Degassing method of electric vacuum display device of plate glass

A technology for display devices and flat glass, which can be used in glass forming, glass reshaping, glass manufacturing equipment, etc., and can solve problems such as the inability to put air getters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

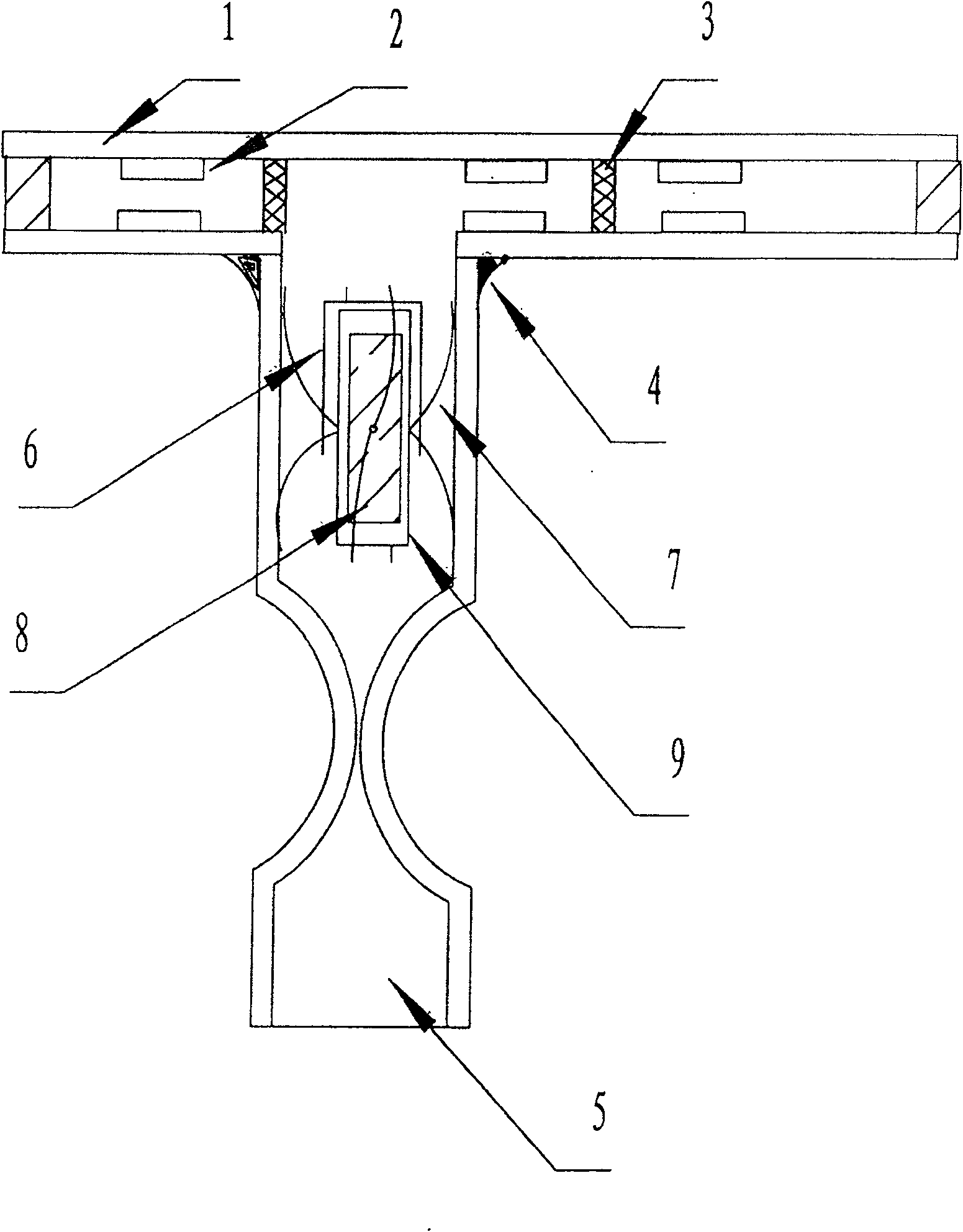

[0014] Press as figure 1 As shown, the air-absorbing device is assembled with the components of the air-absorbing glass tube 5, the anti-diffusion shell 6, the supporting tungsten wire 7, the evaporative air getter 8, and the short-circuit ring 9. The degassing device is sealed with a low-melting glass 4 and sintered and sealed at the sealing place of the glass 1 of the ultra-thin vacuum field emission display device. Assembled and sintered structures such as figure 1 , which is also a schematic diagram of an ultra-thin vacuum field emission display device with a getter.

[0015] After these components are sintered into a box, it can be connected to a vacuum system to draw a vacuum. After the degree of vacuum reaches the requirement, leave the proper length of the exhaust glass tube 5 and seal it with flame. Then put the processed ultra-thin tail tube of the vacuum field emission display device, that is, the exhaust glass tube 5, into the heating induction coil of the high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com