Rotary spraying nozzle

A technology of rotating nozzles and rotating water outlets, which is applied to spraying devices and spraying devices with movable outlets, etc. It can solve the problems of unsatisfactory water intake adjustability, unsuitable spraying radius, and inability to achieve omni-directional spraying or rotary spraying. To achieve the effect of free change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

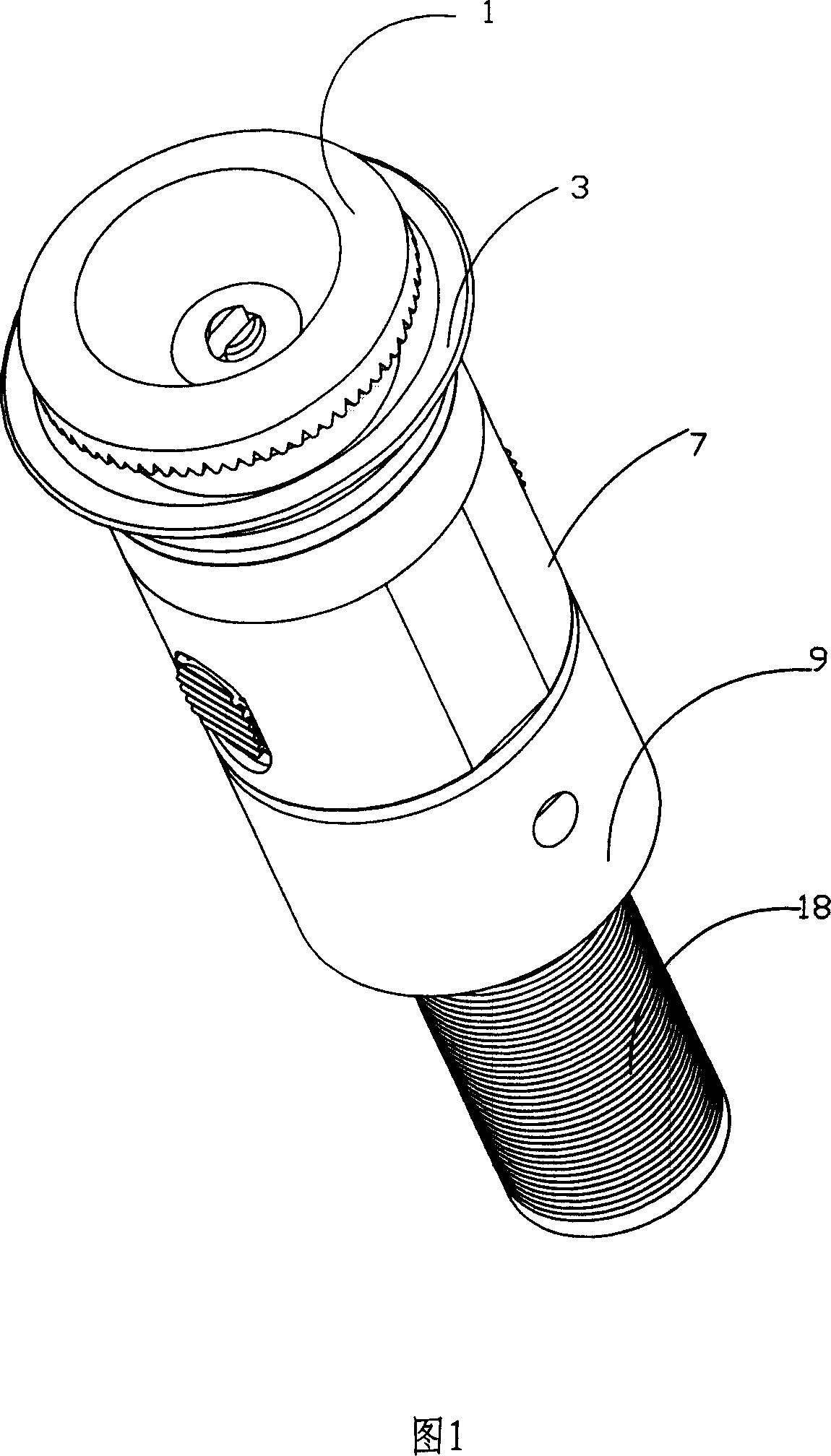

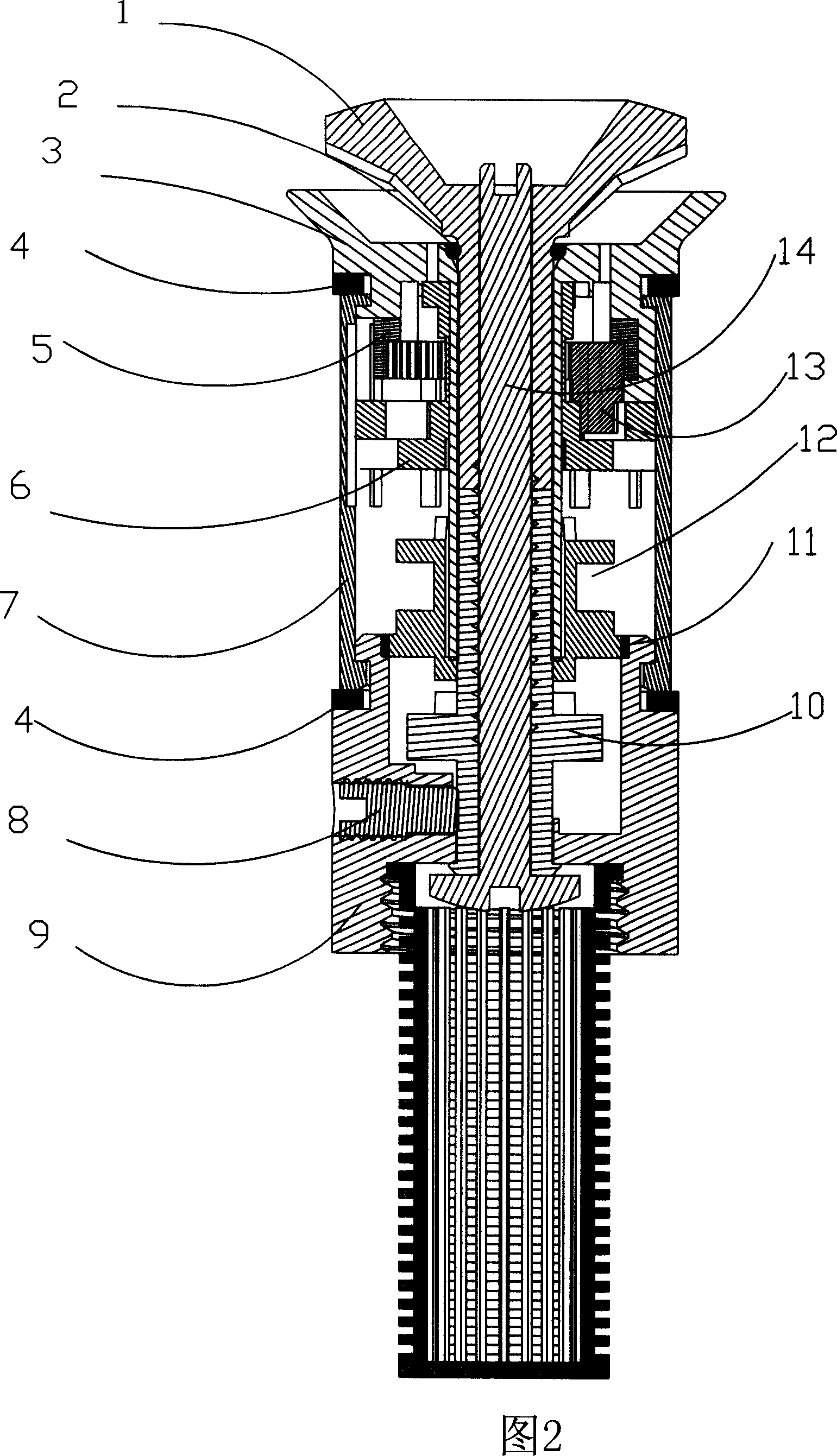

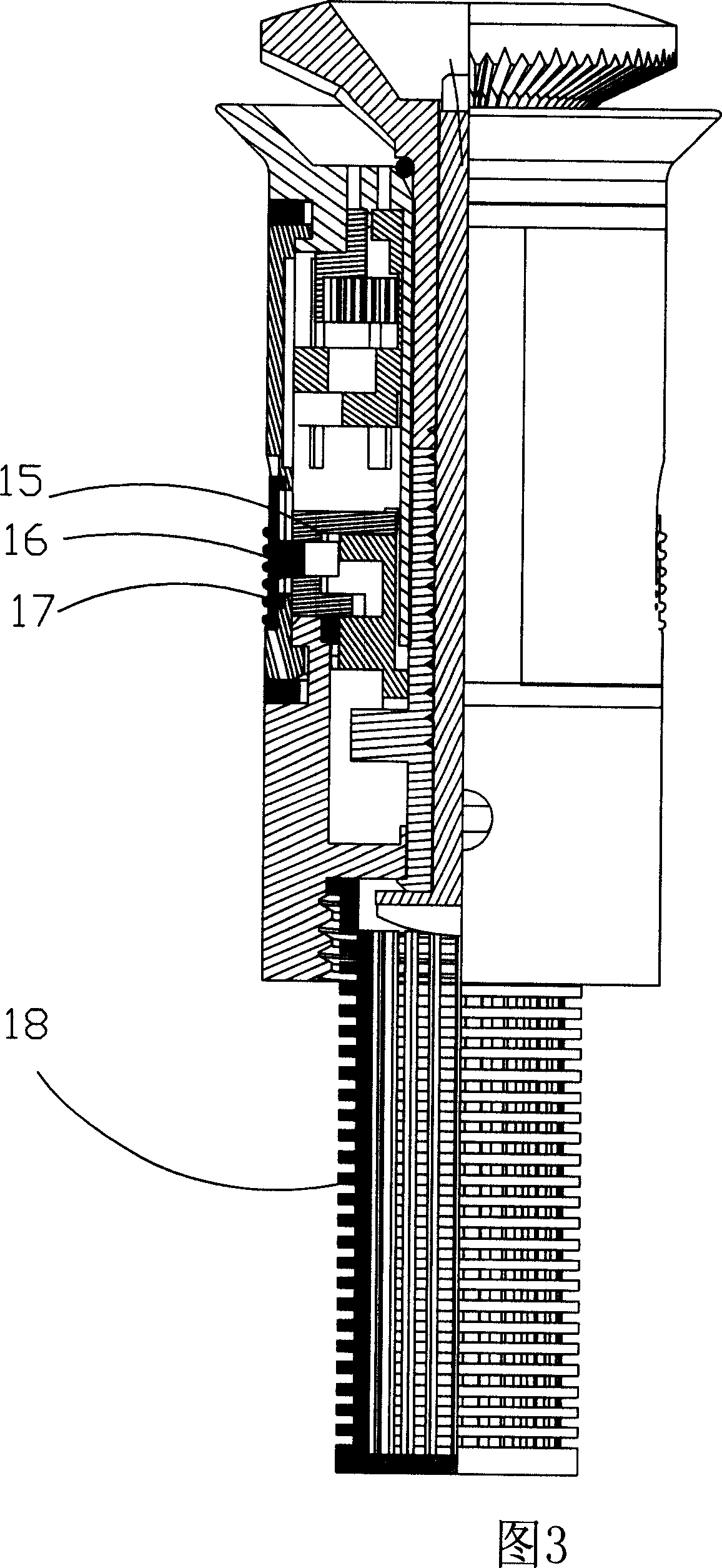

[0028] As shown in Figure 1, Figure 2, and Figure 3, the rotary nozzle includes angle head 1, sealing ring 2, angle seat 3, sealing washer 4, left regulator 5, right regulator 6, adjusting ring 7, speed regulating screw 8 , water seat 9, drive impeller 10, gear ring 11, motion seat 12, transmission gear 13, flow regulating screw 14, switch button 16, motion lock 15, washer 17, filter screen 18.

[0029] The angle head 1 is provided with a water outlet groove 11, the water outlet groove 11 can be a tapered groove, can be of various angles, and can be evenly distributed along the circumference, and is used to cover the spraying area in an all-round way; The extension pipe 37 of the seat 3 is connected with the cylinder 104 on the driving impeller 10, see Fig. 2 and Fig. 3 .

[0030] There is a circular groove 31 on the angle seat 1, which is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com