Rail comprising a rotating frame for a filtration device, and production method thereof

A technology of rotating base frame and filtering equipment, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve problems such as roughness, and achieve the effect of small stress and less wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

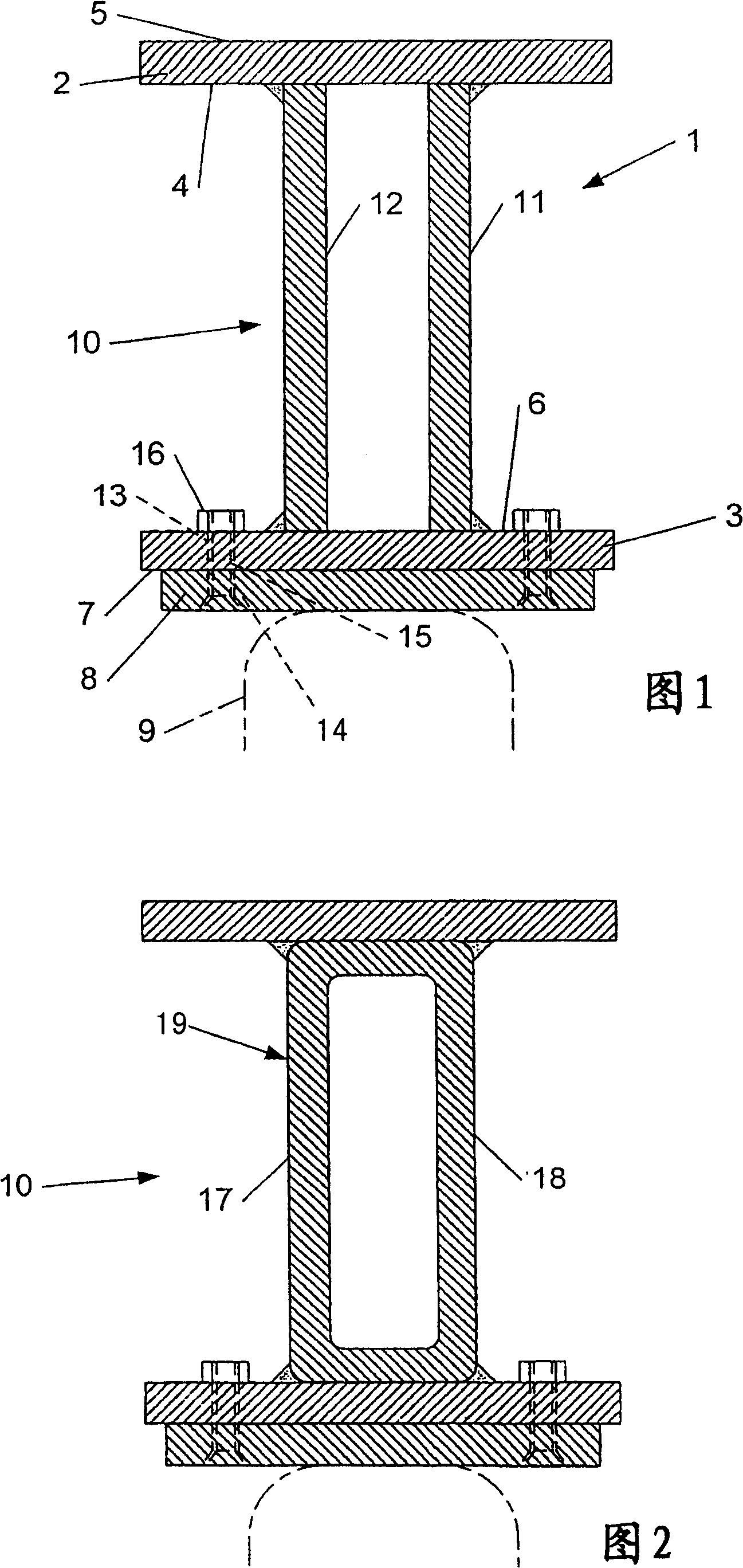

[0026] [26] In Fig. 1, a cross-section of a rail 1 of a rotating base frame of a filtering device with filtering units installed on a circulating conveying mechanism is shown. The track comprises a first flange 2 and a second flange 3 . These flanges are cut from a steel plate in sections each forming a circular or polygonal ring, the tracks thus being able to join one another to form a circle around the pivot of the endless conveyor mechanism. Complete torus or polygonal body.

[0027] [27] Said flange 2 has an inner surface 4 and an outer surface 5 for supporting at least one known, not shown filter unit, and said upper surface is supported directly or via a A structure supports the filter unit.

[0028] [28] Said flange 3 also has an inner surface 6 and an outer surface 7 . On said outer surface is fixed a wear plate 8 which is also cut from a steel plate in such a way that a segment of a circular or polygonal ring is formed. This wear plate 8 is fastened on said flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com