Method and equipment for producing sprouting half-polished rice

A technology for germ rice and germinated brown rice is applied in the processing field of rice products, and can solve the problems of complex processing methods, reducing the whole germination rate of germinated germ rice, and complicated structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

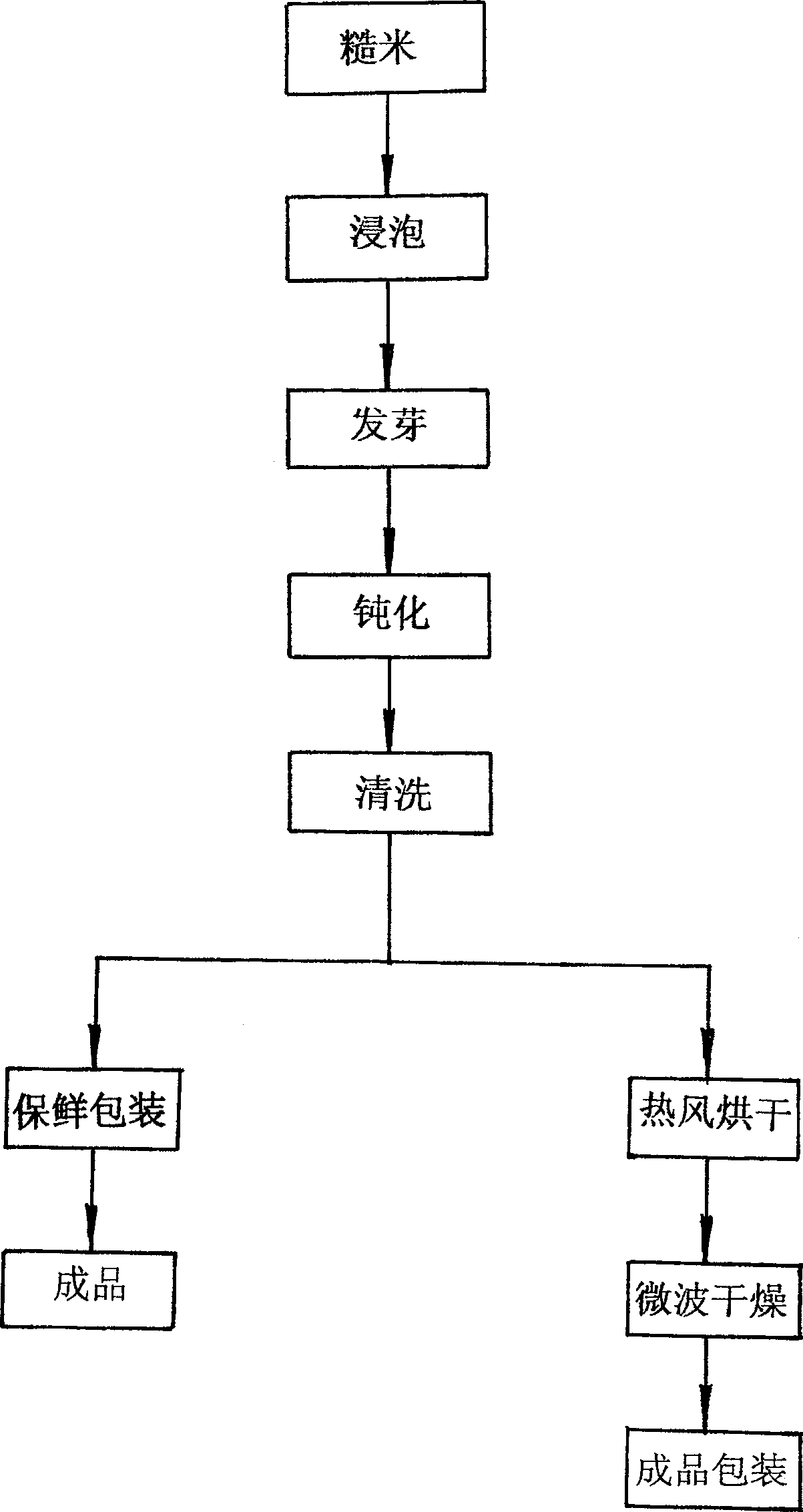

[0037] Example 1, in figure 1 In the flow chart shown, the preparation method of germinated germ rice according to the present invention, its preparation steps are the process flow: take raw brown rice—soaking treatment—germination treatment—passivation treatment—cleaning treatment—fresh-keeping packaging or drying Handling - Finished product packaging. The above drying process is decomposed into the first-level hot air drying and the second-level microwave drying in turn, namely:

[0038] (1) Using brown rice as a raw material, spread the brown rice into a thin layer, add water to soak; at this time, the above-mentioned brown rice is put into a container for soaking, and the soaking time is 8-24 hours, which is 16 hours here. Hour. Certainly, the above soaking time may also be 14 hours, 18 hours, 20 hours, 22 hours, etc.

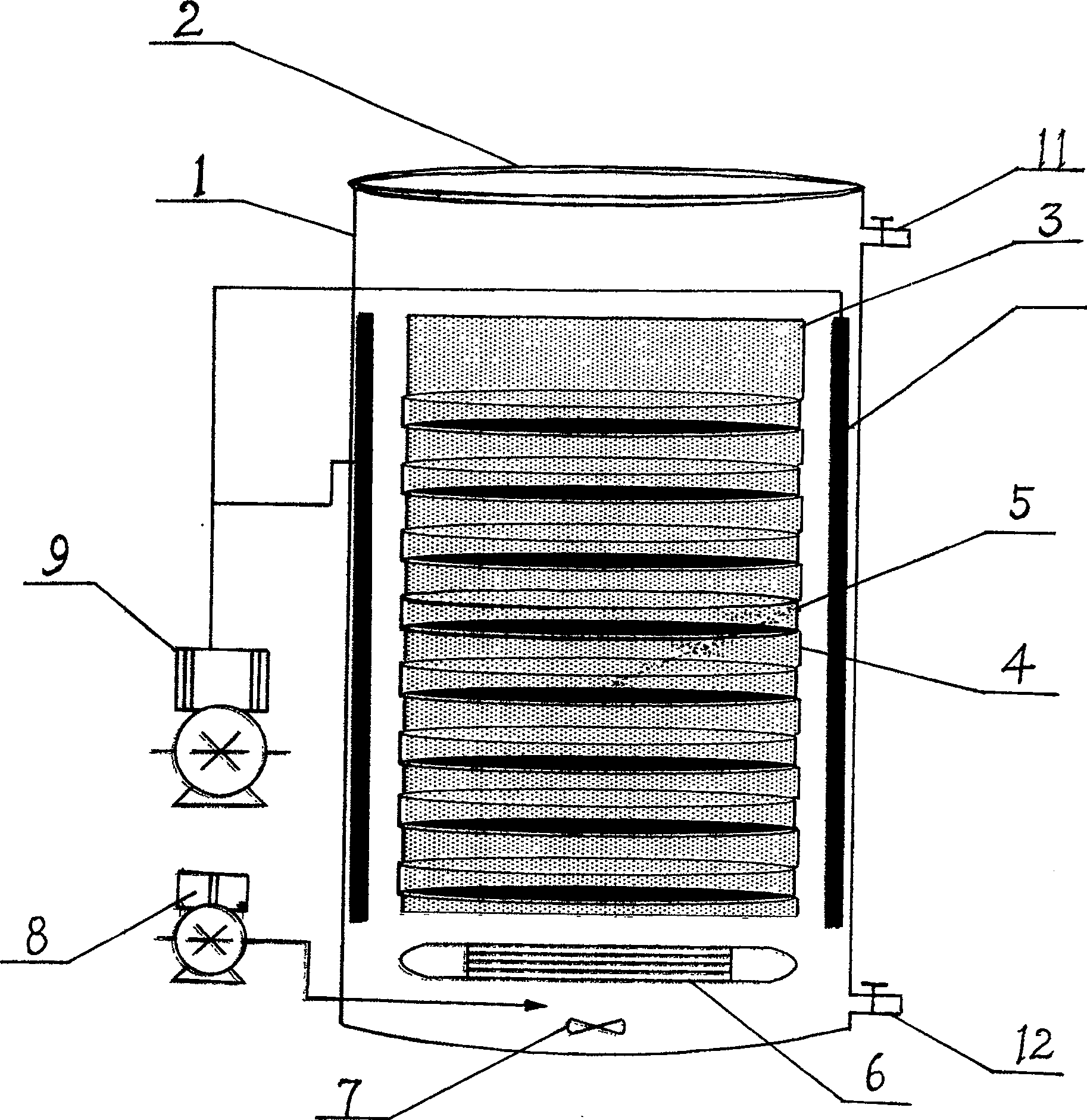

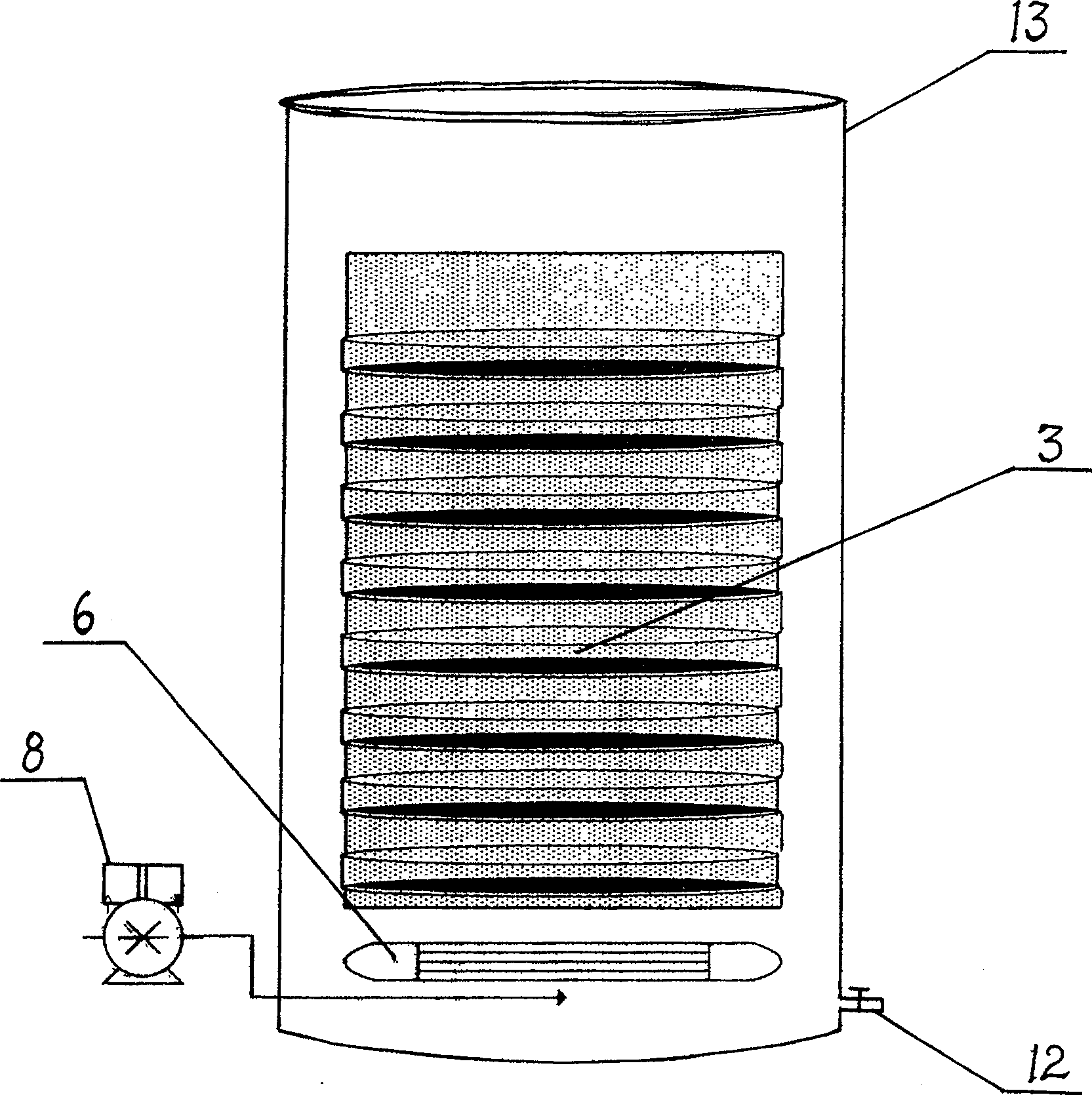

[0039] (2) Spread the soaked brown rice described in the above step (1) into a thin layer, take it out as it has been spread into a thin layer, put it i...

Embodiment 2

[0045] Embodiment 2. In this embodiment, except that the method of spraying atomized water is adopted for the constant humidity treatment, other method steps are the same as those described in Embodiment 1. In this embodiment, in the step (2), atomized water is sprayed into the space where the brown rice is located to perform constant humidity treatment, so that the humidity of the space where the brown rice is located is maintained at 65%-100%. The humidity here is kept at 85%, of course, the humidity can be kept at 65%, 70%, 75%, 80%, 85%, 88%, 92%, 95%, 98%, 100%, etc., which will not be detailed here stated. When the germinated germ rice is prepared by the preparation method described in this example, the germination rate reaches 99%, which is 4-5 percentage points higher than the 94%-95% of the prior art, thereby producing a more substantial progress.

Embodiment 3

[0046]Embodiment 3. In this embodiment, except that the drying process is decomposed into the first-stage hot-air drying and the second-stage microwave drying, other steps and methods are the same as those described in Example 2. In this embodiment, the drying treatment involved in step (5) of the present invention is decomposed into two-stage drying treatment of hot air drying and microwave drying. First, the germinated brown rice is subjected to the first-stage hot air drying treatment, so that It removes surface moisture, and then performs microwave drying treatment on it, so that the germinated brown rice retains 13%-18% of moisture, and 16% of moisture is retained here. The above-mentioned hot air drying temperature is generally 40°C-80°C, and the hot air temperature of the hot air drying here is 60°C, of course, it can also be 40°C, 50°C, 70°C, 80°C, etc., which will not be described in detail here. When the hot air temperature is 60°C, the hot air drying time is gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com