Structure for fixing wheel arch molding

A technology of fixing structure and molding, applied in the directions of superstructure, superstructure sub-assemblies, connecting components, etc., can solve the problem of small wheel track, and achieve the advantages of small size in the vehicle width direction, ensuring wheel track, and improving aesthetics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the present invention will be described based on examples of the present invention shown in the drawings.

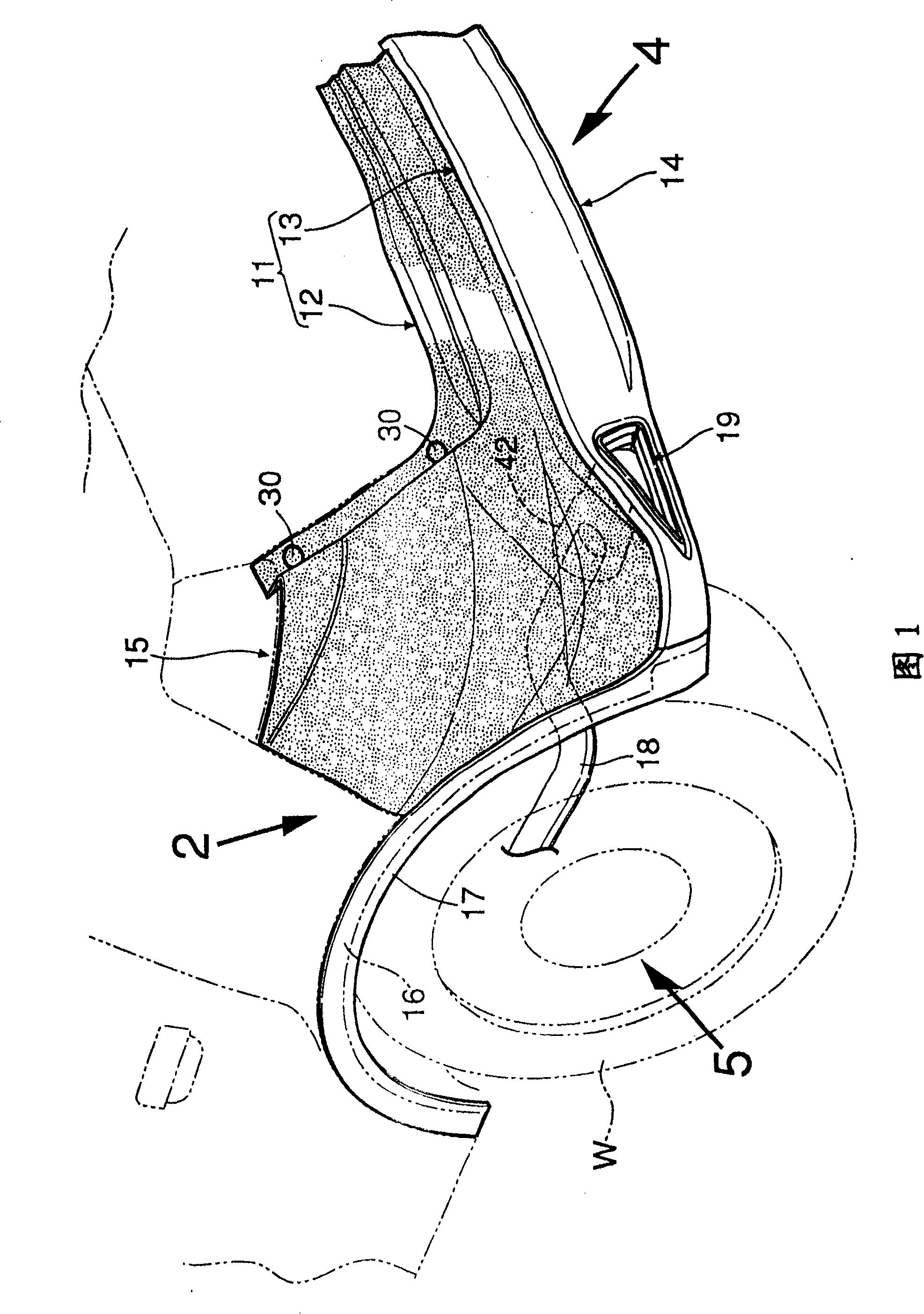

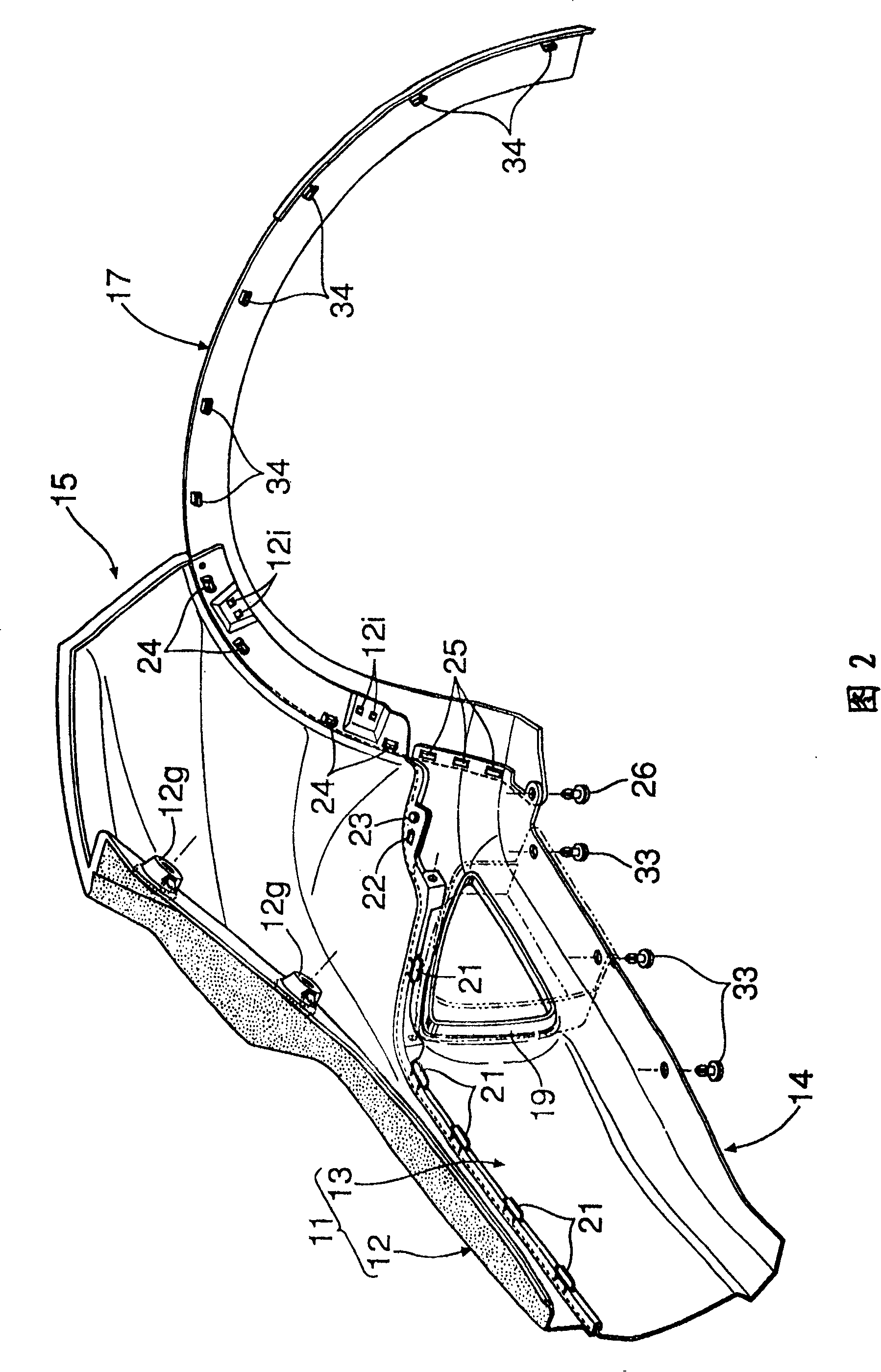

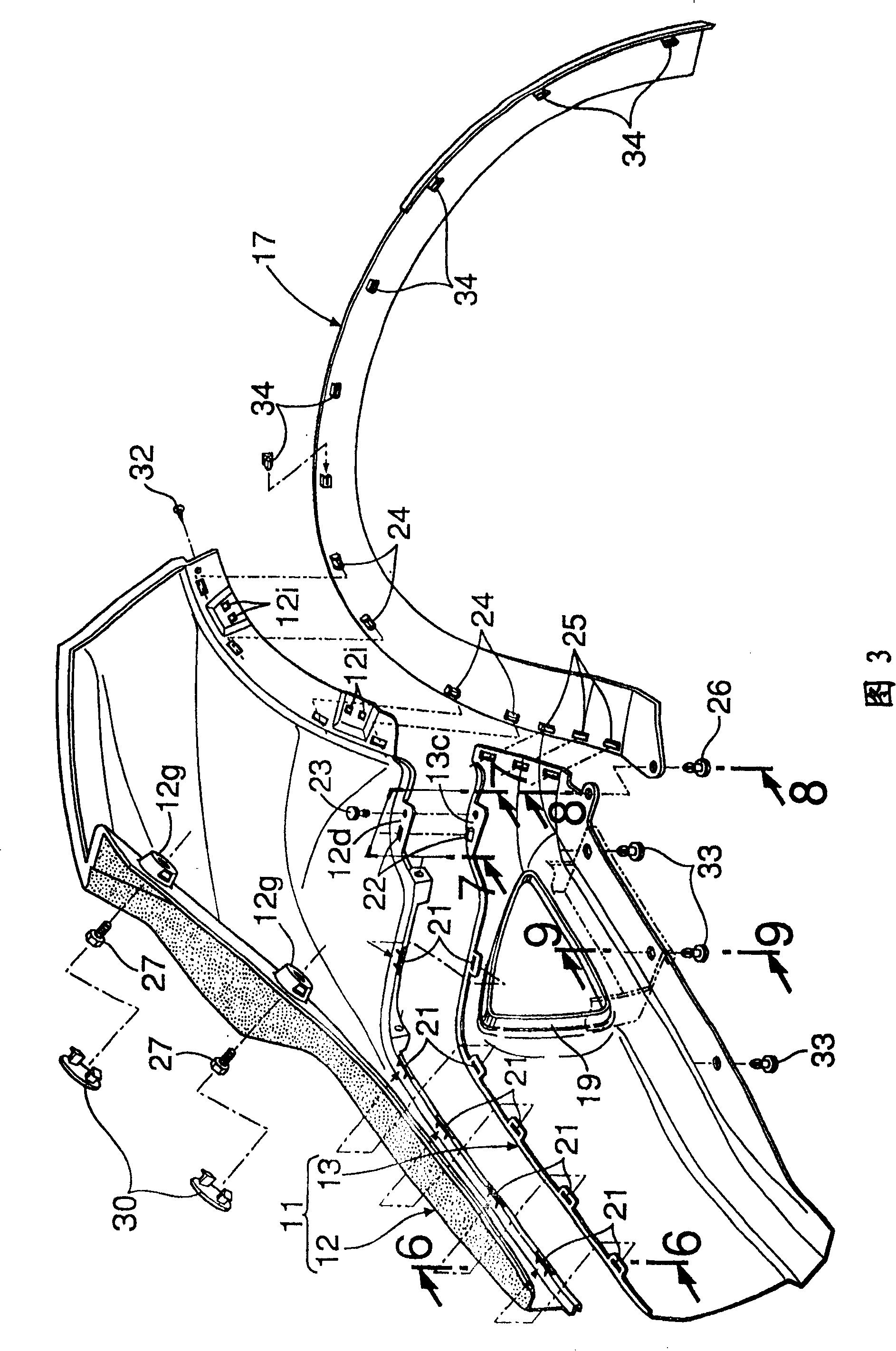

[0024] What Fig. 1~Fig. 15 showed is an embodiment of the present invention, and Fig. 1 is the perspective view of the left half of rear bumper. FIG. 2 is a view of arrow 2 in FIG. 1 . FIG. 3 is an exploded perspective view corresponding to FIG. 2 . FIG. 4 is a view of arrow 4 in FIG. 1 . FIG. 5 is a view from the arrow 5 in FIG. 1 . Figure 6 It is an enlarged sectional view taken along line 6-6 in FIG. 3 . Figure 7 It is an enlarged sectional view taken along line 7-7 in FIG. 3 . Figure 8 It is an enlarged sectional view taken along line 8-8 in FIG. 3 . Figure 9 It is an enlarged sectional view taken along line 9-9 in FIG. 3 . Figure 10 It is an enlarged sectional view taken along line 10-10 in FIG. 4 . Figure 11 It is an enlarged sectional view of each part in FIG. 5 . Figure 12 It is a schematic diagram of the effect of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com