LED driving circuit with the temperature compensation

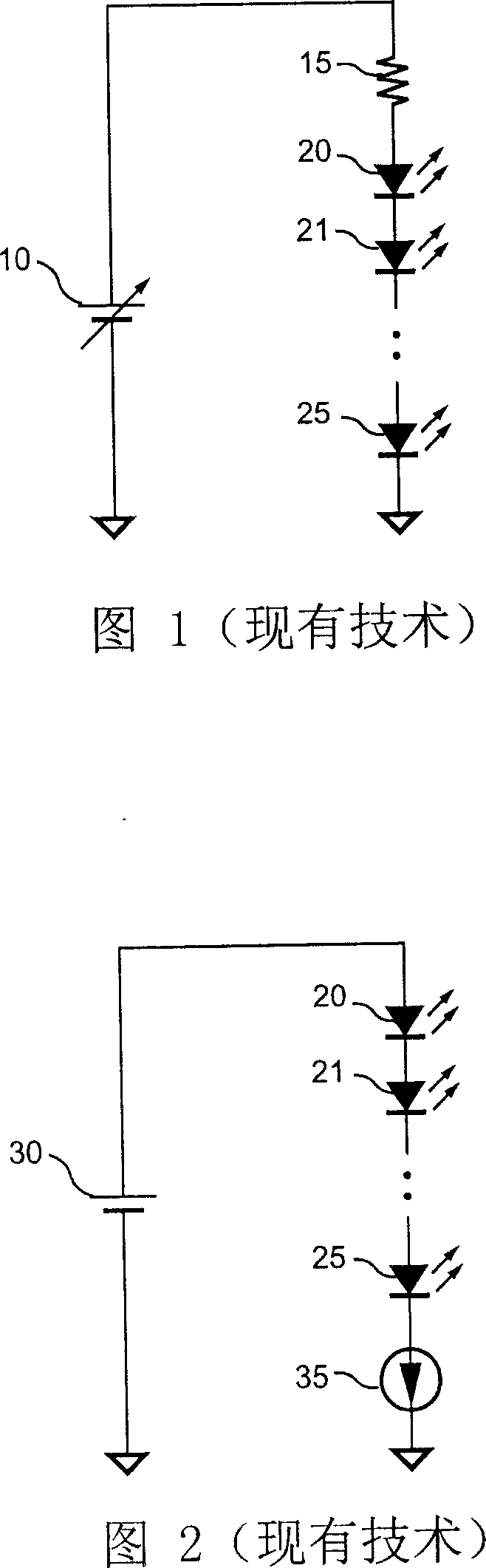

A technology for light-emitting diodes and driving circuits, which is applied in the directions of electroluminescent light sources, electric lamp circuit arrangements, light sources, etc., and can solve problems such as changes in the chromaticity and brightness of light-emitting diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

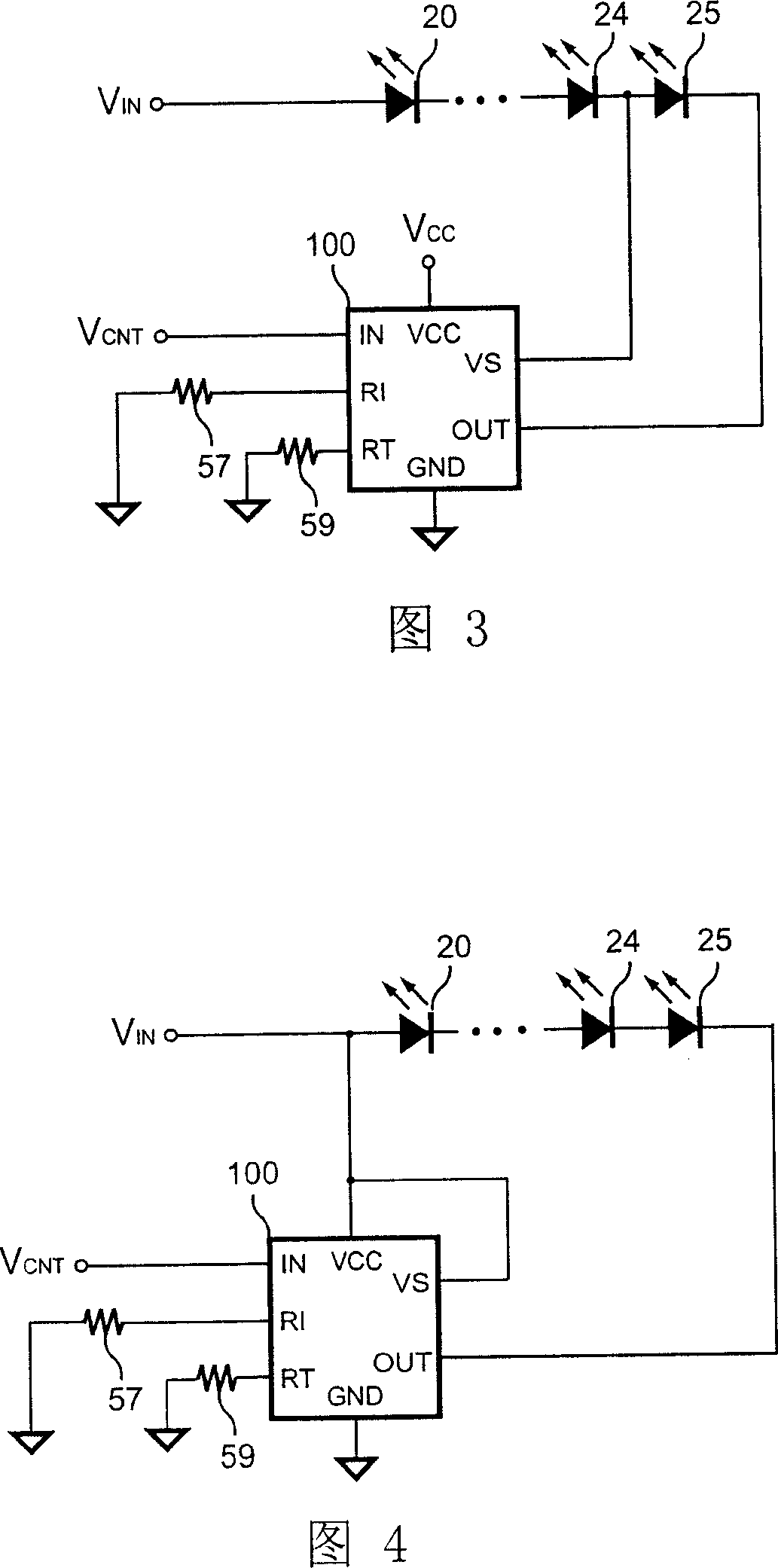

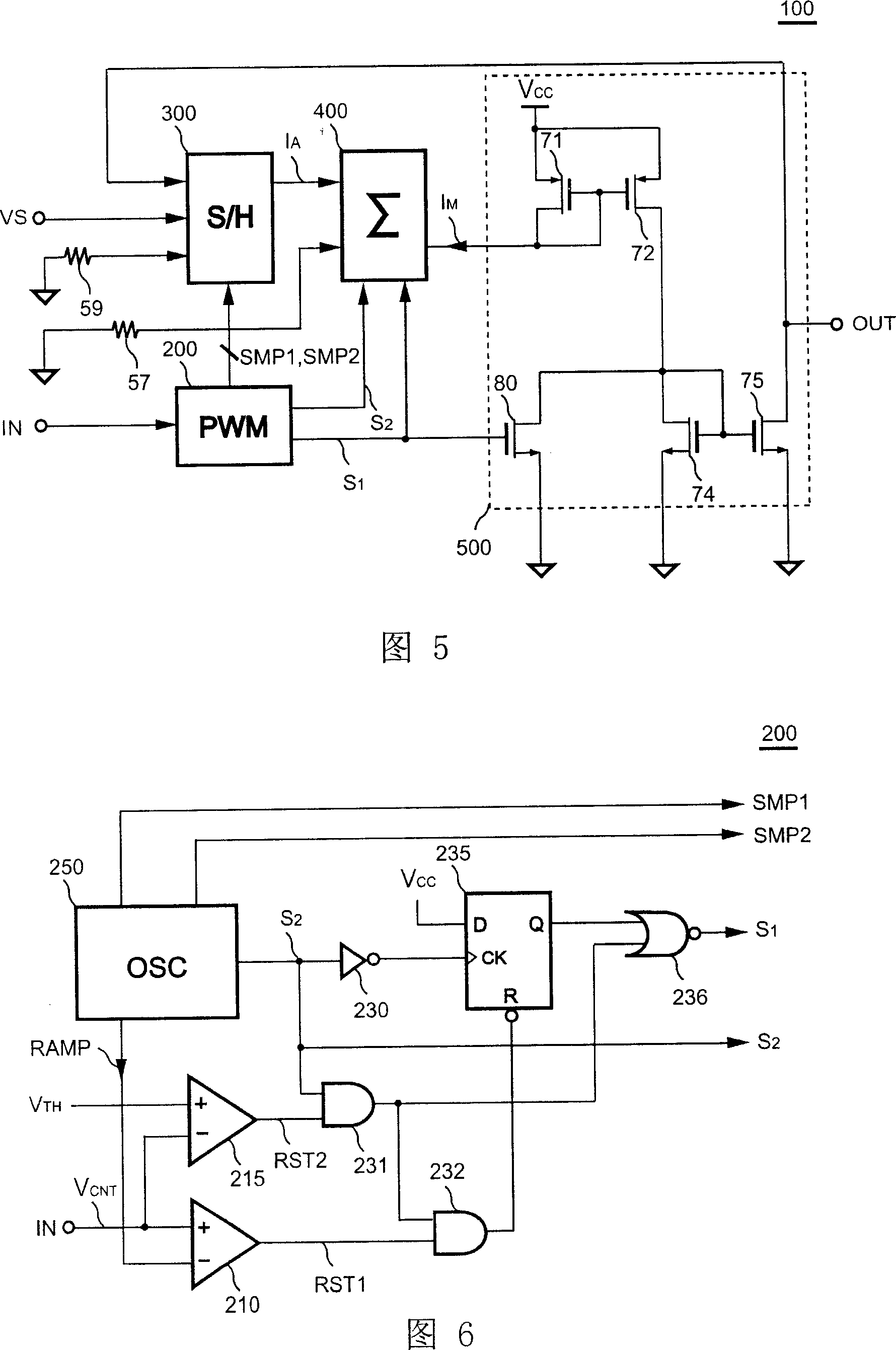

[0079] 3 and 4 are multiple embodiments of an LED driving circuit according to the present invention, wherein the LEDs 20-25 are connected in series. A voltage source V IN It is to supply the light-emitting diodes 20-25. A control circuit 100 is coupled to the LEDs 20-25. FIG. 3 shows that the control circuit 100 is powered by a voltage source VCC. FIG. 4 shows that the power of the control circuit 100 is directly provided by the voltage source VIN. An output terminal OUT of the control circuit 100 generates a LED current for controlling the LEDs 20 - 25 . A first resistor 57 is connected to the control circuit 100 for determining the current value of the LED current. A control terminal IN of the control circuit 100 is used to receive a control signal V CNT , to turn on / off the LED current, and determine the duty cycle of the LED current. A detection terminal VS of the control circuit 100 is connected to the LEDs 20 - 25 for detecting a voltage of the LEDs. The LED volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com