Laser-weldable polymers

A technology of laser welding and polymer, which is applied in the direction of laser welding equipment, welding equipment, manufacturing tools, etc., and can solve the problems of inability to obtain welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Laser transparency part: natural PP

[0032] Laser absorbing part: PP with 1% copper hydroxide phosphate

[0033] A welding speed of 60 mm / s is achieved here. This corresponds to an energy per unit length of 25 J / cm.

Embodiment 2

[0035] Laser transparency fraction: Contains 0.1% 820PP

[0036] Laser absorbing part: PP with 1% copper hydroxide phosphate

[0037] A welding speed of 120 mm / s is achieved here. This corresponds to an energy per unit length of 12.5 J / cm.

Embodiment 3

[0039] For light-colored plastic formulations with TiO 2 formulations

[0040] Laser transparency fraction: Contains 0.1% 820PP

[0041] Laser absorbing part: Contains 0.5% copper hydroxide phosphate and 0.5% TiO 2 PP

[0042] A welding speed of 150 mm / s is achieved here. This corresponds to an energy per unit length of 10 J / cm.

[0043] In strength tests, all specimens tear in the base material but not in the weld. The examples listed illustrate that using a stronger absorber on the absorptive side and optionally a weaker absorber on the laser transparent side accelerates the welding speed by >3 times and the energy per unit length is thus only that of the starting material 1 / 3.

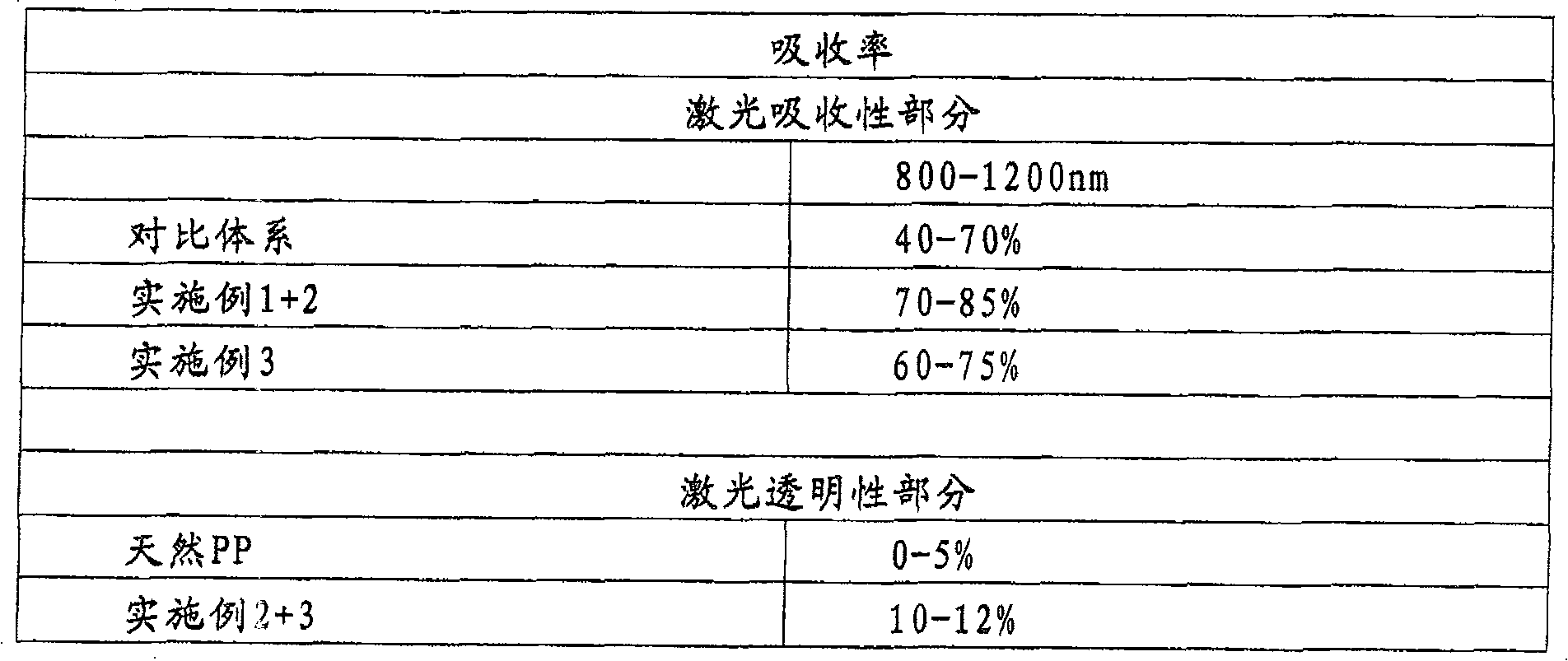

[0044] The values of total transmittance, diffuse transmittance and total reflectance of the plastic flakes used were measured using a Perkin-Elmer instrument (Lamda900) with an Ulbricht sphere. The absorbance in Table 1 is calculated from the total transmittance and total reflectance (10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com