Drive method for increasing gray level

A driving method and gray-scale technology, applied to instruments, static indicators, etc., can solve the problems of increasing circuit complexity and manufacturing costs, and achieve the effects of stable output, reducing crosstalk distortion, and prolonging the life of the panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

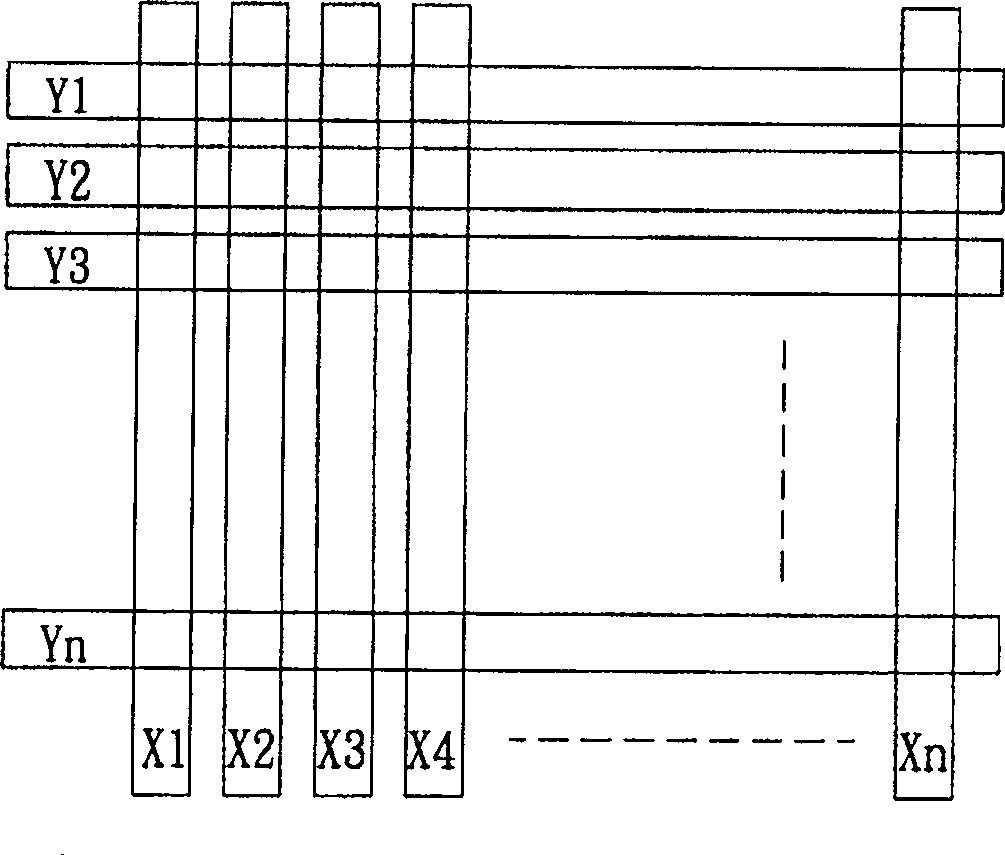

[0027] Relevant detailed content and technical description of the present invention, now in conjunction with accompanying drawing, explain as follows:

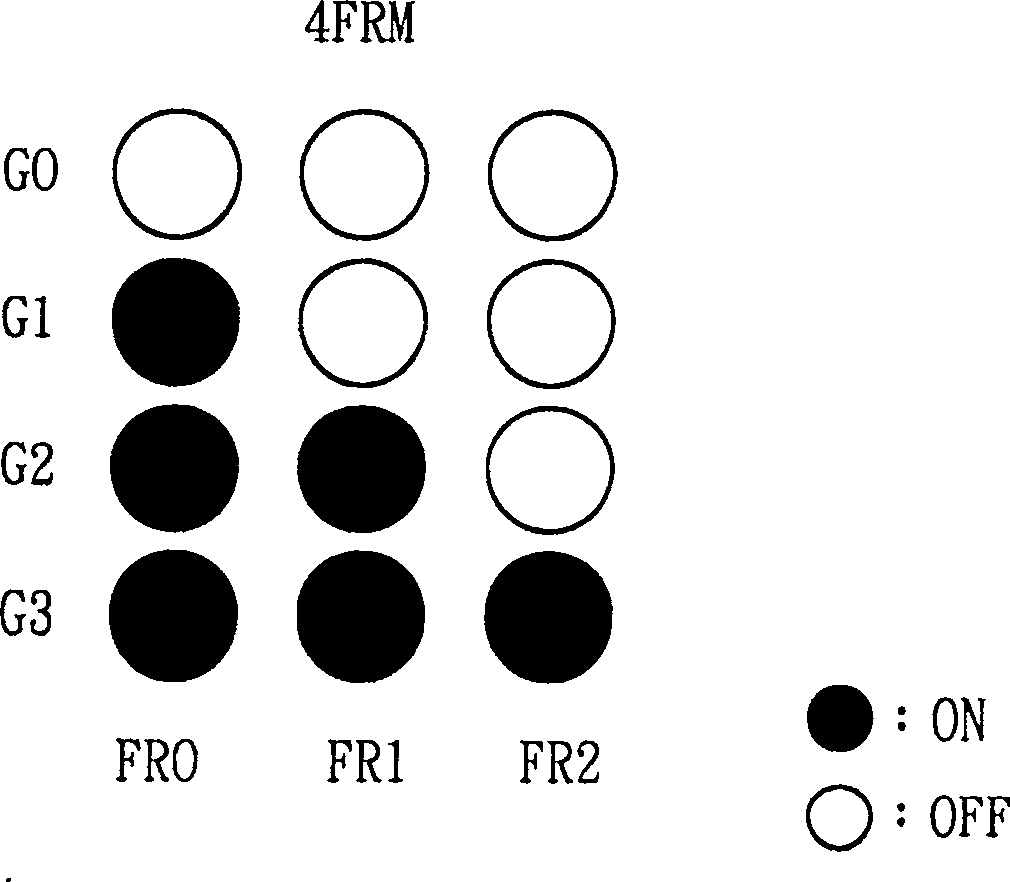

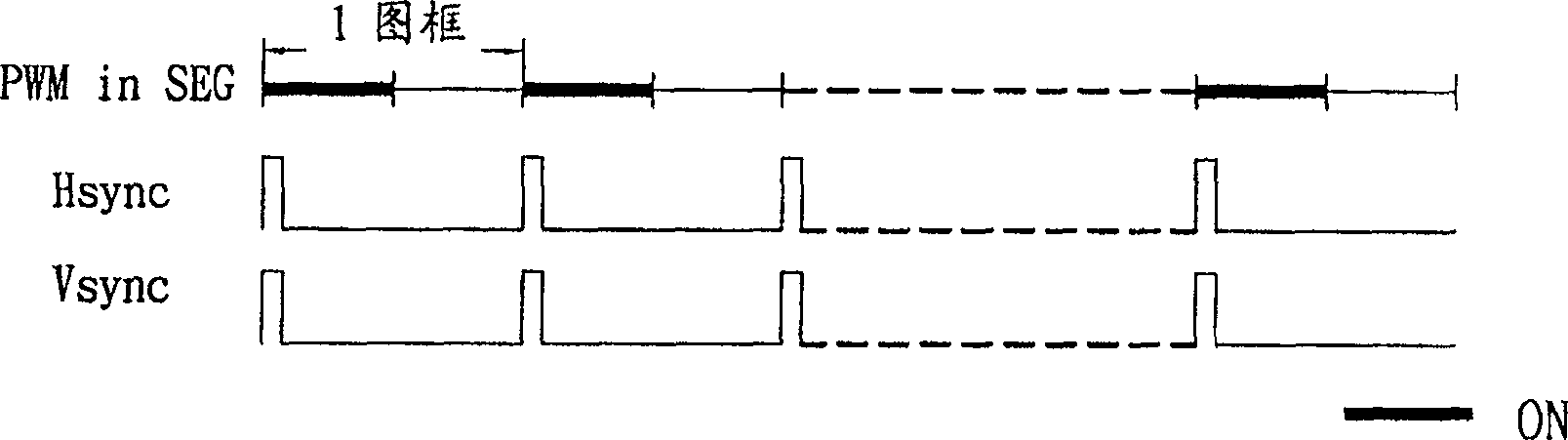

[0028] see Figure 4 As shown, it is a graph of the relationship between the grayscale visual effect and the number of pixel lighting times when the pulse width modulation mode (4FRM+3PWM) is added to the frame frequency modulation mode. The frame rate modulation mode uses the number of times of ON / OFF in N frames per second to determine the gray scale of the pixel at that point. The grayscale principle of FRM is to control the number of lighting times of a pixel, so that the grayscale level of the pixel is determined by the proportion of the number of lighting times in N frames. Taking the number of frames per second as 3 times (4FRM) as an example, in the traditional driving method, there is only the difference between the grayscale (G0~G3) visual effect of the frame frequency modulation (FRM) mode and the number of pixel l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com