Cylinder structure

A cylinder and arc-shaped structure technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of difficult adjustment, difficulty in ensuring the radial coaxiality of the cylinder, and product scrapping, so as to improve the coaxiality of the radial plane and overcome Unstable factors, the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

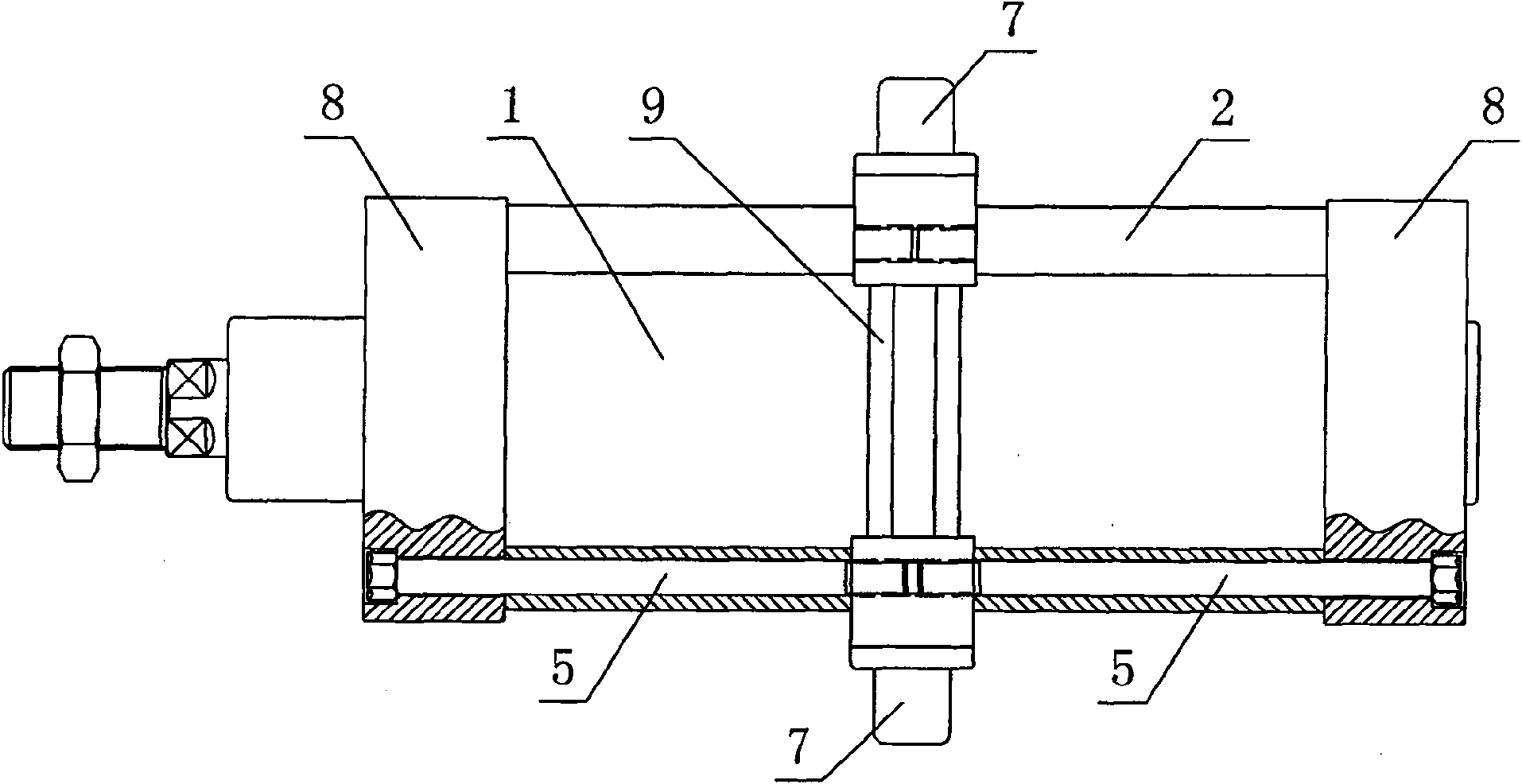

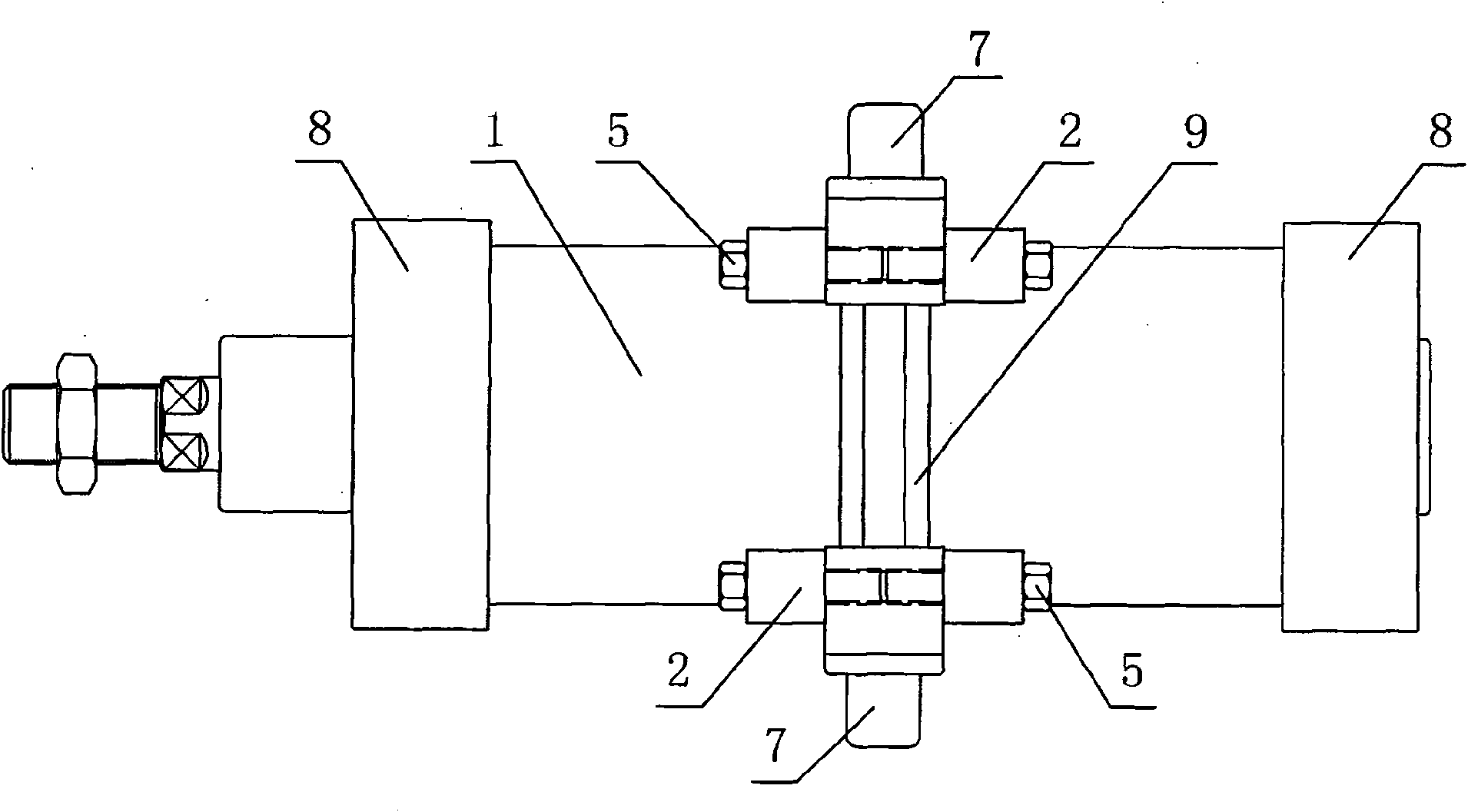

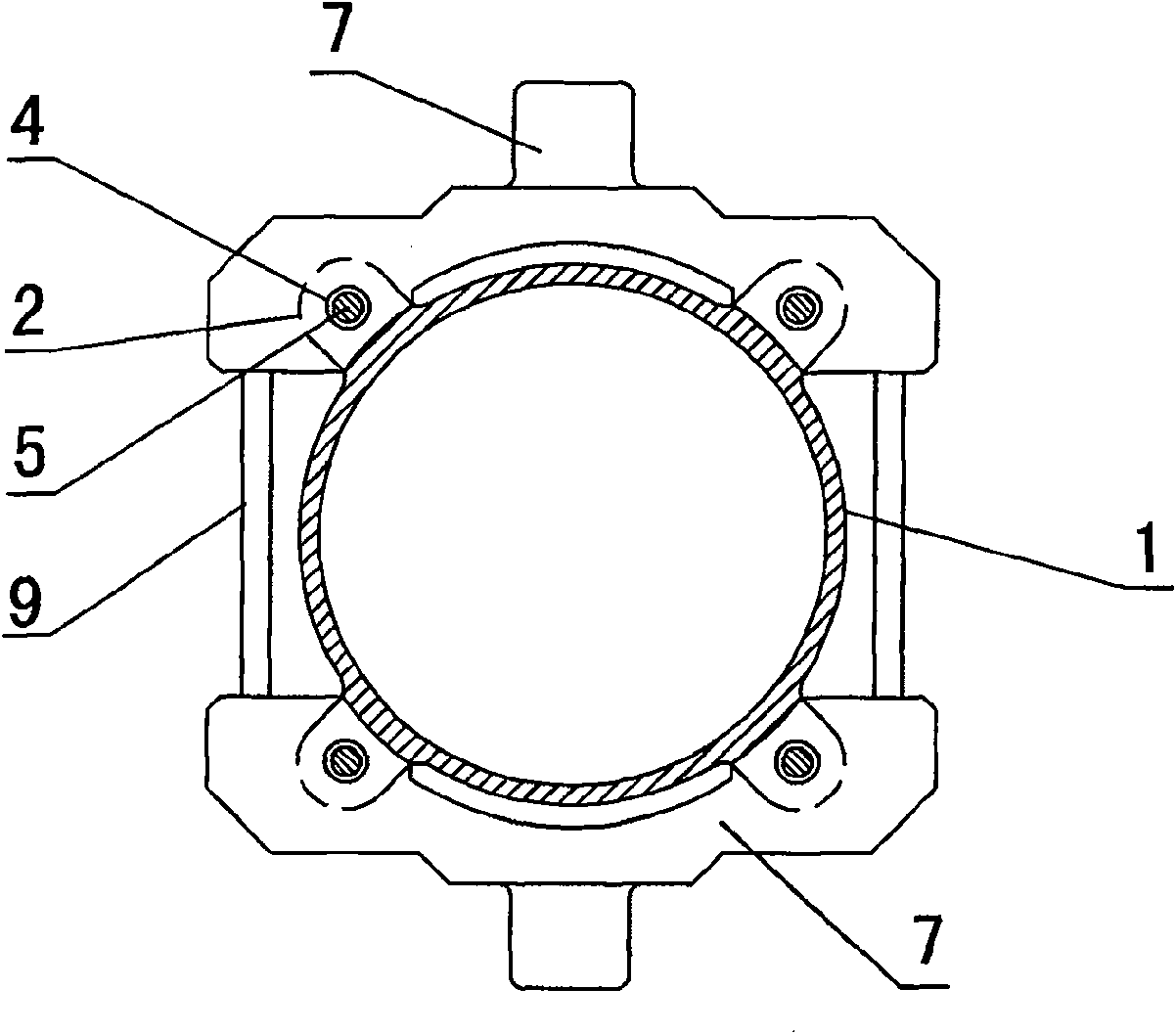

[0024] in such as figure 1 image 3 In the shown embodiment 1, lugs 2 are provided on the outer wall of the cylinder block 1 along the axial direction of the cylinder block 1, and there are four lugs 2, which are symmetrically distributed around the cylinder block 1. The lugs 2 and the cylinder block 1, etc. Long, the lug 2 is provided with a mounting hole 4, and the middle of the lug 2 is provided with a gap 3 (see Figure 4 ), the two sides of the notch 3 are perpendicular to the axis of the cylinder body 1, the width of the notch 3 is consistent with the thickness of the trunnion bracket 7, the trunnion bracket 7 is installed in the notch 3, and matches the mounting hole 4 in the lug 2 The fixed screw rod 5 passes through the front and rear end covers 8 of the cylinder, the lugs 2 and the trunnion bracket 7 (see Figure 7 ) connected. The trunnion brackets 7 are symmetrically arranged on both sides of the cylinder body 1, and are arched structures. The trunnion 71 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com