High pressure water jet flow multiway switch control method and multiple work station automatic cleaner

A multi-channel switching and high-pressure water technology, which is applied in the field of high-pressure water jet operation and cleaning of industrial equipment, can solve problems such as restricting the normal use of equipment, system damage, and difficulties, and achieve good promotion and use value, complete functions, and reliable control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

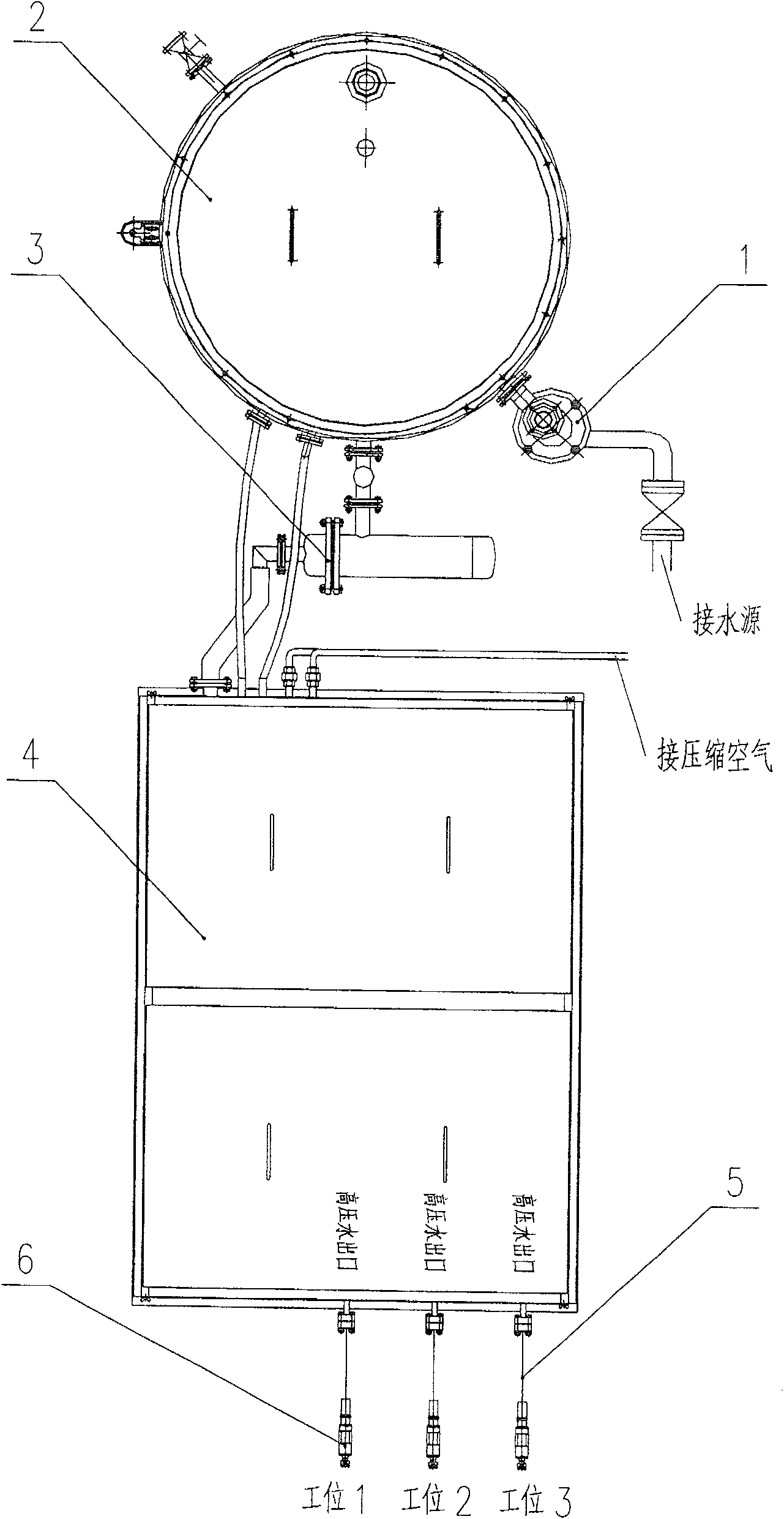

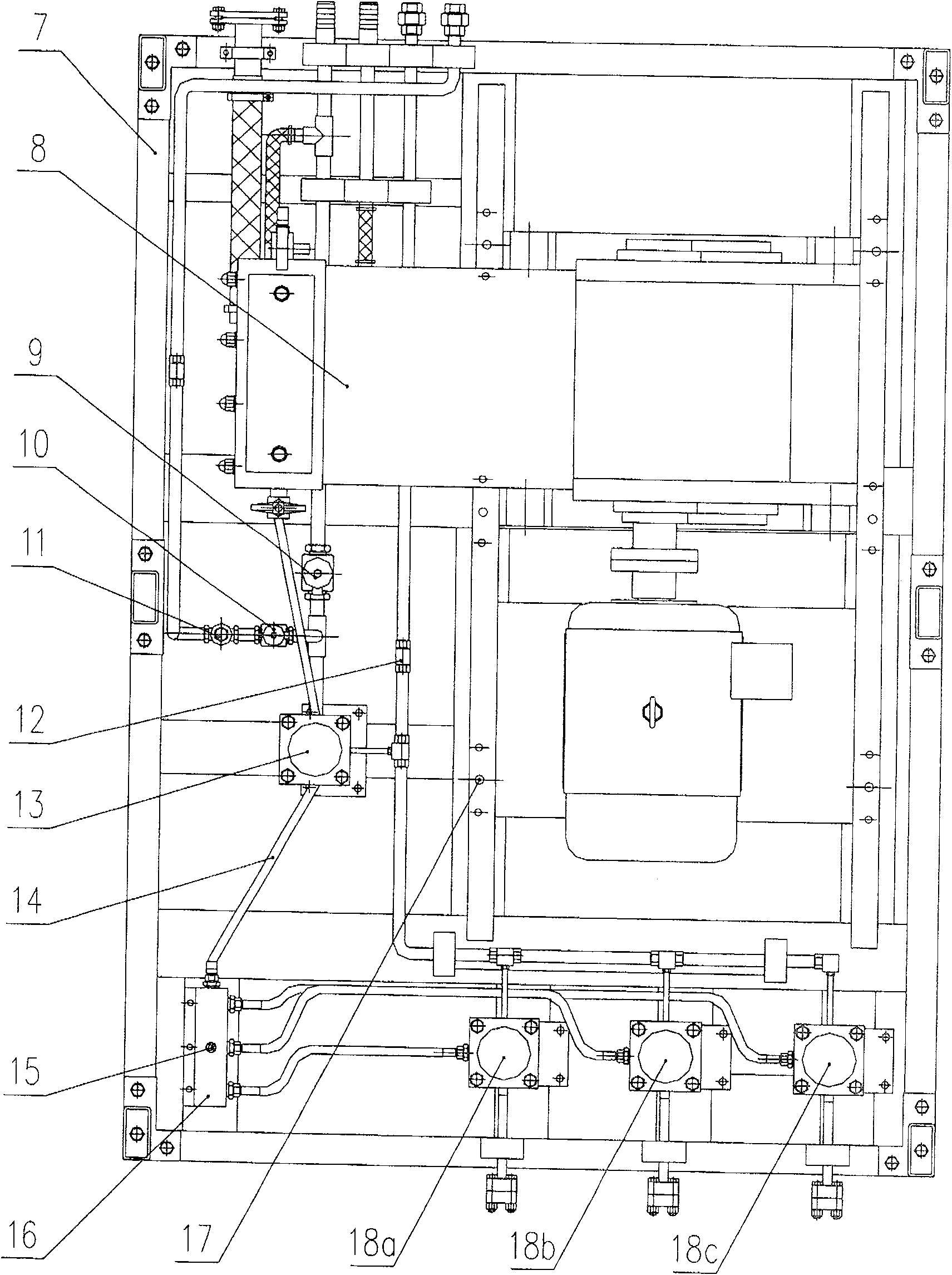

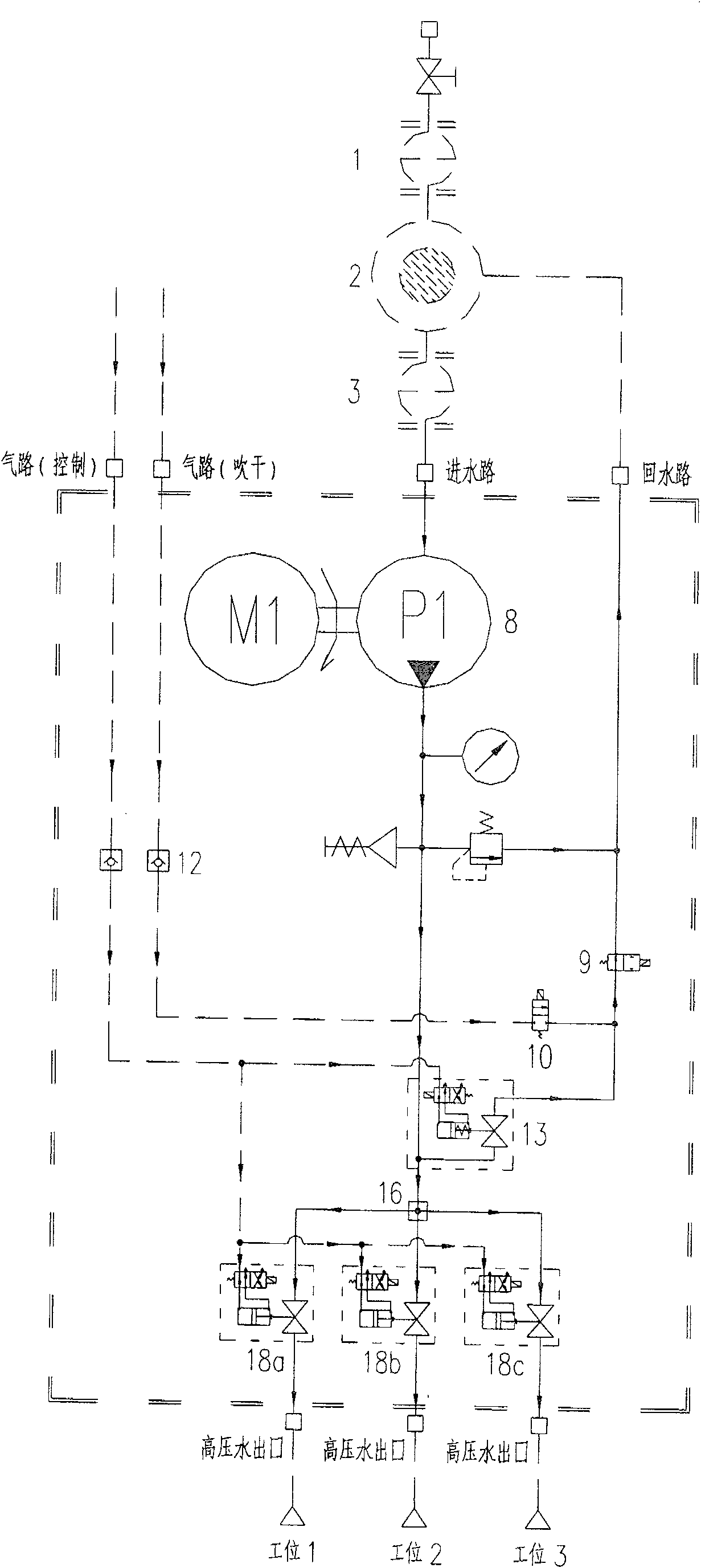

[0021] The embodiment is illustrated by taking 3 stations and 3 high-pressure water branches as an example. In actual application, the preparation of related components and various control process links can be increased or decreased according to specific conditions.

[0022] A multi-station automatic cleaning device capable of realizing automatic on-off switching between multiple high-pressure water branches, which is integrated in a box 7 and sequentially connected to a high-pressure water pump 8 and a high-pressure multi-way valve block 16 to form a high-pressure water supply system , a pressure transmitter 15, an electric control overflow valve 13, an electric control stop valve 18, and corresponding high-pressure pipelines and executive components 6. It is characterized in that an electronically controlled overflow valve 13 that can release the pressure of the working medium in the pipeline is connected in series between the output pipeline of the high-pressure water pump 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com