Front-enclosed pressure balance type vale and its operating method

A closed pressure, balanced technology, applied in the direction of lift valve, valve device, engine components, etc., can solve the problem of large starting driving force, and achieve the effect of small sliding friction, small opening resistance and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

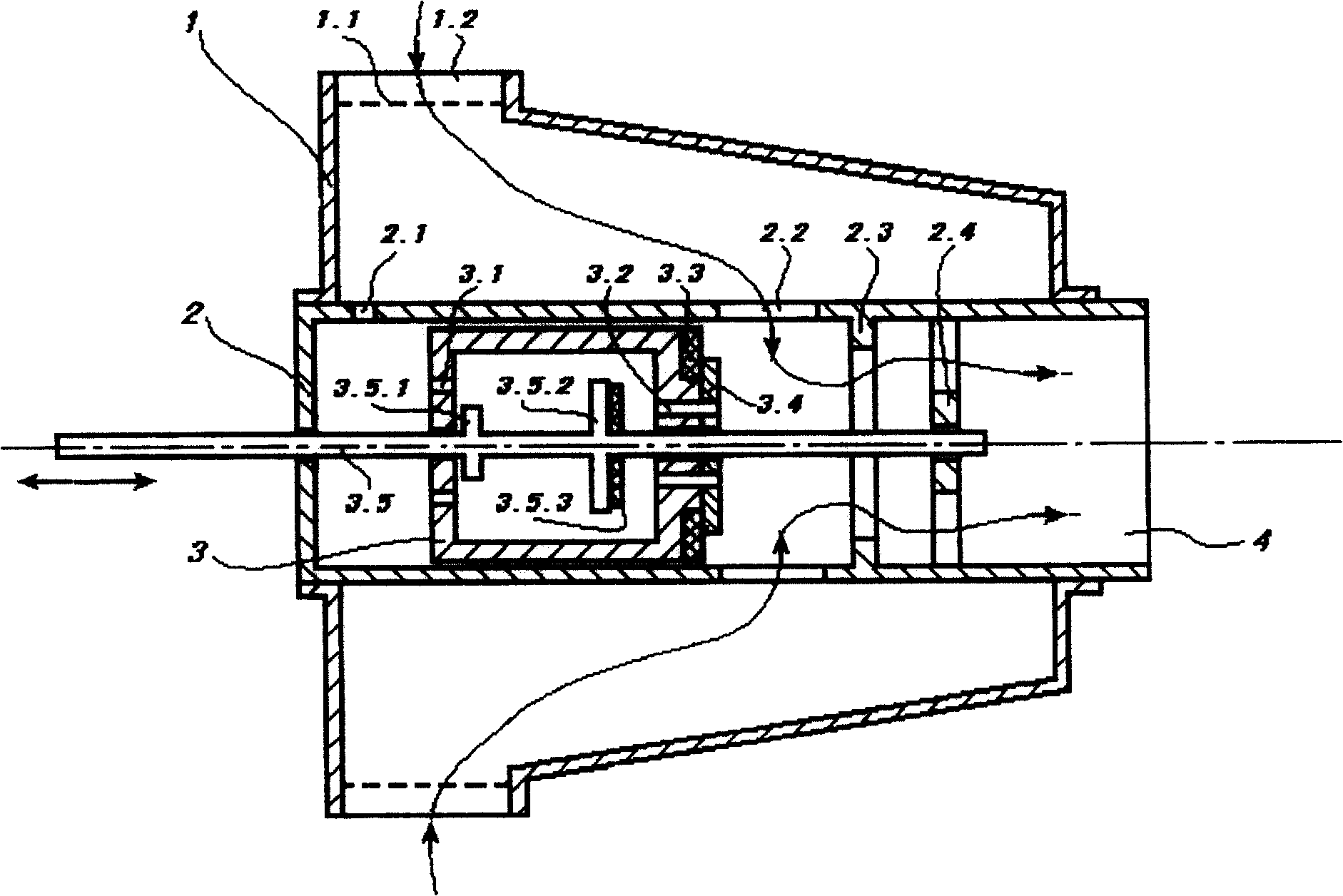

[0036] Front closed pressure balanced valves, such as figure 1 As shown, it includes a valve body shell 1, a valve core sleeve 2, a valve core 3, a power unit and a transmission device.

[0037] A water inlet 1.2 is arranged on the valve body shell 1, and a filter screen 1.1 is arranged on the water inlet 1.2.

[0038] The valve core sleeve 2 is placed in the valve body shell 1 and is in the shape of a sleeve. The spool cover 2 has a bottom wall, a peripheral side wall extending forward from the periphery of the bottom wall and a positioning frame 2.4. Two water inlets 2.2 are symmetrically opened on the peripheral side wall, and both water inlets 2.2 are in the fluid contained in the casing 1 . One or more water inlets 2.2 can also be provided on the peripheral side wall of the valve core sleeve 2 as required, and the multiple water inlets 2.2 are preferably evenly distributed, so that: when the valve core 3 moves to a position corresponding to the water inlet 2.2 When the...

Embodiment 2

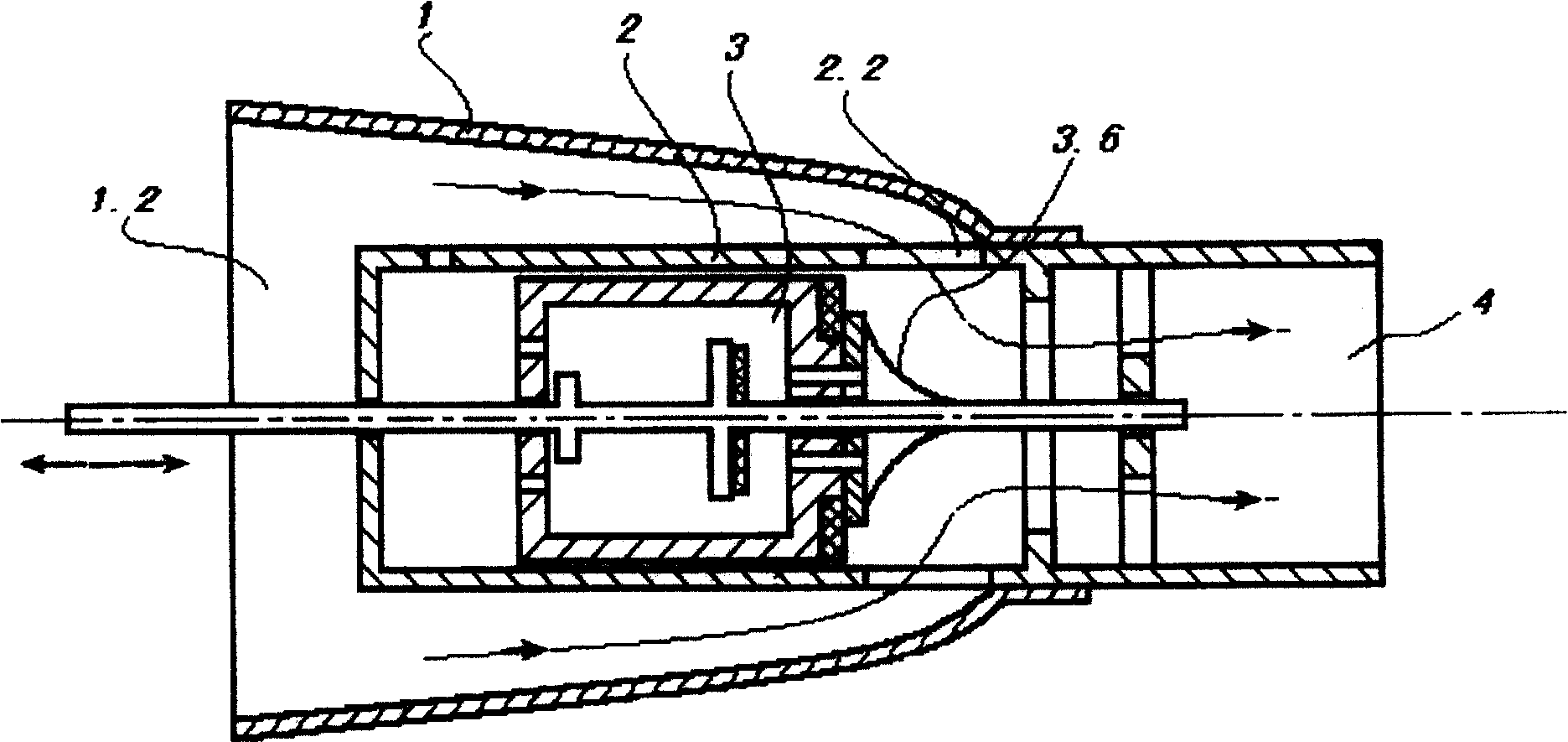

[0051] The difference between this embodiment and Embodiment 1 is that: figure 2 As shown, in a low flow resistance application mode, the front end of the valve core 3 has a deflector 3.6. The shell 1 of valve, spool cover 2, spool cover water inlet 2.2 and the guide plate 3.6 of spool front end, constitute the little streamline channel of fluid flow deflection angle, its water inlet is 1.2, and water outlet is 4.

Embodiment 3

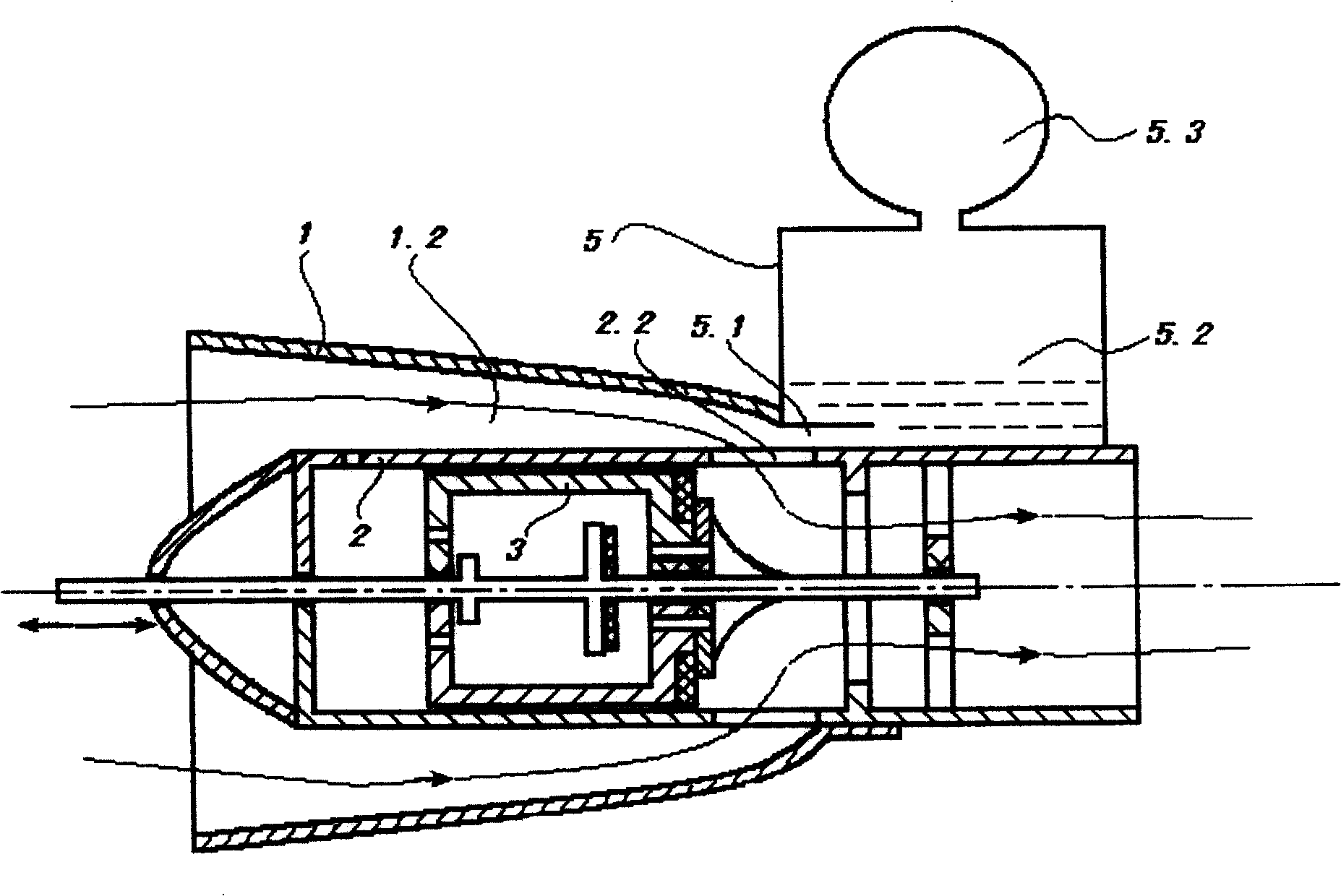

[0053] The difference between this embodiment and Embodiment 1 is that: image 3 As shown, the end of the water inlet 1.2 of the valve body shell 1 is provided with a swirl air buffer tank 5, which includes a swirl chamber 5.2 at the low end and an air chamber 5.3 at the high end. The swirl chamber is circular in cross section The cylindrical cavity, its water inlet 5.1 communicates with the water inlet 1.2 of the valve casing, and the water inlet 5.1 points to the tangential direction along the cylindrical surface of the cyclone chamber cylindrical cavity. When the water inlet 2.2 is closed by the valve core 3, the water flow enters the swirl chamber from the water inlet 5.1, the water flow rotates, the water level rises to compress the air, and the water hammer phenomenon is weakened.

[0054] The difference between this embodiment and Embodiment 1 is that: Figure 4 As shown, a water inlet of the valve of the present invention is an open application situation. There are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com