A Flotation Separation Method of Microfine Copper-Molybdenum Mixed Concentrate Containing Hydrophobic Gangue

A copper-molybdenum mixed concentrate and separation method technology, applied in flotation, solid separation, etc., can solve the problems of unqualified grade of molybdenum concentrate, high cost and energy consumption of mineral processing, high mutual content rate of copper and molybdenum, and achieve flotation The effect of stabilizing the separation process, eliminating adverse effects, and reducing the amount of sodium sulfide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of TMY01 medicine

[0033] ① Preparation of locust bean gum and carboxymethyl cellulose in warm water at about 60°C, using a beaker as a container, stirring under a magnetic stirrer for 20-30 minutes, the pH value of the warm water is 7.0, and the concentration of the drug is 1%;

[0034] ②Mix hydrochloric acid with clear water and use a beaker as a container at normal temperature to prepare a dilute hydrochloric acid solution with a pH value of 3.0;

[0035] ③ dissolving chitosan in the above-mentioned dilute hydrochloric acid solution, stirring under a magnetic stirrer for 20 to 30 minutes and then diluting it with clear water into a neutral chitosan solution, the pH value of the neutral chitosan solution=7.0, and the concentration of the agent is 1%;

[0036] ④ Mix 1 volume of locust bean gum solution, 1 volume of carboxymethyl cellulose solution, and 2 volumes of chitosan solution to obtain TMY01.

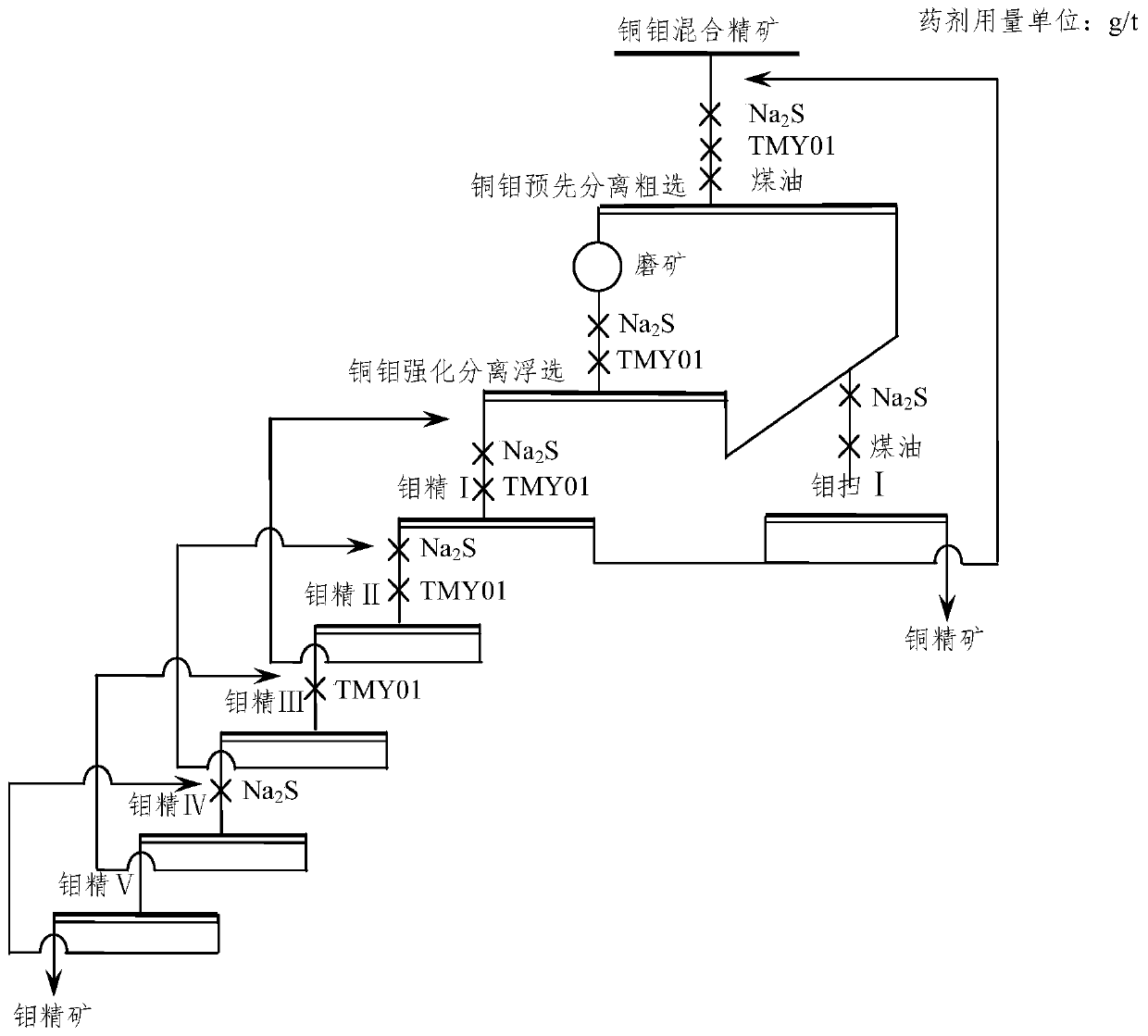

[0037] 2. Mining process

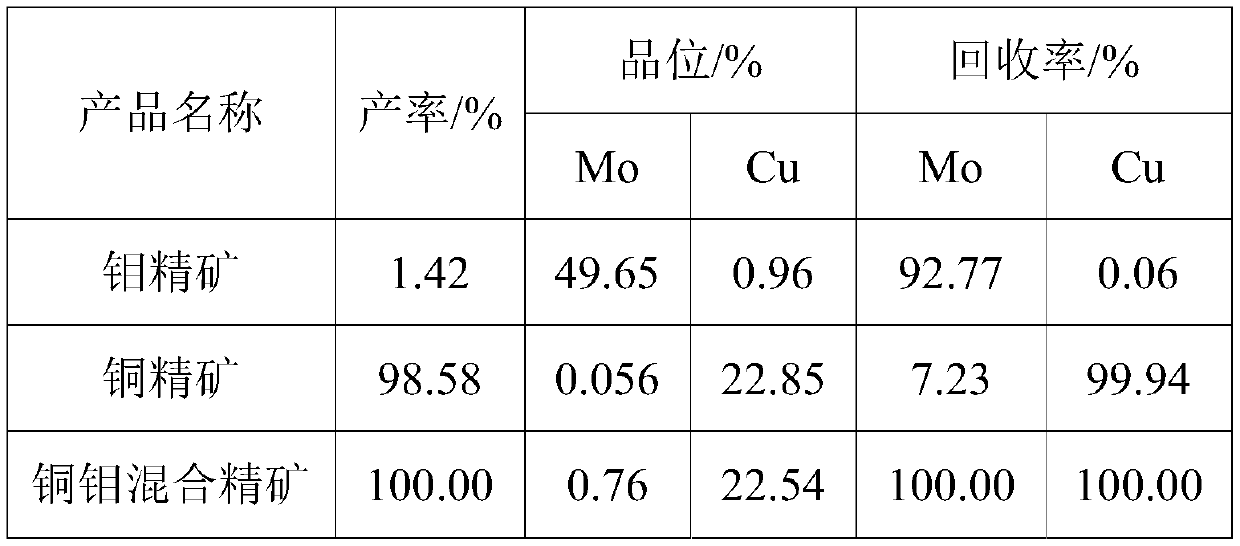

[0038] The selected copp...

Embodiment 2

[0050] 1. Preparation of TMY01 medicine

[0051] ① Prepare gum arabic and hydroxyethyl cellulose in warm water at about 60°C, using a beaker as a container, and stir under a magnetic stirrer for 20-30 minutes. The pH value of the warm water is 7.0, and the drug concentration is 1%;

[0052] ②Mix hydrochloric acid with clear water at room temperature and use a beaker as a container to prepare a dilute hydrochloric acid solution with a pH value of 3.0;

[0053] ③ dissolving chitosan in the above-mentioned dilute hydrochloric acid solution, stirring under a magnetic stirrer for 20 to 30 minutes and then diluting it with clear water into a neutral chitosan solution, the pH value of the neutral chitosan solution=7.0, and the concentration of the agent is 1%;

[0054] ④ Mix 1 volume of gum arabic solution, 1 volume of hydroxyethyl cellulose solution, and 3 volumes of chitosan solution to obtain TMY01.

[0055] 2. Mining process

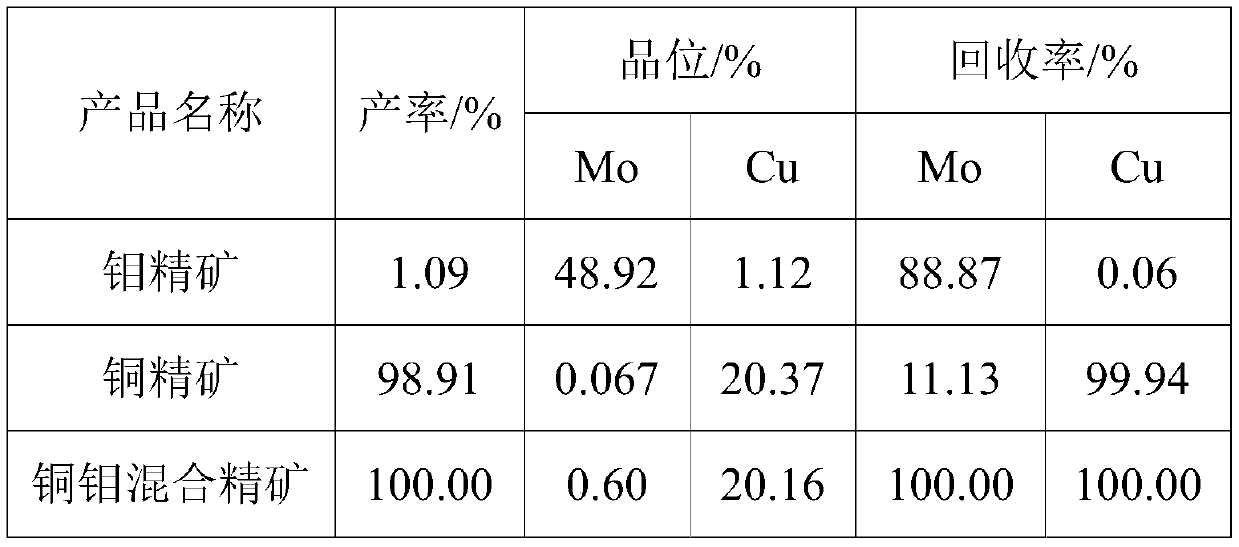

[0056] The selected copper-molybdenum mixed concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com