System and method for merging homogeneous hole in workpiece image files

A technology of part holes and part drawings, which is applied to the system and field of merging similar holes in part drawings, can solve the problems of long time, unable to meet the requirements of mold drawing well, and affect work efficiency, so as to improve drawing efficiency , avoid the impact of subsequent processing, and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

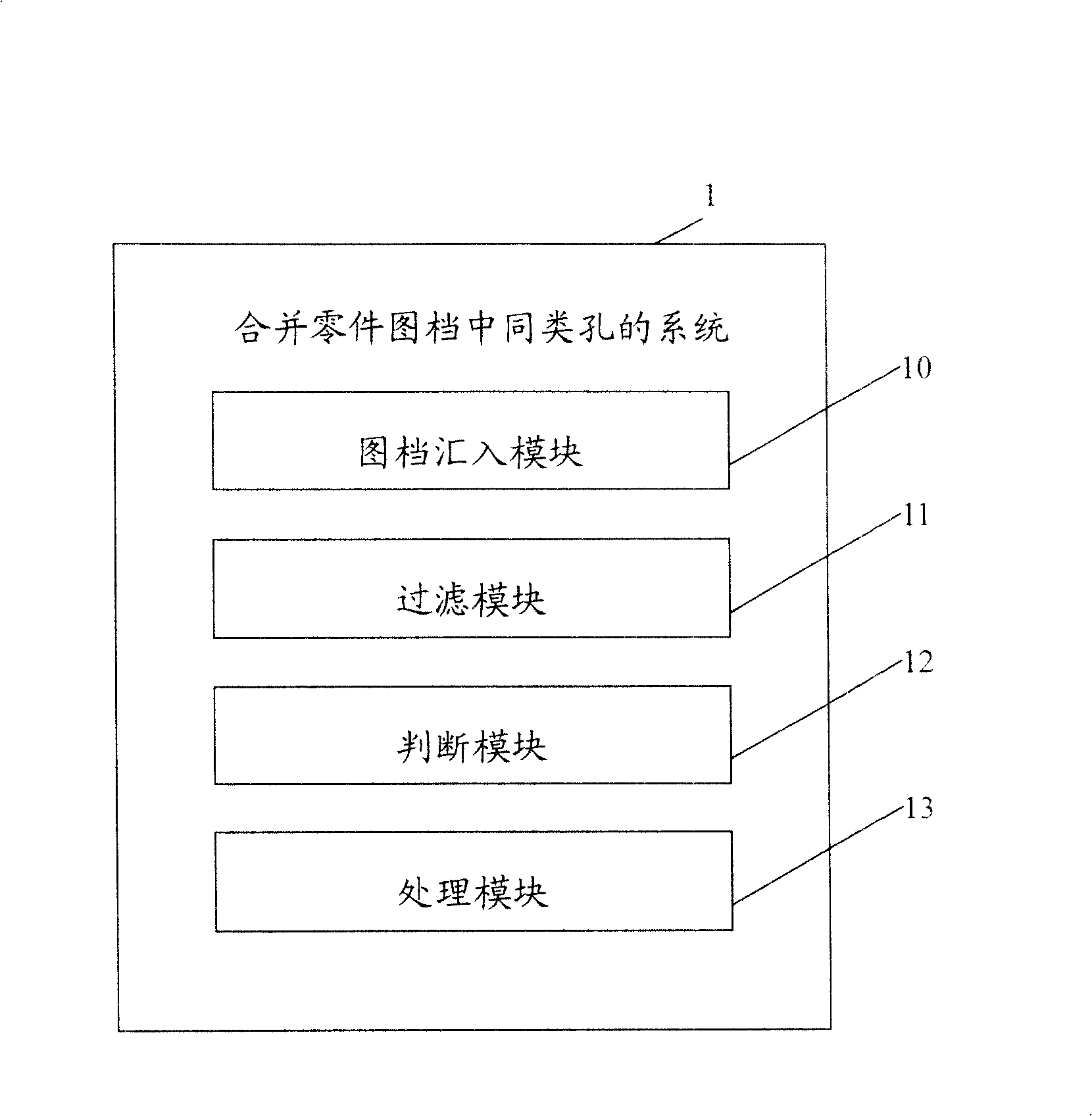

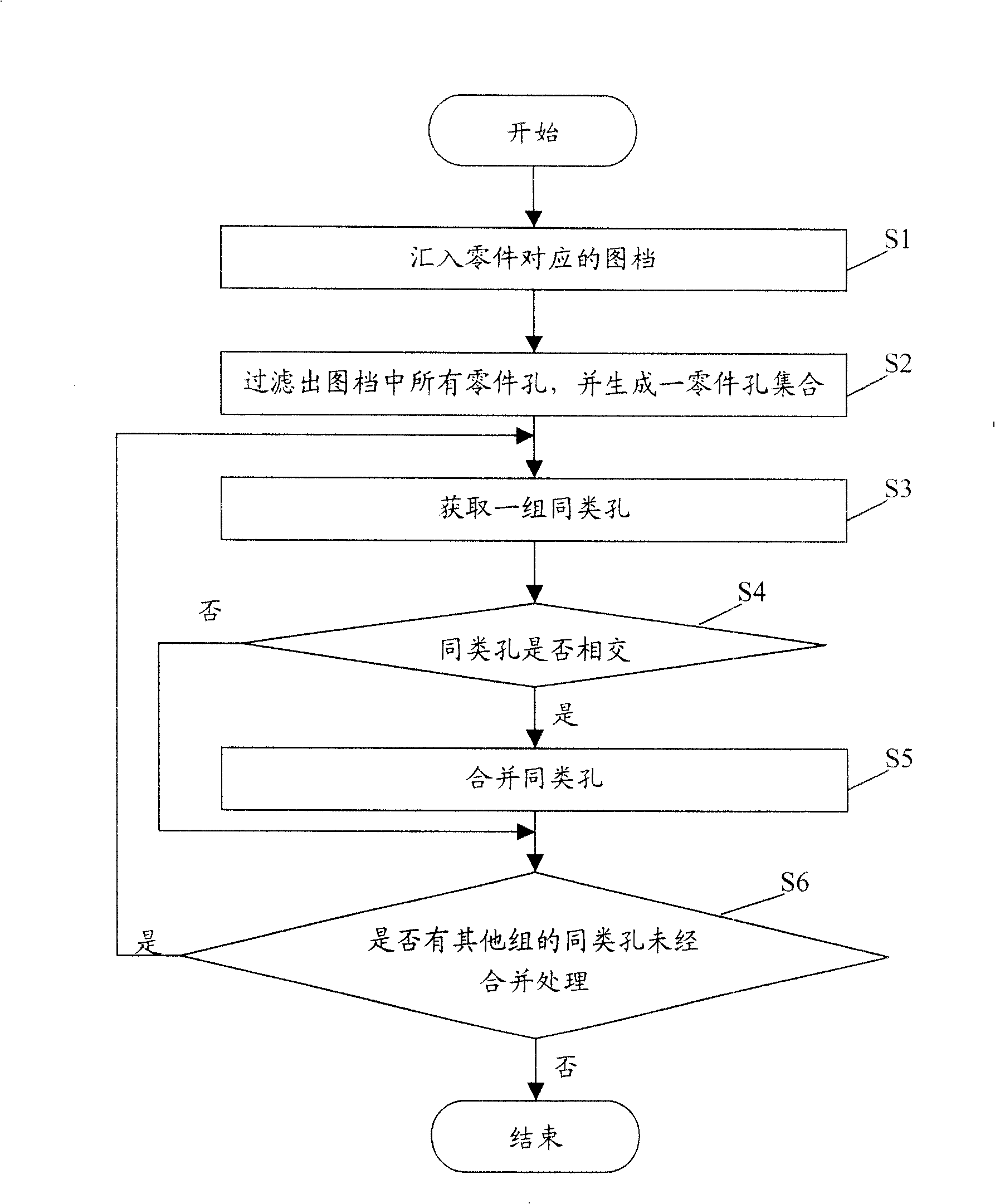

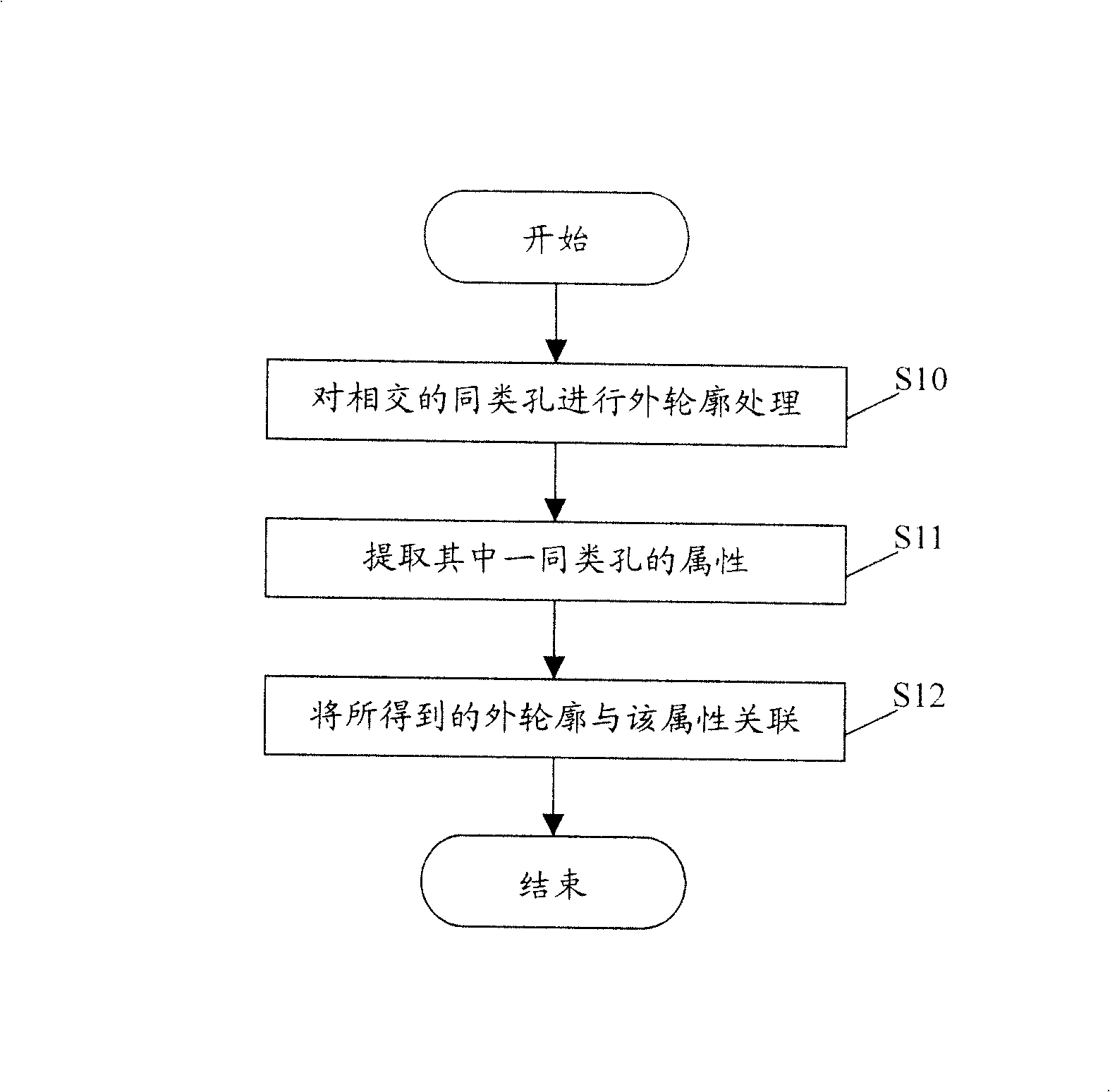

[0015] Such as figure 1 As shown, it is a functional block diagram of a preferred embodiment of the system for merging similar holes in part drawings according to the present invention. The system 1 for merging holes of the same type in part drawings can be installed and run on any computing device (such as a personal computer, not shown), for merging the intersecting holes of the same type in part drawings, which includes four The functional modules are image file importing module 10 , filtering module 11 , processing module 13 and judging module 12 . Wherein, the image file importing module 10 is used to import the image file corresponding to the part, and the image file can be the front view of the part. The filter module 11 is used to filter out all the part holes in the image file and generate a part hole set, and then obtain similar holes from the part hole set. The similar holes are holes with the same attribute, and the attributes include the type of part hole, Data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com