Laser circular cutting punching method and its device

A circumcision and laser technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of expensive equipment, low efficiency, complex technology, etc., and achieve the effect of simple and reliable device structure, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

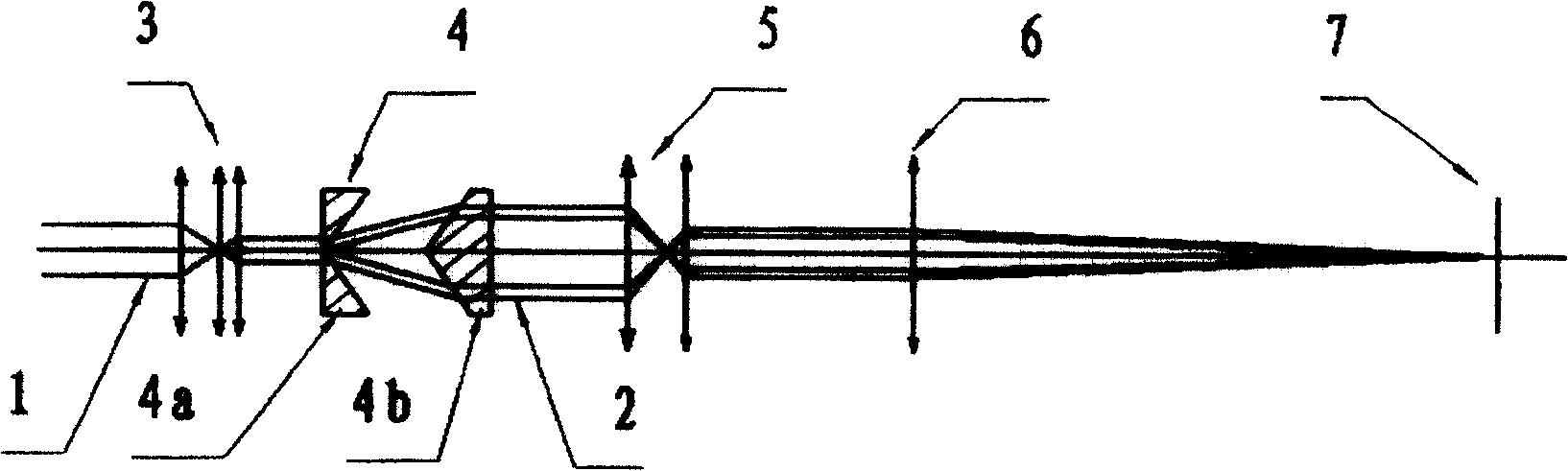

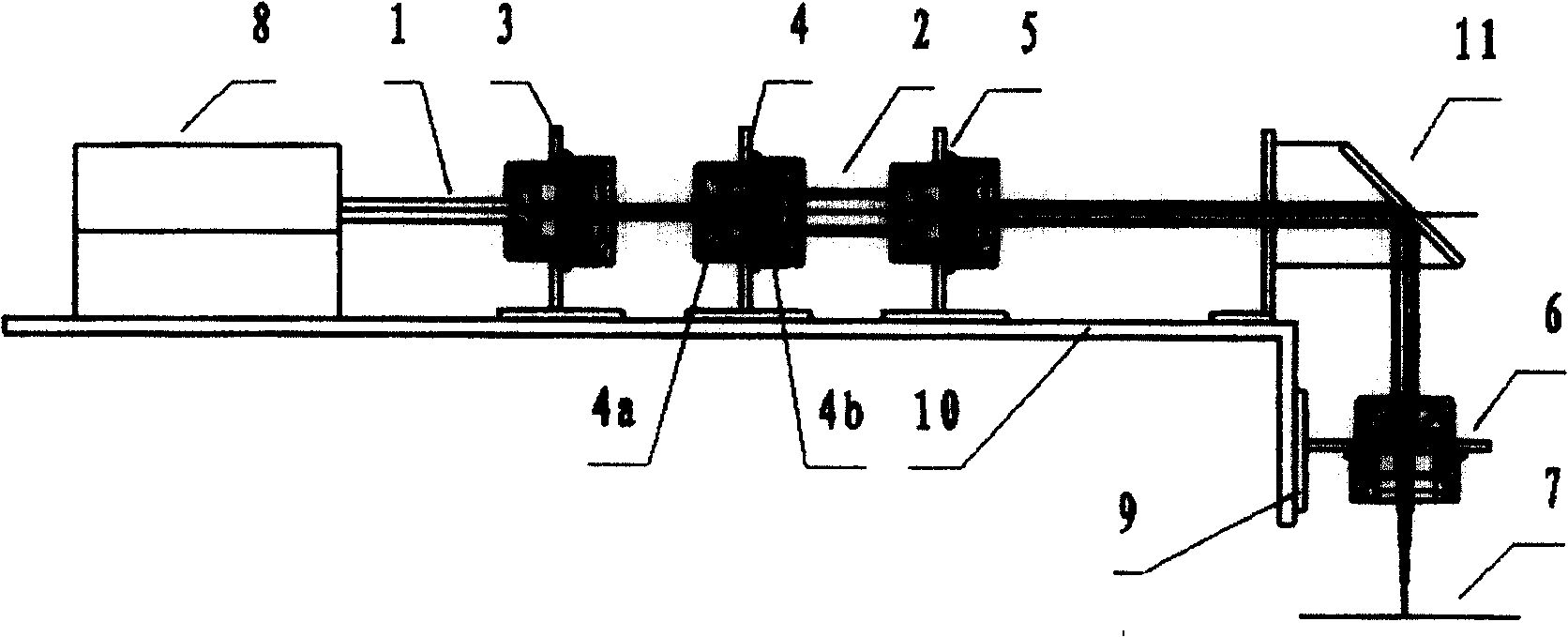

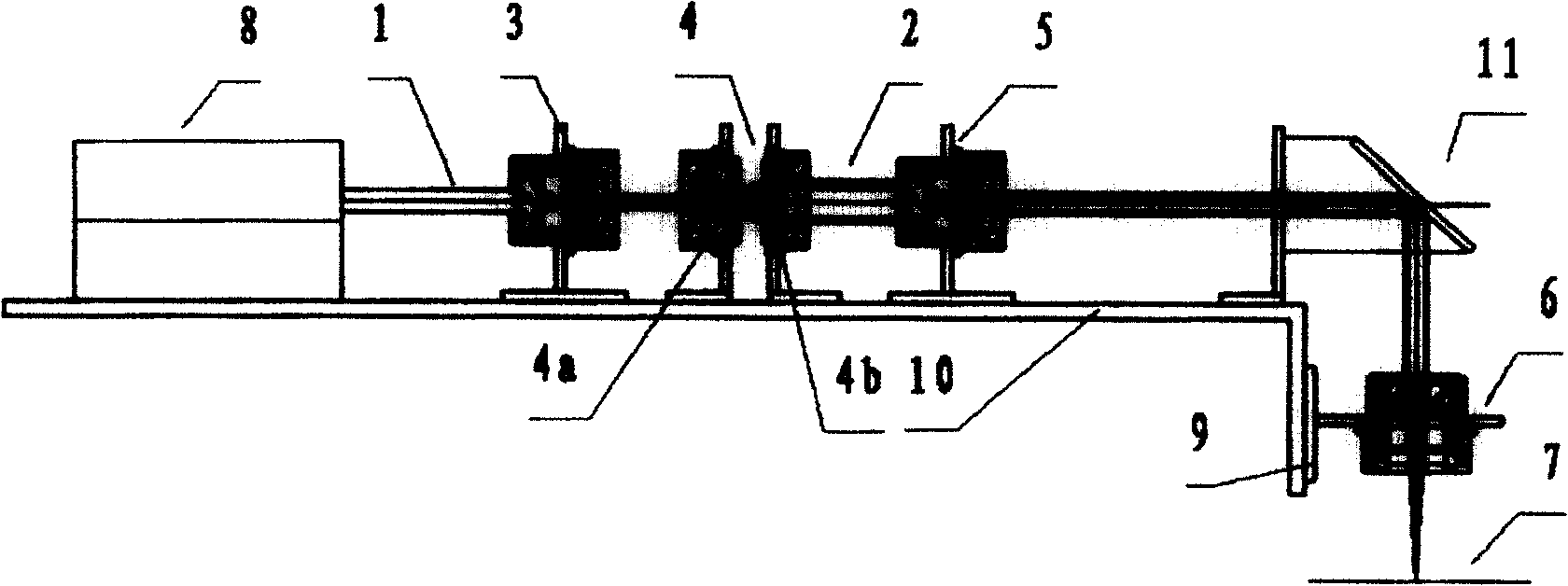

[0012] From figure 1 It can be known from the shown optical path principle of laser ring cutting and perforation that the laser beam 1 with a circular cross section is compressed by a beam compression device 3 and enters the light ring generator 4 . The halo generator 4 is composed of a pair of negative conical light wedges 4a and positive conical light wedges 4b that are relatively separated in space. The centers of the shaped laser beams 1 coincide, and the conical angles of the negative conical light wedge 4a and the positive conical light wedge 4b should avoid total reflection. The circular laser beam 1 refracts and diverges through the negative cone light wedge 4a in the light ring generator 4, refracts and converges through the positive cone light wedge 4b, and outputs a collimated laser beam 2 with a circular cross-section. The laser beam 2 is then compressed and reduced by another beam compression device 5 into a thinner annular laser beam, and finally focused on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com