Shedding method and apparatus using air pressure

A technology of air pressure and vacuum pressure, applied in the field of weaving, can solve the problems of expensive weaving machines and achieve the effect of reducing economic advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In the following detailed description, related embodiments of the present invention are described. It should be understood that unless anything else is specifically indicated, the features of different embodiments may be varied and combined in different ways. It may also be noted that, for the sake of clarity, the dimensions of certain items shown in the drawings may differ from their corresponding dimensions in an actual implementation of the invention. Although numerous specific details are set forth in the following description to provide a better understanding of the invention, it will be apparent to those skilled in the art that these specific details can be modified to practice the invention. In other instances, structures and / or functions that are commonly known to those skilled in the art have not been described in detail so as not to obscure the invention.

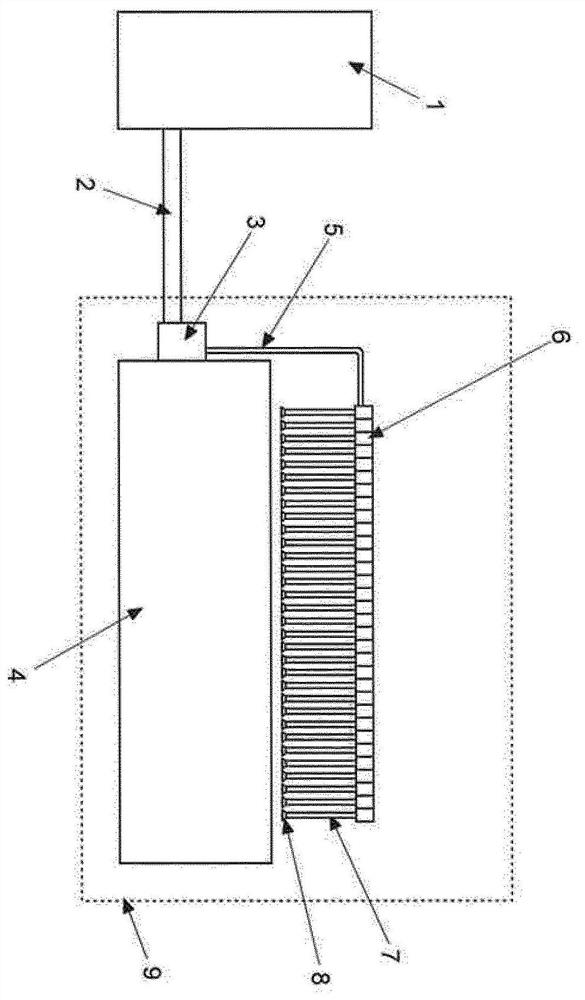

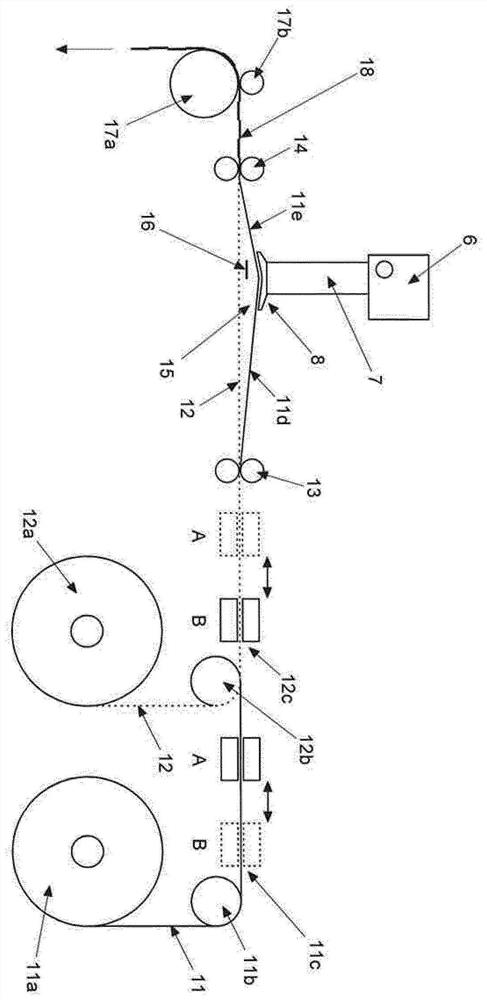

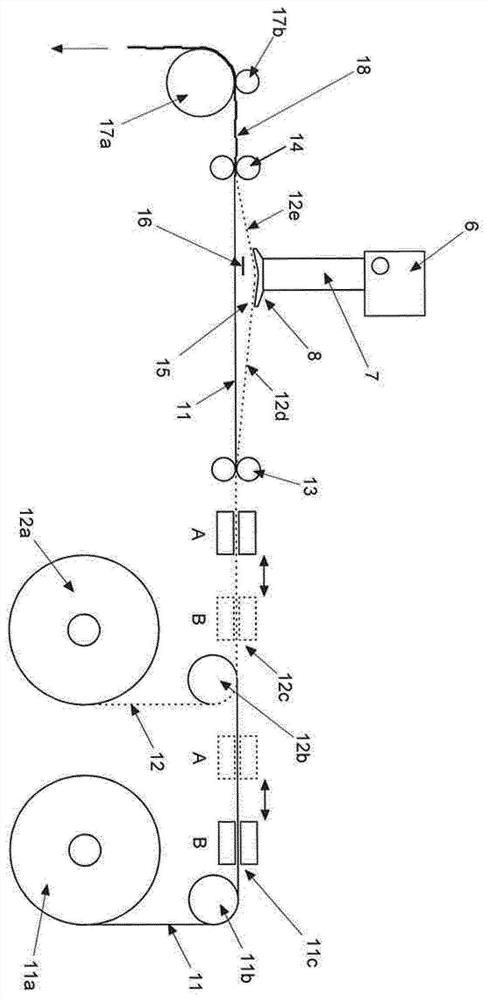

[0063] refer to figure 1 and FIG. 2 , describe the VSS based on the VSM of the present invention. For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com