Enzyme modification method for preparing low gel property high dispersancy soy protein

A soybean protein, high dispersion technology, applied in the direction of plant protein processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Use low-temperature defatted soybean meal as raw material, suspend in an aqueous solution at 30°C with a solid-to-liquid ratio of 1:15g / ml by conventional methods, dissolve in alkali at a pH of 7.4 for 50 minutes, and centrifuge to obtain a supernatant, and adjust the pH of the supernatant to After 7, stir and heat at 50°C for 10 minutes, centrifuge to obtain yogurt curd, add water until the solid content is 13%, adjust the pH to 7.4, add 0.2% protease and 0.3% Peptidase R, and act at 50-60°C for 40 minutes. The obtained hydrolyzate is heated to 120° C. by steam for 5 seconds to inactivate the enzyme, after which it is homogenized, spray-dried and sprayed with phospholipids to obtain soybean protein products. The gel strength of the product is 102.3g, the gel elasticity is 76.7g, the solubility (wt%) of 5% TCA-N is 13.4%, and the Δε% is 3.5%.

[0034] Other conditions are within the scope of conditions listed in the present invention, and only when the supernatant is ad...

Embodiment 2

[0036] Use low-temperature defatted soybean meal as raw material, suspend in an aqueous solution at 30°C with a solid-to-liquid ratio of 1:15g / ml by conventional methods, dissolve in alkali at a pH of 7.4 for 50 minutes, and centrifuge to obtain a supernatant, and adjust the pH of the supernatant to After 4.5, stir and heat at 80°C for 5 minutes, centrifuge to obtain yogurt, add water until the solid content is 13%, adjust the pH value to 7.25, add 0.1% endopeptidase and 0.05% Peptidase R, and act at 50-60°C for 40 minutes. The obtained hydrolyzate is heated to 120° C. by steam for 5 seconds to inactivate the enzyme, after which it is homogenized, spray-dried and sprayed with phospholipids to obtain soybean protein products. The gel strength of the product is 4.9g, the gel elasticity is 3.1g, the solubility (wt%) of 5% TCA-N is 67.5%, and the Δε% is 73.5%.

Embodiment 3

[0038] Use low-temperature defatted soybean meal as raw material, suspend in an aqueous solution at 30°C with a solid-to-liquid ratio of 1:10g / ml by conventional methods, dissolve in alkali at a pH of 7.2 for 60 minutes, and centrifuge to obtain a supernatant, and adjust the pH of the supernatant to After 4.5, stir and heat at 40°C for 30 minutes, centrifuge to obtain yogurt, add water until the solid content is 14%, adjust the pH value to 7.3, add 0.5% endopeptidase and 0.10% Peptidase R, and act for 40 minutes at 50-60°C . The obtained hydrolyzate is heated to 120° C. by steam for 10 seconds to inactivate the enzyme, after which it is homogenized, spray-dried and sprayed with phospholipids to obtain soybean protein products. The gel strength of the product is 53.2g, and the gel elasticity is

[0039]

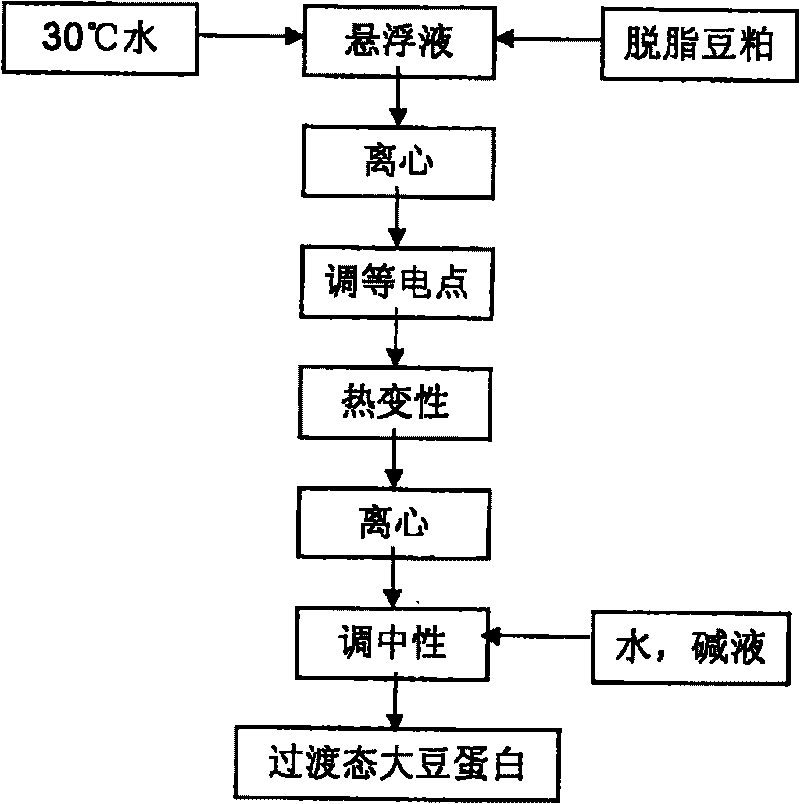

[0040] figure 1

[0041]

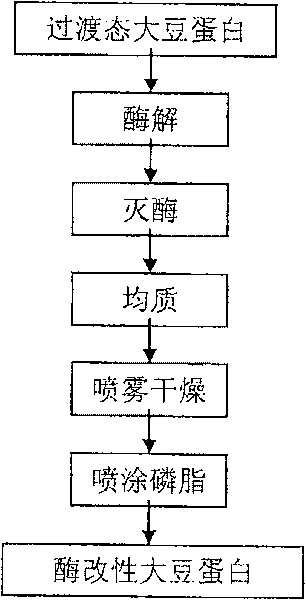

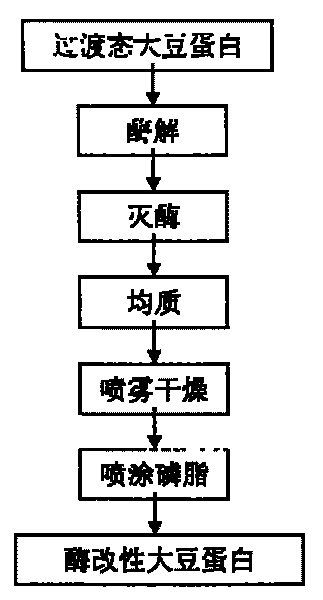

[0042] figure 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel strength | aaaaa | aaaaa |

| gel strength | aaaaa | aaaaa |

| gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com