Nondeforming band tape hub

A wheel hub and tape measure technology, applied to bendable rulers and other directions, can solve problems affecting normal use, radial deformation and distortion, and coil spring rewinding with large pre-tightening force, so as to prolong service life, prevent radial distortion and deformation, Increased blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

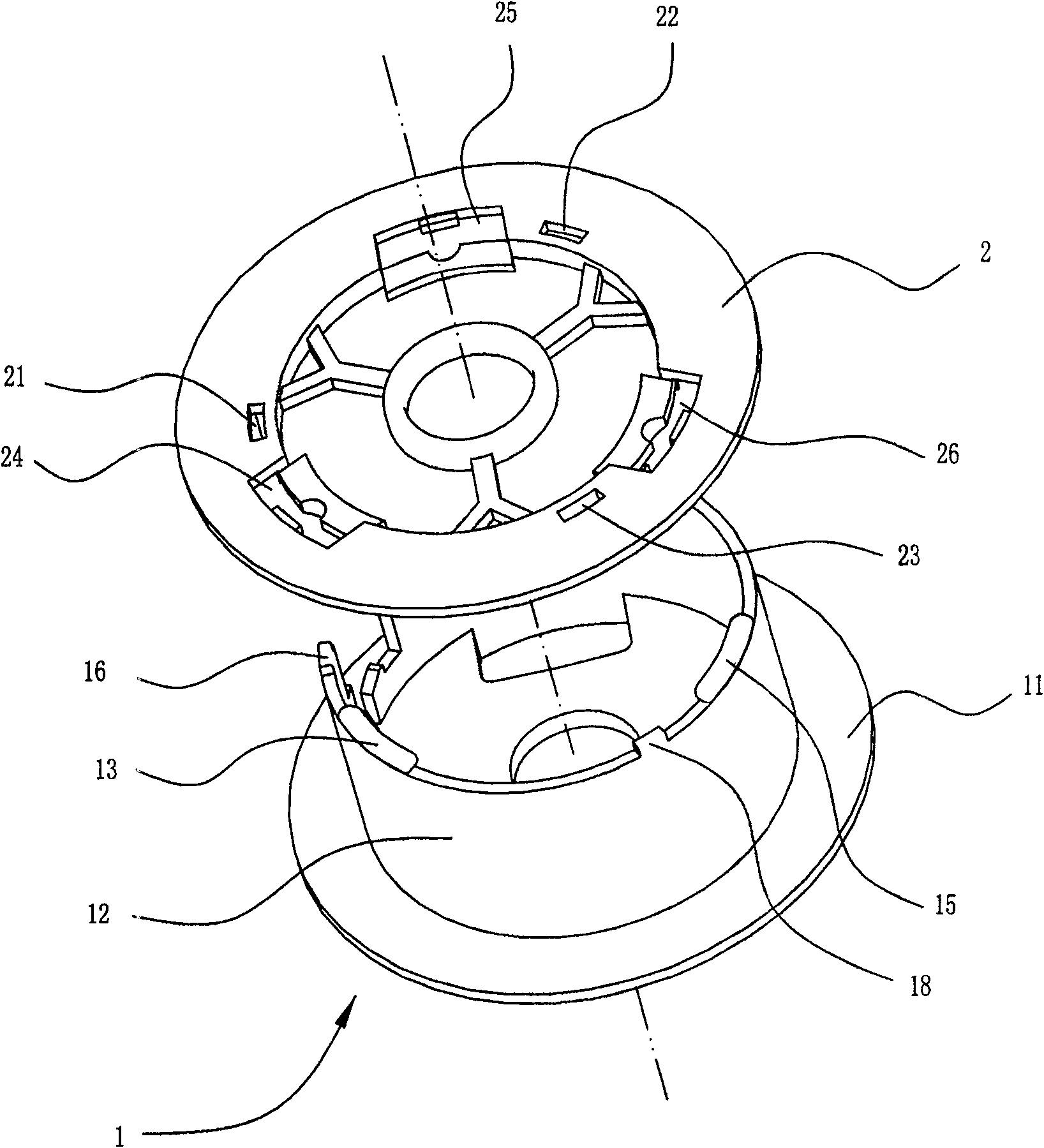

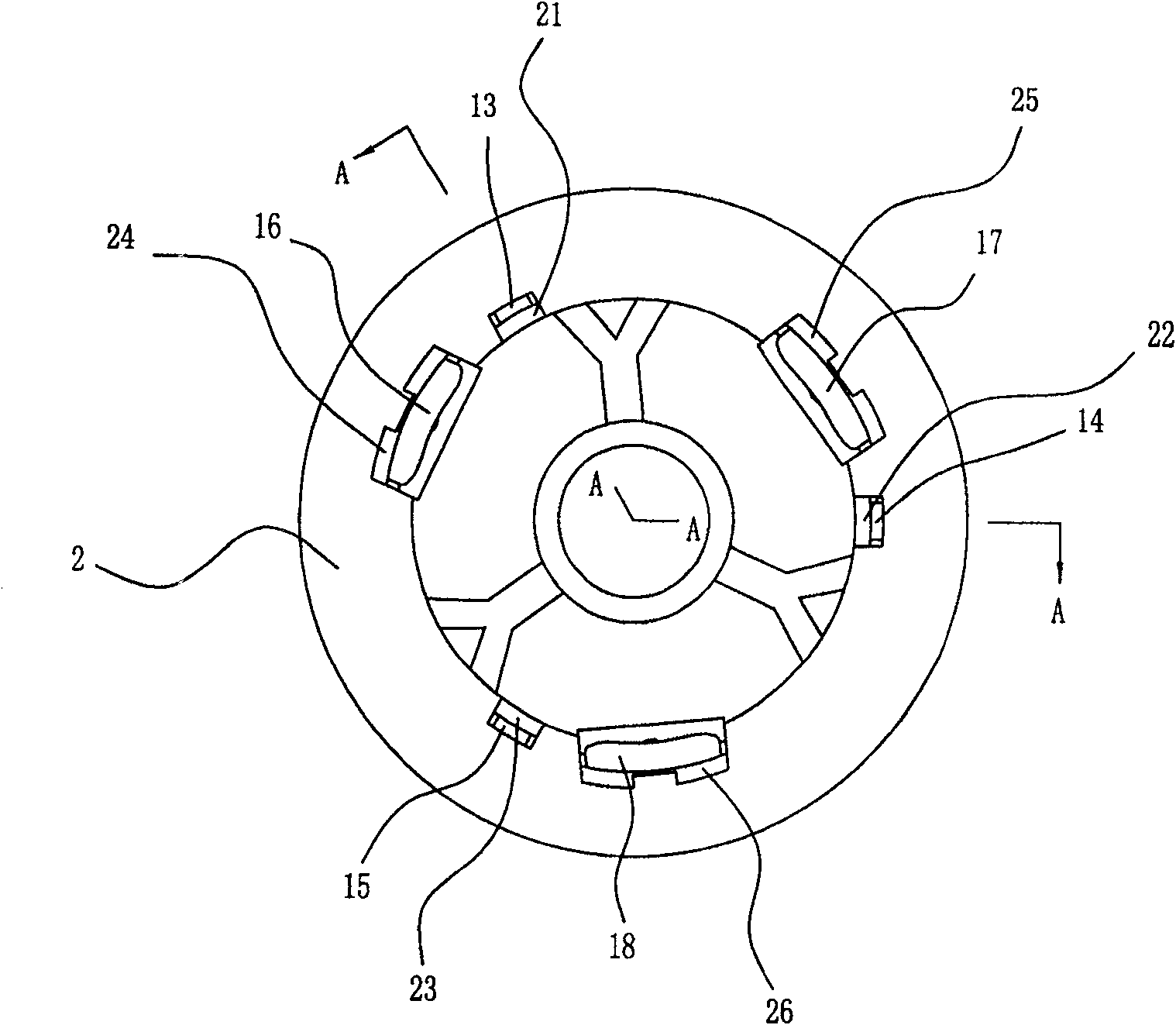

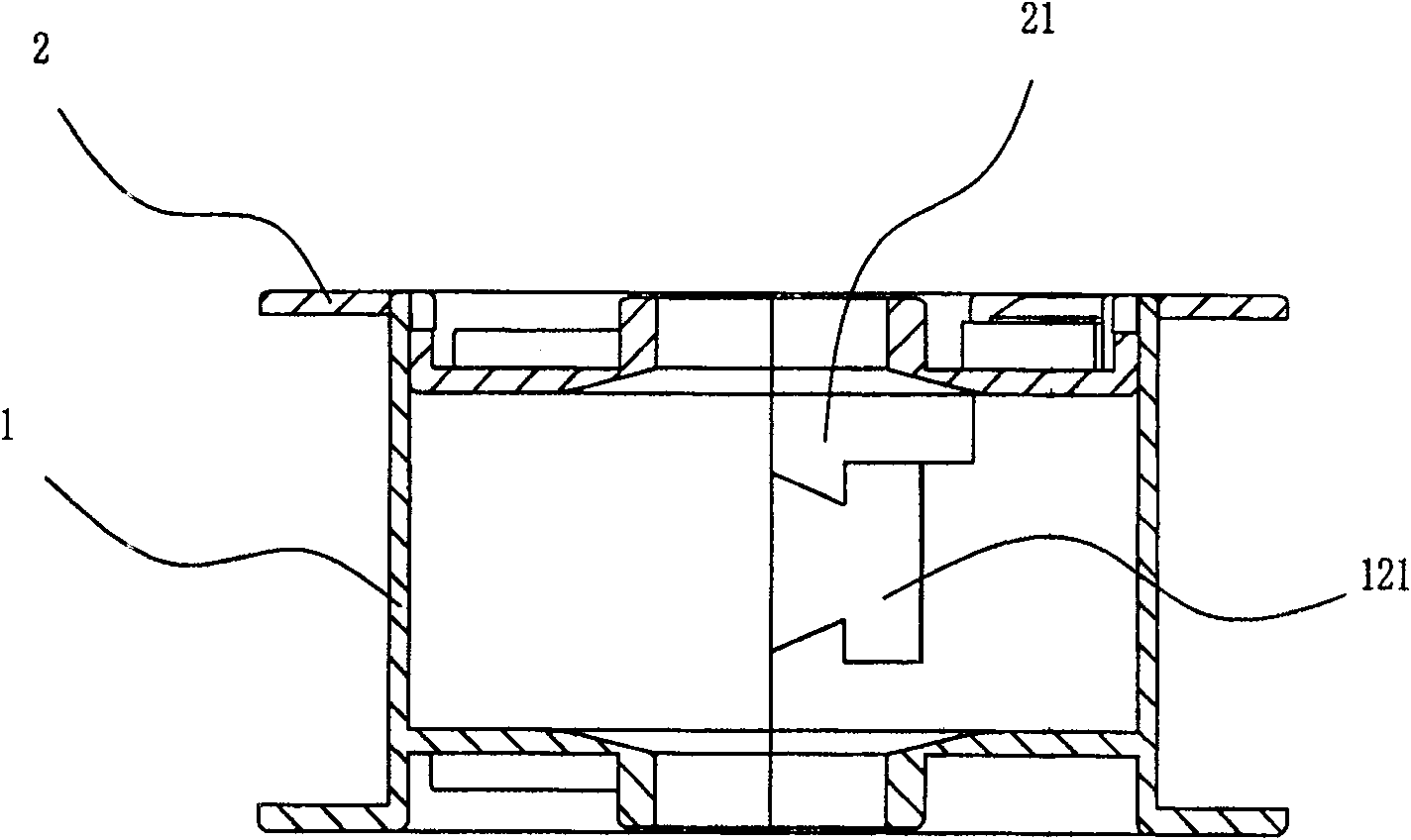

[0016] Such as Figure 1 to Figure 4 As shown, a non-deformable tape measure hub includes a hub seat 1 with a central shaft hole and a hub cover 2 correspondingly provided with a central hole, wherein the hub seat 1 includes a disc 11 and is integrally connected with it, and The cylindrical piece 12 perpendicular to it, the hub cover 2 is buckled on the end of the cylindrical piece 12 in the following way: the cylindrical piece 12 of the hub seat 1 is provided with three axially outward protrusions at its end, and along the The baffles 13, 14, 15 uniformly distributed in the circumferential direction of the cylindrical piece 12 also have radially inwardly convex parts at the ends of the baffles, and the hub cover 2 is provided with limiting holes 21, 22, 23 at corresponding positions. The baffles 13 , 14 , 15 pass through the corresponding li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com