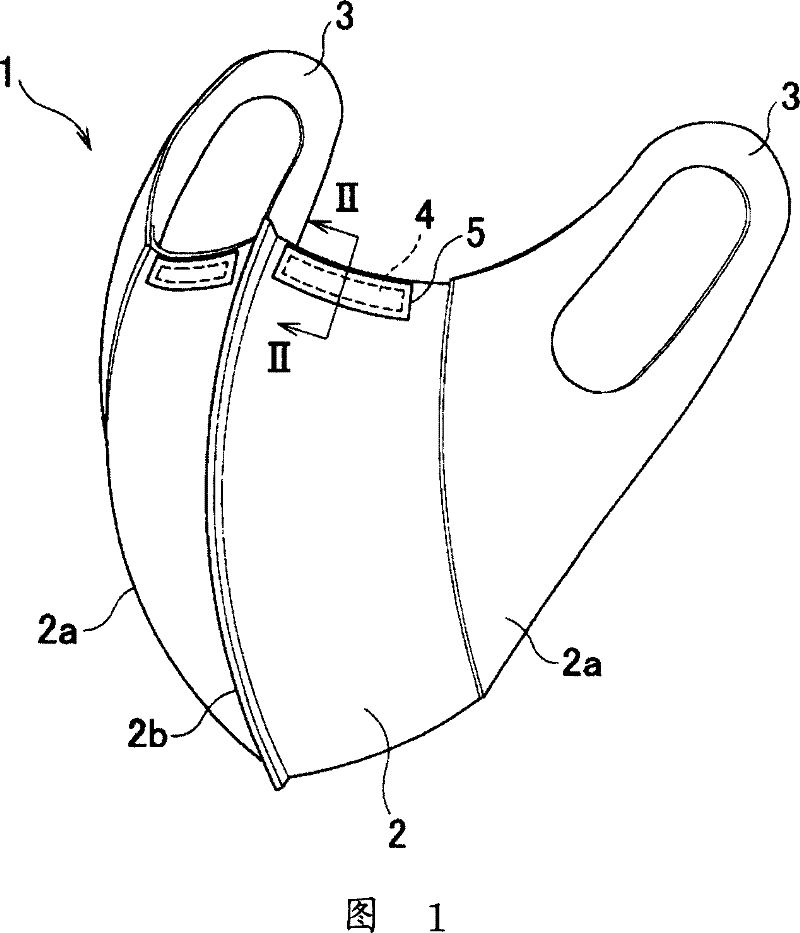

Respirator

A technology of masks and covering parts, which is applied to the field of masks with gaps on both sides, which can solve the problems of not being able to return to the shape, and achieve the effect of improving the wearing feeling and shape retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

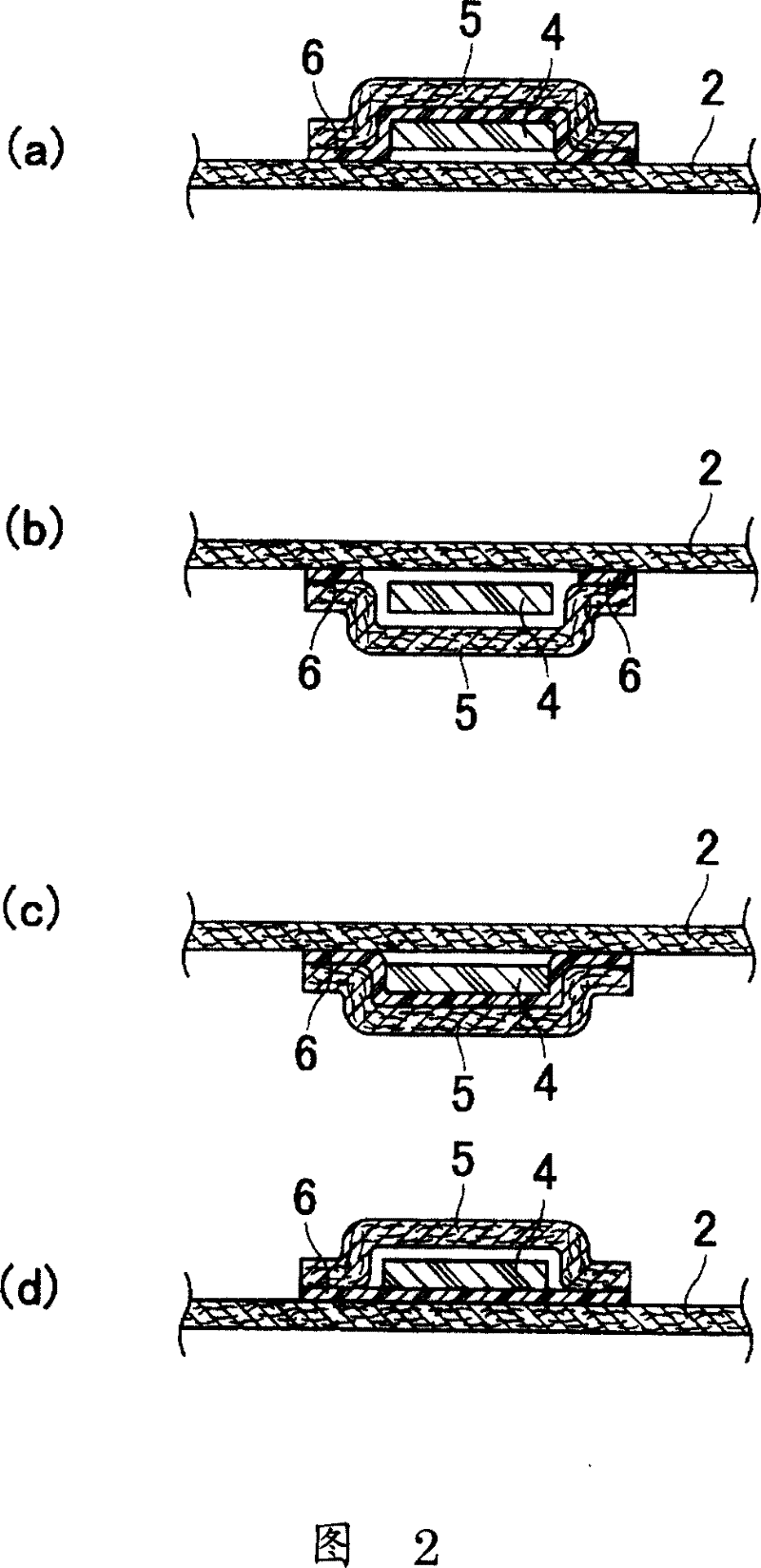

[0033] Such as figure 2 As shown in (a), in this embodiment, the belt-shaped member 4 is attached to the outer side of the covering part 2 . More specifically, after the belt-shaped member 4 is fixed to the covering material 5 with the hot-melt adhesive 6 , the covering material 5 is fixed to the covering part 2 with the hot-melt adhesive 6 . At this time, the belt-shaped member 4 is attached in a free state with respect to the covering part 2 . In addition, when referred to as a free state in the present application, it means that the two members are independent of each other without joining, and even if one is displaced, the other is not directly deformed by the displacement.

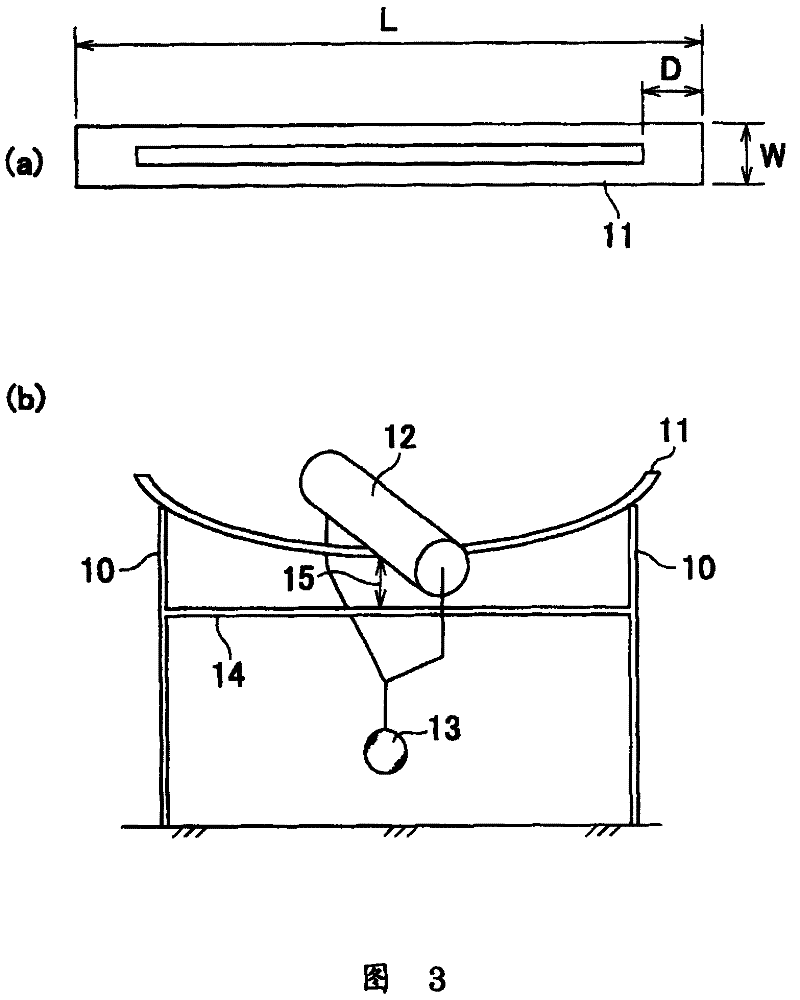

[0034] In the present embodiment, Technorot (registered trademark) H20000 manufactured by Mitsui Chemicals Corporation with a length of 150 mm and a width of 3 mm was used as the belt-shaped member 4 . And, the cover part 2 etc. are made using the following materials as image 3 (a) shows a sample...

Embodiment 2

[0040] Such as figure 2 As shown in (b), in this embodiment, such a sample is produced: the covering material 5 is fixed on the skin side of the covering part 2 by the hot-melt adhesive 6, and the belt-shaped member 4 is packed between the two to form It is in a free state with respect to the covering part 2 and the covering material 5 .

Embodiment 3

[0042] Such as figure 2 As shown in (c), in this embodiment, such a sample is produced: the covering material 5 is fixed on the skin side of the covering part 2 by the hot-melt adhesive 6, and the belt-shaped member 4 is fixed on the covering material 5 to face each other. The covering part 2 is in a free state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com