Three-way flow guide valve

A diverter valve and three-way technology, which is applied to multi-way valves, valve devices, engine components, etc., can solve the problems of high manufacturing and use costs, narrow application range, and difficulty in general use, and achieve the effect of convenient use and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

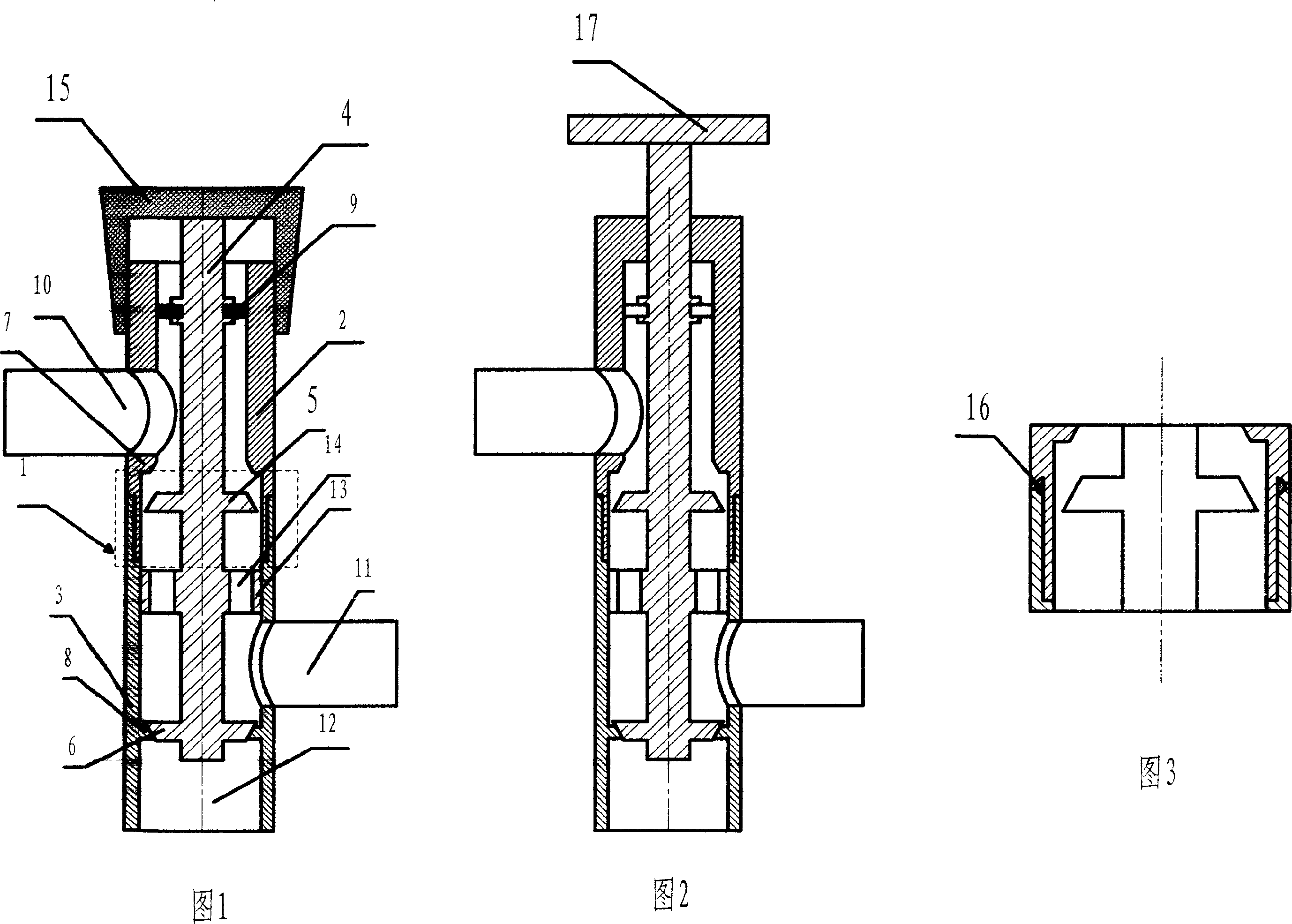

[0015] As shown in Figure 1, the present invention includes a valve body 1 with a tubular inner cavity. The valve body 1 is formed by screwing the upper valve body 2 and the lower valve body 3. The inner cavity of the valve body 1 is provided with a valve body that can slide up and down. The spool 4 is provided with two upper and lower bosses 5,6 on the spool 4, and two conical steps 7 are arranged on the two bosses 5,6 corresponding to the spool 4 in the upper valve body 2 and the lower valve body 3 respectively. , 8, the upper part of the valve core 4 and the inner chamber of the valve body 1 are provided with a sealing ring 9 for sealing, and the valve body 1 is respectively provided with an upper guide hole 10 and two conical steps between the sealing ring 9 and the upper conical step 5 There is a middle guide hole 11 between the steps, a lower guide hole 12 is opened under the lower conical step 6, and a guide flange 13 adapted to the inner cavity of the valve core is also...

Embodiment 2

[0018] As shown in FIG. 2 , the difference between embodiment 2 and embodiment 1 is that the valve core 4 protrudes from the upper end of the valve body 1 and connects with a runner 17 , and the valve core 4 and valve body 1 are connected by threads. Embodiment 2 is suitable for use when the flow rate is relatively large.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com