Light guide lamp for vehicle

A technology of light guides and lamps, which is applied in the direction of light guides, light guides of lighting systems, semiconductor devices of light-emitting elements, etc., can solve the problems of long light guide structure, light leakage, and inability to achieve visual effects, etc., to reduce difficulty, reduce cost, and reduce processing effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the drawings.

[0031] In this embodiment, the diameter of the light guide ring of the vehicle light guide lamp is 40 mm.

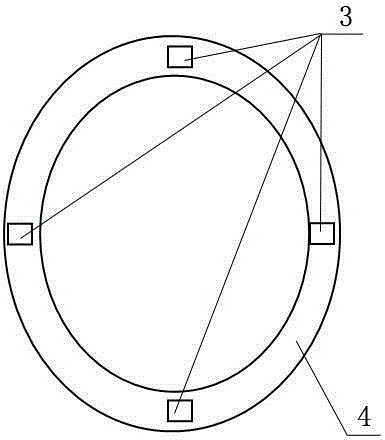

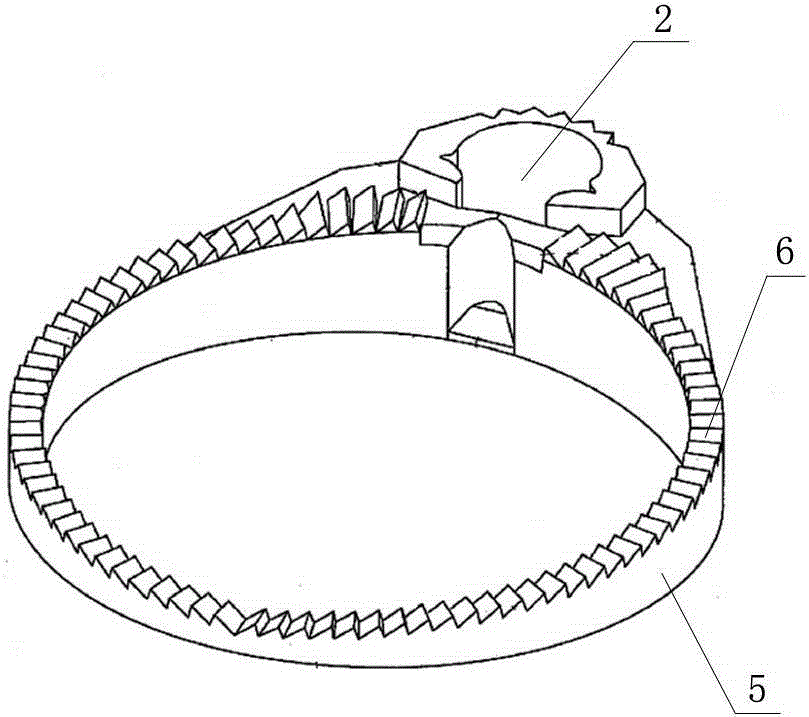

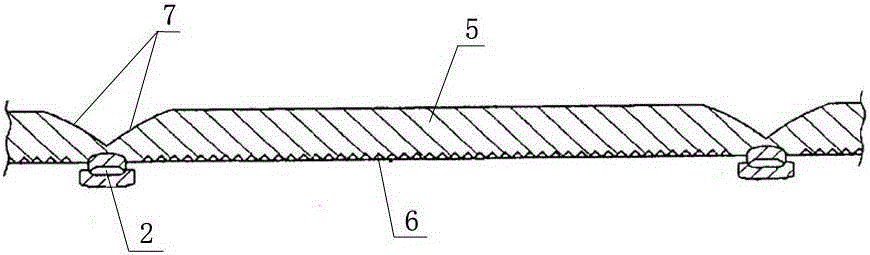

[0032] Such as Figure 1 to Figure 10 The car light guide lamp shown includes a light guide ring 1 and an LED light source 2. The light guide ring 1 is formed by one-time injection molding of PC plastic with titanium oxide added. The LED light source 2 is composed of a single LED lamp, and the LED lamp is a lens. For packaged SMD LEDs, the light emitted by the LED light source 2 enters the light guide ring 1; the top of the light guide ring 1 has two light collection surfaces 11 and a flat light exit surface 12, and the bottom is a toothed reflection surface 13; The light collecting surface 11 is a parabolic surface with the plane where the LED light source 2 is located as the main axis. The two light collecting surfaces 11 have a common focal point and are connected symmetricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com