Recombinant staphylococcus aureus enterotoxin M and its preparation and application

A technology of staphylococcus enterica and staphylococcus, which is applied in the field of bioengineering, can solve the problems of antigenic determinant and product activity change, poor adsorption selection specificity, etc., and achieves the effect of fast purification and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the gene cloning of SEM and the construction of pGEM-T-SEM recombinant plasmid

[0030] PCR amplification of the mature peptide gene sequence encoding the SEM protein containing restriction sites: design the following pair of primer sequences:

[0031] SEQ ID NO.4 (upstream primer, the underlined part is the BamH I restriction site): 5'-ca g gat cc t ttt gct att cgc aaa atc ata tcg ca-3′

[0032] SEQ ID NO.5 (downstream primer, the underlined part is the Xho I restriction site) 5'-gc c tcg ag t caa ctt tcg tcc tta taa gat att tct ac-3’

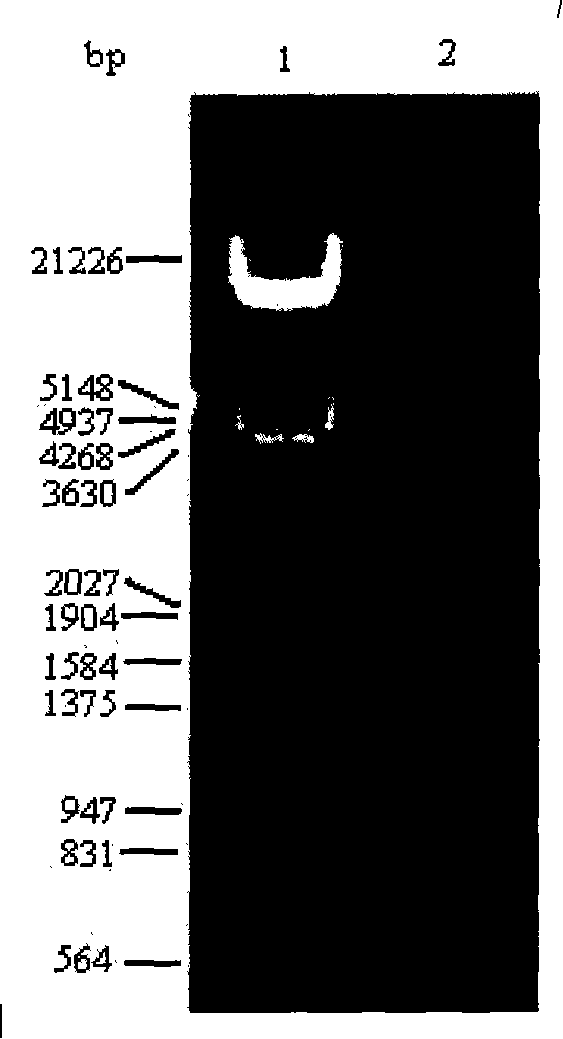

[0033] Using the Staphylococcus aureus (FRI 1230) genome template, perform PCR amplification according to the following conditions, and obtain a 703bp DNA fragment. For the gel electrophoresis diagram of the PCR result, see figure 1 , where Lane 1: Nucleic acid standard control (Marker); Lane 2: PCR product of the mature peptide gene encoding SEM protein containing restriction sites.

[0034] PCR system:

[0035]...

Embodiment 2

[0051] Embodiment 2: the expression of recombinant SEM

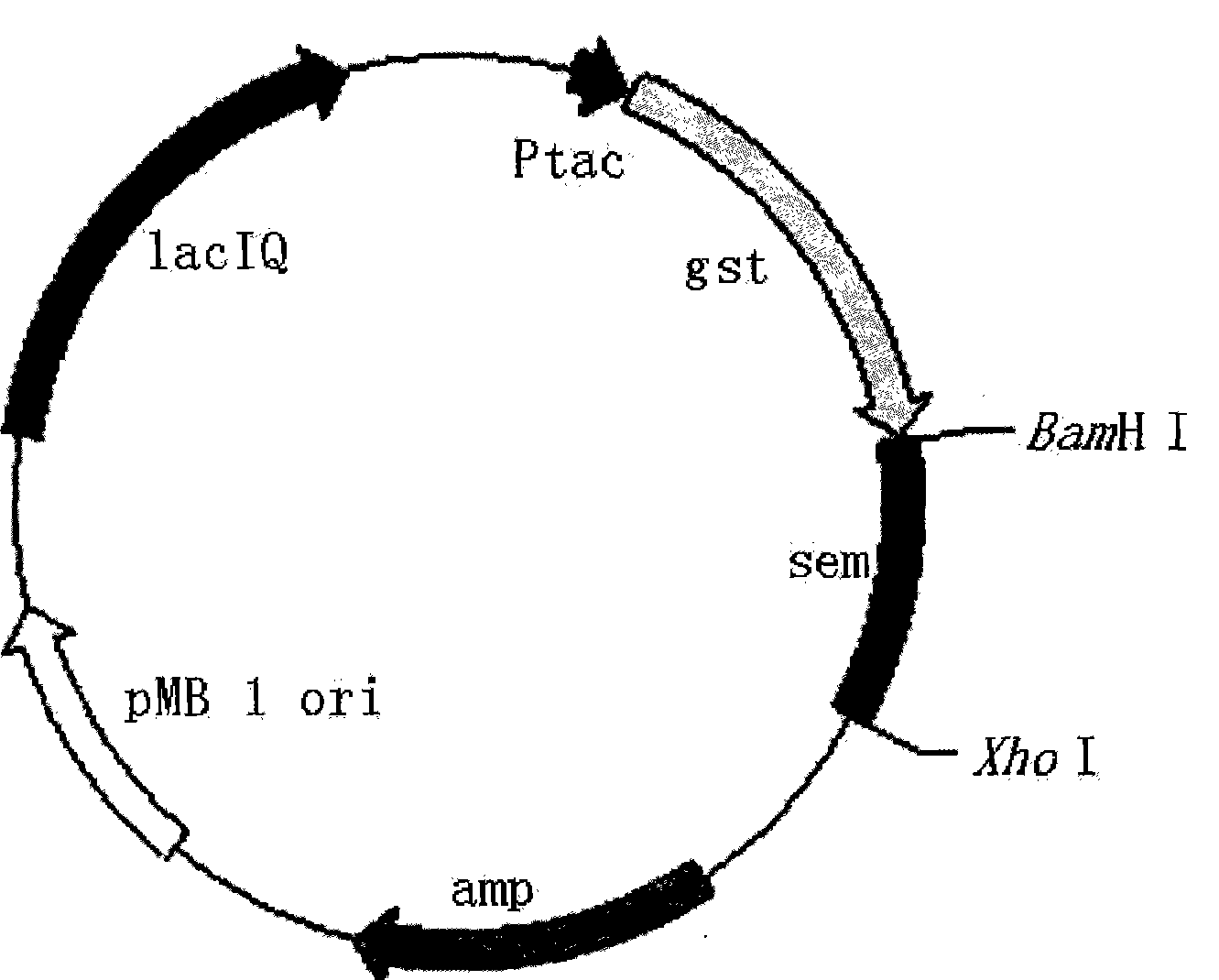

[0052] Construction of SEM expression strain: Extract the plasmid from Escherichia coli DH5α containing the pGEX-4T-1-SEM recombinant plasmid, transform it into Escherichia coli BL21 (DE3), and screen positive clones through antibiotic resistance to obtain a large amount of expression GST- Engineering strains of SEM fusion protein.

[0053] Expression of the fusion protein GST-SEM: Inoculate a single colony of the above-mentioned engineered bacteria into 5 mL of LB medium containing ampicillin, culture with shaking at 37° C. for 6 h, and use it as a seed solution. Inoculate the seed solution in 2×YT medium containing ampicillin with an inoculum amount of 1-5%, culture with shaking at 37°C for 4 hours, and add 0.1mol / L isopropyl-β at a volume ratio of 0.01%-0.1% -D-thiogalactoside (IPTG) induced expression for 5h.

Embodiment 3

[0054] Embodiment 3: the purification of recombinant SEM

[0055]Pretreatment of samples: the bacterial solution induced by IPTG was centrifuged at 10,000 rpm at 4°C, and the supernatant was discarded to collect the precipitate. The precipitate was resuspended in phosphate buffered saline (PBS) that was 1 / 10 the volume of the original bacterial solution, and the suspension was placed in a FRENCH cell disruptor and crushed at 700 psi, and the suspension was viscous. Afterwards, continue to sonicate for 2 min with a sonicator to degrade the nucleic acid and reduce the viscosity of the cell lysate. After sonication, 20% Triton-100 was added to the cell lysate to a final concentration of 1%, mixed thoroughly, and left to stand in an ice bath for 30 minutes. After standing still, the cell lysate was centrifuged at 12000 rpm at 4°C for 30 min, and the supernatant was stored at low temperature for later use. The supernatant was sampled for SDS-PAGE detection, and there was a relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com