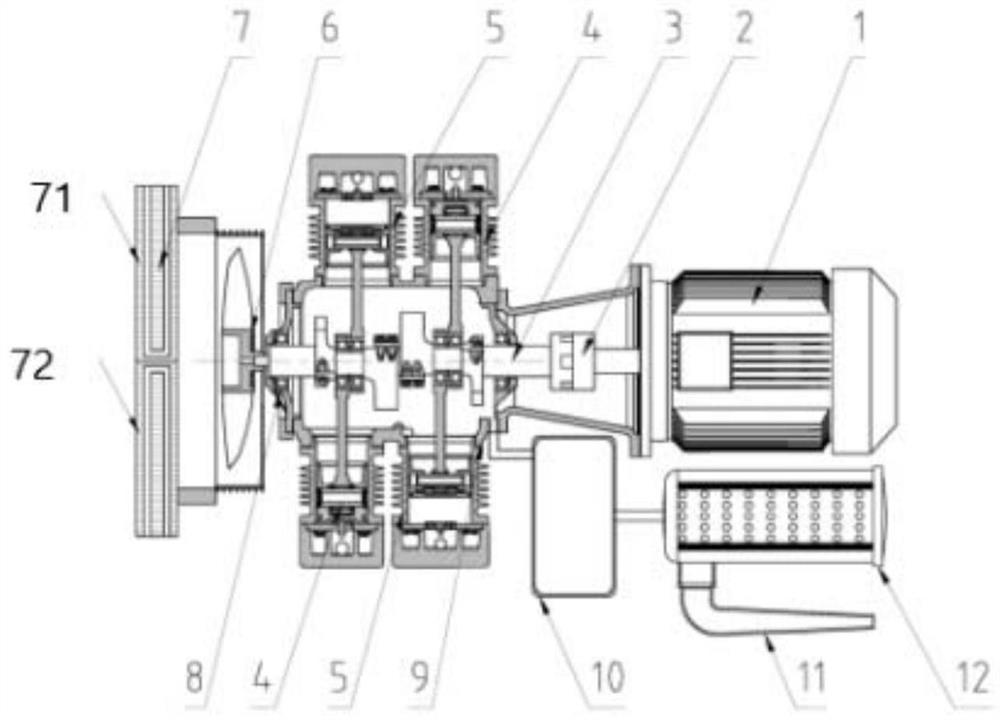

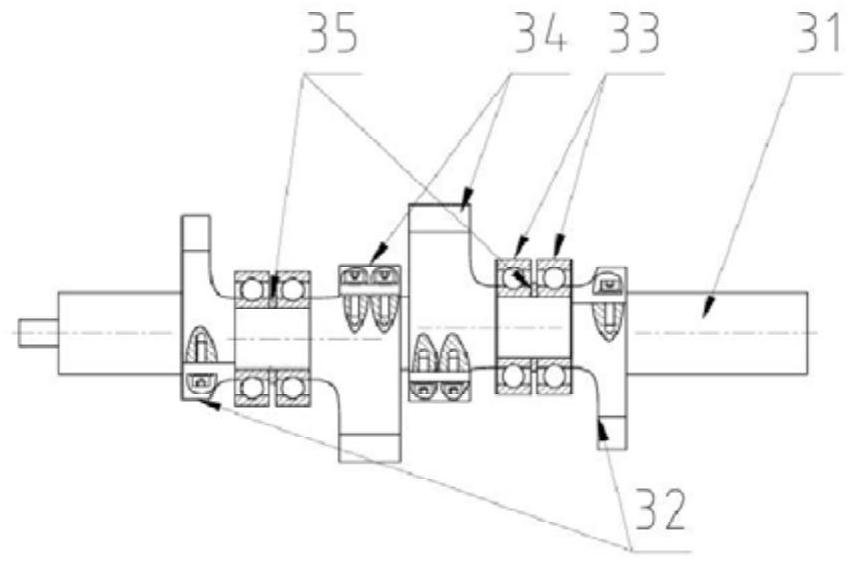

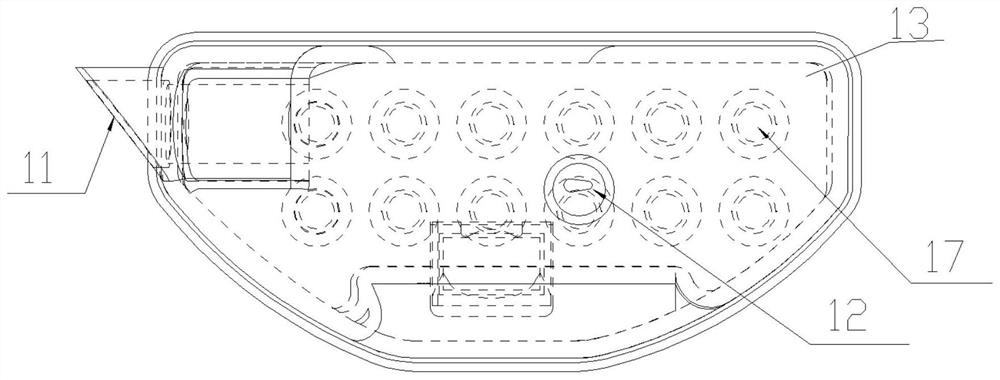

Drive assembly of pulsator washing machine

InactiveCN103422323AImprove transmission efficiencyAccurate clutch controlOther washing machinesTextiles and paperPull in voltageClutch control

The invention relates to a drive assembly of a pulsator washing machine. The drive assembly comprises a mounting tray. A spindle and a shaft sleeve sleeved on the spindle are rotatably disposed on the mounting tray. A reduction electromagnetic clutch mechanism is disposed between the spindle and the shaft sleeve. A drive mechanism is disposed on the lower portion of the spindle. The reduction electromagnetic clutch mechanism is an electromagnetic clutch mechanism having a function of electromagnetic clutch planetary gear reduction. The reduction electromagnetic clutch mechanism is provided with a planetary gear component and an electromagnetic clutch component. The drive mechanism is an external rotor direct-drive motor comprising a rotor and a stator. The stator is fixedly connected to the mounting tray. The rotor is fixedly connected with the spindle. The spindle and the electromagnetic clutch and planetary gear reduction mechanism are directly driven by an external rotor motor, and accordingly defects such as complex ratchet and pawl structure, large size and low control accuracy in the prior art are broken through. Electromagnetic clutching is high in transmission efficiency, accurate in transmission and clutching control and low in noise; the whole drive assembly is light in weight, pull-in voltage and holding voltage are less demanded in electromagnetic clutching, and energy consumption is reduced effectively.

Owner:CHANGZHOU XINYA ELECTROMOTOR

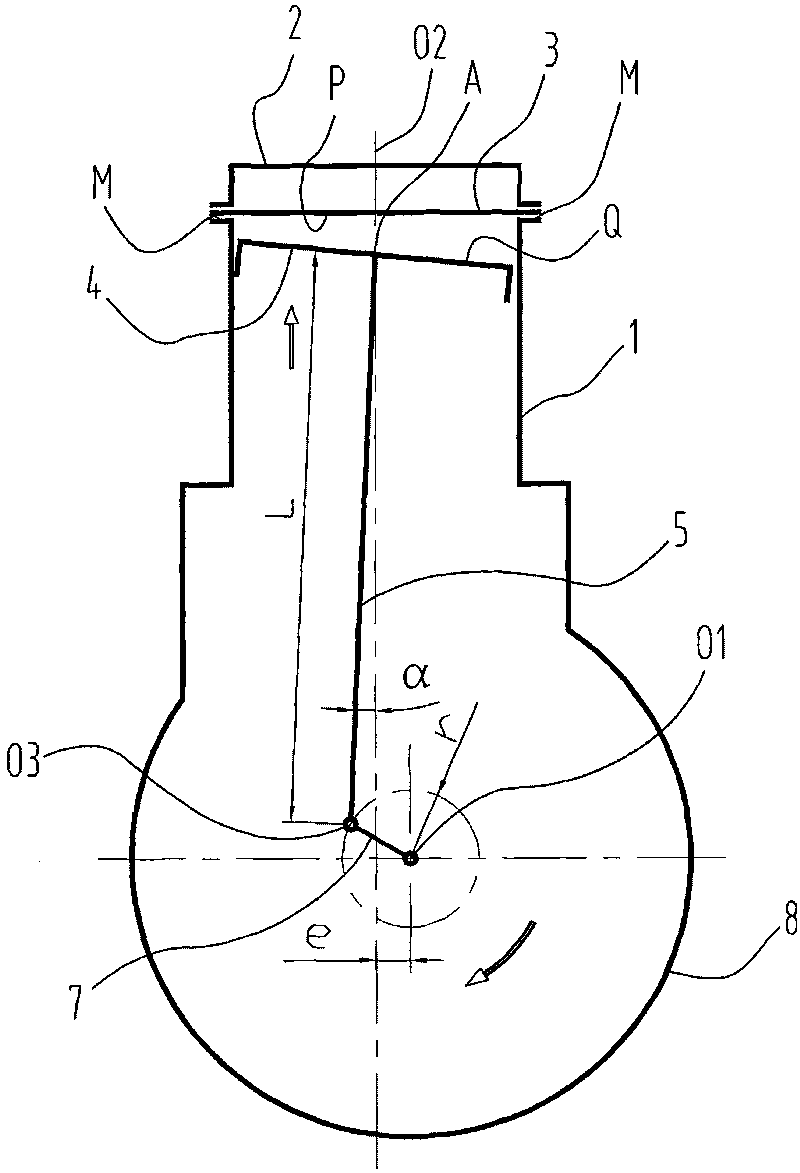

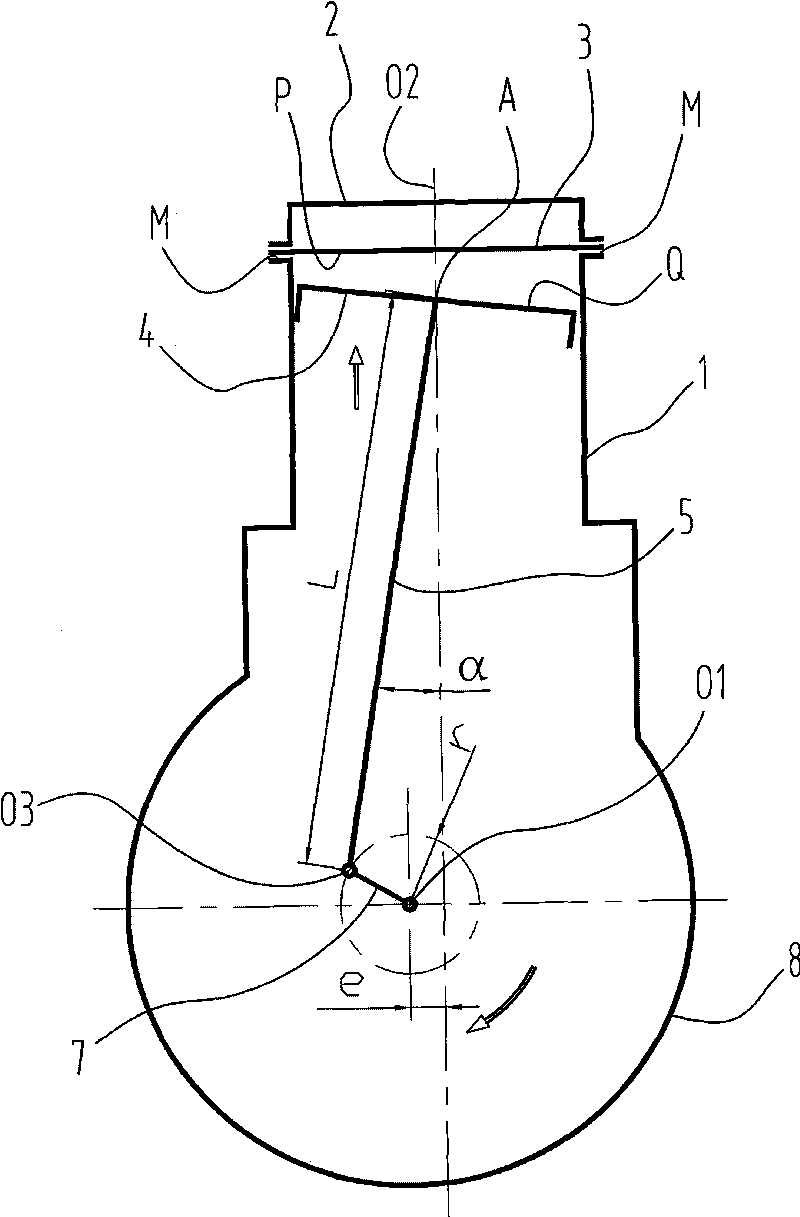

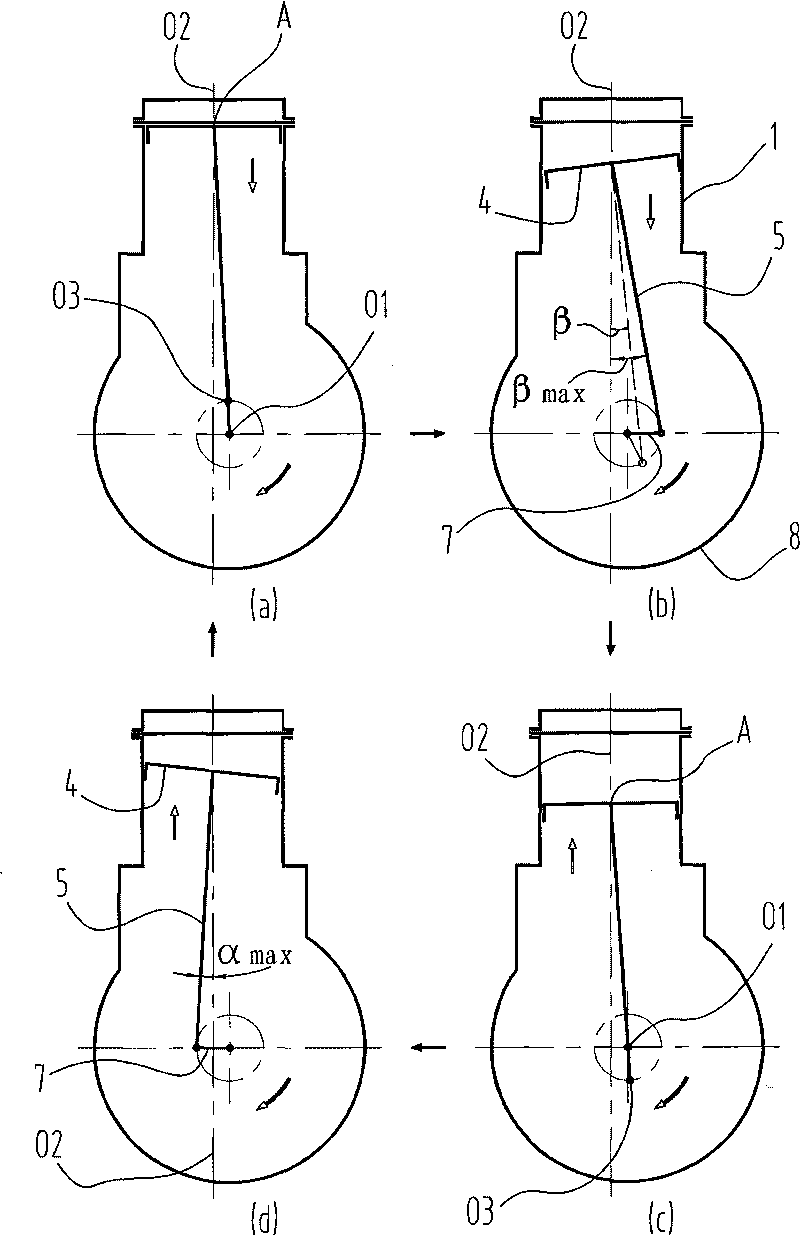

Reciprocating-piston type oil-less air compressor

InactiveCN101737297AReduce side pressureReduce slapping intensityPositive displacement pump componentsPiston pumpsInlet channelLinear compressor

The invention relates to a reciprocating-piston type oil-less air compressor. In the invention, a piston of a compressor is fastened with a connecting rod or integrally manufactured with the connecting rod; and the piston is arranged in an air cylinder and reciprocates and swings relative to the air cylinder. The reciprocating-piston type oil-less air compressor is characterized in that: the air cylinder adopts an offset structure, which means the axial line of the air cylinder is not intersected with the axial line of a crankshaft, so the offset angle of the piston relative to the air cylinder is reduced in the compression stroke, and the lateral pressure and panting strength of the piston on the air cylinder and the abrasion loss of a sealing ring or a sealing rubber cup are reduced; besides, the oval deformation of the sealing ring or the sealing rubber cup is reduced, so the fatigue state thereof is relieved and the screech which is generated by the leakage at an oval gap and the escape of gas is reduced; and moreover, structures such as a closed crankcase structure, a crankcase air inlet soundproofing chamber, an air inlet channel and the like are adopted for effectively reducing the induction noise and the induction jetting noise and an exhaust soundproofing housing is adopted for reducing the exhaust noise, so the reciprocating-piston type oil-less air compressor can be used for manufacturing the air compressor, an air pump, a vacuum pump or a fluid pump.

Owner:ZHEJIANG HONGYOU AIR COMPRESSOR MFG

Blower for vehicles

ActiveUS8235649B2Avoid deformationReduce suction noisePump componentsWind motor controlAir filterInjection moulding

The present invention relates to a blower for vehicles, which includes guide walls formed on a bypass passageway formed between a scroll case and an outer case to send the indoor air and the outdoor air to a lower suction opening of the scroll case, thereby reducing suction noise by guiding a uniform flow of air introduced into the lower suction opening, preventing deformation of the outer case, and preventing a droop of the air filter by supporting a lower portion of an air filter when an intake duct injection-molded in a vertically parted mold is applied thereto.

Owner:HANON SYST

Blower for vehicles

ActiveCN101284490AAvoid deformationPrevent saggingAir-treating devicesVehicle heating/cooling devicesAir filterEngineering

The present invention relates to a blower for vehicles, which includes guide walls formed on a bypass passageway formed between a scroll case and an outer case to send the indoor air and the outdoor air to a lower suction opening of the scroll case, thereby reducing suction noise by guiding a uniform flow of air introduced into the lower suction opening, preventing deformation of the outer case, and preventing a droop of the air filter by supporting a lower portion of an air filter when an intake duct injection-molded in a vertically parted mold is applied thereto.

Owner:HANON SYST

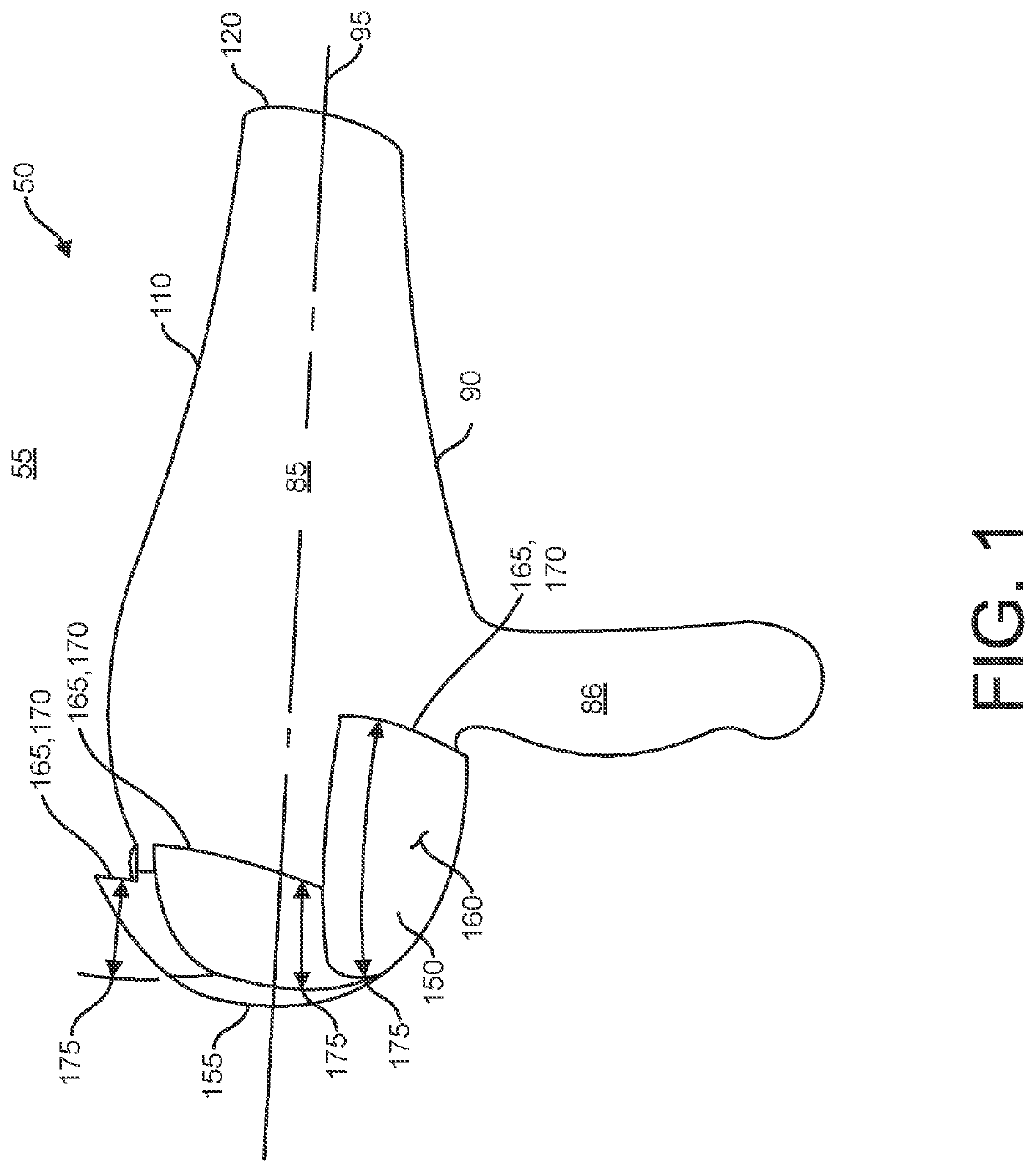

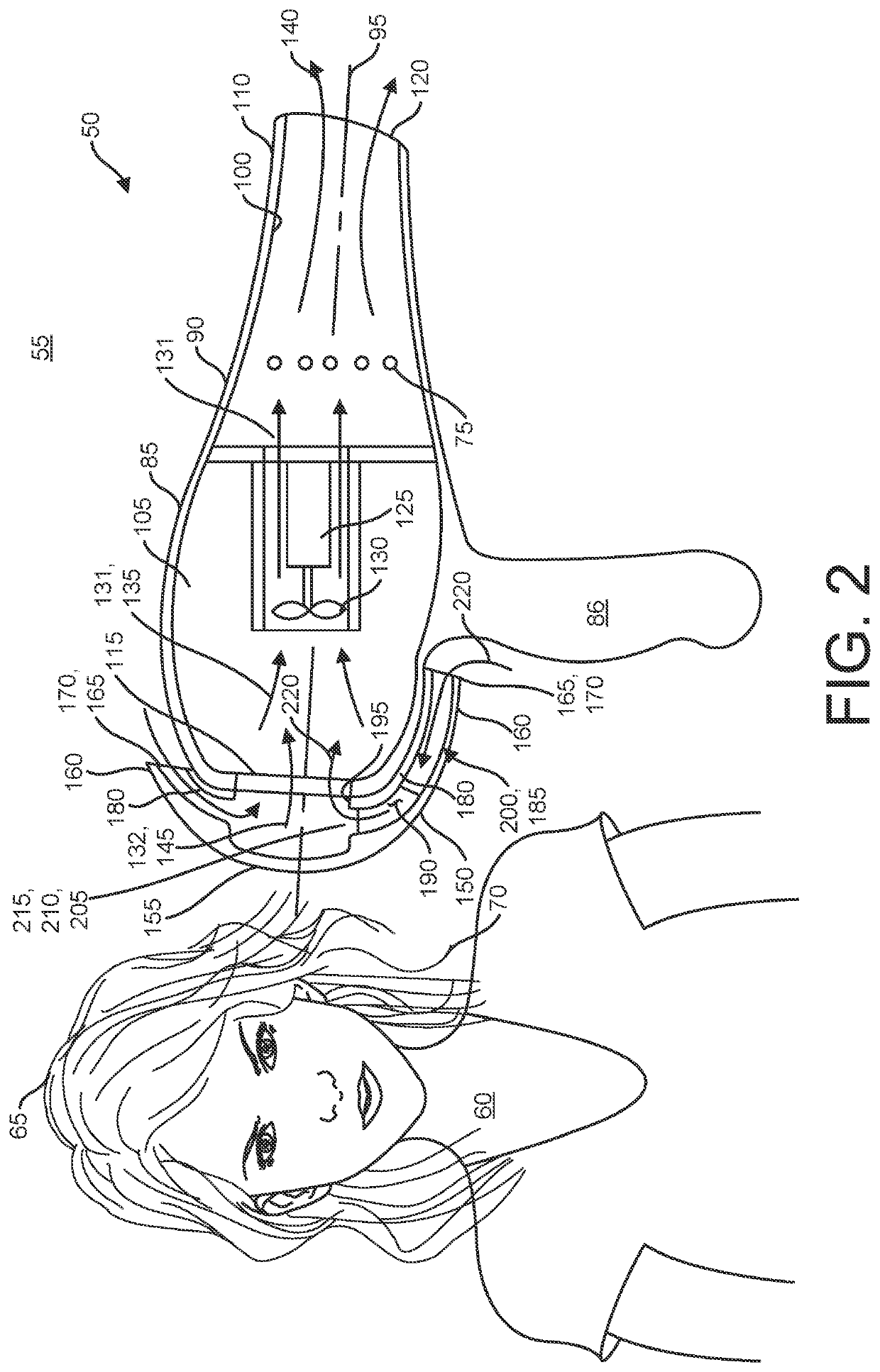

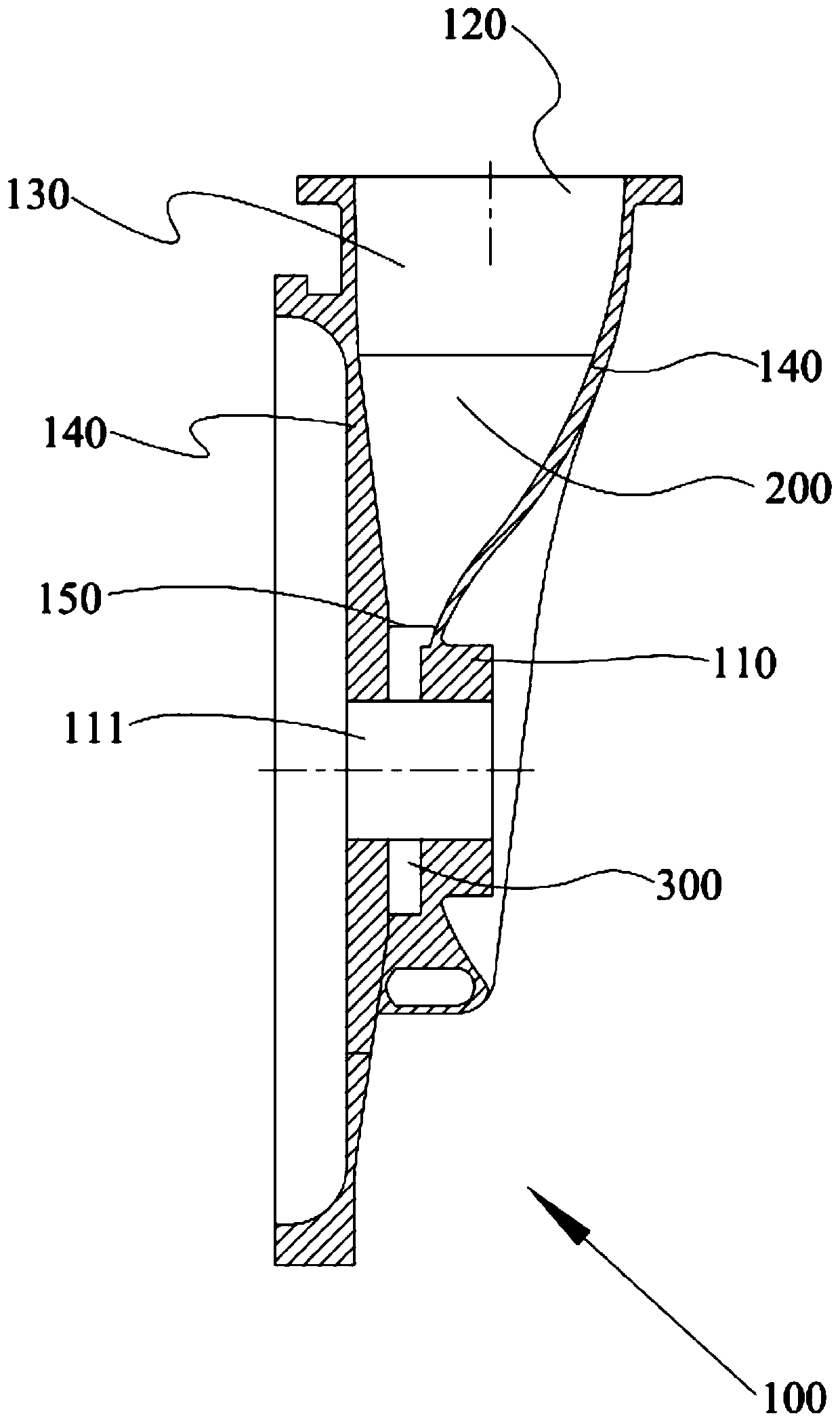

Hair Dryer Apparatus

ActiveUS20210345750A1Facilitate fluid communicationReduce suction noiseHair dryingPhysicsElectric machinery

A hair dryer apparatus includes a housing with a surrounding sidewall having an inner surface defining an interior and an opposing outer surface, further the sidewall having an inlet and an opposing outlet. In addition, the hair dryer apparatus includes a motor driven blower disposed within the interior, the blower drives airflow from the inlet to the outlet. Additionally, the hair dryer apparatus includes a handle extending from the sidewall and a suction shroud that includes a solid base with an outer surrounding sidewall extending from the base, wherein the outer surrounding sidewall has an outer termination portion that is scarfed such that the outer termination portion extends from the base to offset lengths toward the sidewall outlet thus ultimately the blower suction being adjacent to the sidewall outlet for noise attenuation and reducing user hair entanglement in the blower suction.

Owner:DEPOYIAN JACQUES

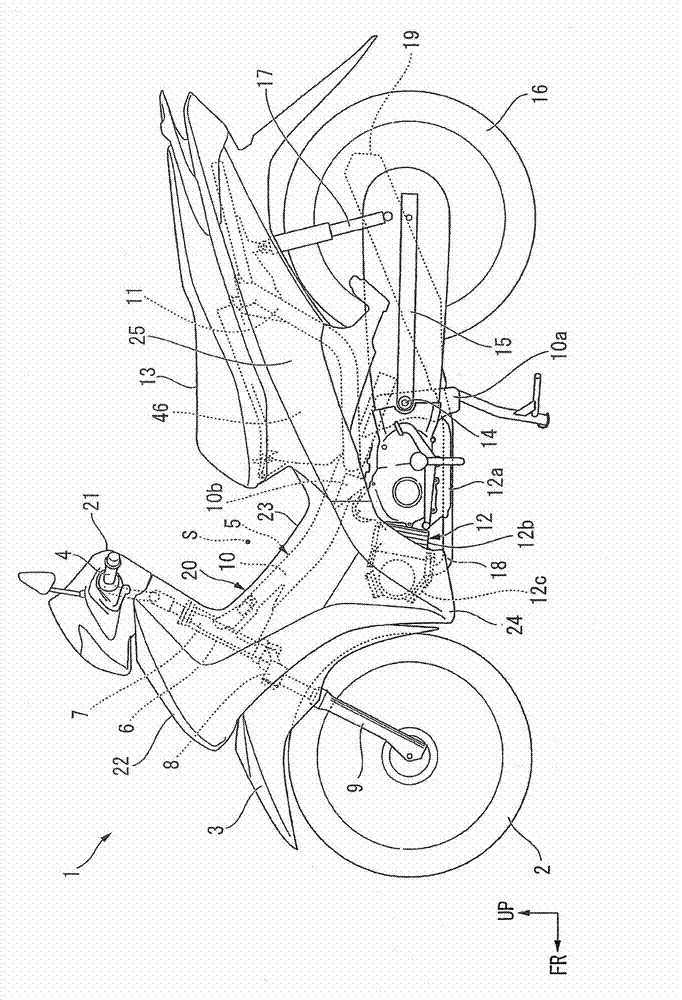

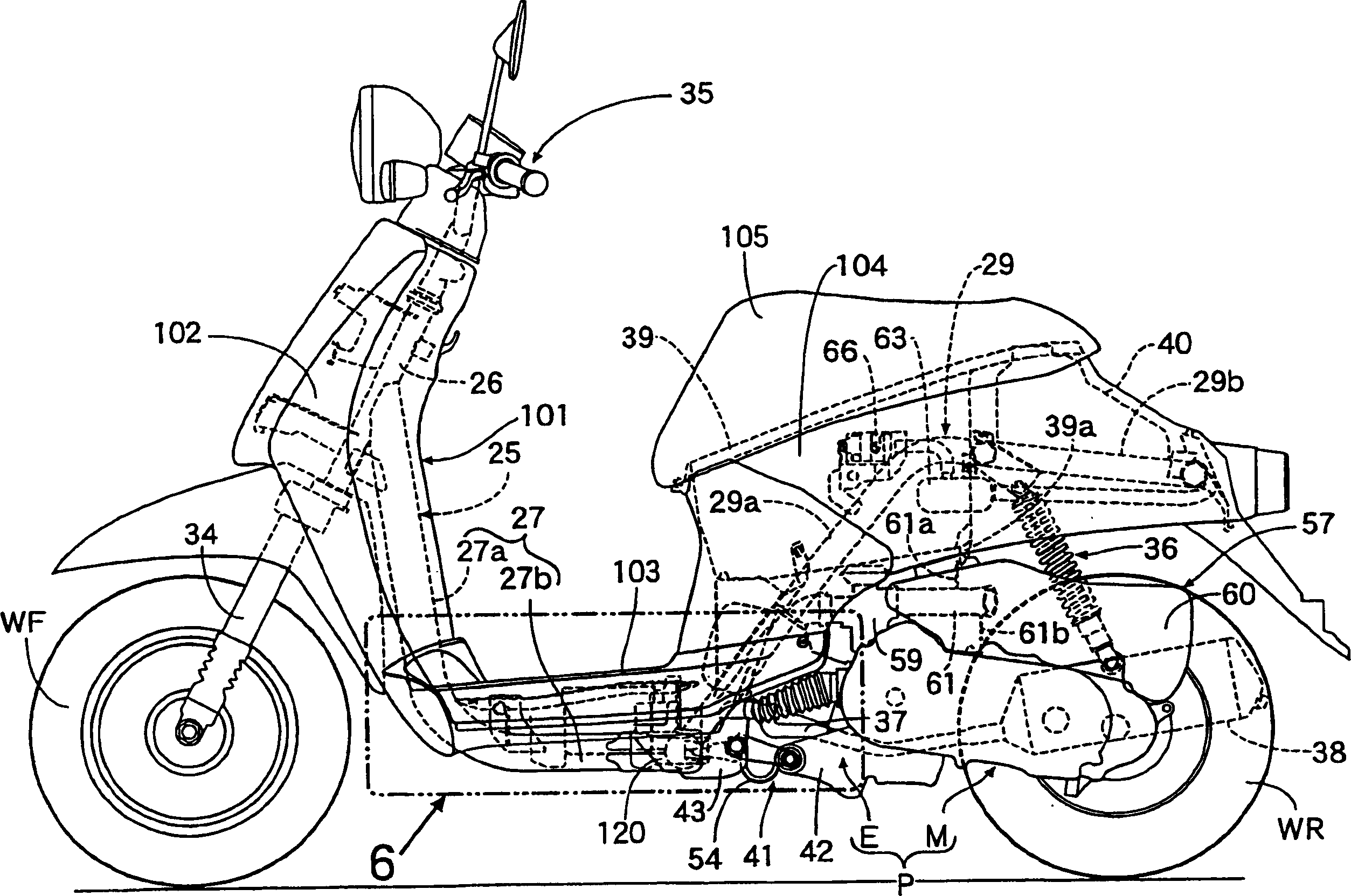

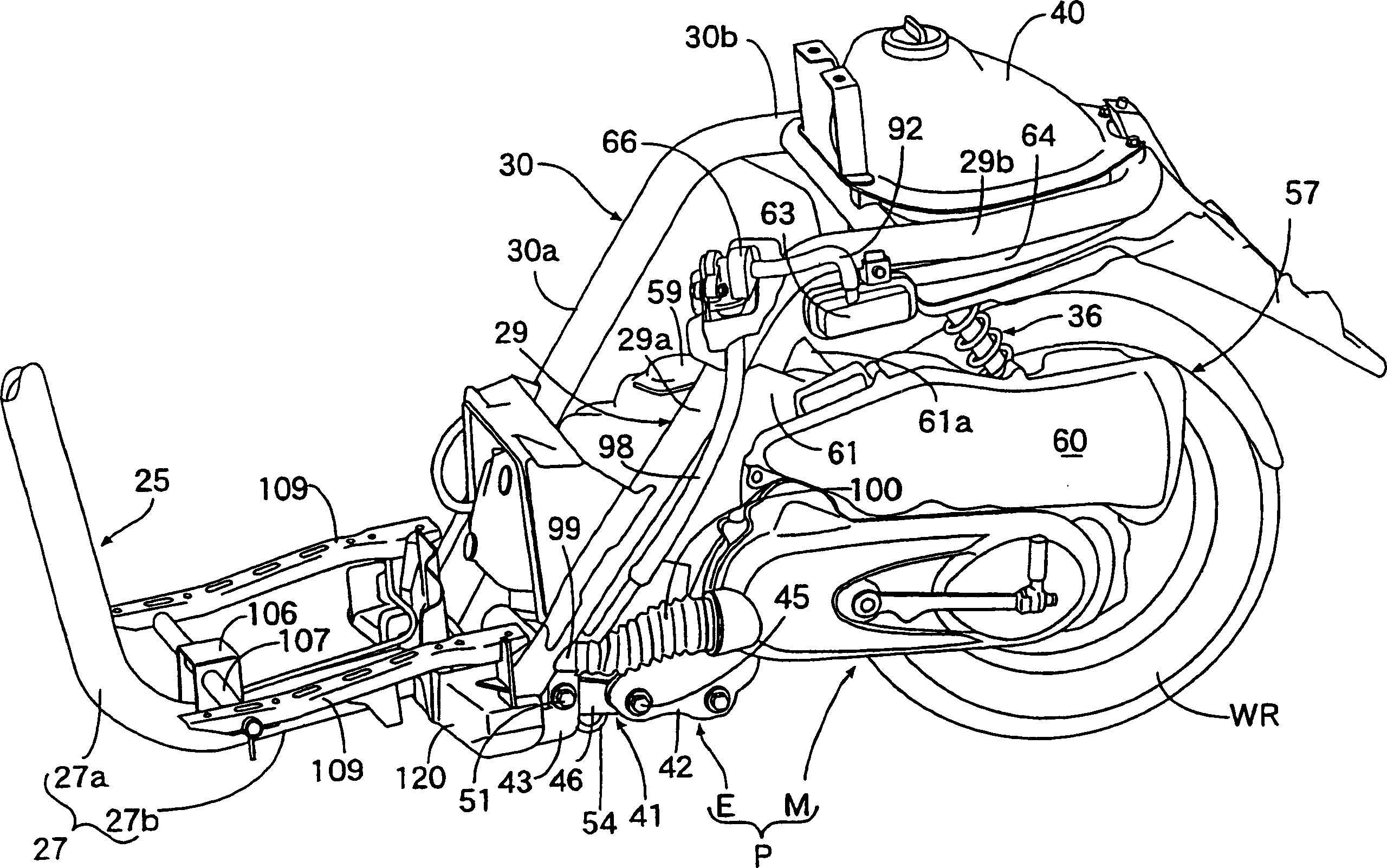

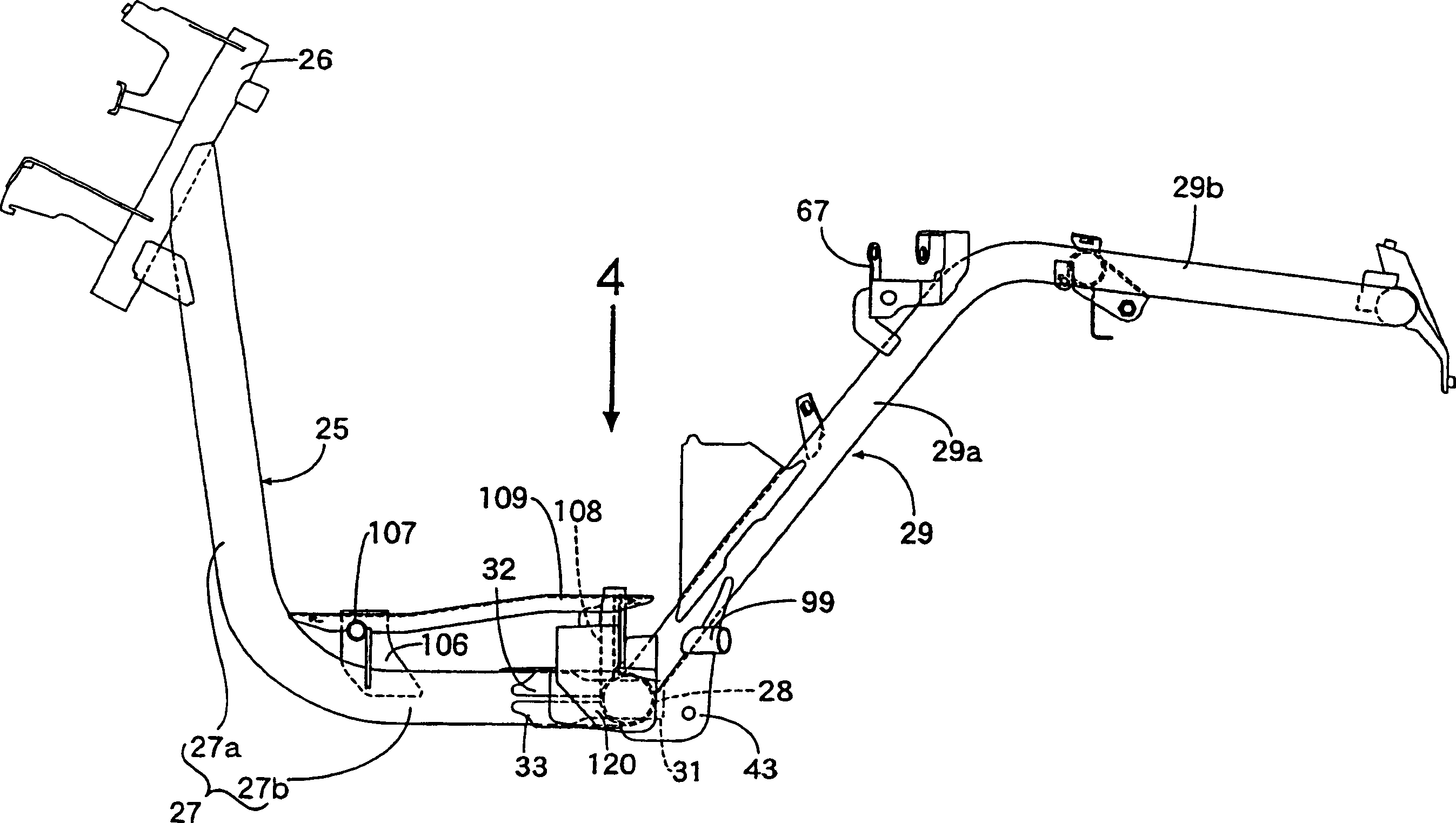

Structural arrangement for battery for saddle-ridden vehicle

ActiveCN103097235ARealization of thin wall miniaturizationPrevent the situation where the leapfrogging becomes worseMotorised scootersArticle supporting devicesEngineeringElectrical and Electronics engineering

Disclosed is a structural arrangement for a battery for a saddle-ridden vehicle wherein the main frame is formed of one frame passing above the centre line of the vehicle, and further the battery is disposed below the main frame.

Owner:HONDA MOTOR CO LTD

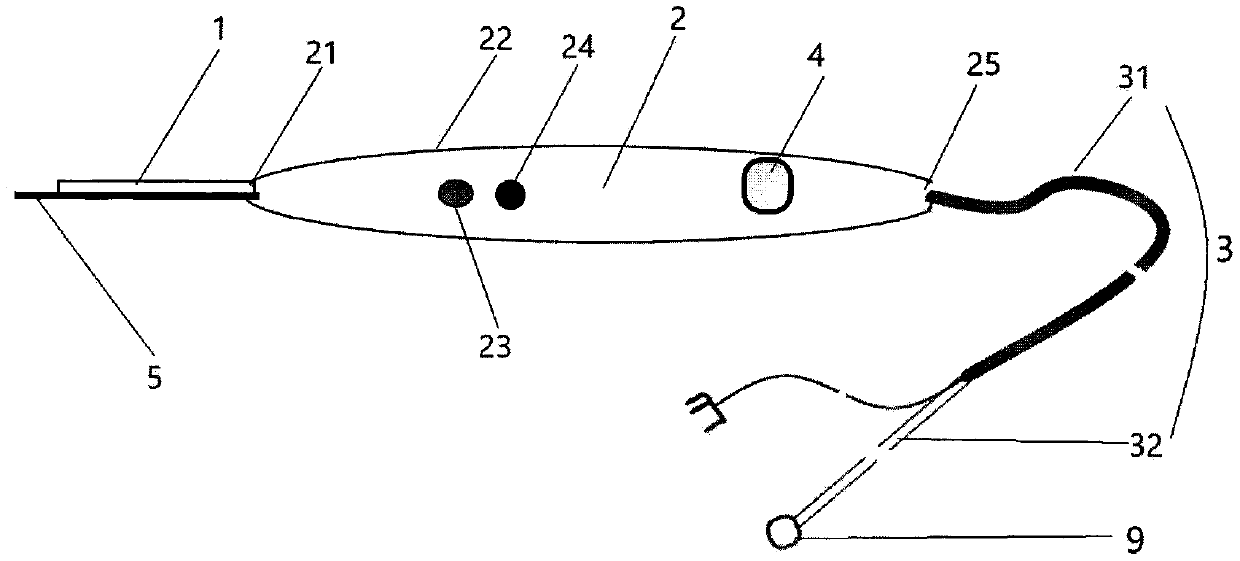

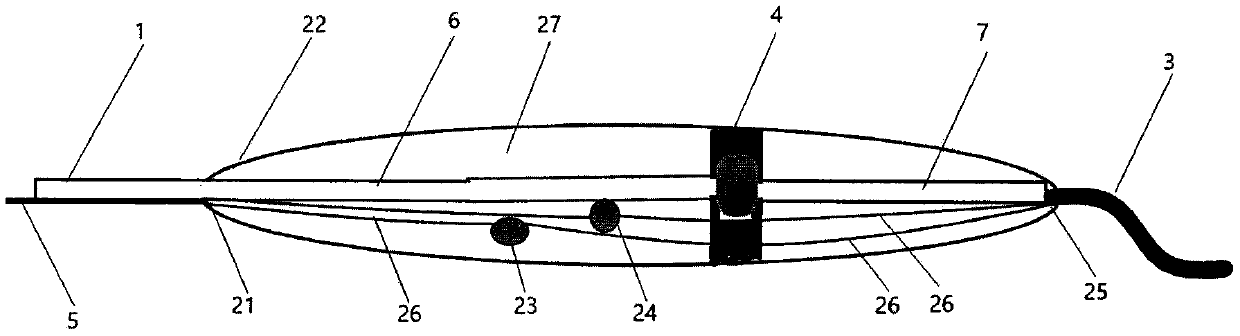

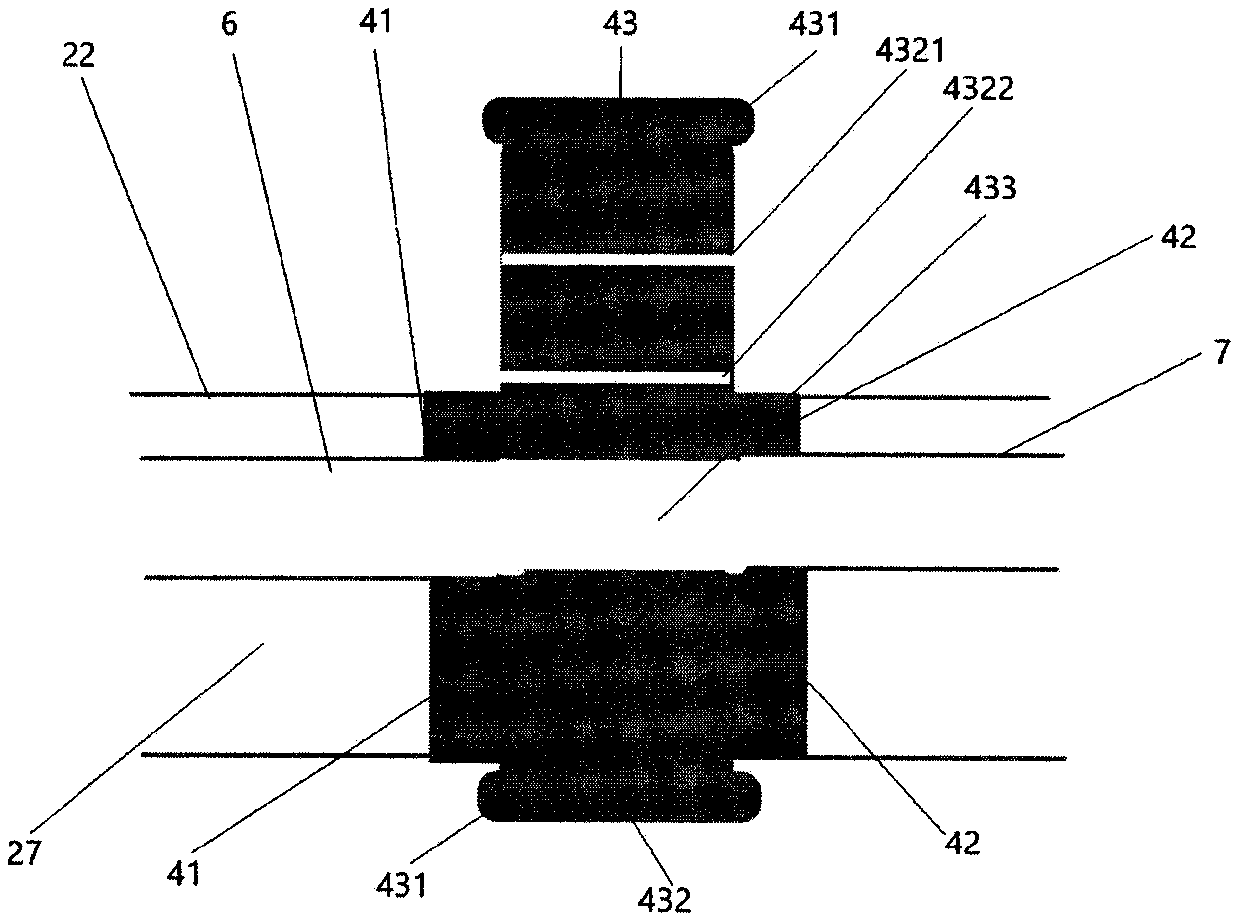

Vacuum suction monopolar electrocoagulation and electro-excision pen

InactiveCN110123441AReduce local temperatureIncrease the efficiency of attracting smokeSurgical instruments for heatingSurgical instruments for aspiration of substancesElectricityElectrocoagulation

A vacuum suction monopolar electrocoagulation and electro-excision pen comprises a monopolar electrocoagulation and electro-excision pen body and a vacuum suction duct system, wherein the monopolar electrocoagulation and electro-excision pen body comprises an electrode head, a handle, and a connection wire; the vacuum suction duct system comprises a hollow duct and a control device. The vacuum suction monopolar electrocoagulation and electro-excision pen allows a user to perform electrocoagulation and electro-excision, suck off smoke and suck away oozing blood and liquid by one hand; occupational injury is avoided, personnel is reduced, and efficiency is improved.

Owner:XIAMEN BONAI MOLD DESIGN CO LTD

Drive assembly of pulsator washing machine

InactiveCN103422323BImprove transmission efficiencyAccurate clutch controlOther washing machinesTextiles and paperPull in voltageClutch control

Owner:CHANGZHOU XINYA ELECTROMOTOR

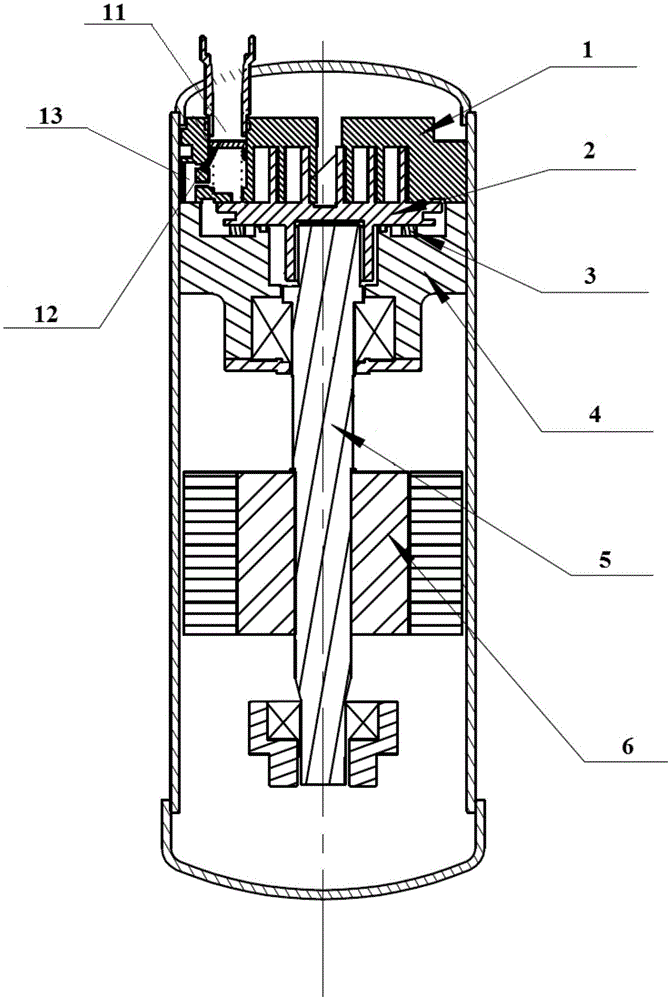

Linear compressor

ActiveCN109723620ASmall form factorIncrease inspiratory capacityPositive displacement pump componentsPiston pumpsLinear compressorEngineering

The invention discloses a linear compressor. The linear compressor comprises a linear motor, a hollow stepped shaft piston and a stepped hole cylinder; a bearing hole of the linear motor is formed inthe stepped hole cylinder; one end of the hollow stepped shaft piston is arranged in the linear motor and fixedly connected with a rotor of the linear motor; the hollow stepped shaft piston slides linearly in the axial direction of the bearing hole; and the other end of the hollow stepped shaft piston penetrates out of the linear motor through the bearing hole and is inserted into the stepped holecylinder to form a compression space in the stepped hole cylinder. A resonant spring is placed in the linear motor, so that an internal space of the linear motor is capable of being effectively utilized, and the external dimension of the linear compressor is reduced; and the stepped hole cylinder and the bearing hole of the linear motor are integrally formed in the form of the stepped hole cylinder, so that the phenomenon that the stepped hole cylinder and the hollow stepped shaft piston are clamped after being externally arranged is capable of being effectively avoided.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

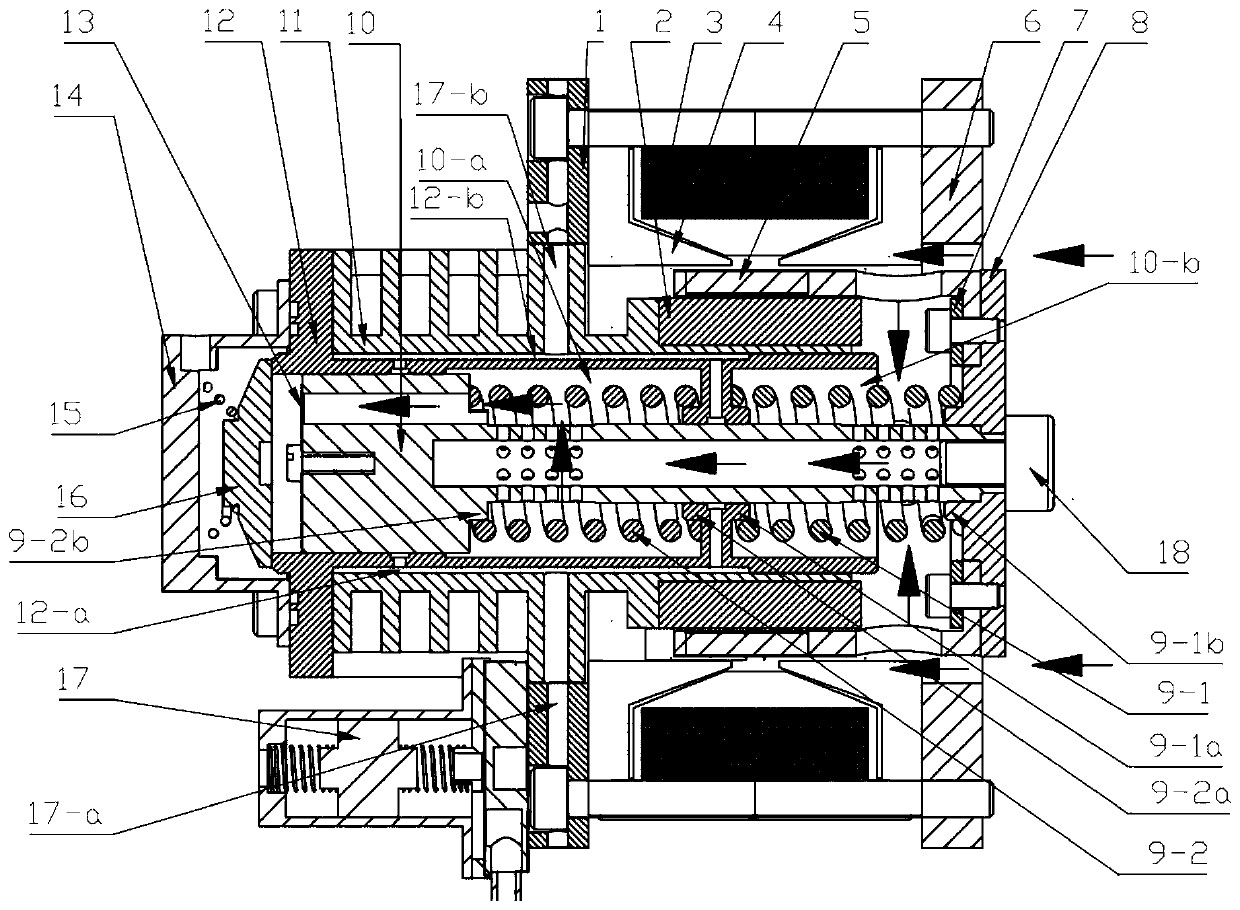

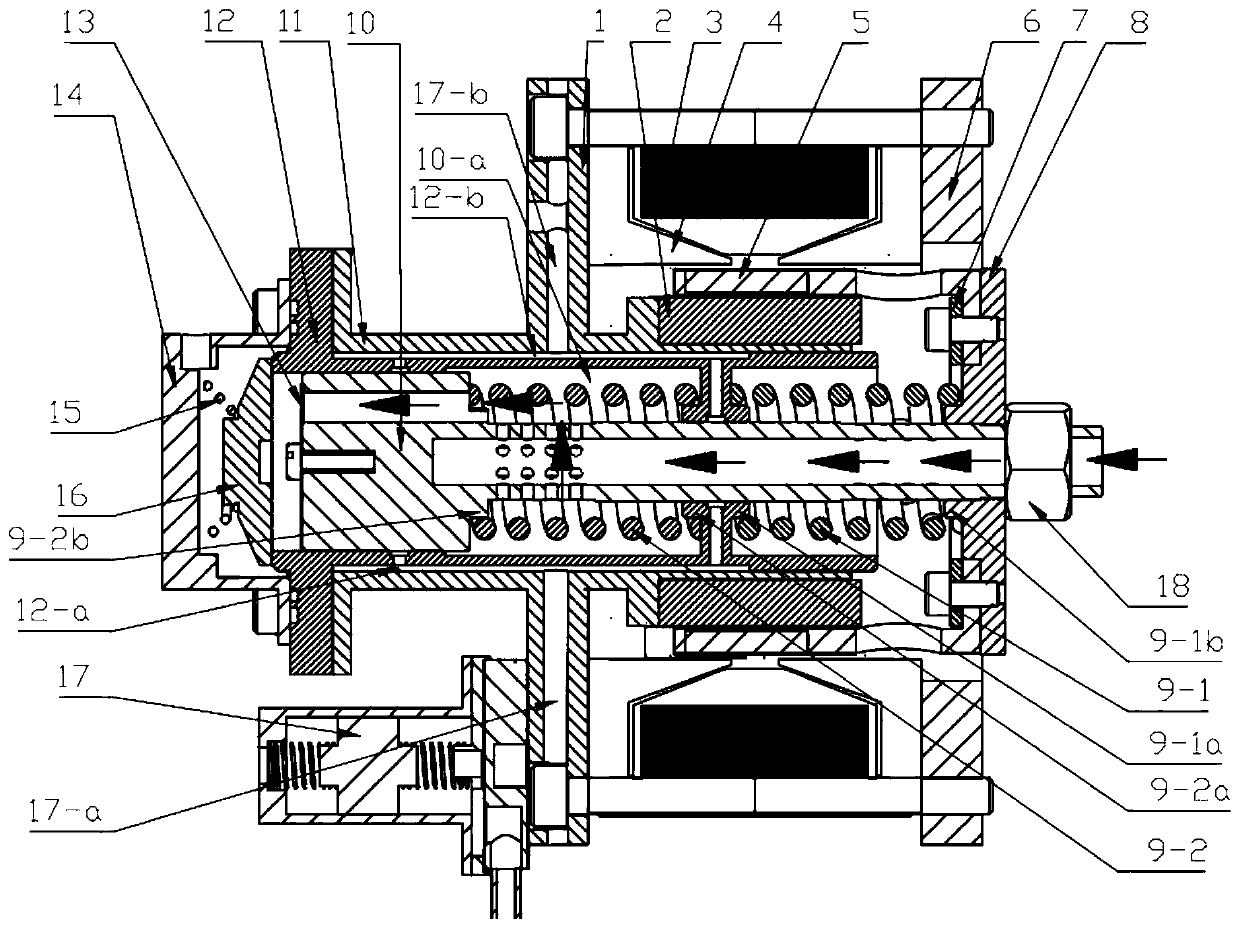

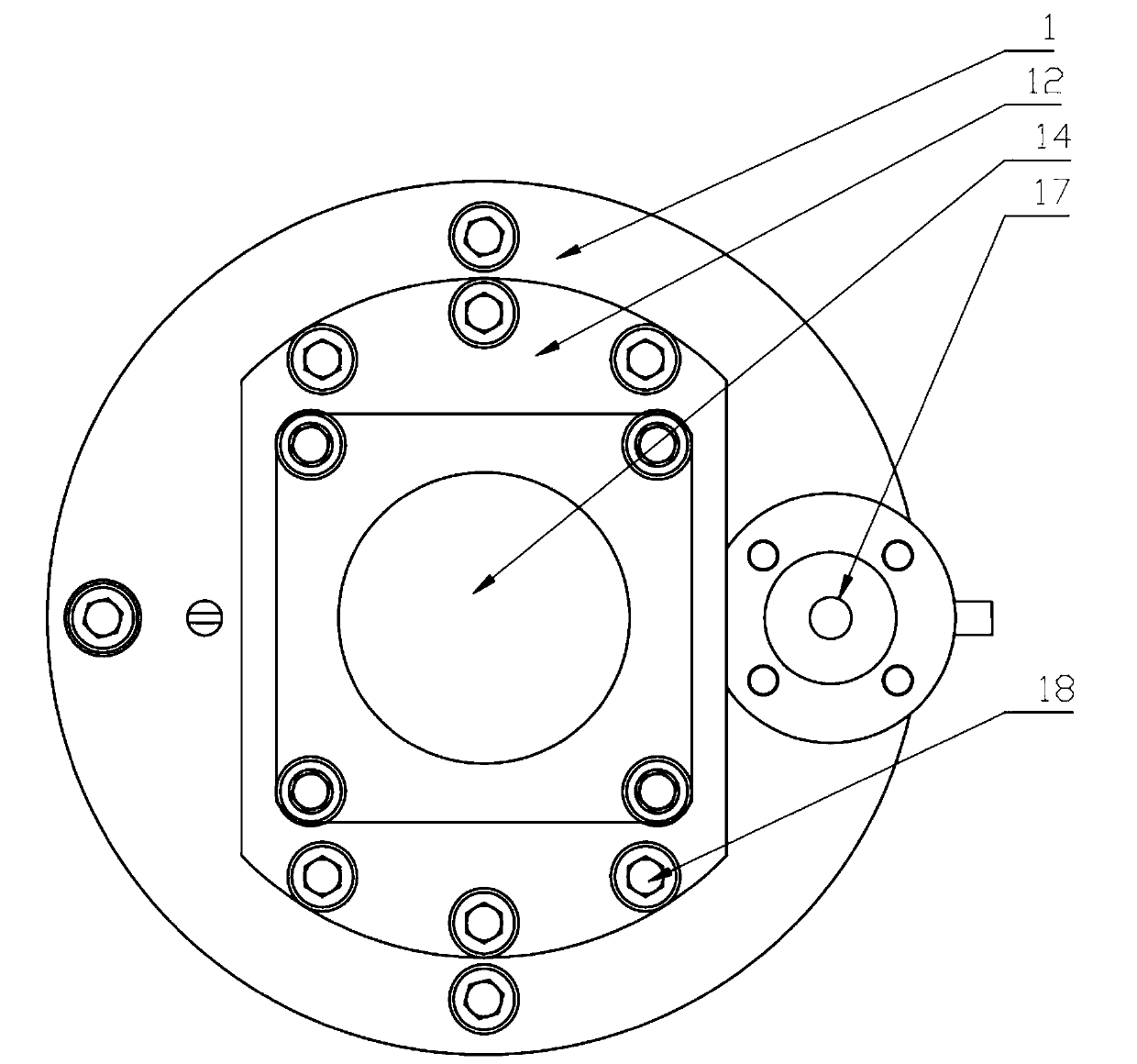

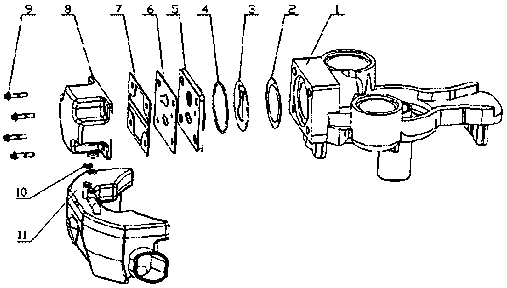

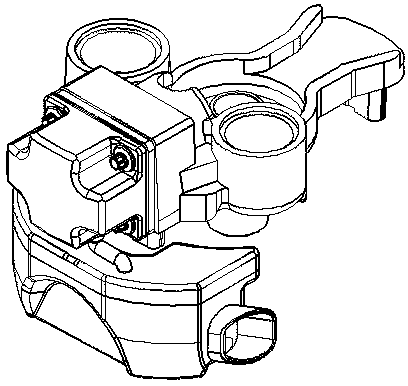

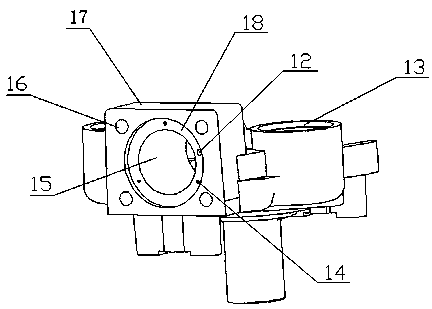

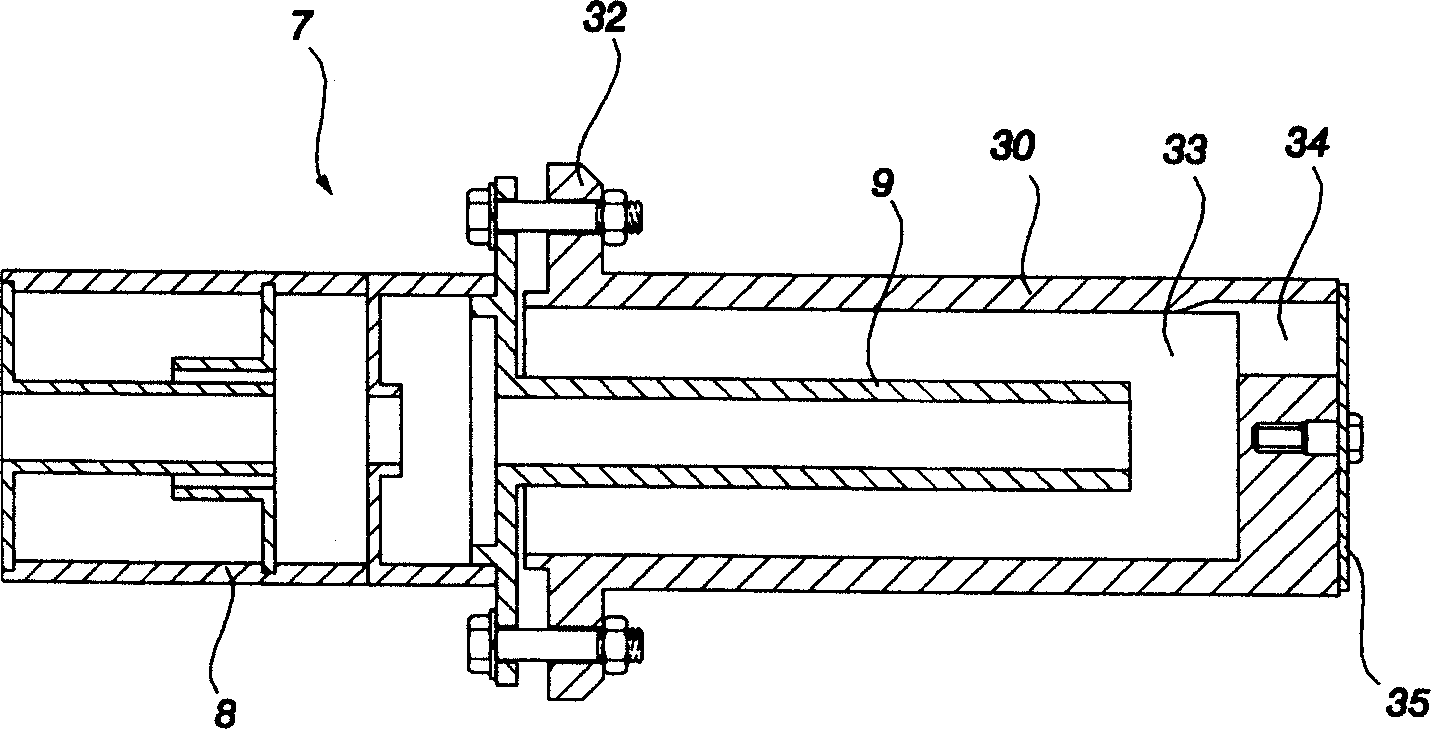

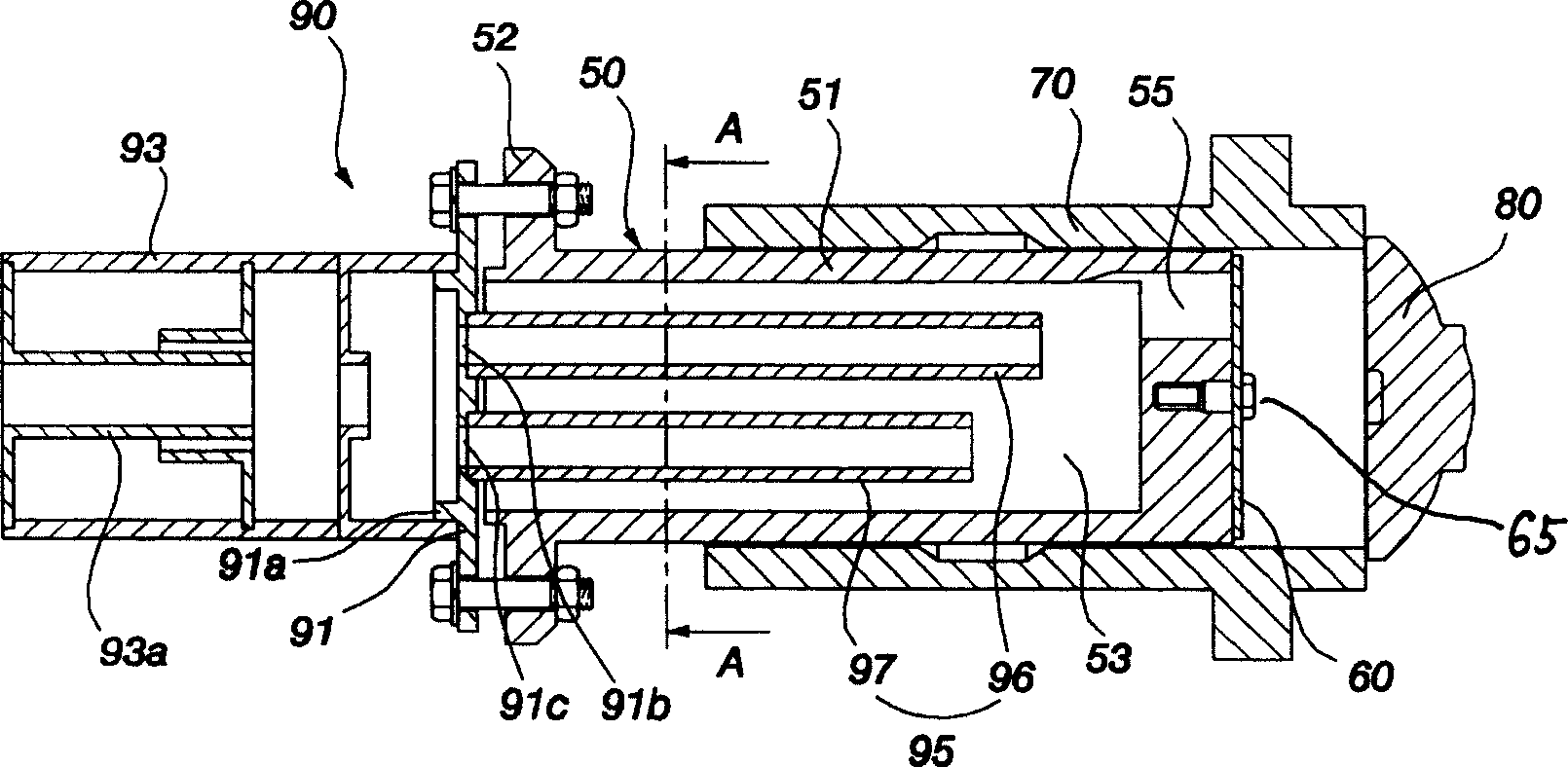

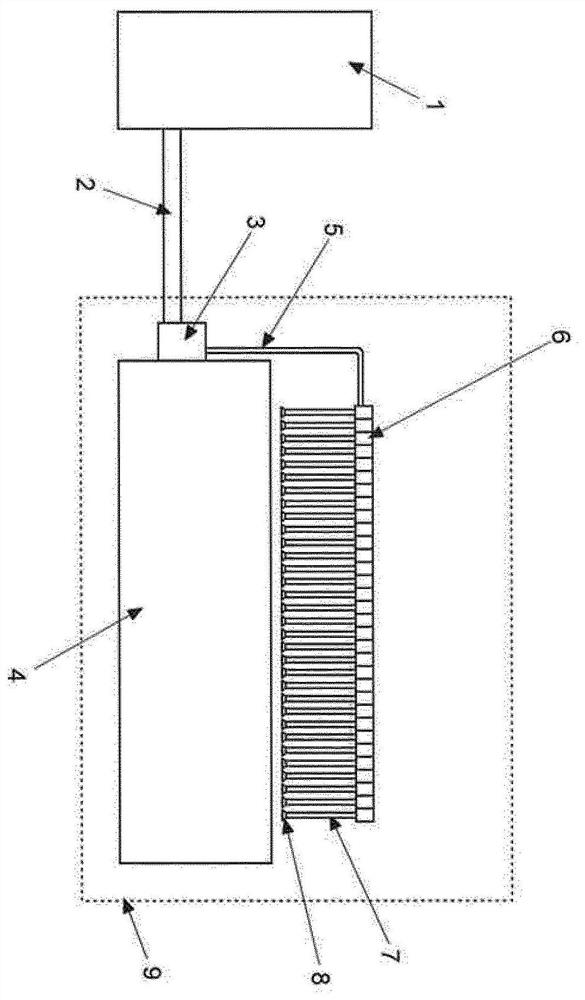

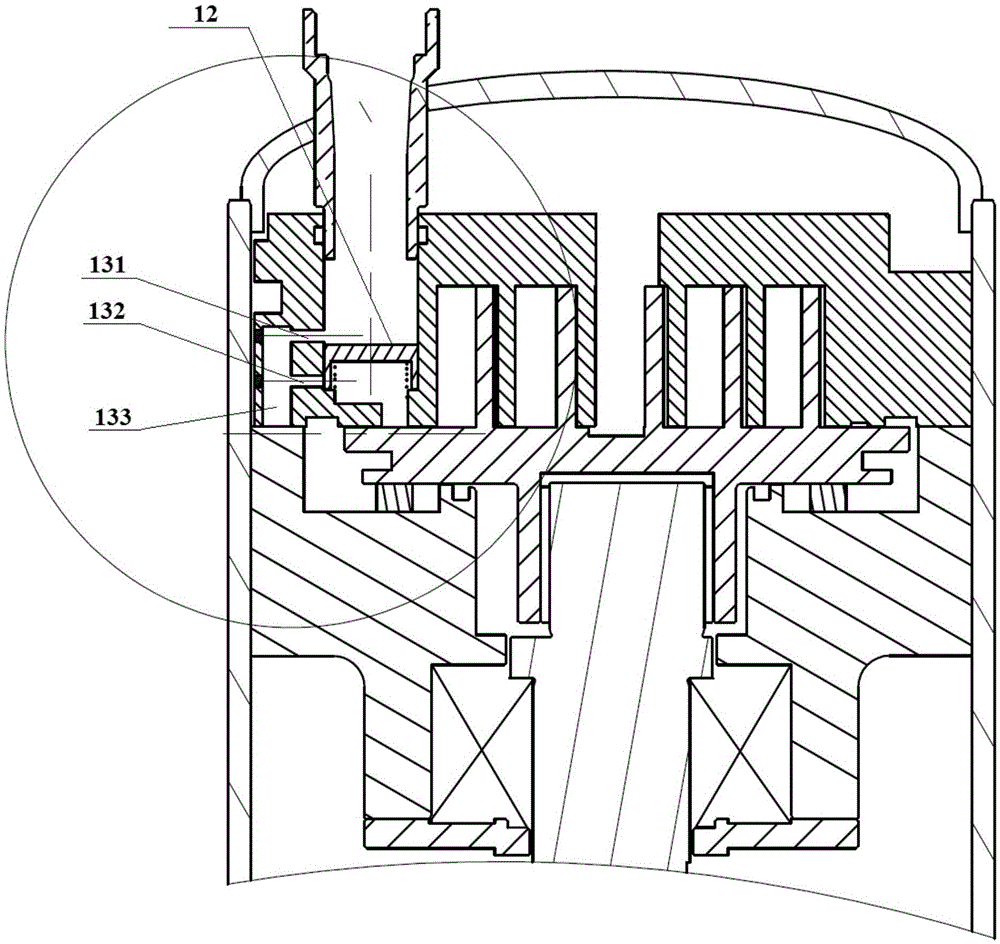

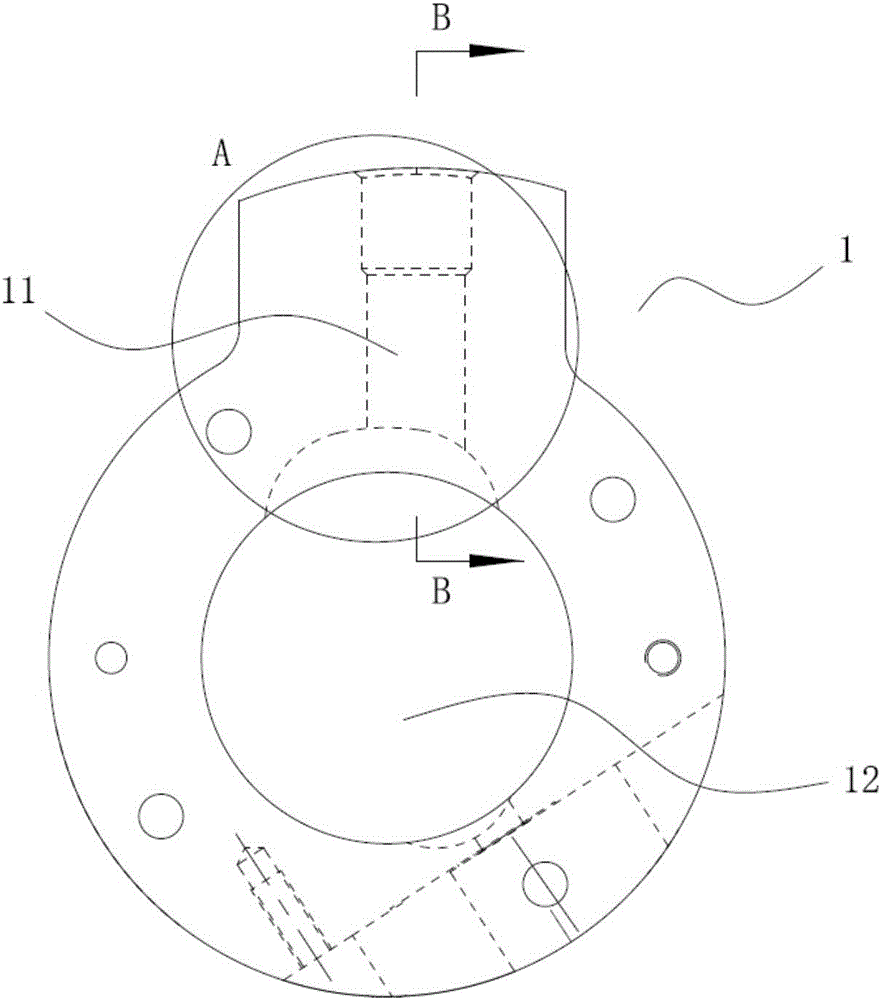

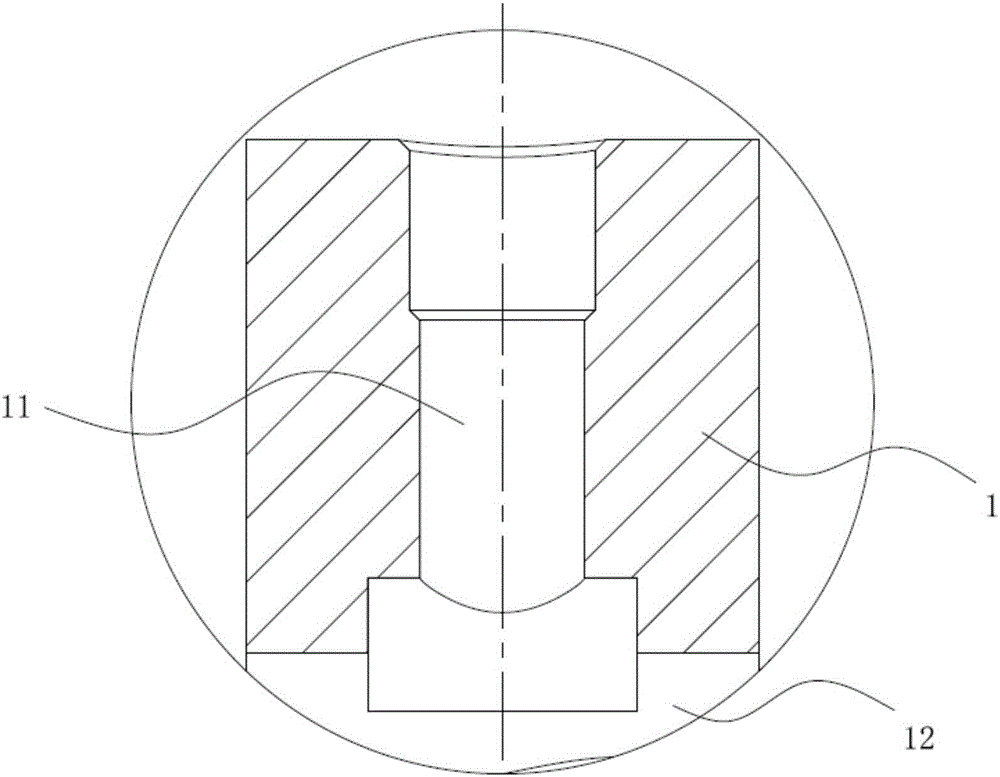

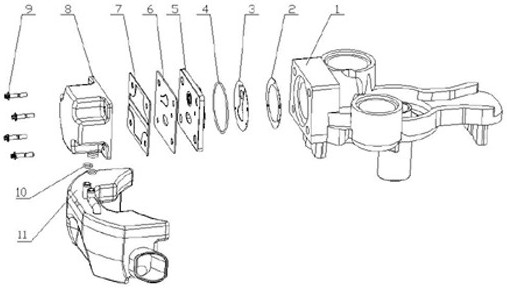

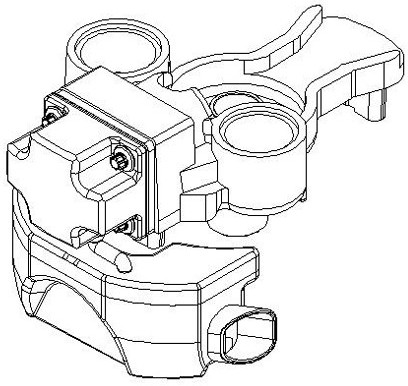

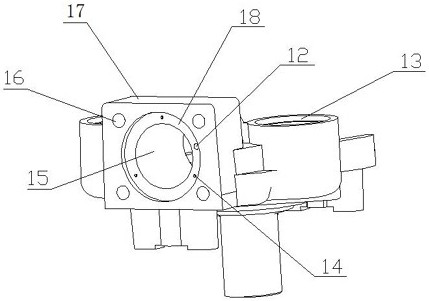

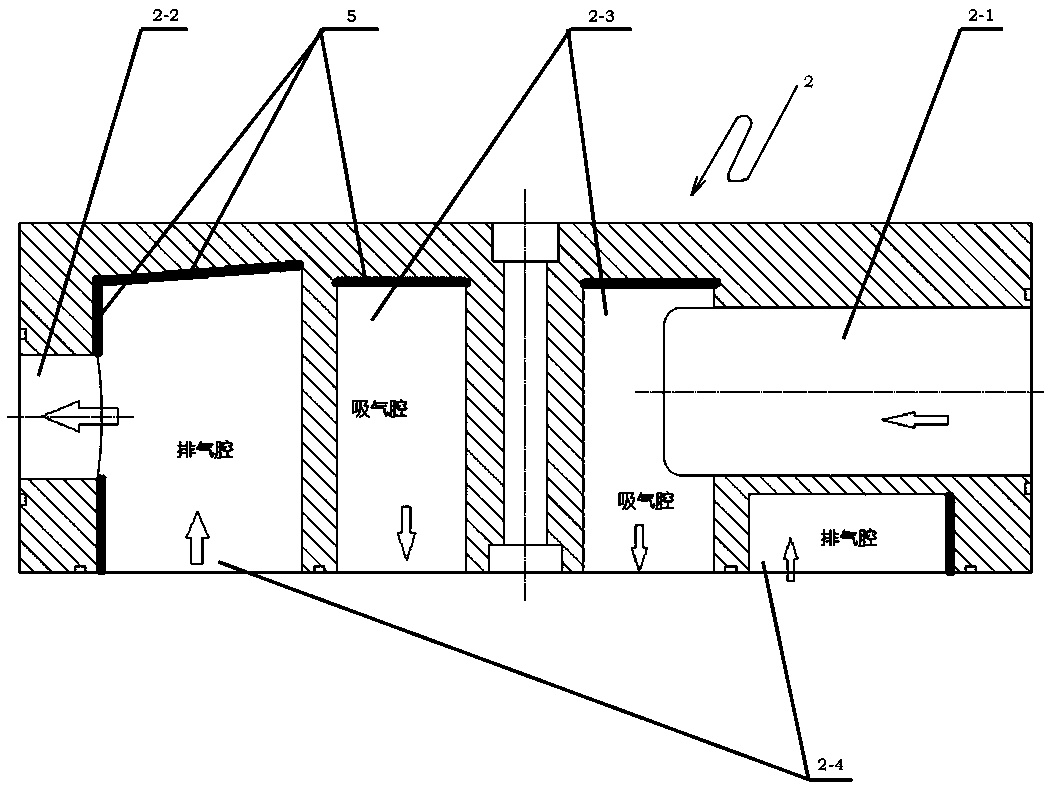

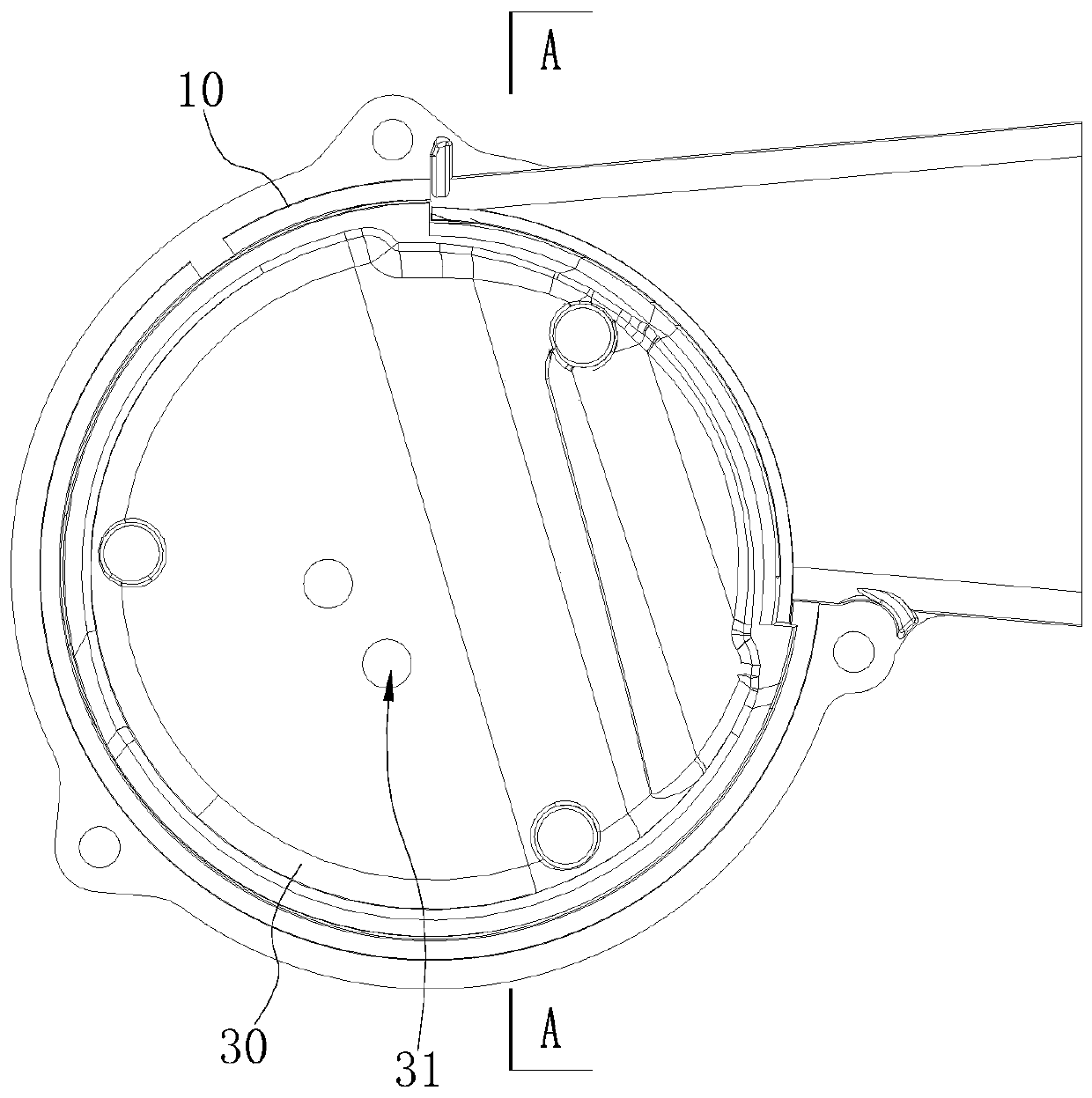

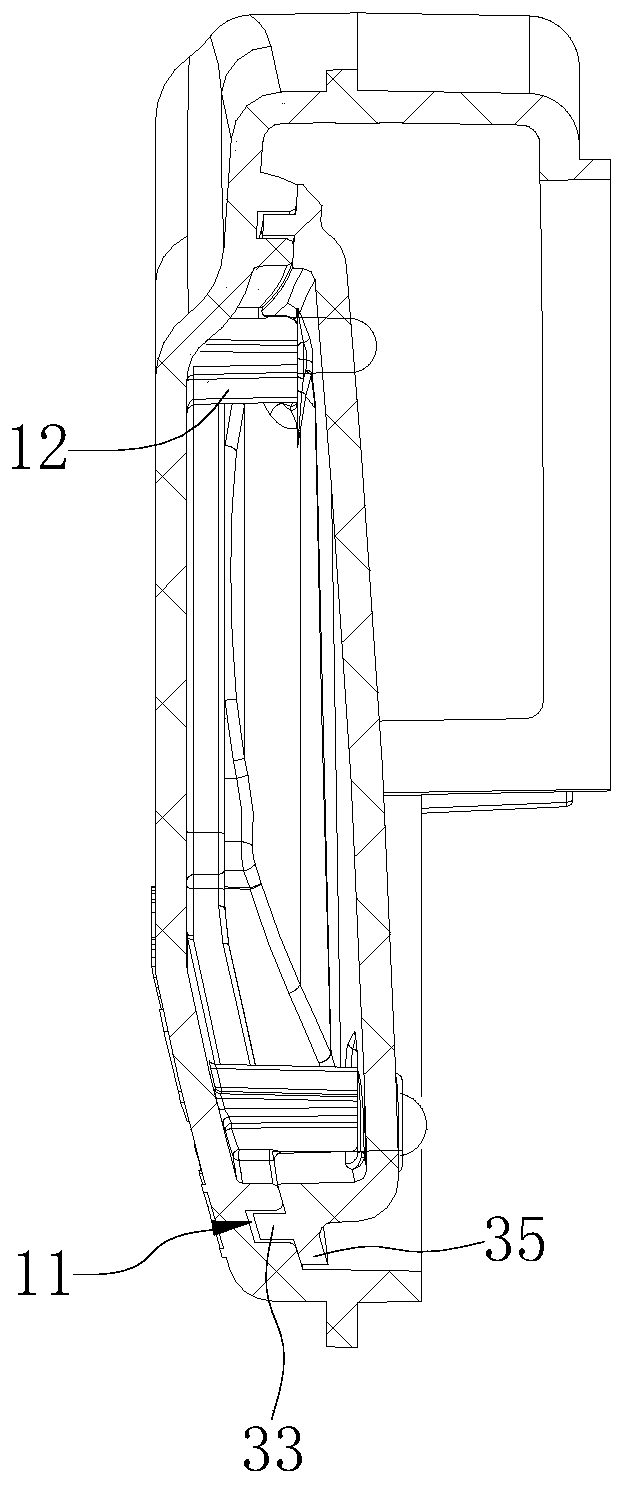

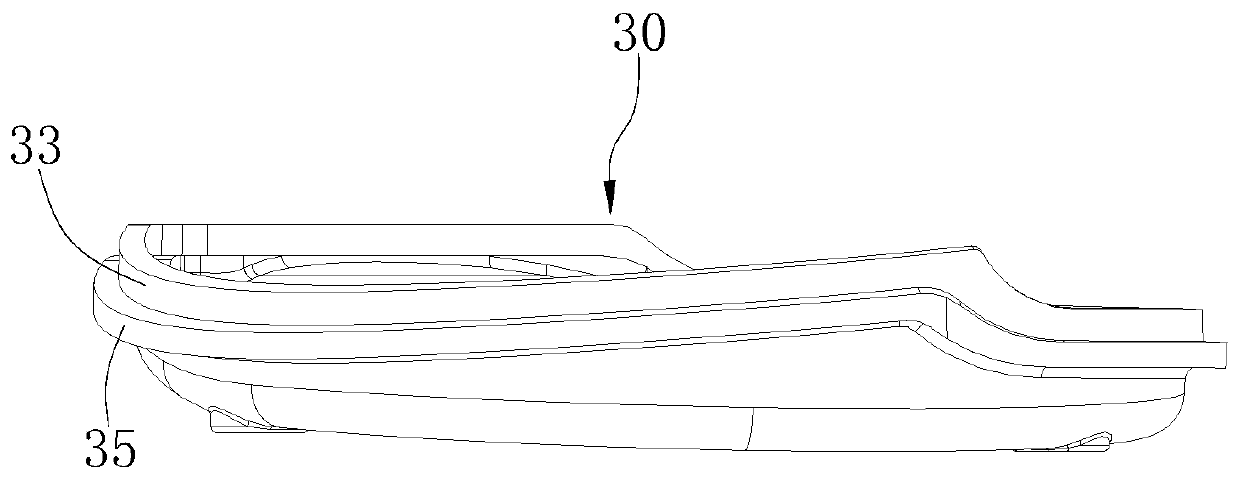

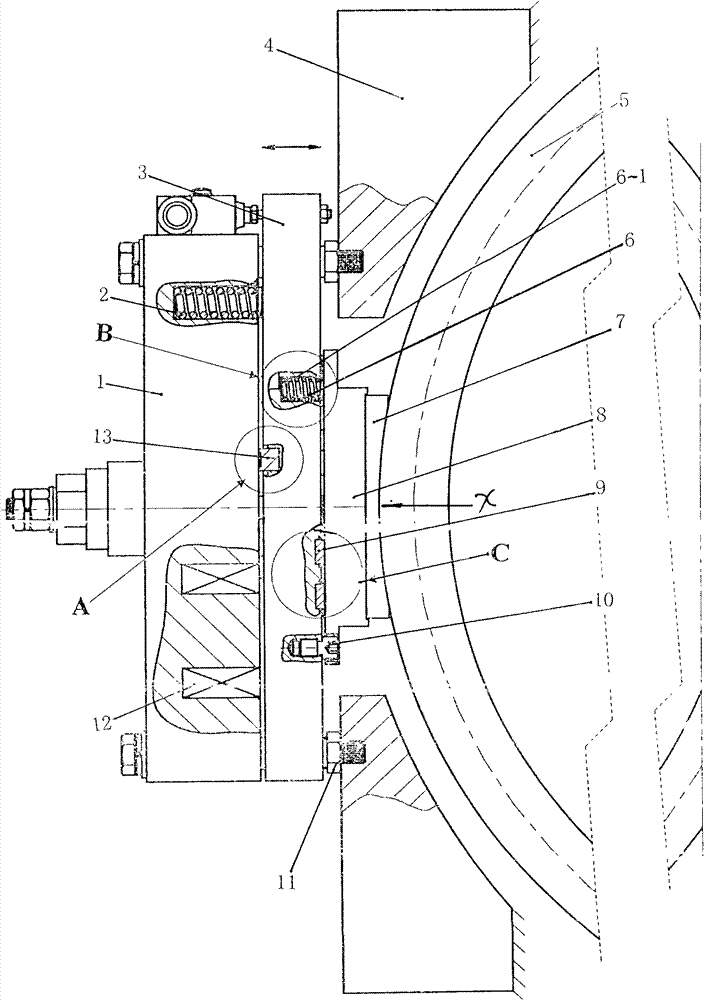

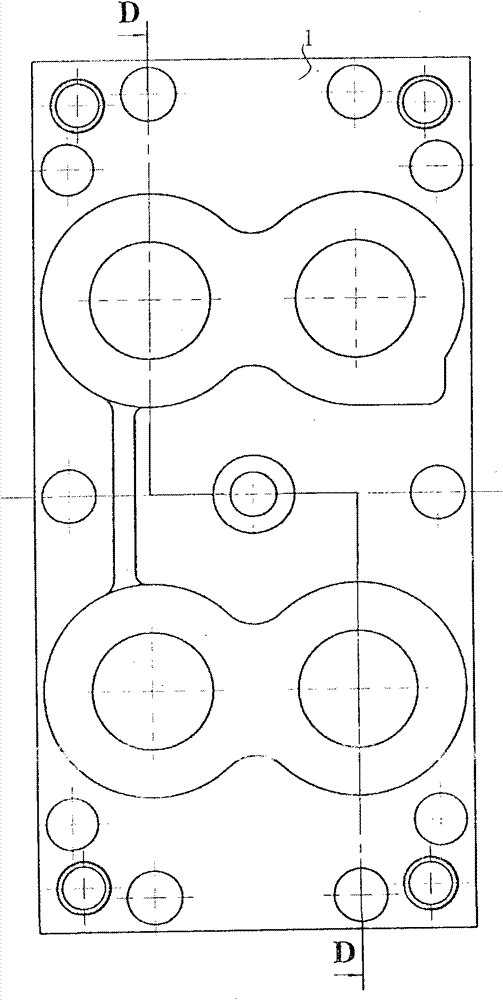

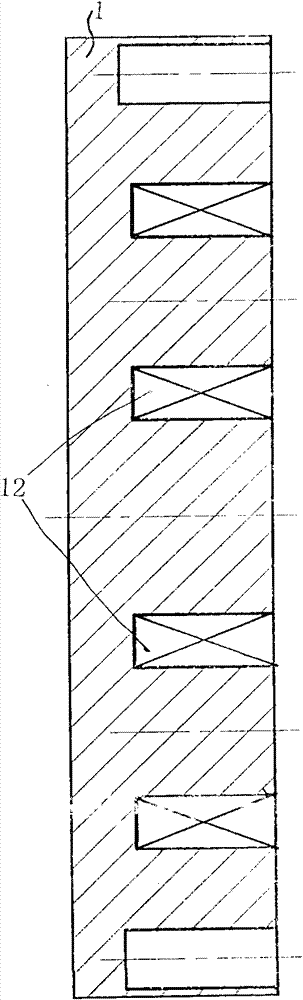

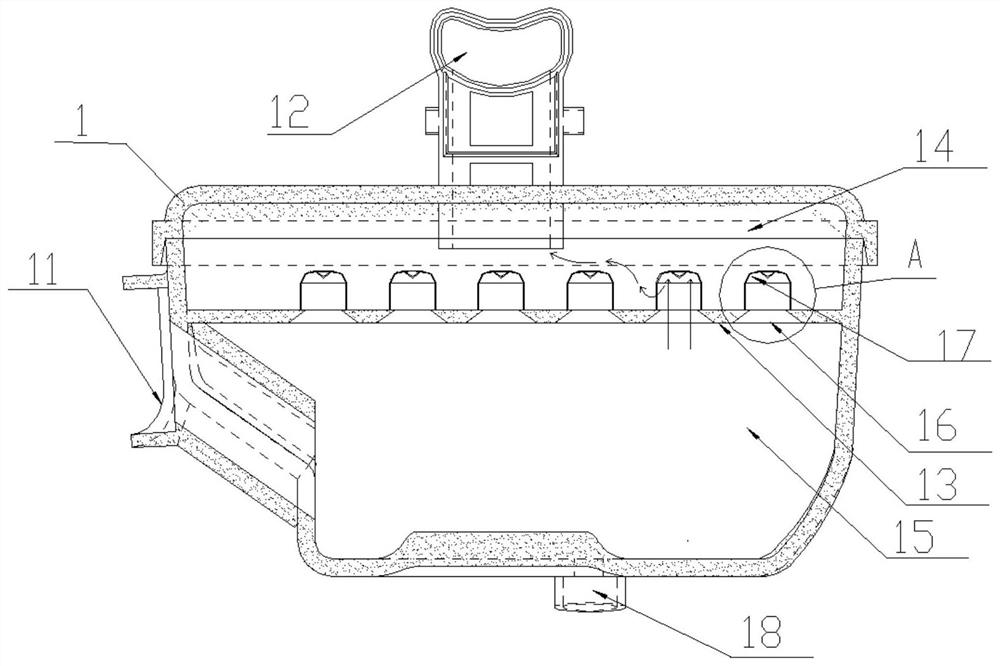

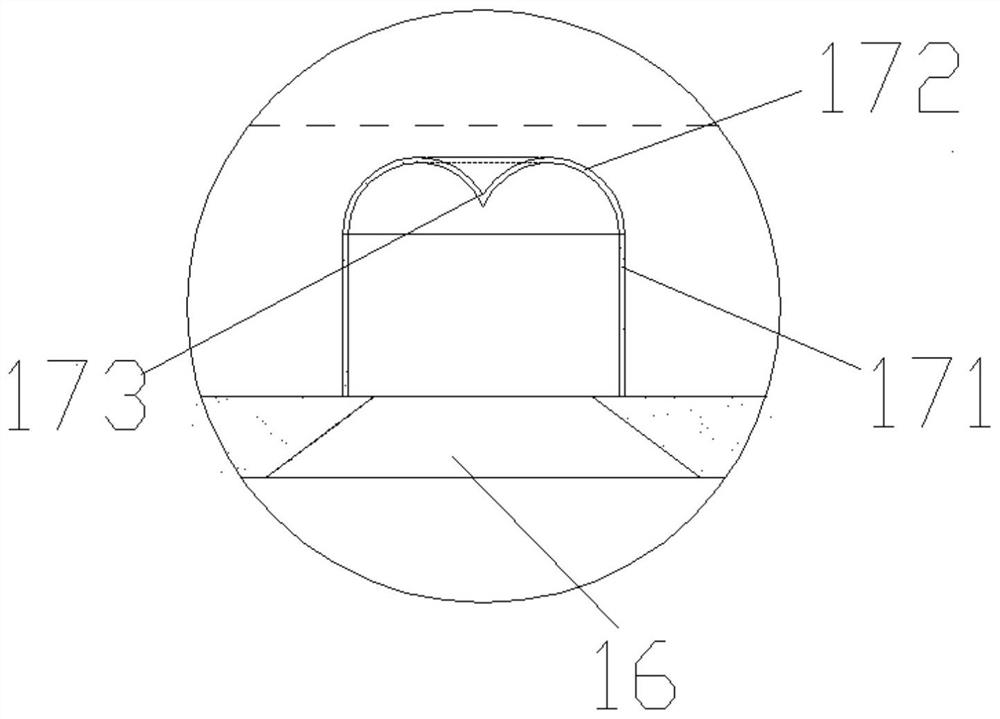

Gas suction and discharge structure for compressor

ActiveCN110410297AReduce suction noiseGuaranteed air tightnessPositive displacement pump componentsPositive-displacement liquid enginesCrankcaseMuffler

The invention discloses a gas suction and discharge structure for a compressor. The gas suction and discharge structure comprises a crankcase (1), a valve plate seal gasket (2), a gas suction valve disc (3), a valve plate (5), a gas discharge valve disc (6), a cylinder cover seal gasket (7), a cylinder cover (8), a mounting screw (9) and a gas suction silencer (11). The end face of a cylinder body(17) of the crankcase (1) is provided with a step hole (18), a valve plate locating hole (14) and a first exhaust outlet (12). The rear end face of the valve plate (5) is provided with a round boss (57), a locating column (52) and a fifth exhaust outlet (51). An exhaust cavity (81) and a gas suction cavity (83) are formed in the cylinder cover (8). A gas discharge valve disc limiting column (84)is arranged in the exhaust cavity (81). The bottom face of the gas suction cavity (83) is provided with an oil leakage hole (85) and two gas inlet pipes connected with a gas outlet pipe of the gas suction silencer (11). Through the gas suction and discharge structure, gas leakage can be reduced, gas transfer efficiency of the compressor is promoted, gas suction noise of the compressor is lowered,and the gas suction and discharge structure has wide market prospects.

Owner:CHANGHONG HUAYI COMPRESSOR CO LTD

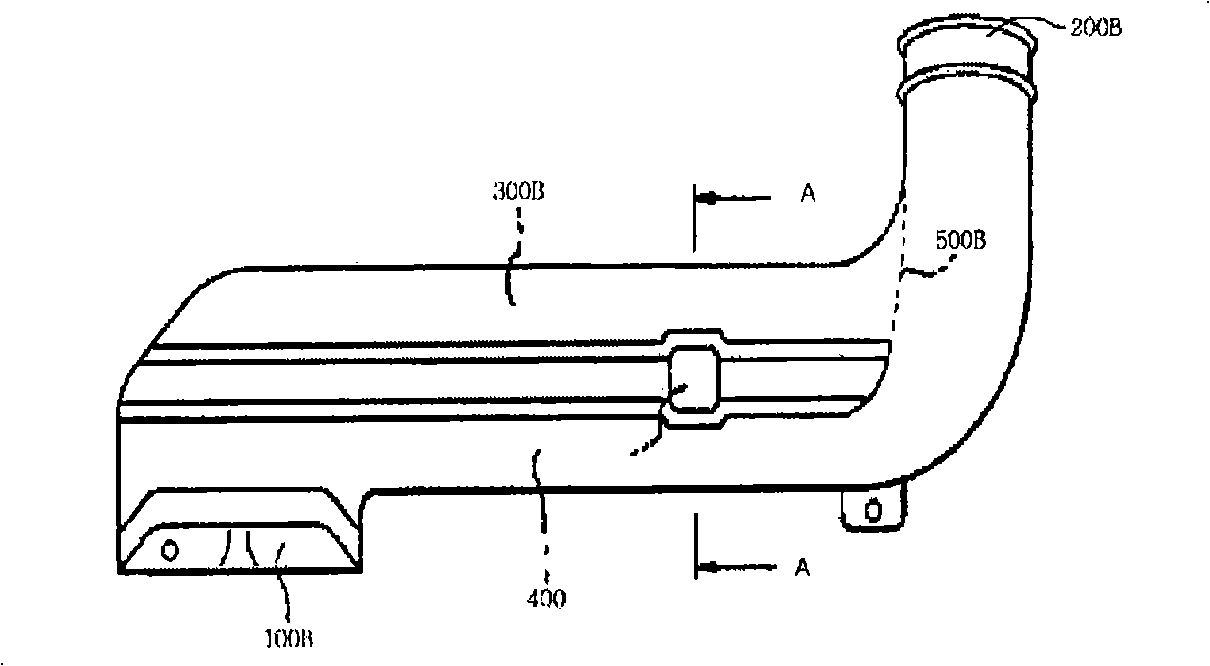

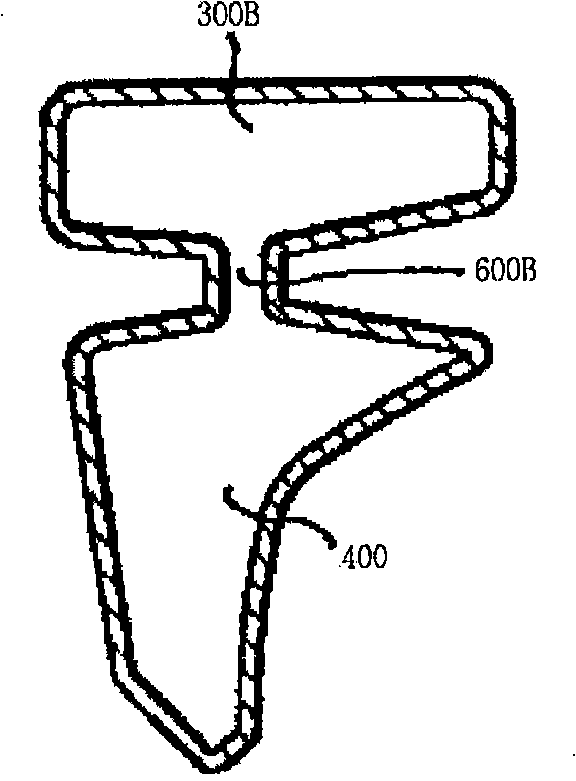

Air induction device for automobile

InactiveCN101317005AReduce suction noiseImprove exercise quietnessMachines/enginesIntake silencers for fuelResonanceThrottle

Provided is an air induction device for an automobile capable of reducing suction noise generated by the suction air to improve stillness in driving. The air induction device for an automobile includes: a main body having a suction manifold mounted on an engine, a throttle body installed in the suction manifold, an air cleaner connected to the throttle body by an air suction duct, an air suction pipe connected to the air cleaner to introduce the external air and having an opening installed at a rear part of a radiator, a suction port formed at a front part thereof, and a space formed therein; a discharge pipe formed at one side of the main body and connected to the suction pipe to be in communication with the space; ; and a resonance part formed inside the main body to remove noise generated during air suction, characterized in that the resonance part is formed of a cylindrical pipe and has a closed end opposite to the discharge pipe and an oval opening formed at the other end toward the discharge pipe, and the opening is formed to be connected to an inlet port of the discharge pipe and installed at a rear surface inside the main body to be opposite to the suction port of the main body.

Owner:KOREA WECOSTA CO LTD

Blower for vehicles

ActiveCN101284490BAvoid deformationPrevent saggingAir-treating devicesVehicle heating/cooling devicesAir filterAir blower

The present invention relates to a blower for vehicles, which includes guide walls formed on a bypass passageway formed between a scroll case and an outer case to send the indoor air and the outdoor air to a lower suction opening of the scroll case, thereby reducing suction noise by guiding a uniform flow of air introduced into the lower suction opening, preventing deformation of the outer case, and preventing a droop of the air filter by supporting a lower portion of an air filter when an intake duct injection-molded in a vertically parted mold is applied thereto.

Owner:HANON SYST

Noise reducing apparatus of linear compressor

InactiveCN1766323AReduced suction noiseImprove suction efficiencyPositive displacement pump componentsPiston pumpsLinear compressorEngineering

The invention discloses a noise reduction device of linear compressor, which is characterized by the following: multiple insert pipes of different lengths are set behind the piston in connection with the suction flow path of piston; the suction inlet is formed in front of the piston. The longer insert pipe is set near the suction inlet, which improves the suction efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Centrifugal blower with efficient aerodynamic efficiency

InactiveCN110080999AImprove air intake efficiencyImprove aerodynamic efficiencyPump componentsRadial flow pumpsImpellerAerodynamic load

The invention discloses a centrifugal blower with efficient aerodynamic efficiency. Symmetrical curved surface main guide blade segments and symmetrical curved surface secondary guide blade segments are arranged in an air intake flow channel of an air intake shell of the centrifugal blower with the efficient aerodynamic efficiency; the symmetrical curved surface main guide blade segments are closeto an air inlet relative to the symmetrical curved surface secondary guide blade segments; guide blade sides of the two sides of the symmetrical curved surface main guide blade segments and the symmetrical curved surface secondary guide blade segments respectively correspond to the shapes of the front inner shell wall and rear inner shell wall of the air intake shell and extend; each blade of animpeller comprises a forward type blade segment located at one end close to an axial air inlet, and a backward type blade segment located at one end close to an radial air outlet; and the forward typeblade segment is connected to the backward type blade segment by a radial blade segment. The structures of the air intake shell and the impeller blades are specially designed, so that the centrifugalblower has multiple technical effects of high intake efficiency, high aerodynamic efficiency, high aerodynamic load and low aerodynamic noise; and finally the centrifugal blower with efficient aerodynamic efficiency is obtained.

Owner:江苏乘帆压缩机有限公司

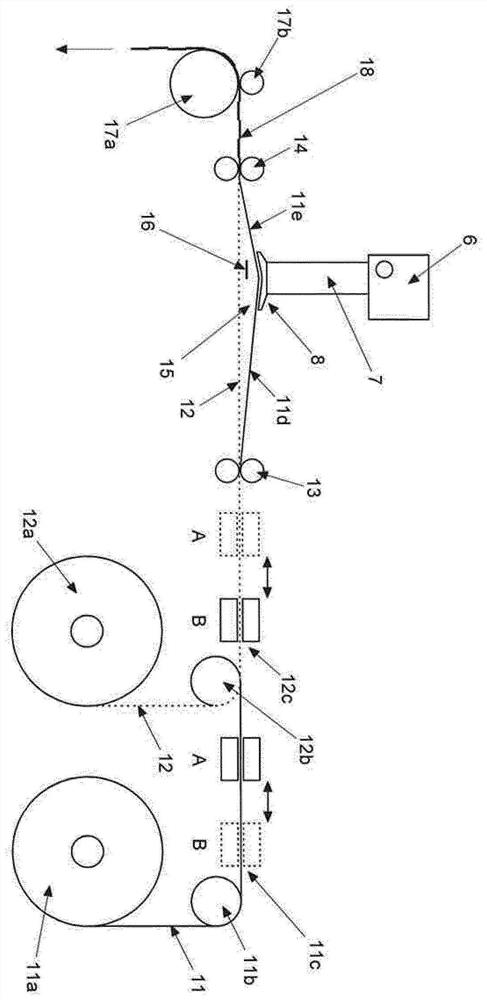

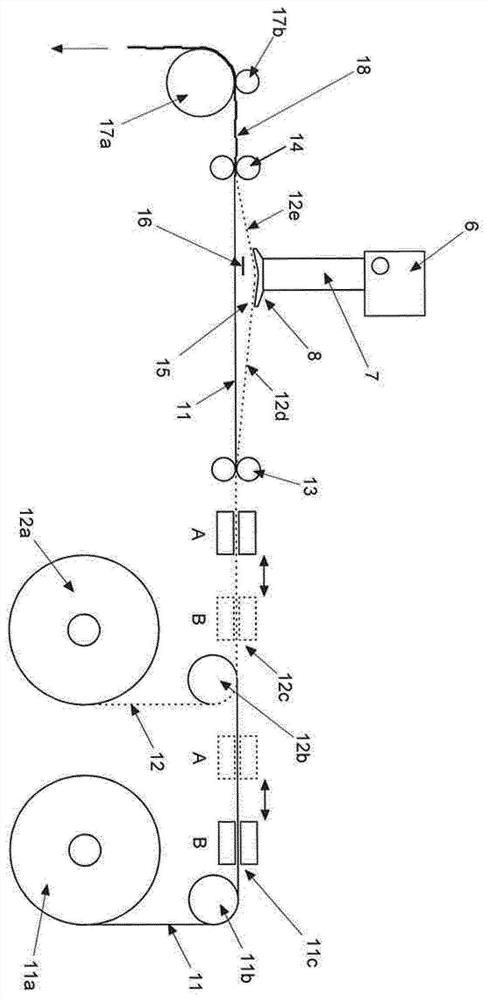

Shedding method and apparatus using air pressure

The present invention discloses a method and an apparatus for producing a woven material from tape-like warps and wefts, comprising a warp supply source for tape-like warps; a shed forming device to form a shed by said warps; a weft insertion device for inserting tape-like weft in the shed formed by said warps; and a take-up device for taking-up the produced woven material. Each of the warps extend in warp paths between the warp supply source and the take-up device. Further, the shed forming device comprises an air pressure system arranged to apply pressure on the face of at least some of the warps in an intermediate position of the warp paths, between the warp supply source and the take-up device, the applied air pressure being sufficient to displace said at least some warps in essentially the thickness direction of the tape-like warps.

Owner:TAPE WEAVING SWEDEN

Static scroll assembly and scroll compressor

ActiveCN105485004AReduced suction noiseImprove work performanceRotary piston pumpsRotary piston liquid enginesAirflowWork performance

The invention relates to the technical field of scroll compressors, in particular to a static scroll assembly and a scroll compressor. The static scroll assembly comprises an air suction channel and a static scroll. The static scroll is used for being matched with a dynamic scroll so that a compression cavity can be formed, and air suction airflow enters the compression cavity through the air suction channel. The static scroll assembly further comprises a silencing structure used for reducing the noise strength of the air suction airflow. The silencing structure comprises a neck channel and a silencing cavity which is communicated with the air suction channel through the neck channel. Based on the static scroll assembly, due to the fact that the static scroll assembly further comprises the silencing structure provided with the neck channel and the silencing cavity, the silencing cavity is communicated with the air suction channel through the neck channel, thus, when the air suction airflow flows through the air suction channel, the silencing structure can reduce air suction noise of the scroll compressor, and the work performance of the scroll compressor is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

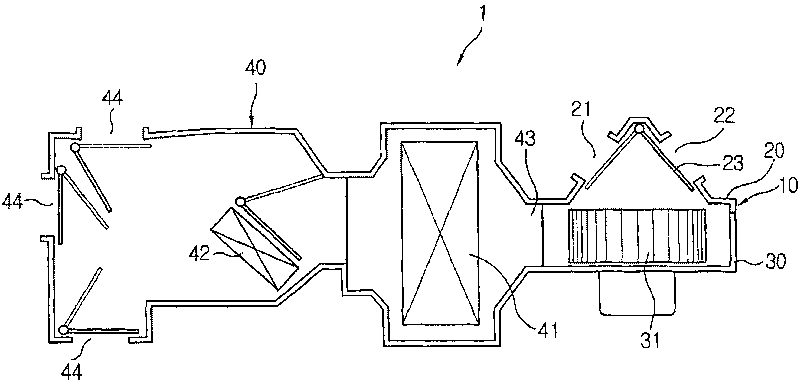

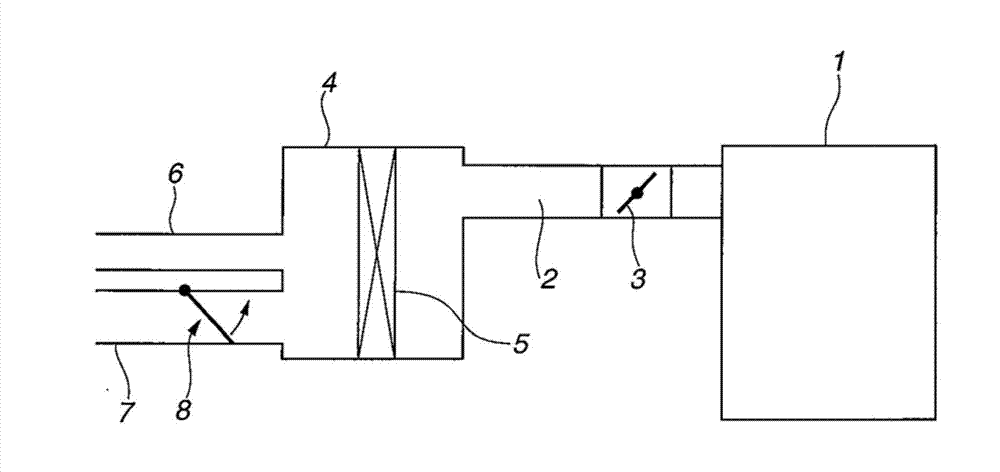

Intake apparatus for internal combustion engine

InactiveCN103161623AReduce suction noiseGuaranteed suction efficiencyEngine controllersMachines/enginesEngineeringInternal combustion engine

The invention relates to an intake apparatus for internal combustion engine. The intake apparatus including two intake ducts and a flap mechanism disposed in one of the two intake ducts, the flap mechanism including a main flap, a damper flap, a damper chamber cooperating with the damper flap to form a damper space, and a biasing member biasing the main flap in a closing direction. When the main flap is located in an angular range between the fully closing position and a predetermined opening angle, a peripheral edge of the damper flap is opposed to an inner wall surface of the damper chamber with a fine clearance to thereby render the damper space substantially closed. When the main flap is located with an opening angle larger than the predetermined opening angle, a communication passage to open the damper space is formed between the inner wall surface of the damper chamber and the peripheral edge of the damper flap.

Owner:MAHLE FILTER SYST JAPAN CORP

Air suction structure of rotary cylinder piston compressor and rotary cylinder piston compressor

ActiveCN106640663AInhalation is smooth and smoothImprove machine efficiencyRotary/oscillating piston pump componentsLiquid fuel engine componentsNoise levelMuffler

The invention discloses an air suction structure of a rotary cylinder piston compressor and the rotary cylinder piston compressor, belongs to the technical field of compressors, and is designed to solve the problem that the existing structure has a limited muffler effect. The air suction structure of the rotary cylinder piston compressor disclosed by the invention comprises a cylinder liner, wherein a refrigerant inlet pipeline is arranged on the side wall of the cylinder liner; the refrigerant inlet pipe is communicated with the inner chamber of the cylinder liner and a dispenser; a muffler chamber main body is arranged on the upper end surface, the lower end surface and / or the side wall of the cylinder liner; a neck passage is connected between the side wall of the refrigerant inlet pipeline and the muffler chamber main body; a sealing cover is arranged on the outer side surface of the muffler chamber main body. According to the air suction structure of the rotary cylinder piston compressor and the rotary cylinder piston compressor disclosed by the invention, the air suction pressure pulsation is reduced, so that the air suction of the rotary cylinder piston compressor is steadier and smoother; the overall noise level is reduced; the loss of the air suction power consumption is reduced, and the overall efficiency of the rotary cylinder piston compressor is improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

A suction and discharge structure for a compressor

ActiveCN110410297BReduce suction noiseGuaranteed air tightnessPositive displacement pump componentsPositive-displacement liquid enginesEngineeringCrankcase

The invention discloses a gas suction and discharge structure for a compressor. The gas suction and discharge structure comprises a crankcase (1), a valve plate seal gasket (2), a gas suction valve disc (3), a valve plate (5), a gas discharge valve disc (6), a cylinder cover seal gasket (7), a cylinder cover (8), a mounting screw (9) and a gas suction silencer (11). The end face of a cylinder body(17) of the crankcase (1) is provided with a step hole (18), a valve plate locating hole (14) and a first exhaust outlet (12). The rear end face of the valve plate (5) is provided with a round boss (57), a locating column (52) and a fifth exhaust outlet (51). An exhaust cavity (81) and a gas suction cavity (83) are formed in the cylinder cover (8). A gas discharge valve disc limiting column (84)is arranged in the exhaust cavity (81). The bottom face of the gas suction cavity (83) is provided with an oil leakage hole (85) and two gas inlet pipes connected with a gas outlet pipe of the gas suction silencer (11). Through the gas suction and discharge structure, gas leakage can be reduced, gas transfer efficiency of the compressor is promoted, gas suction noise of the compressor is lowered,and the gas suction and discharge structure has wide market prospects.

Owner:CHANGHONG HUAYI COMPRESSOR CO LTD

Air induction device for automobile

InactiveCN101317005BReduce suction noiseImprove exercise quietnessMachines/enginesIntake silencers for fuelResonanceEngineering

Provided is an air induction device for an automobile capable of reducing suction noise generated by the suction air to improve stillness in driving. The air induction device for an automobile includes: a main body having a suction manifold mounted on an engine, a throttle body installed in the suction manifold, an air cleaner connected to the throttle body by an air suction duct, an air suction pipe connected to the air cleaner to introduce the external air and having an opening installed at a rear part of a radiator, a suction port formed at a front part thereof, and a space formed therein;a discharge pipe formed at one side of the main body and connected to the suction pipe to be in communication with the space; ; and a resonance part formed inside the main body to remove noise generated during air suction, characterized in that the resonance part is formed of a cylindrical pipe and has a closed end opposite to the discharge pipe and an oval opening formed at the other end toward the discharge pipe, and the opening is formed to be connected to an inlet port of the discharge pipe and installed at a rear surface inside the main body to be opposite to the suction port of the mainbody.

Owner:KOREA WECOSTA CO LTD

Air valve noise suppression system and suppression method for rail transit oil-free air compressor

ActiveCN105736318BPrevent spillageReduce noisePositive displacement pump componentsPositive-displacement liquid enginesComing outAir filter

Owner:SHIJIAZHUANG JIAXIANG PRECISION MASCH CO LTD

Air inlet component, air filter and motor vehicle

PendingCN109958561AImproved inhalation sound qualityReduce suction noiseMachines/enginesAir cleaner and silencer combinationAir filterEngineering

The invention relates to an air inlet component, an air filter and a motor vehicle. The air inlet component comprises an air inlet cover used for being arranged on an air filter body and a noise lowering cover used for being arranged on the inner surface of the air inlet cover in a sealed manner, wherein the noise lowering cover is provided with an air passing through hole, and the noise loweringcover, the air passing through hole and the air inlet cover are matched to form a noise lowering structure. Since the noise lowering cover is arranged on the inner surface of the air inlet cover in the sealed manner, the noise lowering cover divides a cavity between the air inlet cover and the air filter body into a first cavity and a second cavity, and the first cavity and the second cavity are in communication through the air passing through hole. Thus, in the air inlet process, the noise lowering structure is formed through cooperation of the noise lowering cover, the air passing through hole and the air inlet cover, the first cavity can effectively absorb pressure waves in the second cavity through the air passing through hole, gas located in the second cavity is sufficiently expandedin time, accordingly, the air absorbing noise can be lowered, and the comfort feeling and experience feeling during vehicle idling can be improved.

Owner:JIANGMEN DACHANGJIANG GROUP CO LTD

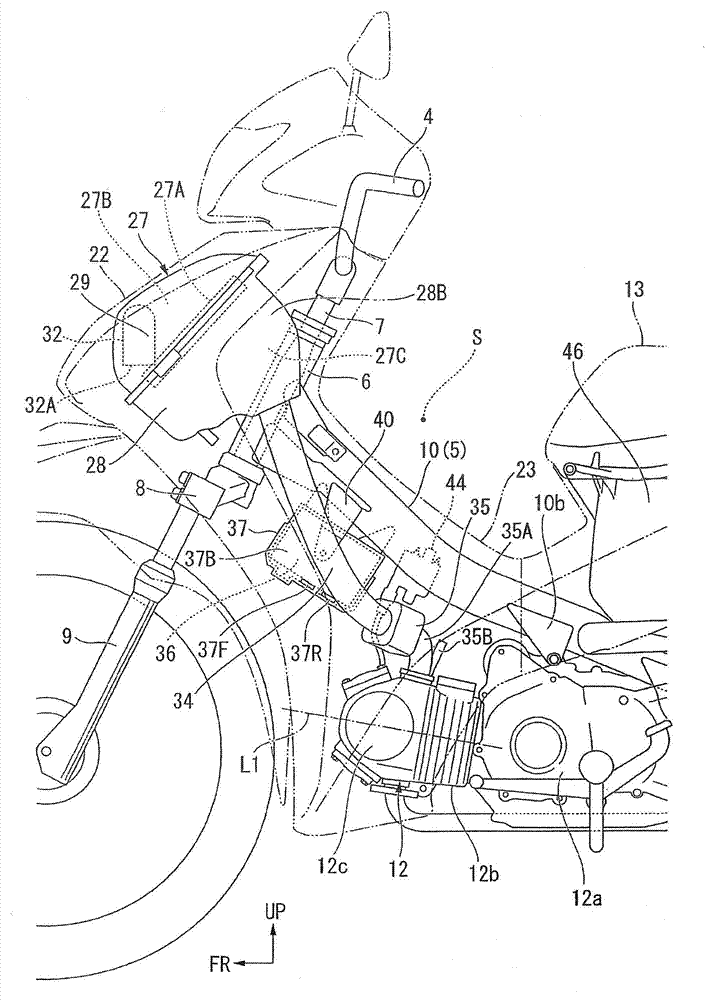

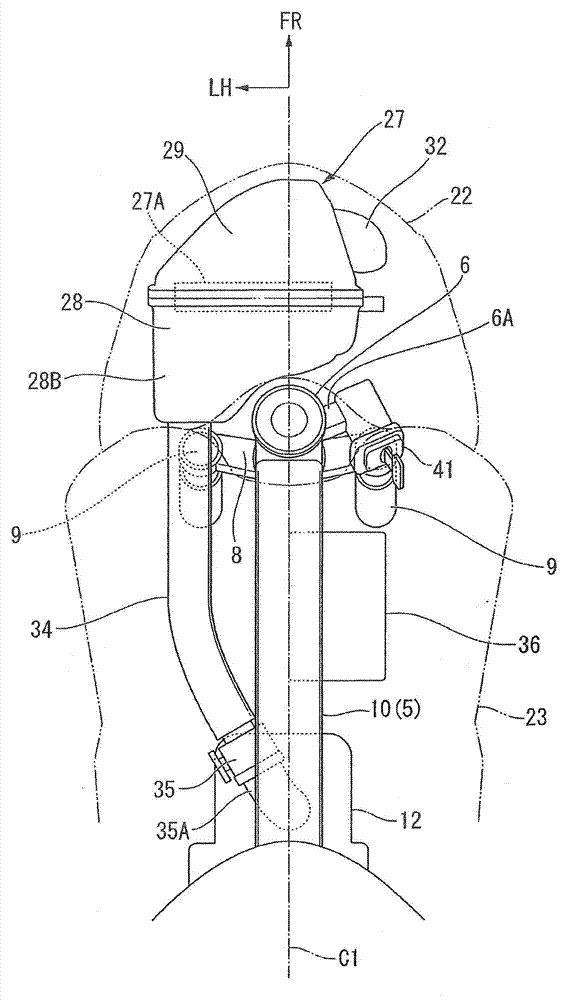

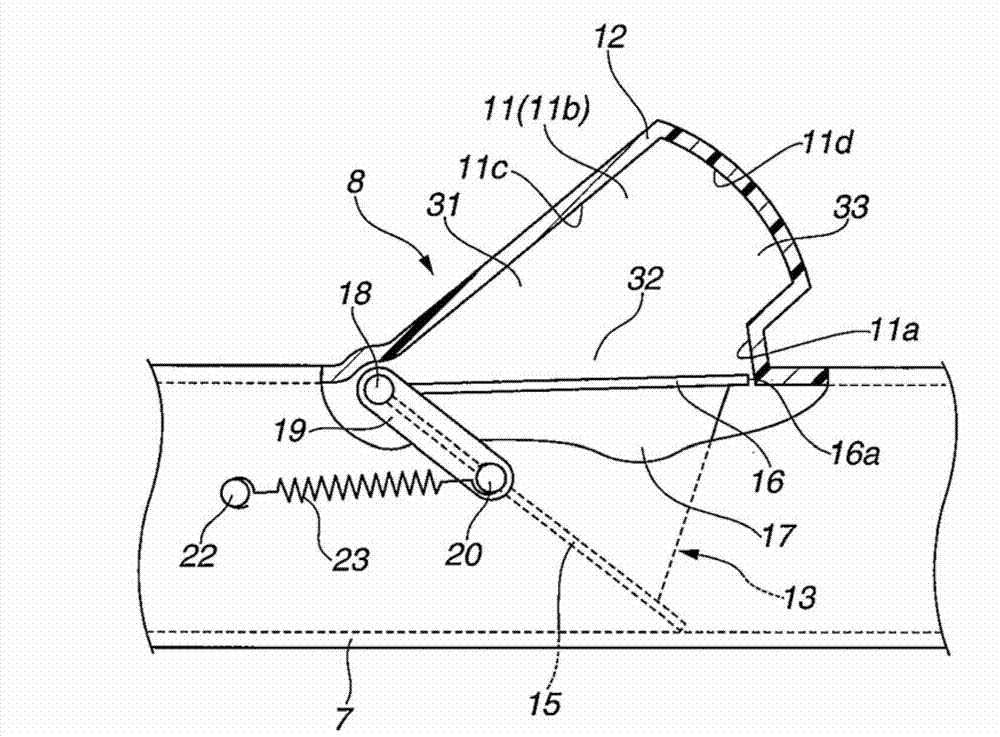

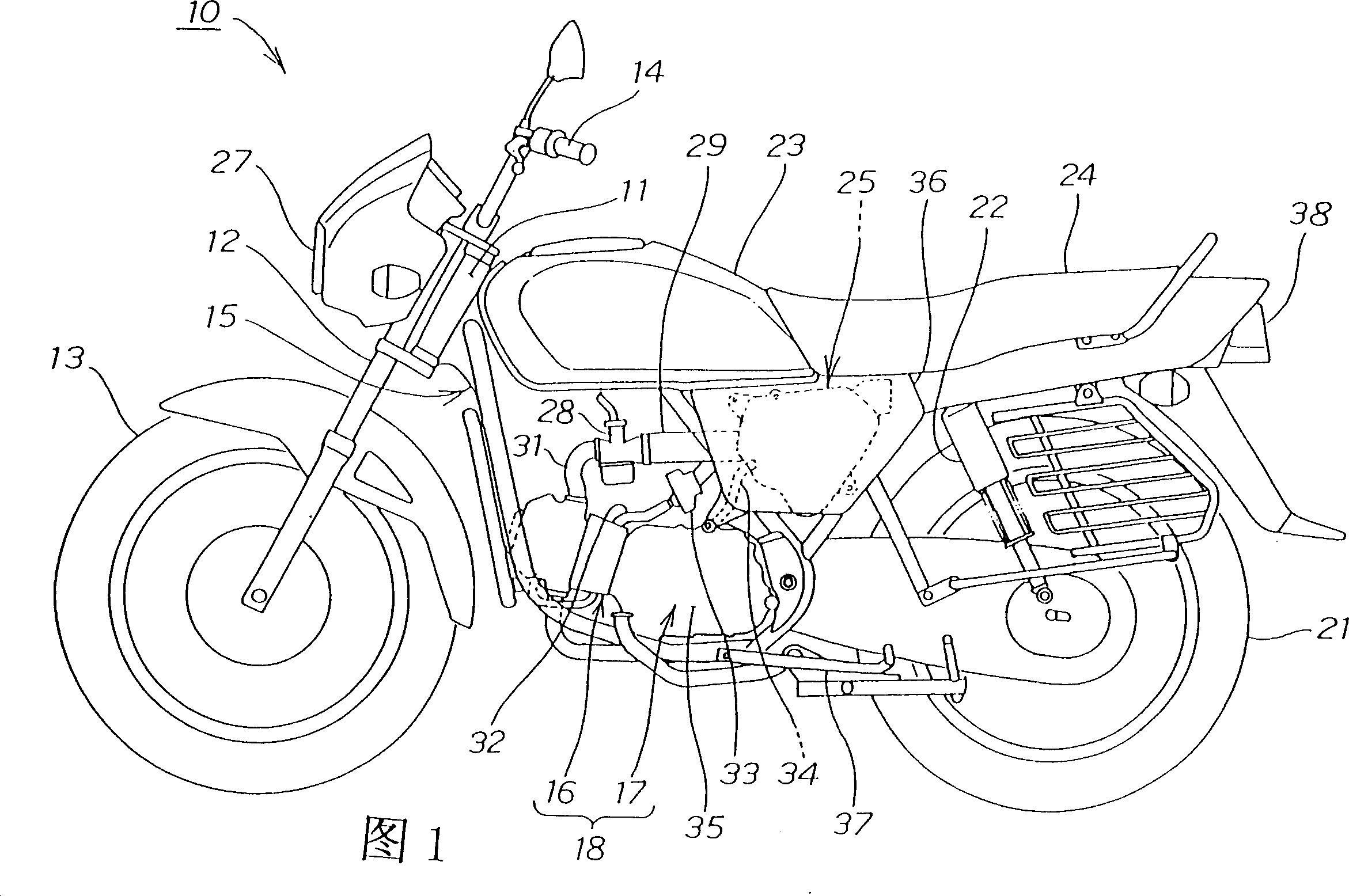

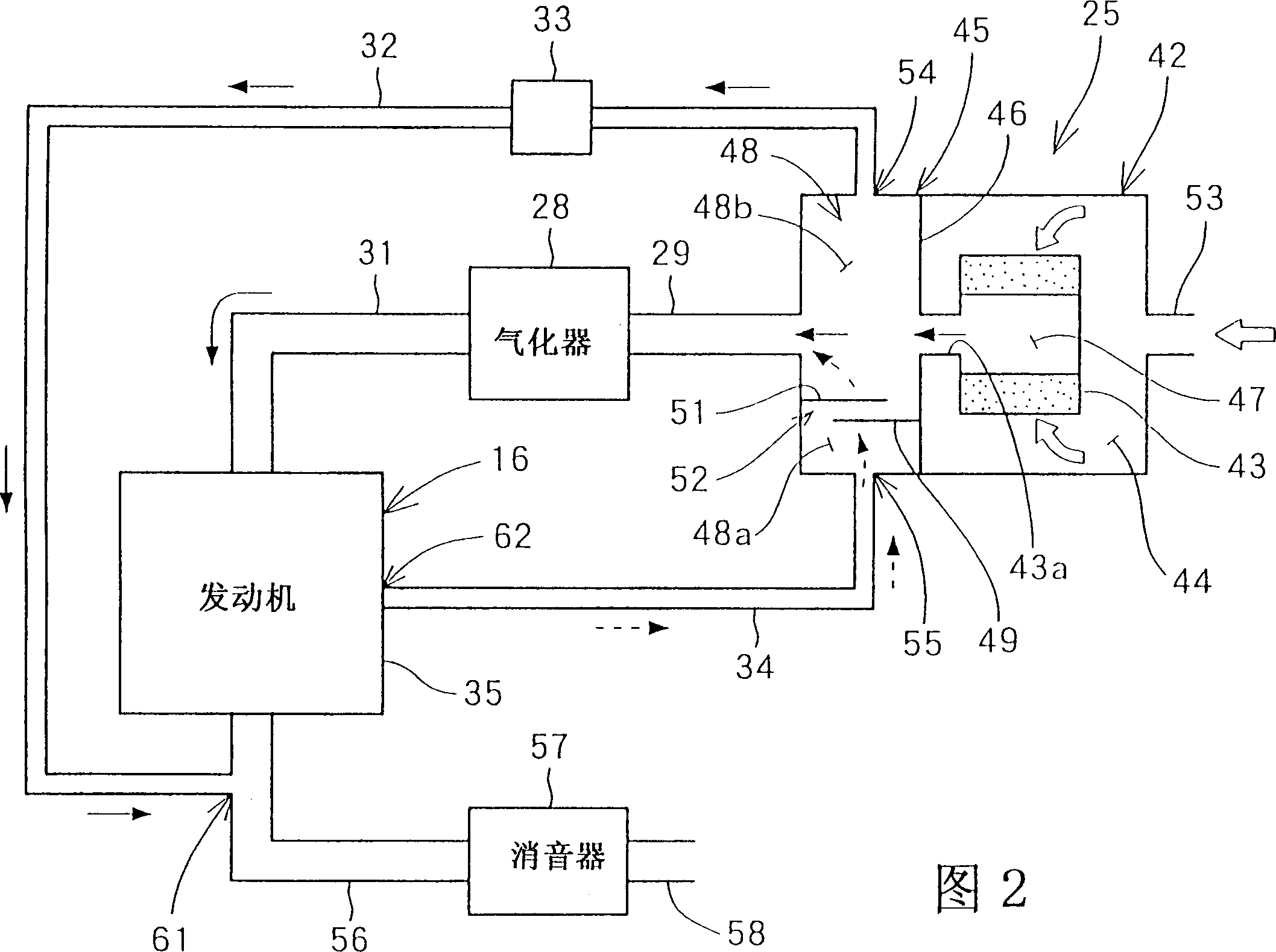

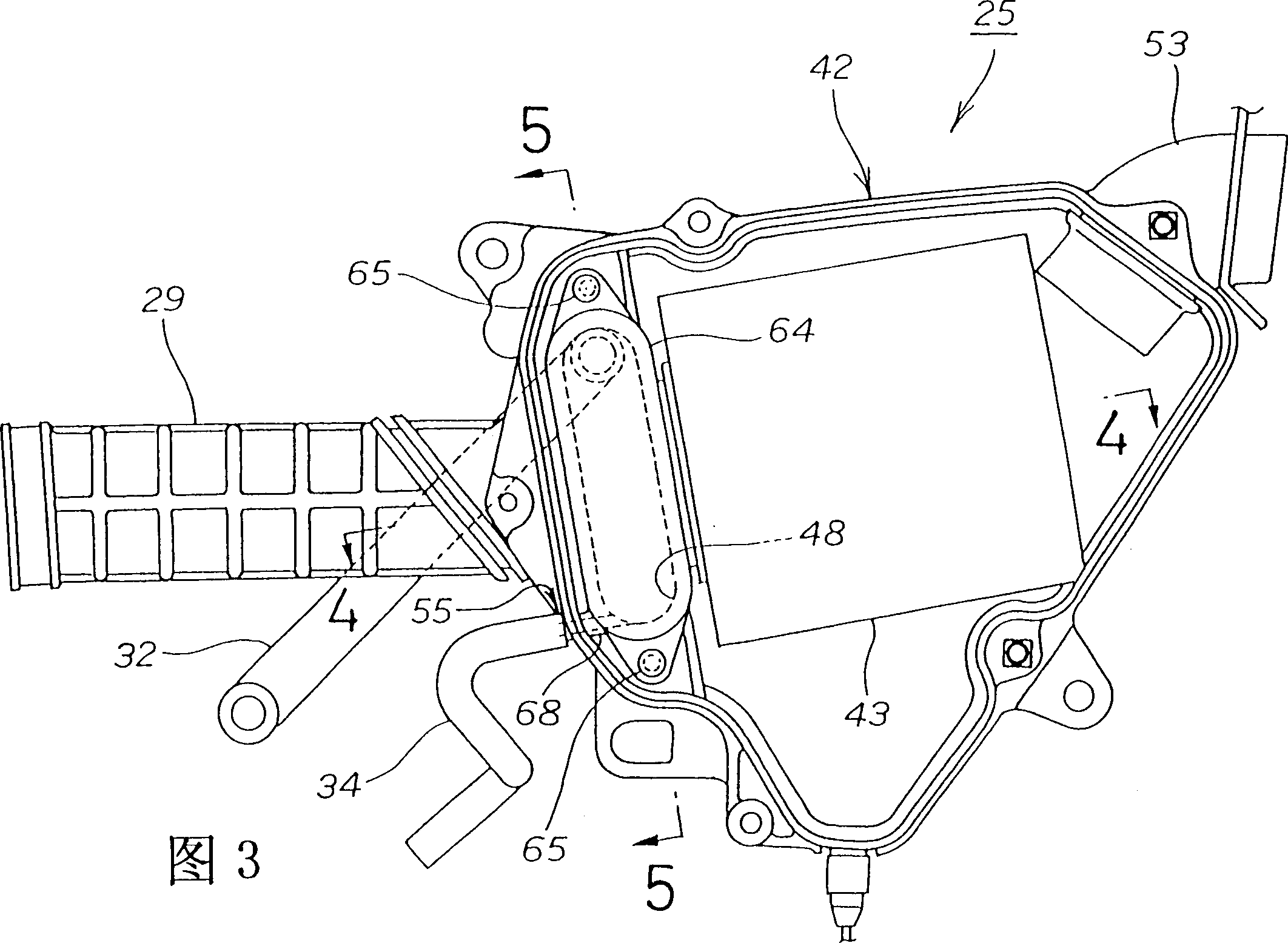

Secondary air supply device for motor-driven two wheeler

The invention relates to a secondary air supplying device for a motorcycle to facilitate the maintenance of an air cleaner for a secondary air, to eliminate the necessity of mounting an excess component to connect a suction tube to a frame pipe, and to reduce a cost, in which the part of a passage for supplying the secondary air to an exhaust system of an engine mounted in a body frame having the frame pipe having the frame pipe is formed in the frame pipe. The downstream end of the suction tube 64 is connected to the suction port of the air cleaner 3 for the secondary air supported to the body frame 25 disposed at the outside of the frame 25, and the upstream side of the tube 64 is inserted into the end opening of the frame pipe 30 by interposing a soundproof material 65 between the tube 64 and the inner surface of the pipe 30.

Owner:HONDA MOTOR CO LTD

Air compressor

PendingCN113374670AImprove stabilityReduce wearPositive displacement pump componentsPiston pumpsEngineeringIntercooler

The invention discloses an air compressor. The air compressor comprises a crankcase, two high-pressure cylinder assemblies, two low-pressure cylinder assemblies and a motor, wherein a crankshaft assembly is arranged in the crankcase, the two high-pressure cylinder assemblies are correspondingly arranged on the two sides of the crankcase and connected to the crankshaft assembly, the two low-pressure cylinder assemblies are correspondingly arranged on the two sides of the crankcase and connected to the crankshaft assembly, the motor is connected to the crankshaft assembly through an elastic coupler, after the motor is started and drives the crankshaft assembly to rotate through the elastic coupler, sucked environment air is subjected to first-stage compression through the low-pressure cylinder assemblies, and the environment air subjected to first-stage compression enters an intercooler to be cooled, the high-pressure cylinder assemblies are used for carrying out second-stage compression on the environment air subjected to first-stage compression and cooling, the environment air subjected to second-stage compression enters an aftercooler to be cooled, and finally compressed air is output. According to the air compressor, a buffer chamber is arranged in front of the crankcase, so that the air suction buffer volume is further increased, and the air suction noise is reduced.

Owner:QINGDAO SRI TECH CO LTD

Safety brake of elevator tractor

The invention relates to a safety brake of an elevator tractor, which comprises a tank plate of windings, an armature, a compression spring which is positioned on one end of a spring hole of the tank plate and is in contact with one end surface of the armature, a tongue plate installed on the other end surface of the armature, and a friction piece. The safety brake is characterized in that the number of the windings is 2n; and the windings are symmetrically or uniformly distributed on the tank plate, wherein n is a natural number. The invention has high braking performance, low cost and low noise.

Owner:成都瑞迪智驱科技股份有限公司

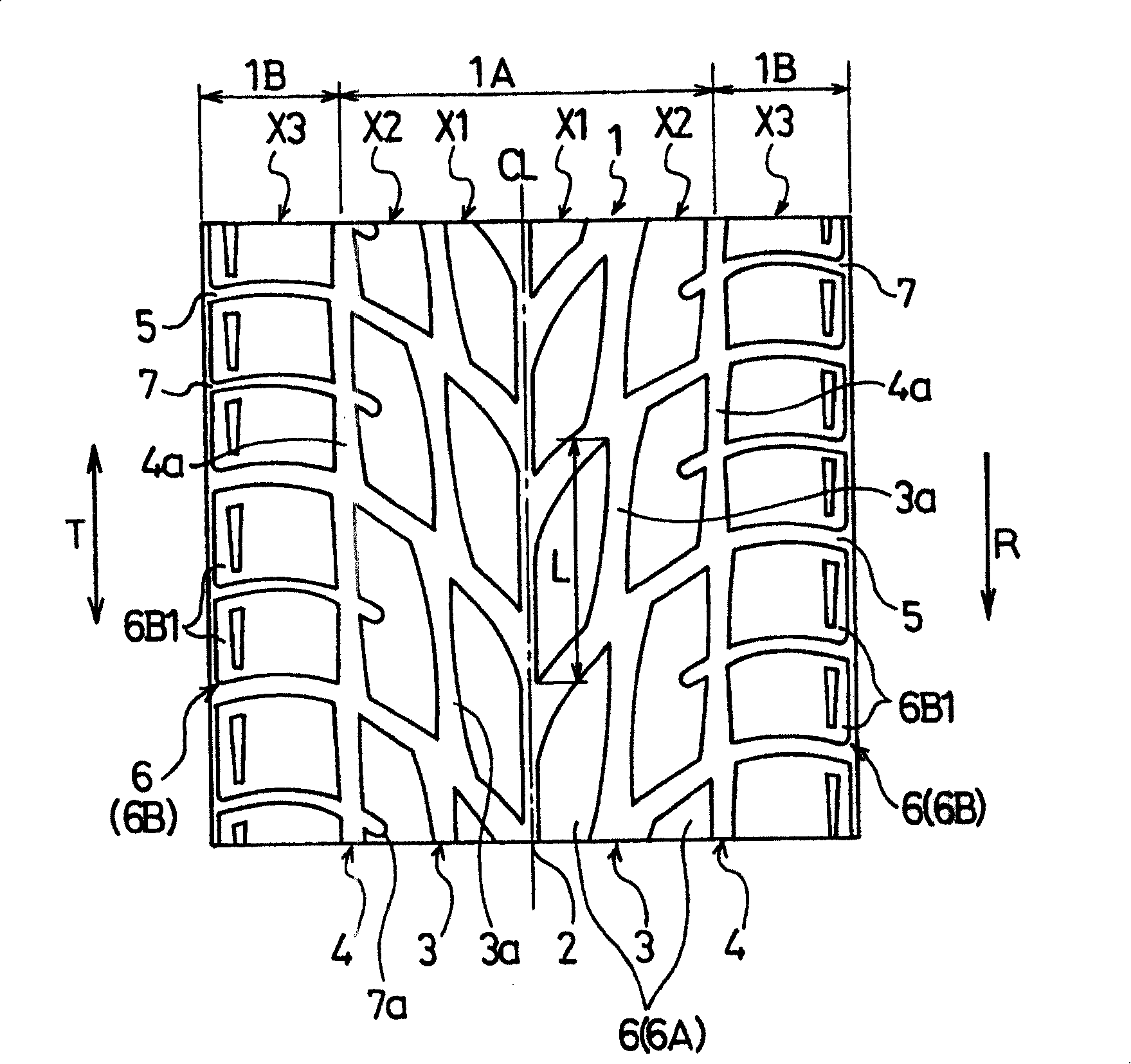

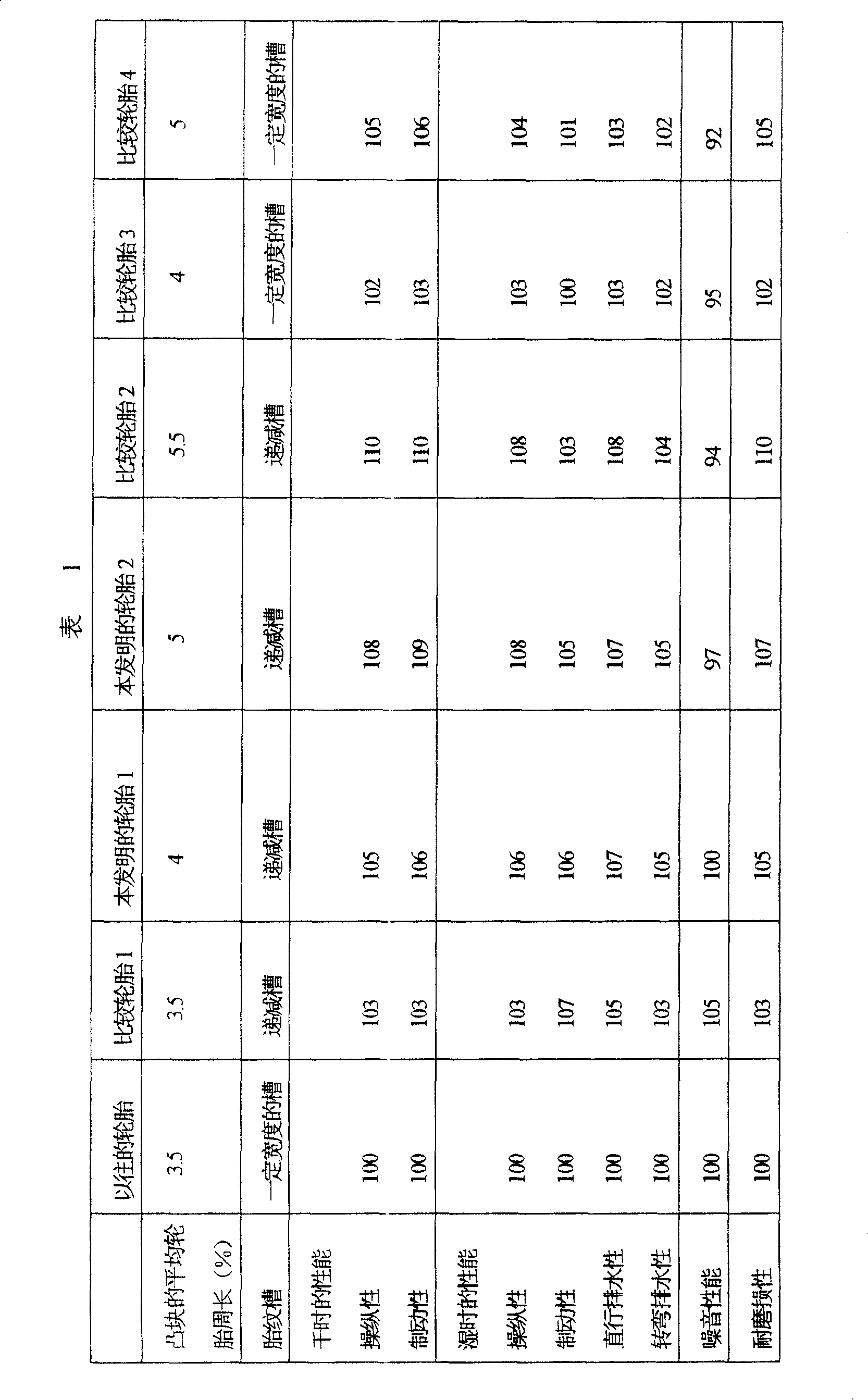

Aeration tyre

InactiveCN100400315CRealize white noiseReduce suction noiseTyre tread bands/patternsGroove widthEngineering

Six block rows extending in a tire circumference direction are formed by a central narrow groove, side main grooves and left and right lug grooves in a tread surface, the rotating direction of which is specified to one direction. The average tire circumference direction length of the blocks of the block rows in the center area of the tread surface is 4 to 5 % of the tire full circumference length on the tire center line. Each of the left and right lug grooves is formed as a tapered groove having wider groove width at the tire center line. Left and right main groove portions located between the lug grooves are formed as inclined grooves inclining so as to expand towards the reverse direction to the rotating direction of the tire. Subgrooves crossing the blocks in the tire width direction are formed on the surfaces of the blocks in the shoulder areas.

Owner:THE YOKOHAMA RUBBER CO LTD

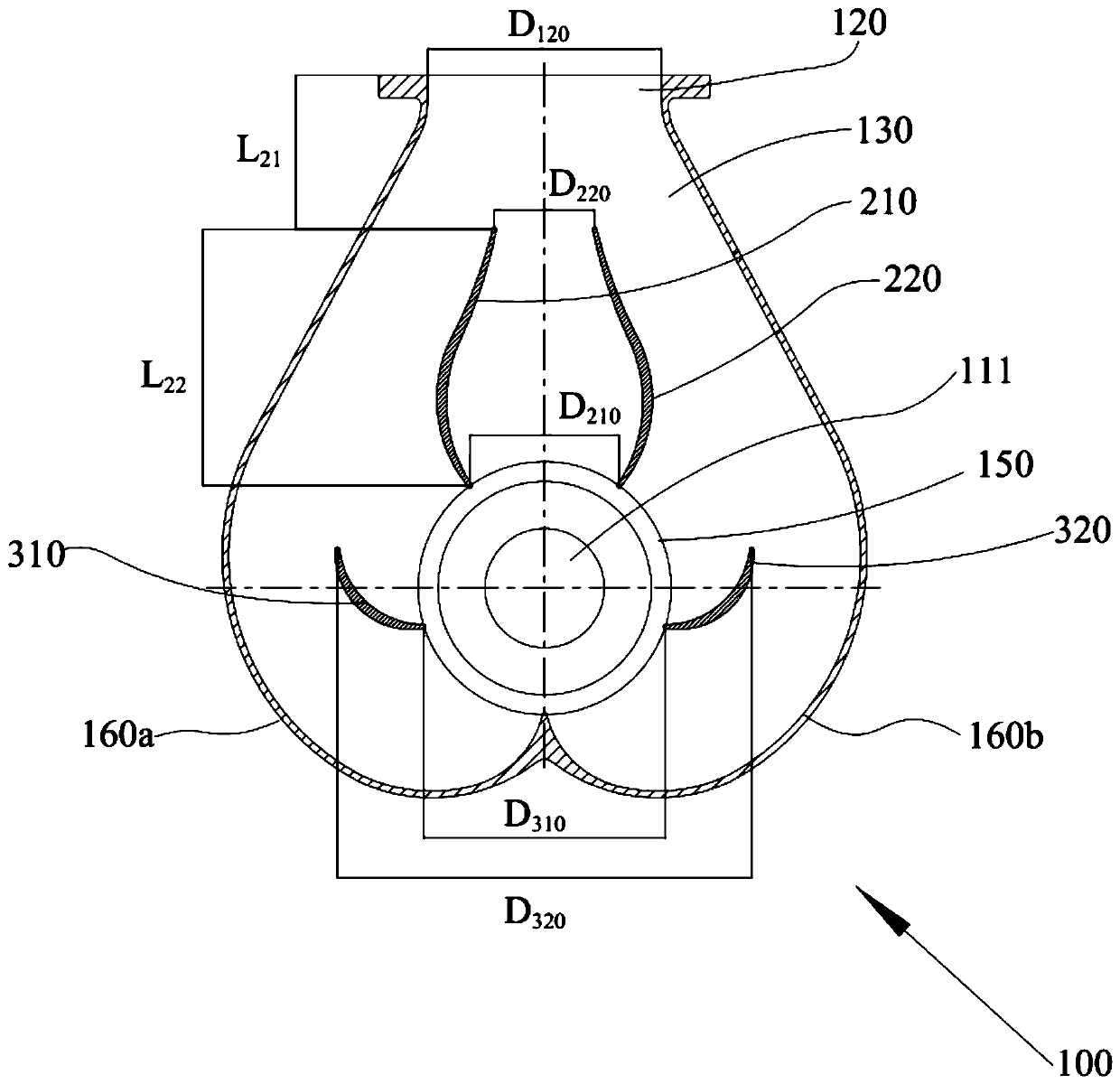

Suction muffler, compressor, refrigerator

ActiveCN111894832BReduce suction noiseReduce local pressure lossPositive displacement pump componentsPositive-displacement liquid enginesIceboxMuffler

The invention provides a suction muffler, a compressor, and a refrigerator, wherein the suction muffler includes a casing, the casing is configured with an air inlet and an exhaust port, and the inner cavity of the casing is provided with A baffle, the baffle divides the inner cavity into an upper cavity corresponding to the exhaust port and a lower cavity corresponding to the air inlet, and the baffle is configured with a The multiple through holes of the cavity also include multiple oil-gas separation covers, and the multiple oil-gas separation covers are respectively one-to-one covered on the multiple through holes and are located on the side of the partition facing the upper chamber. On the side, the oil-gas separation cover has a flow hole to pass through the upper chamber and the lower chamber. According to the suction muffler, compressor, and refrigerator of the present invention, the amount of oil carried by the suction of the cylinder can be reduced, and at the same time, the resistance of the suction air flow and the noise of suction can be reduced, so that the suction is more uniform and smooth.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Air filter for motor driving bicycle

InactiveCN1123691CReduce manufacturing costSmall sizeExhaust apparatusCombustion-air/fuel-air treatmentMotor driveAir filter

To reduce a size of an air cleaner case, reduce manufacturing cost by forming the case readily, reducing intake noises, and furthermore reduce a size of an air cleaning device as compared with a device including a reserve tank and an air chamber separately provided from a sub chamber 48. This air cleaning device 25 for an engine includes an air cleaner case 42 divided into the dirty side and the clean side by a filter element 43. A sub chamber 48 is formed by partially partitioning a space of the clean side of the air cleaner case 42, and an outlet 55 of a blowby hose 34 for circulating blowby gas from a crank case 35 of an engine 16 and an inlet 54 of a secondary air supplying pipe 32 for supplying secondary air to an exhaust system of the engine 16 are connected to the sub chamber 48.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com