Operating lever device

A technology for operating levers and buffer devices, applied in mechanical control devices, fluid pressure actuation devices, devices for preventing/limiting/restoring the movement of parts of a control mechanism, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

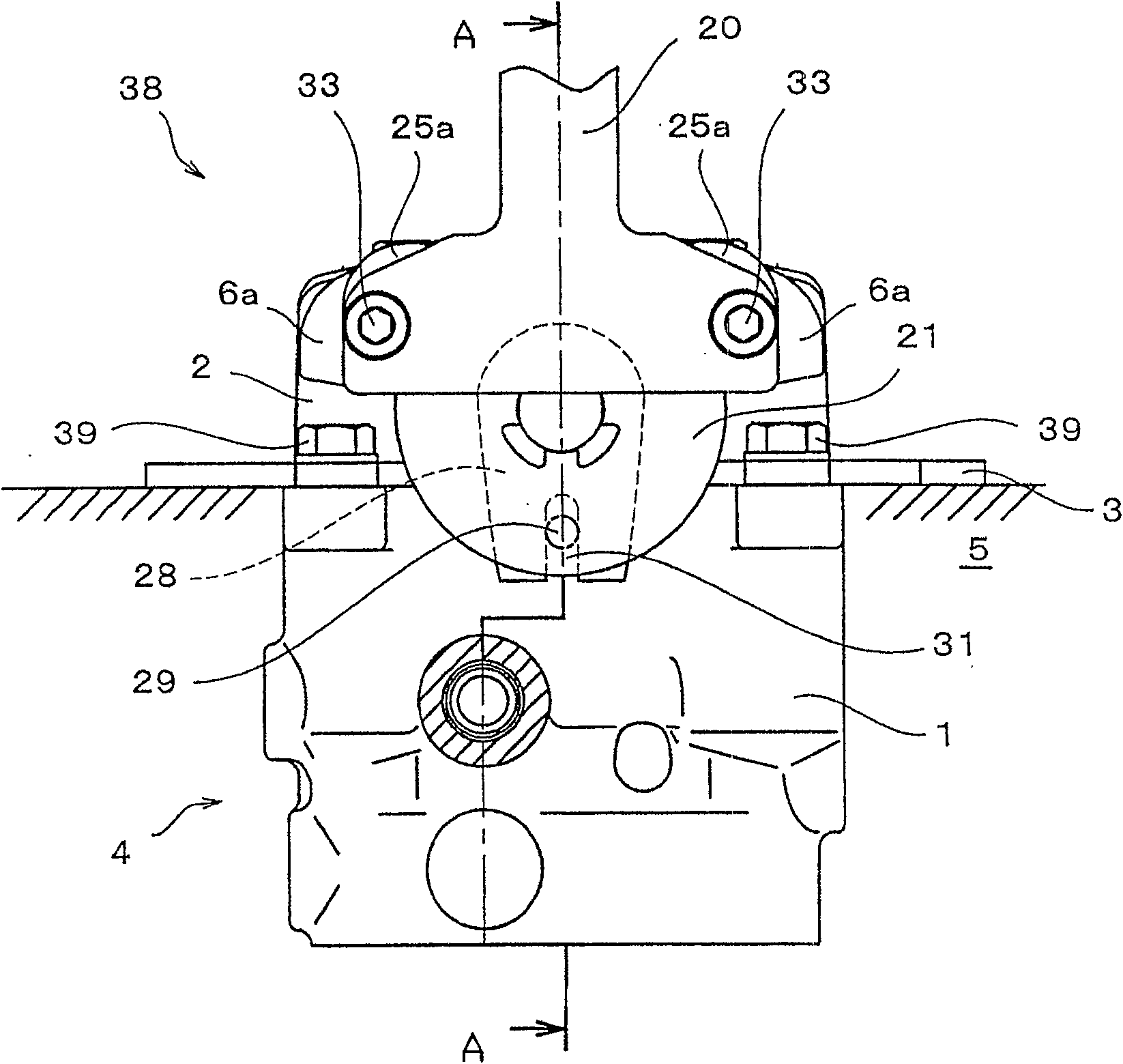

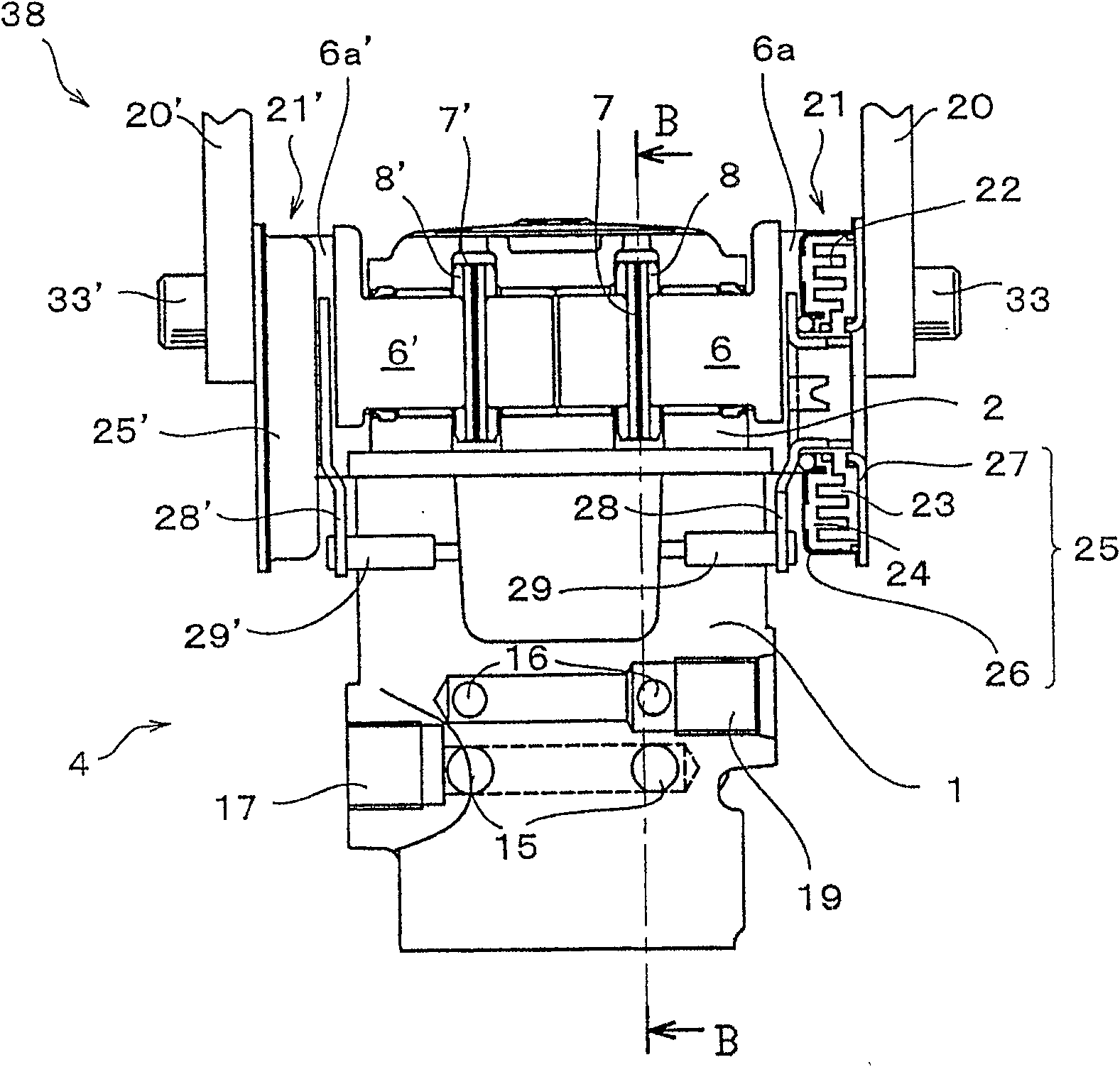

[0086] Such as figure 1 As shown, an operating lever device 38 is provided on the floor 5 of a cab or the like of a construction machine. The operating lever device 38 is fixed to the floor 5 with bolts 39 via the plate 3 . Such as figure 2 , Figure 4 As shown, the operating rod device 38 has: operating rods 20, 20' constituted by a pair of left and right groups; rotary damper devices 21, 21'; shafts 6, 6'; formed on the shafts 6, 6' The flange portions 6a, 6'a of the shaft and the shaft support body 2 which rotatably supports the shafts 6, 6', and the like. The shaft support body 2 is mounted on the main body 1 in which the valve body 4 is accommodated by fixing bolts 36 .

[0087] The operating levers 20, 20', the rotary damper devices 21, 21', the shafts 6, 6', and the flange portions 6a, 6'a are constituted by a pair of right and left pairs. The members of each group perform the same operation by tilting operation of the operating lever 20 or the operating lever 20...

Embodiment 2

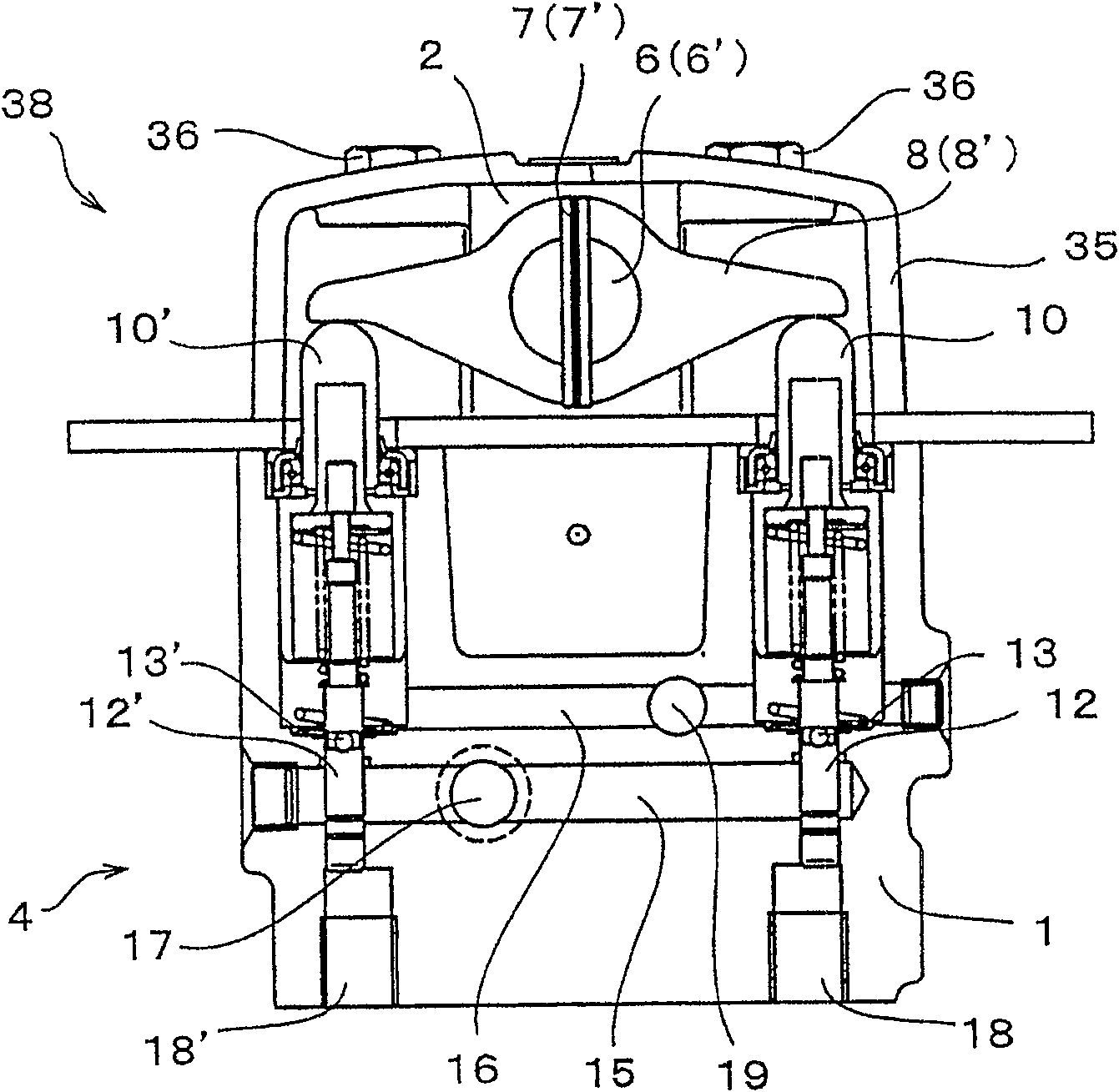

[0129] Figure 7 It is another embodiment 2 which shows the invention of this application. In the second embodiment, the configuration is the same as that of the first embodiment except that the fixing pin 29 is disposed above the shaft 6 . In addition, the operation as the operation lever device in the second embodiment can also play the same function as that of the operation lever device in the first embodiment. Therefore, in the description of the second embodiment, the same member symbols as those used in the first embodiment are used for the same structure as the first embodiment, and the description of the members is omitted. The following description focuses on the configuration different from that of the first embodiment.

[0130] Such as Figure 7 As shown, the fixing pins 29, 29' are disposed above the shafts 6, 6'. As the fixing pins 29, 29' are arranged above the shafts 6, 6', the long grooves of the damper rods 28, 28' are also arranged upward.

[0131] Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com