Display device and back light module thereof

A backlight module and display technology, applied in the direction of static indicators, optics, instruments, etc., can solve the problems of light leakage, inconvenient assembly, easy light leakage, etc., and achieve the effect of improving assembly efficiency and reducing the probability of light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are specifically listed below and described in detail in conjunction with the accompanying drawings.

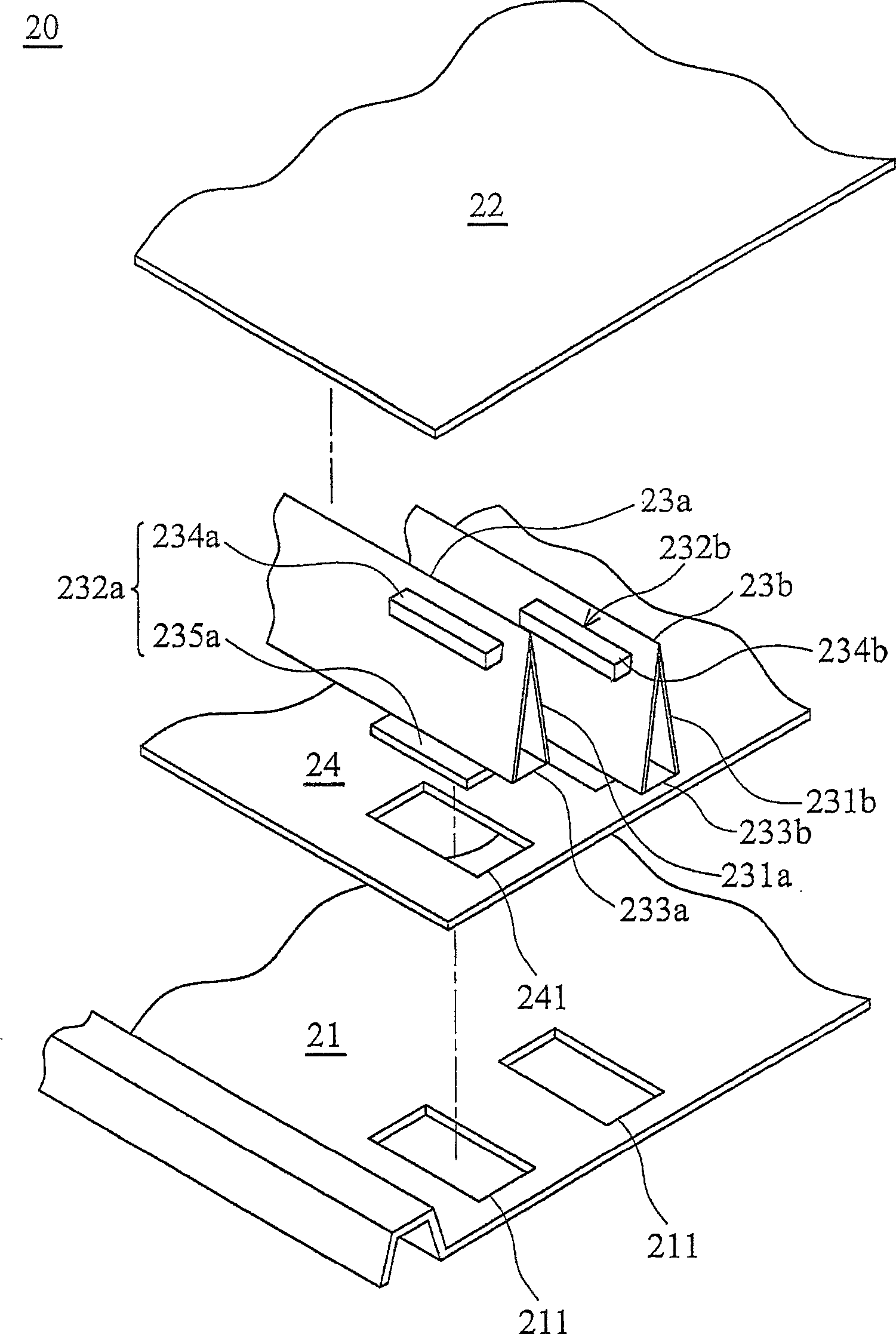

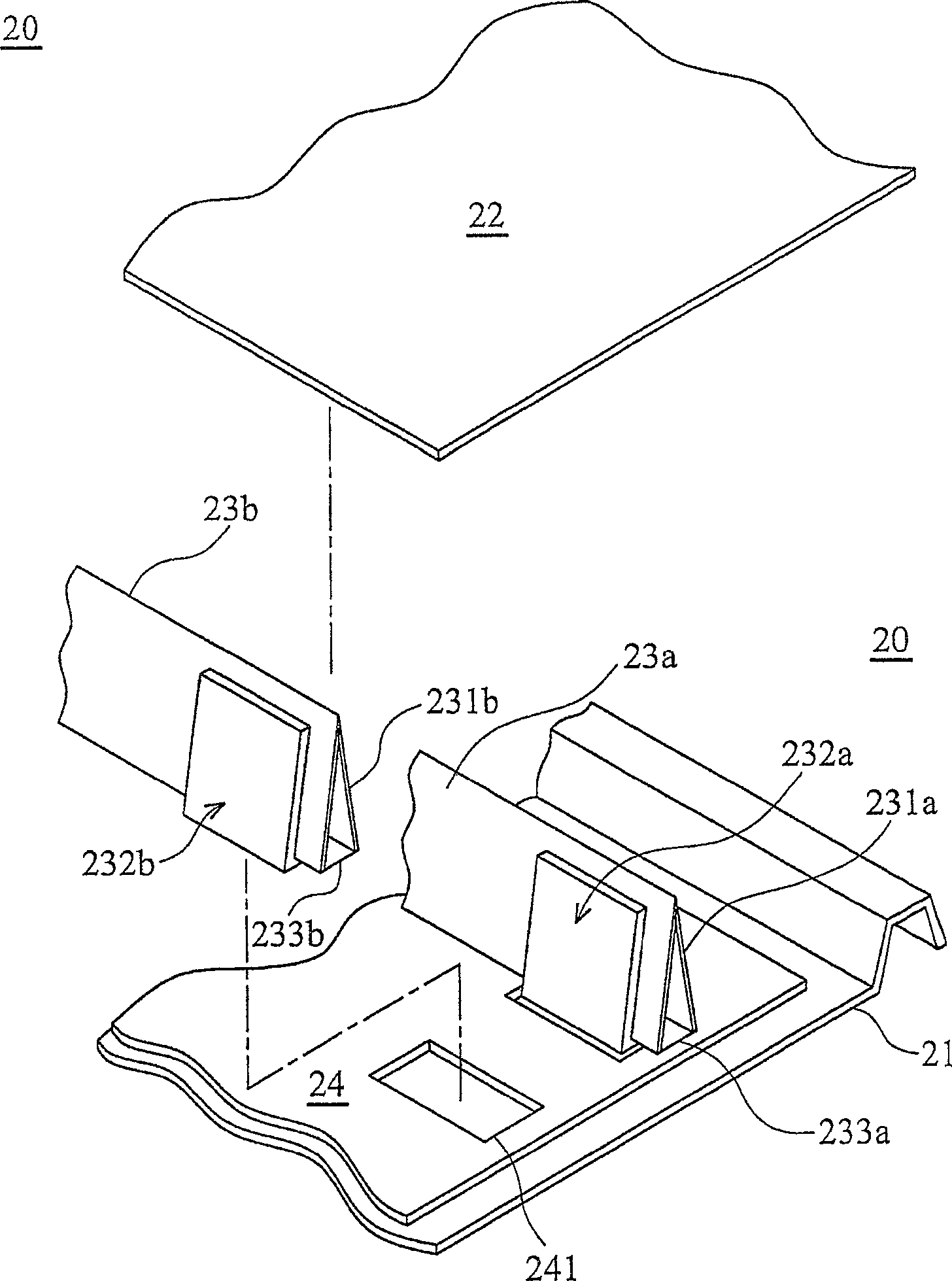

[0045] see figure 2 , 3 The backlight module 20 of the present invention includes a bottom plate 21, a diffusion plate 22, support units 23a, 23b, and a circuit board 24. The circuit board 24 is arranged on the bottom plate 21 and includes at least one positioning hole 241, and the bottom plate 21 is also provided with There are positioning holes 211, and when the circuit board 24 overlaps with the bottom plate 21, the positioning holes 241 and the positioning holes 211 overlap each other, and the support units 23a, 23b include reflective parts 231a, 231b and engaging parts 232a, 232b. The parts 232a, 232b fix the supporting units 23a, 23b on the bottom plate 21 and the circuit board 24. It should be noted that the engaging parts 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com