Air compressor

An air compressor, ambient air technology, used in mechanical equipment, machines/engines, liquid variable capacity machinery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

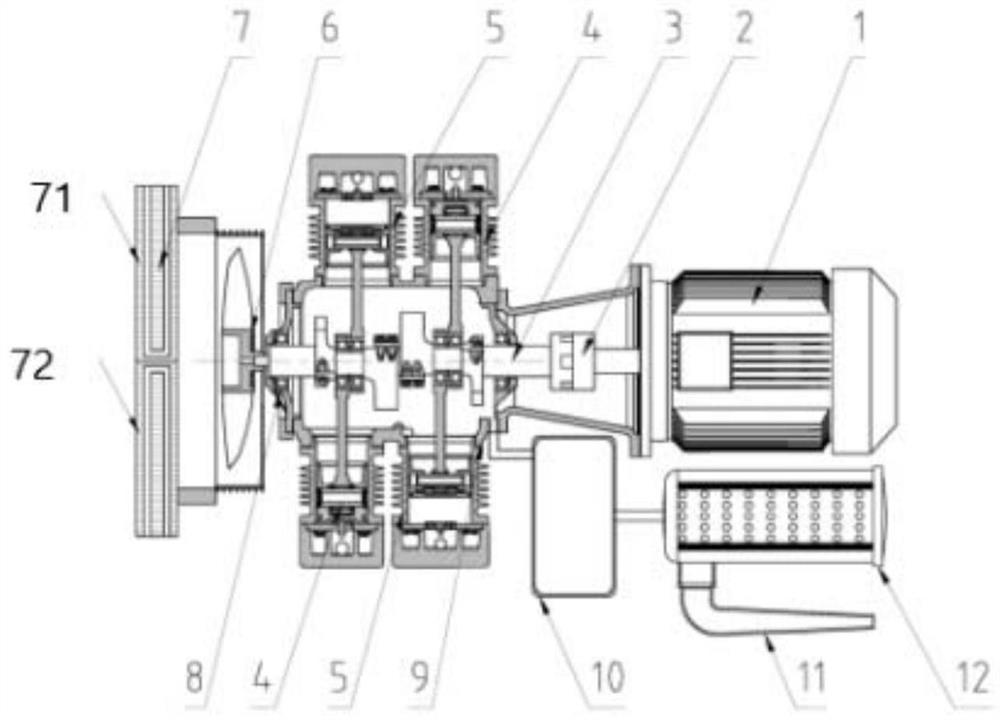

[0041] In order to make the purpose, technical solutions and advantages of the present application clearer, the present application will be described and illustrated below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present application, and are not intended to limit the present application. Based on the embodiments provided in the present application, all other embodiments obtained by persons of ordinary skill in the art without creative efforts shall fall within the protection scope of the present application.

[0042] Obviously, the accompanying drawings in the following description are only some examples or embodiments of the present application, and those skilled in the art can also apply the present application to other similar scenarios. In addition, it can also be understood that although such development efforts may be complex and lengthy, for those of ...

Embodiment 2

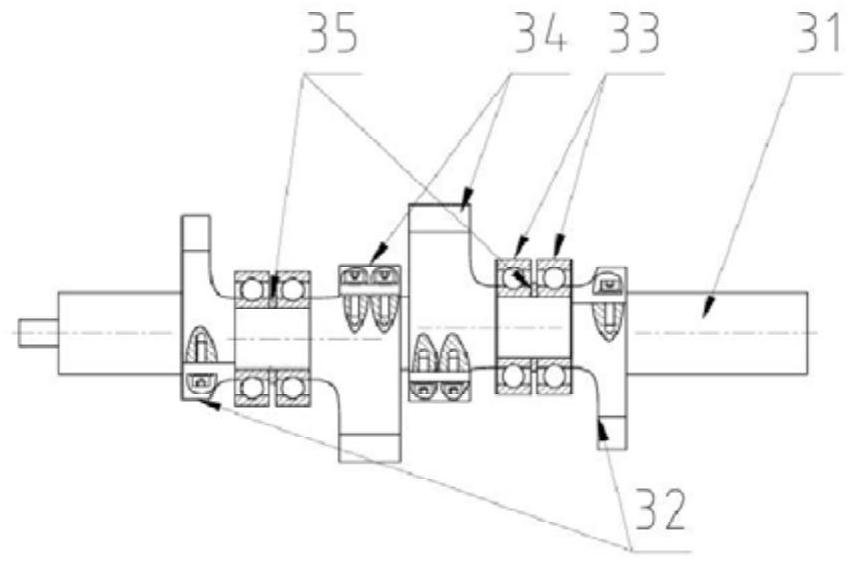

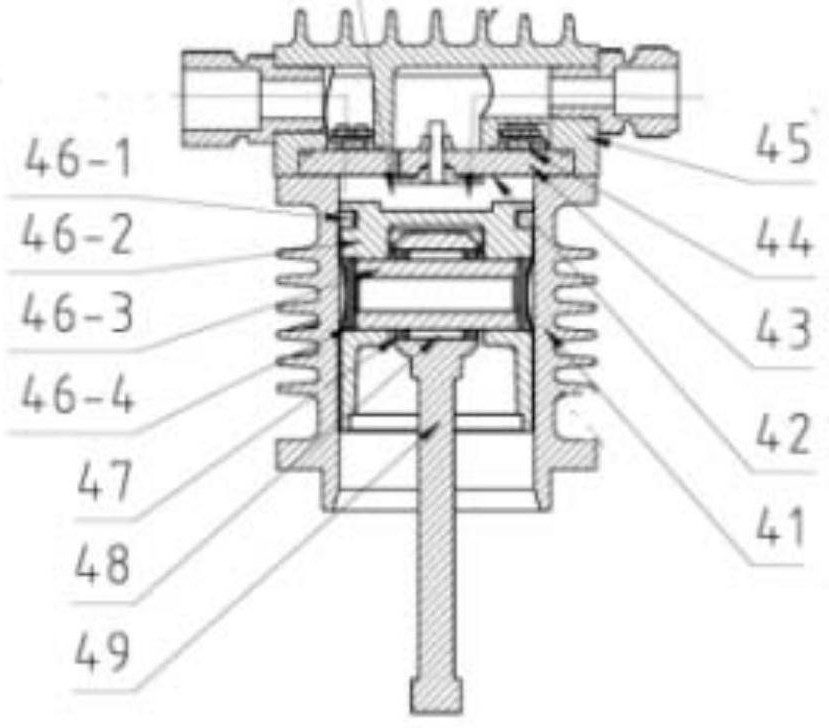

[0053] An air compression method using the above-mentioned air compressor: After the motor is started, the motor drives the crankshaft assembly to rotate through the elastic coupling. There are two turning grooves in the crankshaft, and the turning grooves drive the piston through the connecting rod during the eccentric movement Perform reciprocating motion. When the piston in the low-pressure cylinder assembly moves toward the center of the crankcase, the compressed air chamber of the low-pressure cylinder generates negative pressure, and the intake valve in the low-pressure cylinder assembly opens and the exhaust valve closes. After the intake valve is opened, the compressed air chamber of the low-pressure cylinder communicates with the crankcase, buffer chamber, and air filter. Under the action of atmospheric pressure, the air in the environment is filtered by the suction duct → air filter → buffer chamber → Crankcase → pipeline → is sucked into the compressed air chamber o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com