Pressure self-adjusting full-automatic exhaust gas controller

A fully automatic, controller-based technology, which is applied to washing devices, hand irons, textiles and papermaking, etc., can solve problems such as unsuitable steam pipelines, achieve long-term smoothness, significant energy-saving effects, and reduce working procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

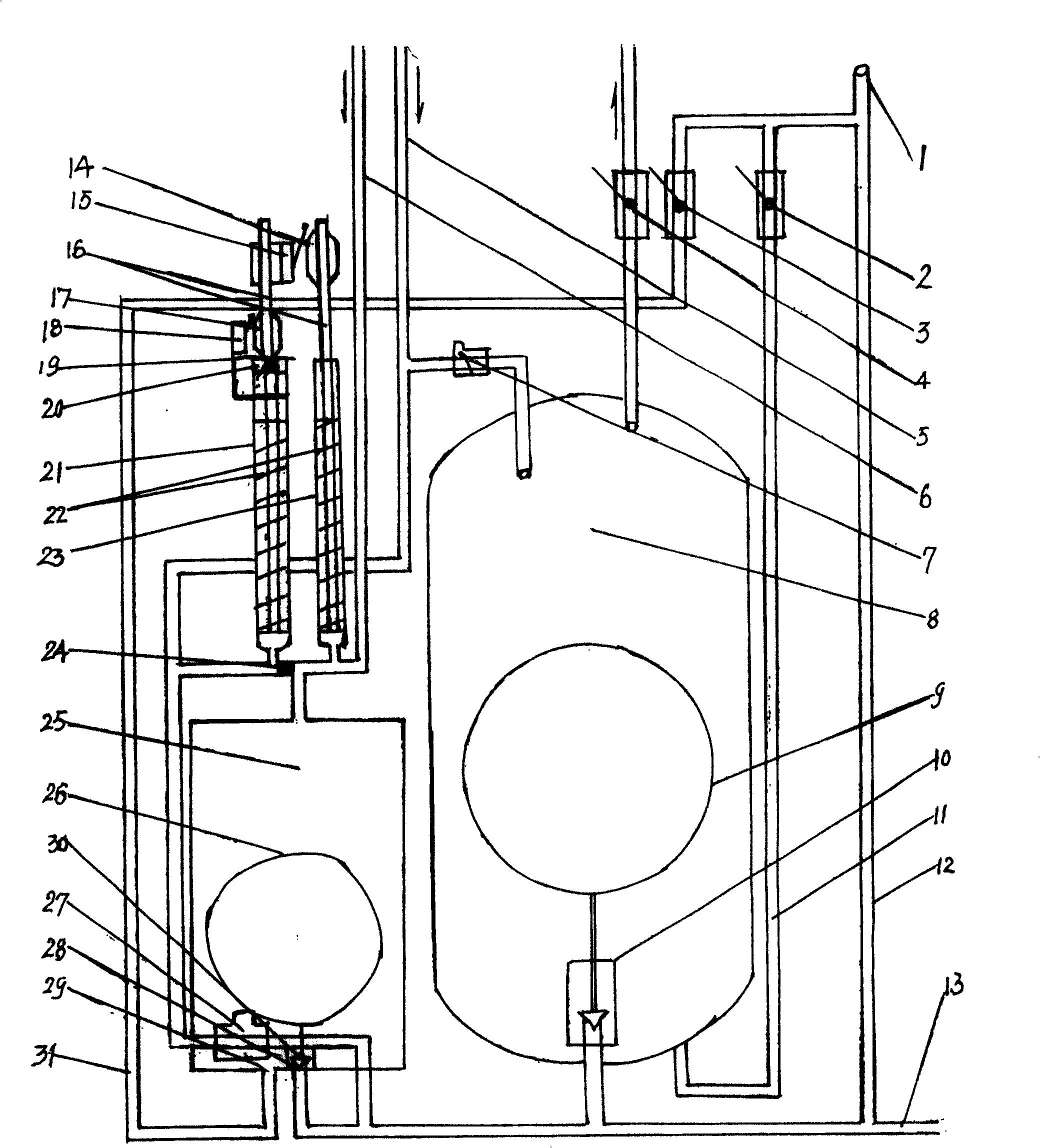

[0008] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0009] see figure 1 , a pressure self-adjusting automatic tail steam controller, which is composed of a main steam water filter 25 and a secondary steam water filter 8, the main steam water filter 25 is provided with the interface of the steam pipe 6 before the iron, and the iron The lower part of the front steam pipeline 6 is provided with a positive pipe cylinder 23, and the bottom of the main steam water filter 25 is provided with an automatic water outlet 28 and a manual standby water outlet 29, and a main float 26 and a main float switch 30 are arranged inside, and the positive pipe Cylinder 23 is a one-way steam inlet, built-in return spring 22 and ejector rod 16, and stroke bumper 14 is installed on ejector rod 16, and the upper part of auxiliary pipe 5 leads to auxiliary steam water filter 8 through check valve 7, and the middle part leads to au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com