Sheet processing apparatus and image forming apparatus

A processing device and sheet technology, which are applied in thin material processing, stack receiving device, electrical recording process applying charge pattern, etc., can solve problems such as paper jam, inability to preempt sheet restriction, sheet damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

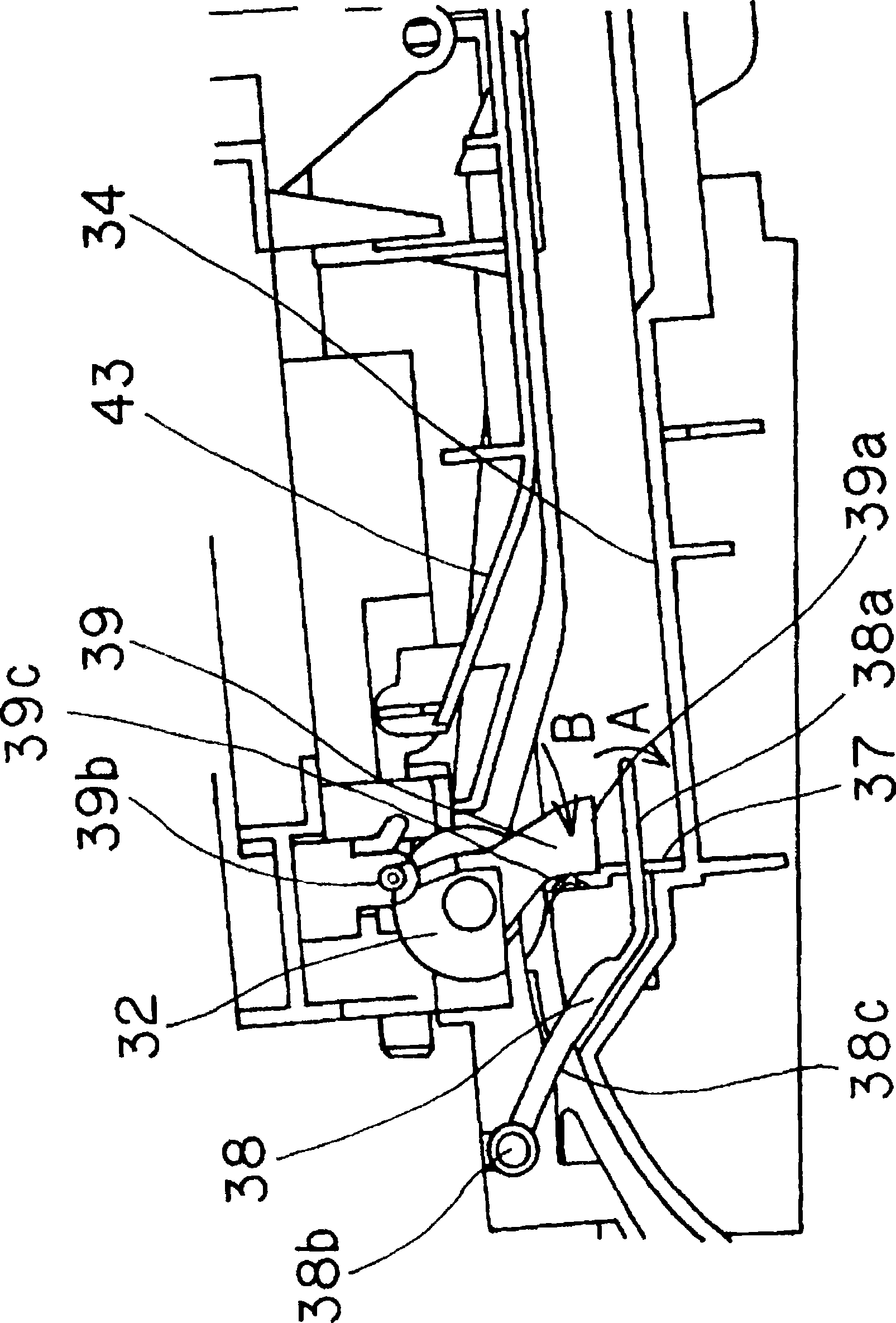

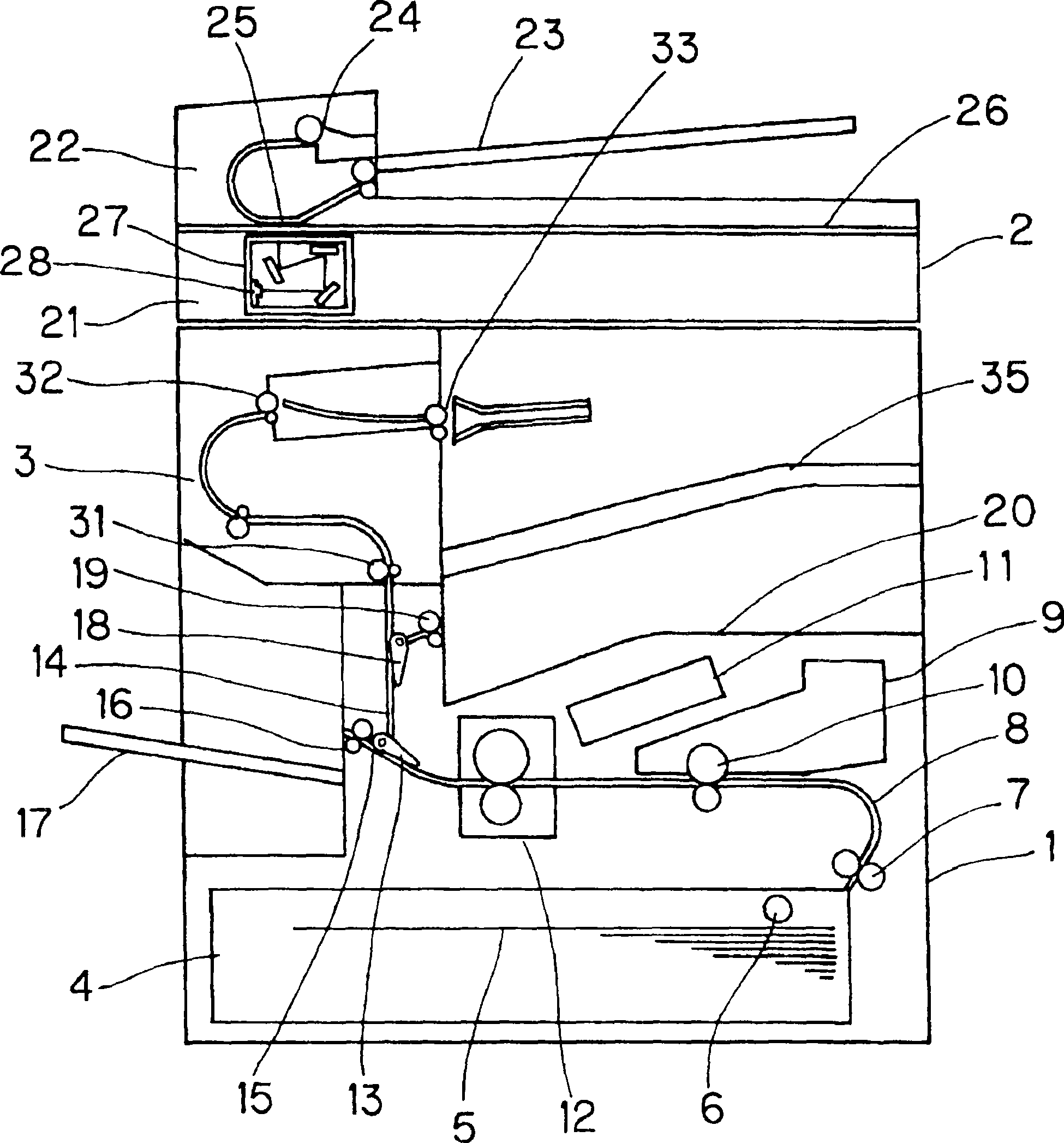

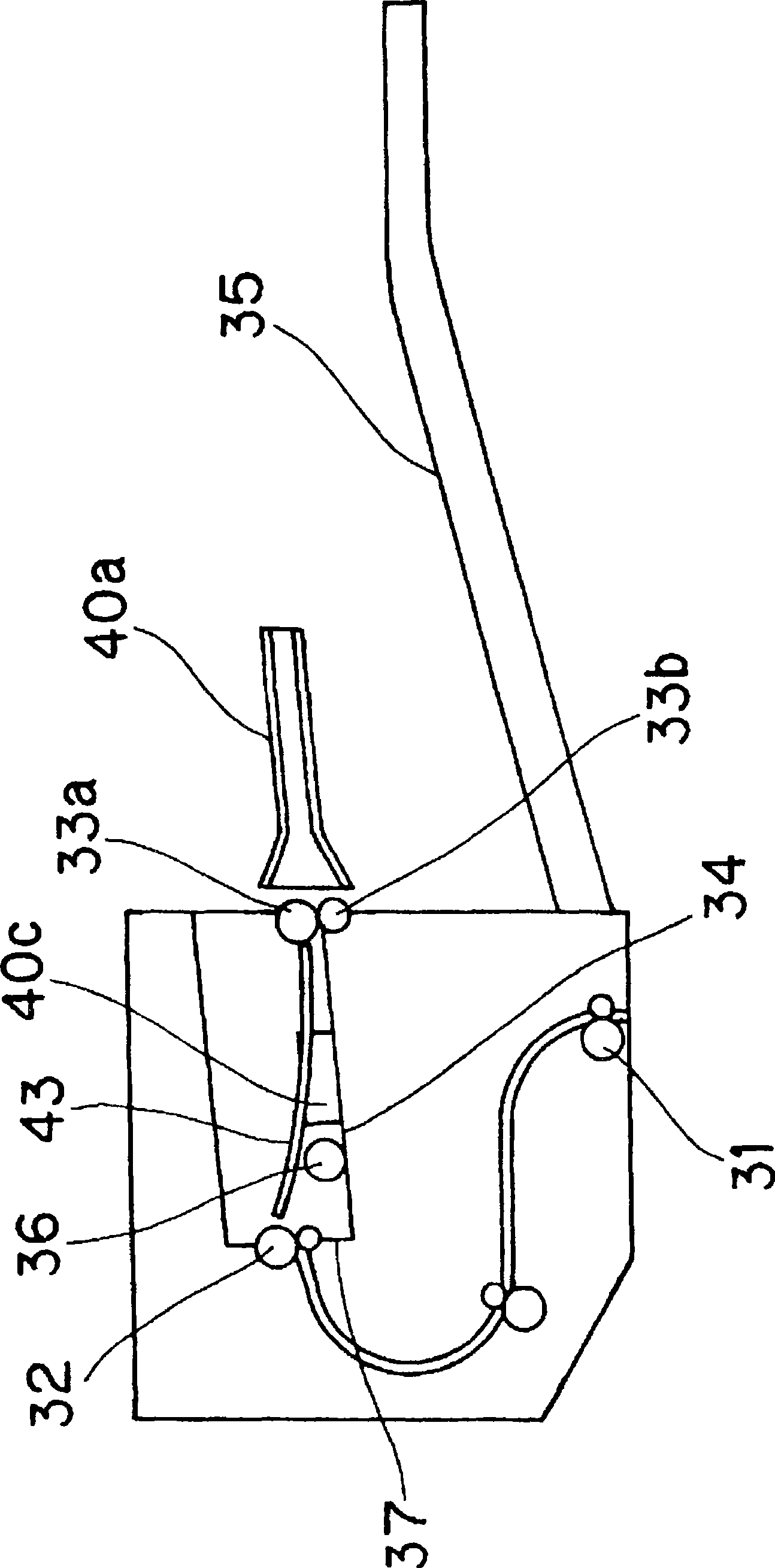

[0039] figure 2 An image forming apparatus as a sheet processing apparatus according to the first embodiment of the present invention is shown. Such as figure 2 As shown, the image forming apparatus of the first embodiment includes an image forming unit 1 , an image reading unit 2 , and a sheet processing unit 3 . The image forming unit 1 forms an image on a sheet. The image reading unit 2 reads information described in a document. The sheet processing unit 3 is an independent unit that performs predetermined processing such as stapling on the sheets on which images have been formed by the image forming unit 1 described above. The sheet processing unit 3 is disposed sandwiched between the image forming unit 1 and the image reading unit 2 , and is connected to the image forming unit 1 and the image reading unit 2 .

[0040] Additionally, if figure 2 As shown, the image forming section 1 separates and feeds a plurality of sheets 5 stacked on the supply cassette 4 one by ...

no. 2 Embodiment approach

[0074] Next, a sheet processing apparatus according to a second embodiment of the present invention will be described. Figure 10 with Figure 11 It is a figure explaining the 2nd Embodiment of this invention. In addition, description of the same configuration as that of the first embodiment is omitted.

[0075] In the configuration of the second embodiment, a solenoid 45 that drives the first pressing member 38 is provided as a switching member. And, by this solenoid 45, the first pressing member 38 can be Figure 10 The retreat position shown is the same as Figure 11 Switch between the limit positions shown.

[0076] And, when the subsequent sheet S2 is conveyed, the sensor as the sheet detection means detects the subsequent sheet S2. Thus, if Figure 10 As shown, the switching member drives the solenoid 45 before abutting against the first pressing member 38 to move the first pressing member 38 to the withdrawn position. At this time, the preceding sheet S1 on the int...

no. 3 Embodiment approach

[0082] Next, a sheet processing apparatus according to a third embodiment of the present invention will be described. Figure 12 with Figure 13 It is a figure explaining the 3rd embodiment of this invention. Note that descriptions of the same configurations as those of the first and second embodiments are omitted.

[0083] In this third embodiment, a sensor 46 is provided as a position detecting member for detecting the position of the first pressing member 38, and by detecting the detecting portion 47 of the first pressing member 38, it is detected that the first pressing member 38 has not returned to the specified position. The restricted position of this state.

[0084] Such as Figure 12 As shown, when the first pressing member 38 should be located at the restricted position, the sensor 46 may detect that the first pressing member 38 has not returned to the restricted position due to the extreme bending of the rear end of the sheet S or the like. In this case, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com