Trunnion support of cylinder

A technology of trunnions and cylinders, which is applied in the direction of fluid pressure actuators, etc., can solve the problems of difficult adjustment, difficulty in ensuring radial coaxiality of cylinders, product scrapping, etc. Stability factor, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

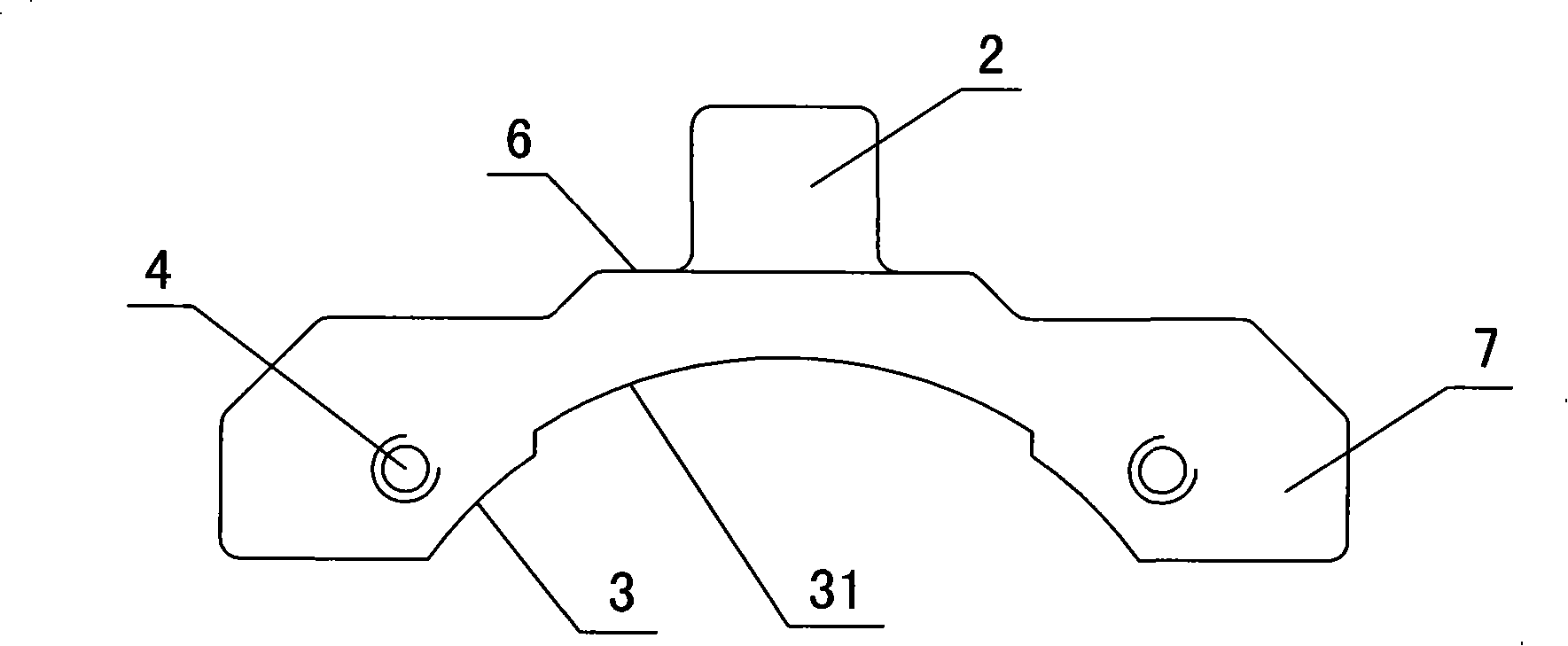

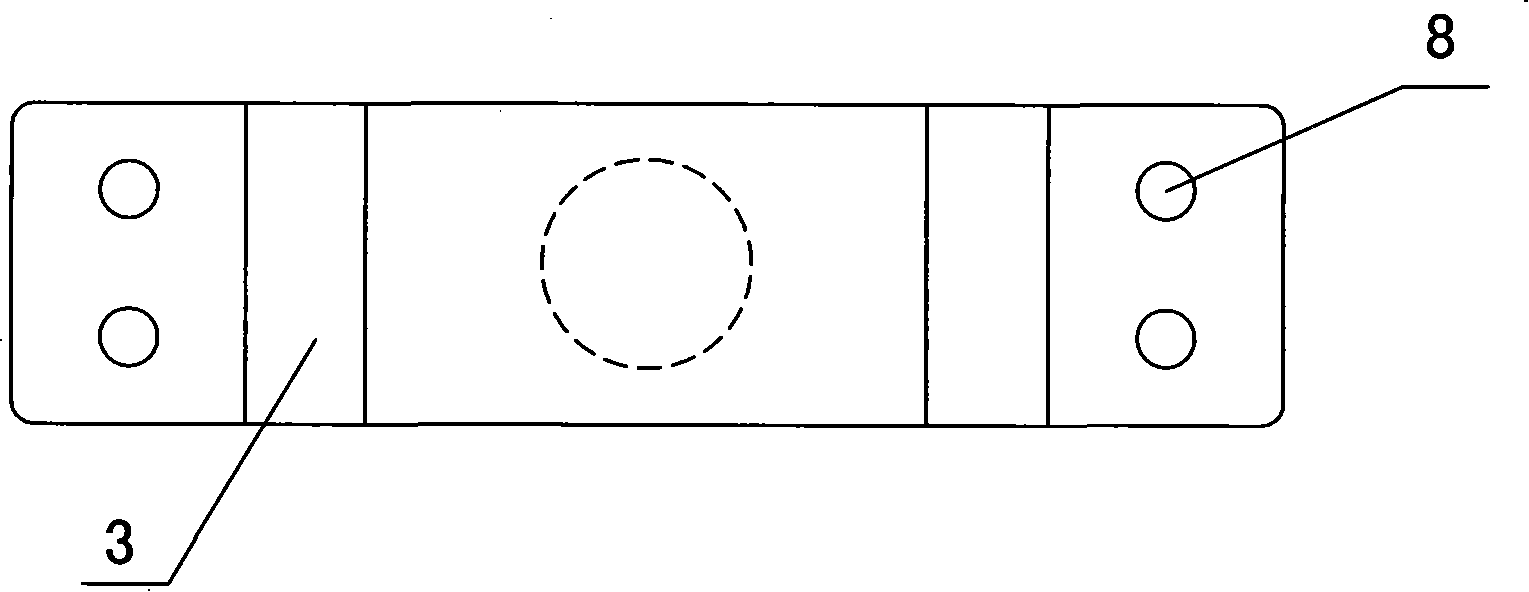

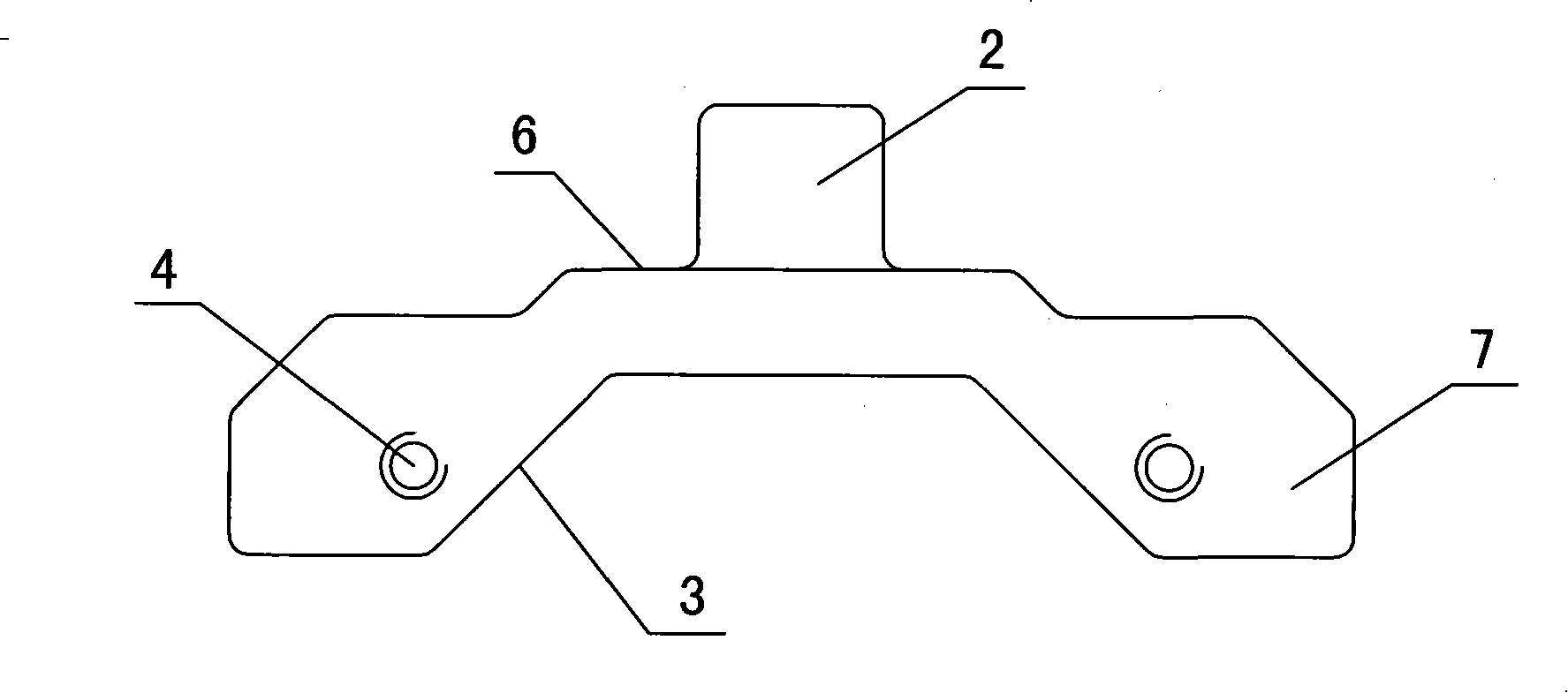

[0021] in such as Figure 4 Figure 6 In the shown embodiment 1, there are two trunnion supports, which are arranged symmetrically on both sides of the cylinder body 1. The shape is an arch structure. It is an arc-shaped structure, and the central angle corresponding to the arc surface of the cylinder contained in the arc-shaped structure is 110 degrees. There is an arc-shaped gap 31 in the middle of the arc-shaped structure, and a platform 6 is arranged between the trunnions 2 and the arc-shaped gap 31. (See figure 1 ). Both sides of the arch surface 3 are provided with fixing holes 4, the fixing holes 4 are screw holes, the outside of the fixing holes 4 is an arch extension structure 7, and the bottom surface of the extension structure 7 is provided with a pillar hole 8, two on each side, and the pillar hole 8 is the pin hole (see figure 2 ). Prop 9 is housed on the prop hole 8, respectively two on both sides. Cylinder body 1 is provided with lug 12, and lug 12 is fou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com