Packaging method of hollow packaging LED (light emitting diode) display module

A display module and packaging method technology, which is applied in the field of LED light sources, can solve problems such as increasing enterprise costs, bad disassembly, and affecting efficiency, and achieve the effects of reducing labor costs, improving assembly efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

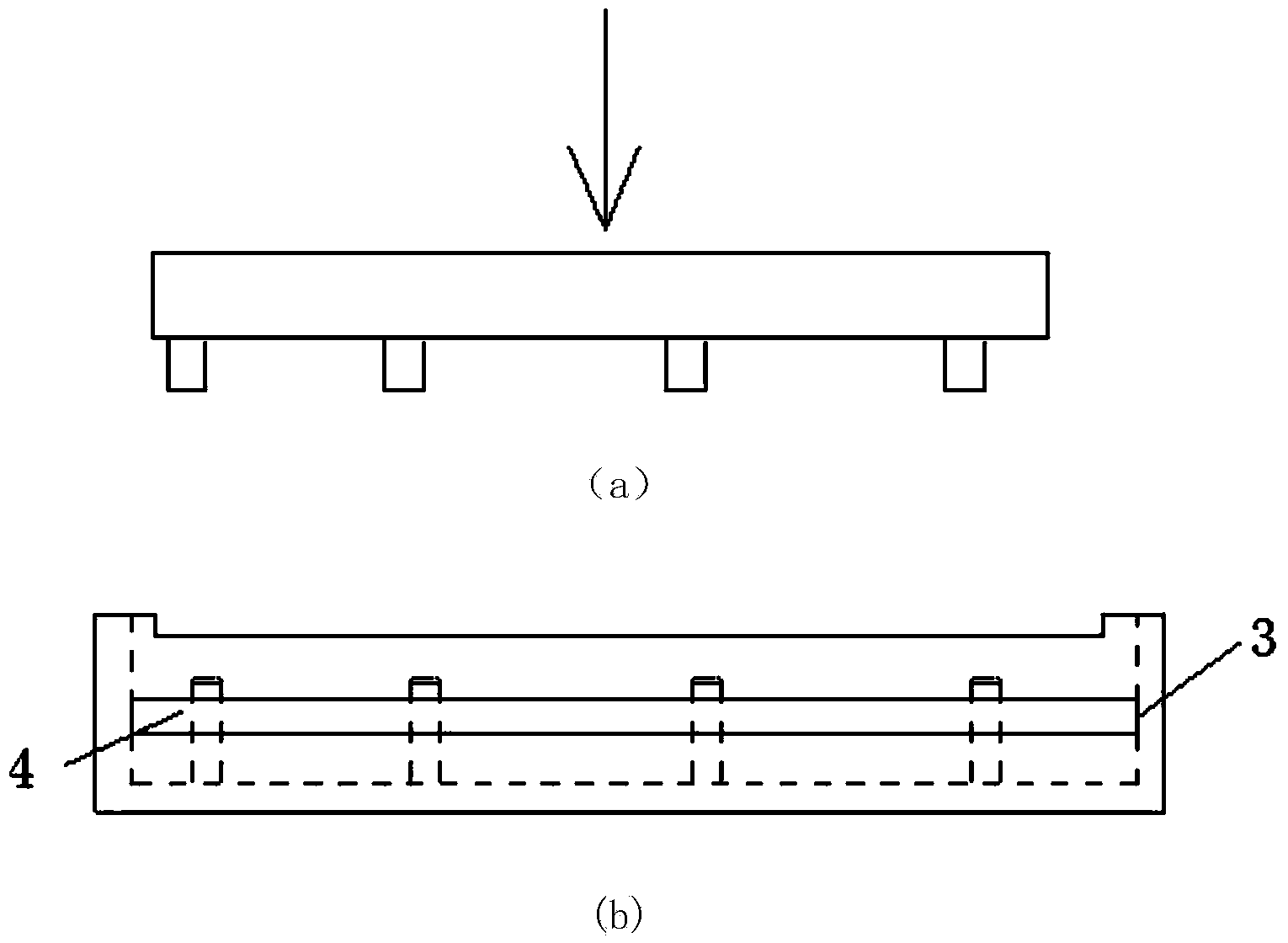

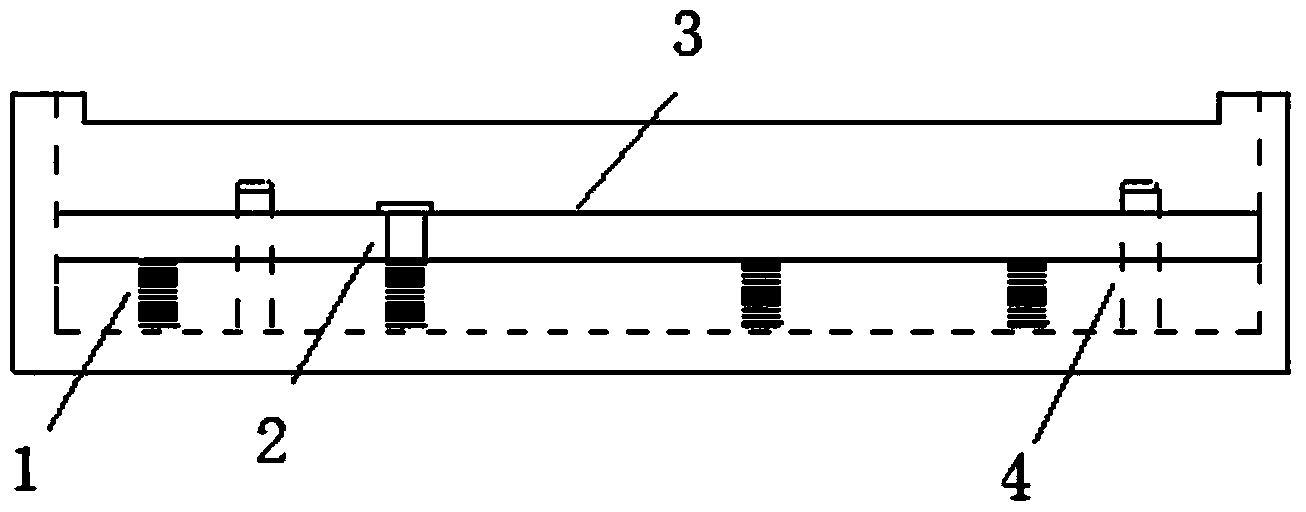

[0023] Such as figure 1 Shown is a schematic diagram of an existing encapsulation method, figure 1 (a) is a module that matches the air-sealed LED display module, figure 1 (b) Air-sealed LED display module. The packaging method of the existing air-sealed LED display module is to use the method of pressing the positioning column 4 with the mold, and after inserting the positioning hole in the PCB board 3 into the positioning column 4 in the plastic case, the part beyond the PCB board 3 can be used. The module flattens it to achieve the purpose of combining with the PCB board 3 .

[0024] In order to save costs and improve efficiency, a new type of packaging method was invented, which can effectively reduce costs and facilitate disassembly when defects are found. A packaging method for an air-sealed LED display module of the present invention com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com