Surgical appliance for milling acetabulum

A surgical operation and instrument technology, applied in the field of surgical instruments for milling acetabulum, can solve the problems of difficulty and increase in applying axial machining force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

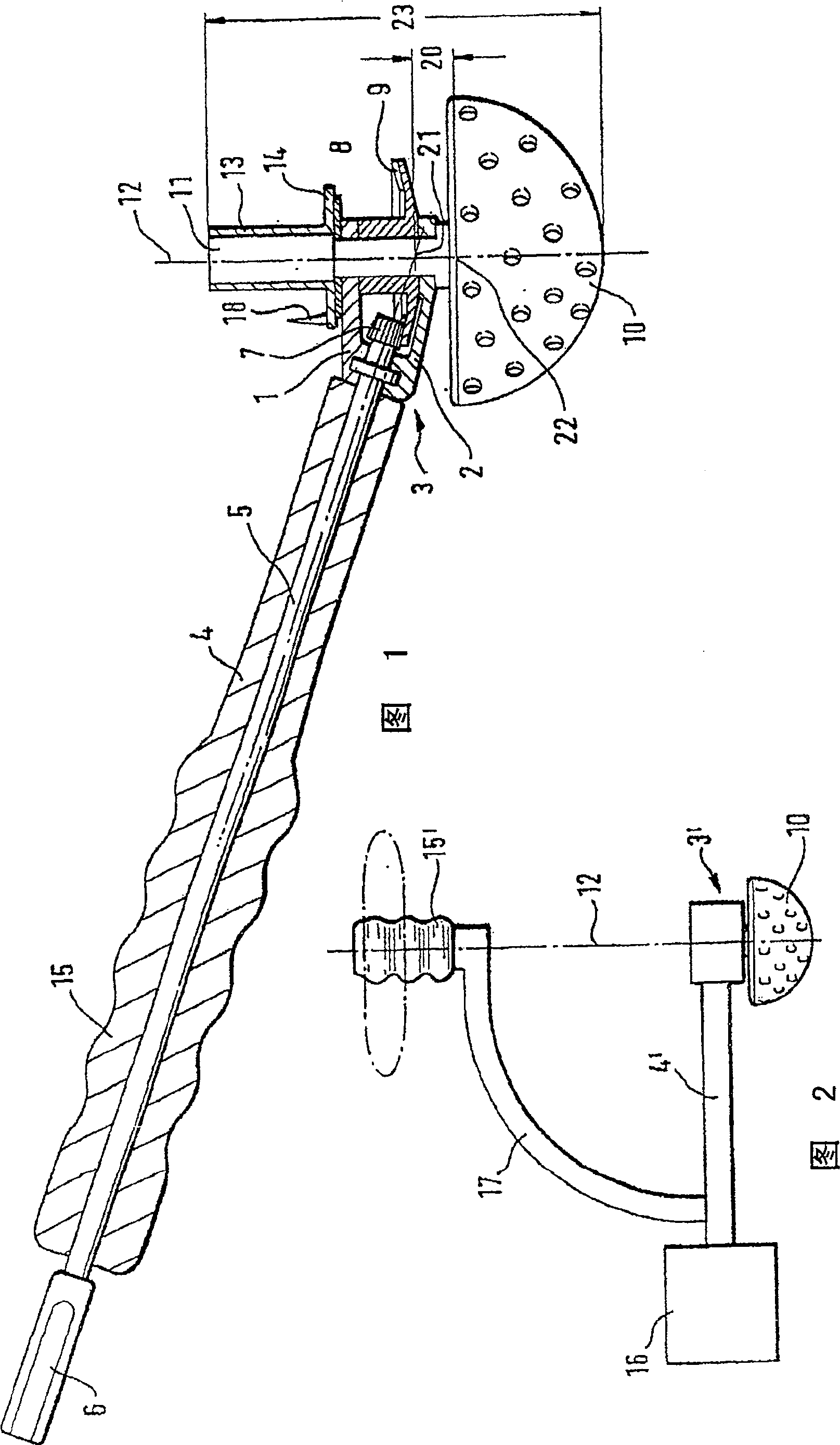

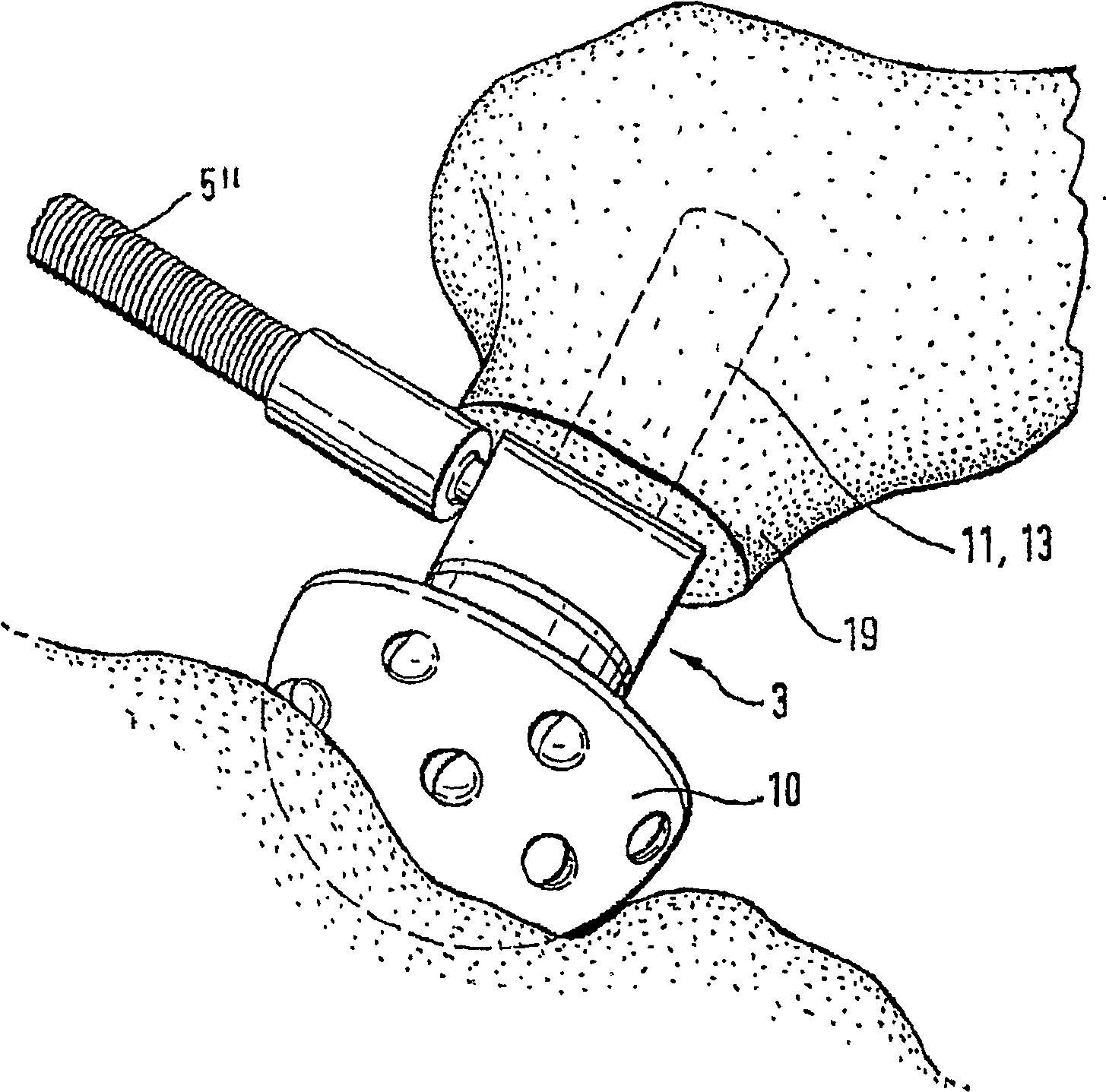

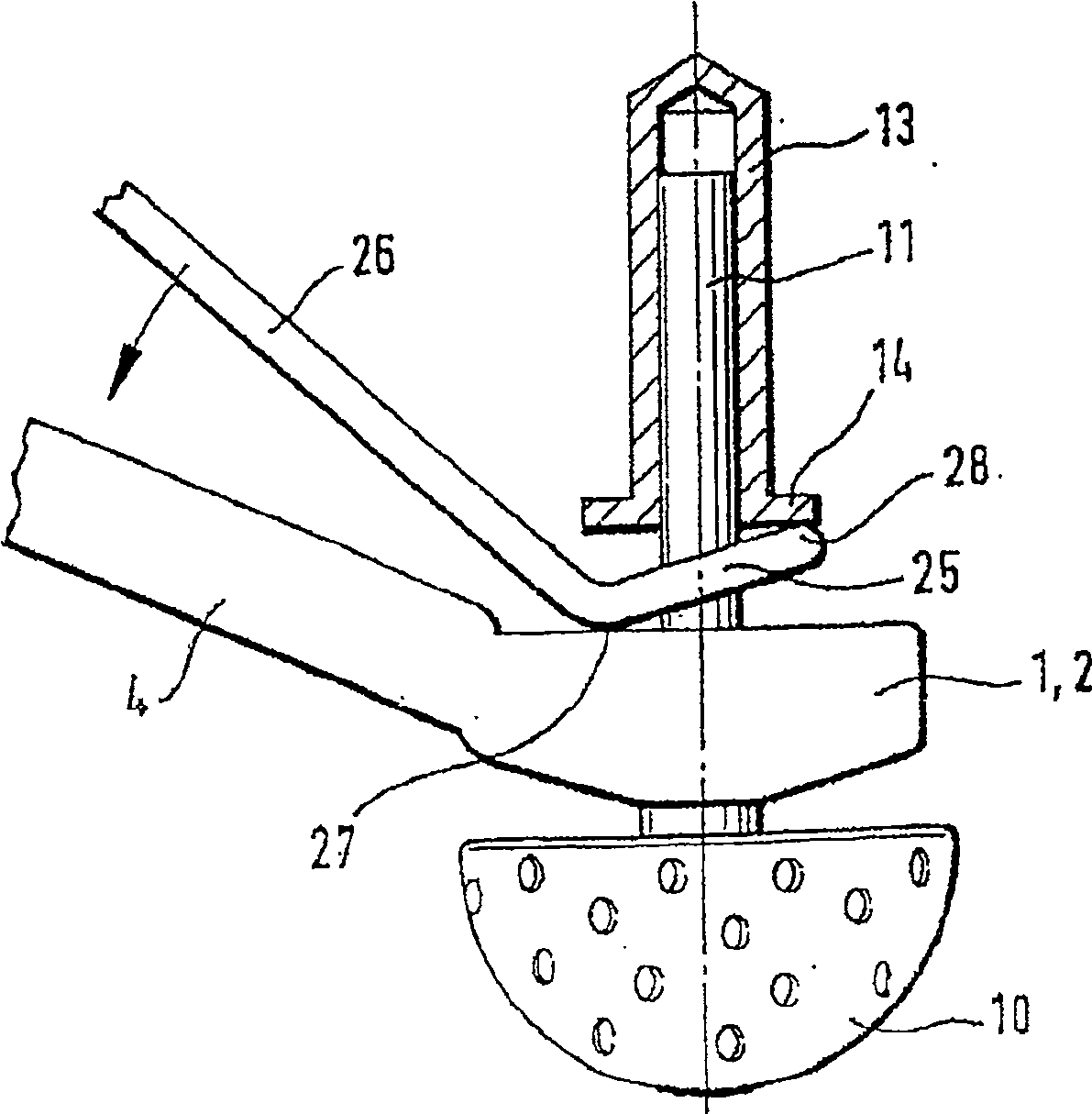

[0018] The housing parts 1, 2 of the instrument head 3 shown in Fig. 1 are firmly connected to a rod 4, which constitutes a handle 15 and includes a drive shaft 5, the free end 6 of which can be connected to a drive motor or manually in a known manner. The drive is connected with a handle. Inside the housing 1 , 2 a drive pinion 7 is mounted on the drive shaft 5 .

[0019] A milling cutter shaft 8 is mounted rotatably transverse to the drive shaft 5 in the housing 1 , 2 of the instrument head 3 . The angle between the milling cutter shaft and the drive shaft is suitably 90°-135° (110° in the example shown). A bevel gear 9 is mounted on the milling cutter shaft, the teeth of which mesh with the teeth of the driving pinion 7. In this way, the milling cutter shaft 8 can be driven in rotation by the drive shaft 5 . Of course, this is only one example of a drive connection between the two shafts. Other transmission forms can also be used, for example, a worm gear transmission. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com