Vacuum tightness technique for soil and film

A vacuum and vacuuming technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of easy aging and damage, affecting the construction period, uneven particles, etc., to avoid sunlight exposure, reduce soil quality requirements, and overcome thickness. uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

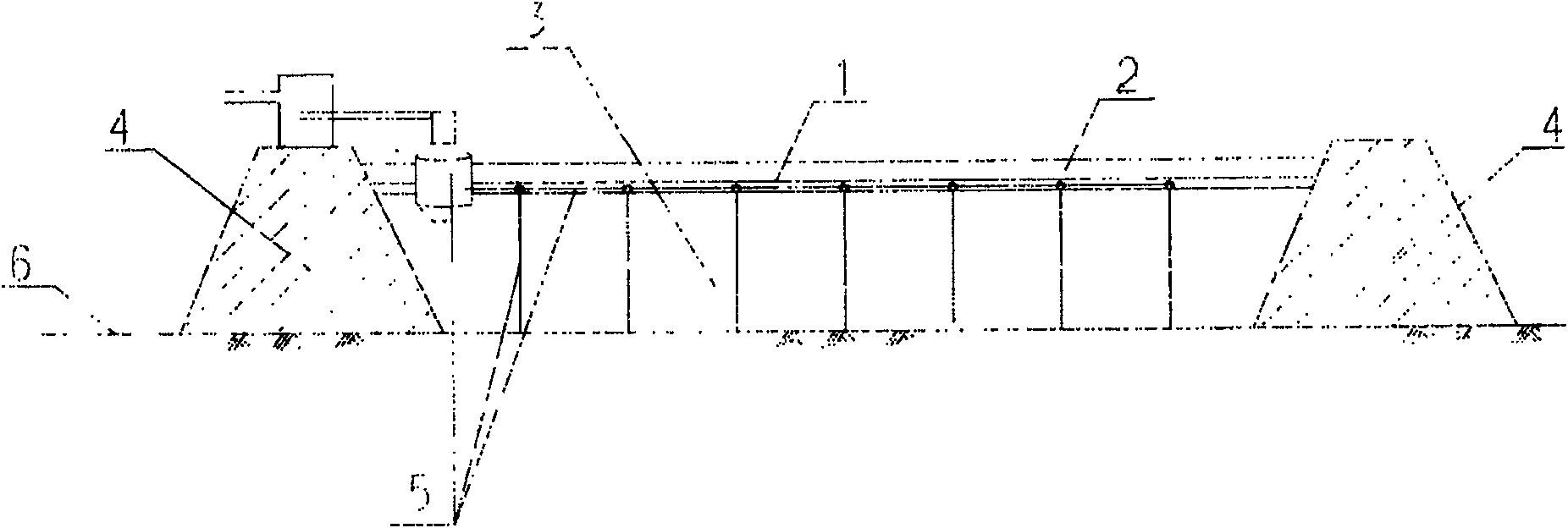

[0028] Such as figure 1 As shown, 6 is the ground, at first construct the dam 4 (when the top surface of the sealing layer is flush with the ground, the dam may not be established), the periphery is sealed and anti-seepage treated, then fill in the silt to be treated, slag 3, etc., insert Drainage boards are laid, vacuum drainage system 5 is laid, the surface is leveled and cleaned, sealing film 1 is laid, and then a thin layer of mud seal layer 2 is blown and filled for composite sealing, and finally vacuumized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com