Clamping strap upward and downward turning over nail nipper

A technology of nail clippers and pressure plates, applied in the field of nail clippers, can solve the problems of affecting the life of the clipper head, unhooking, and the width of the jaws cannot be too large, and achieve the effect of improving the connection mode, rational structure, and liberating limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

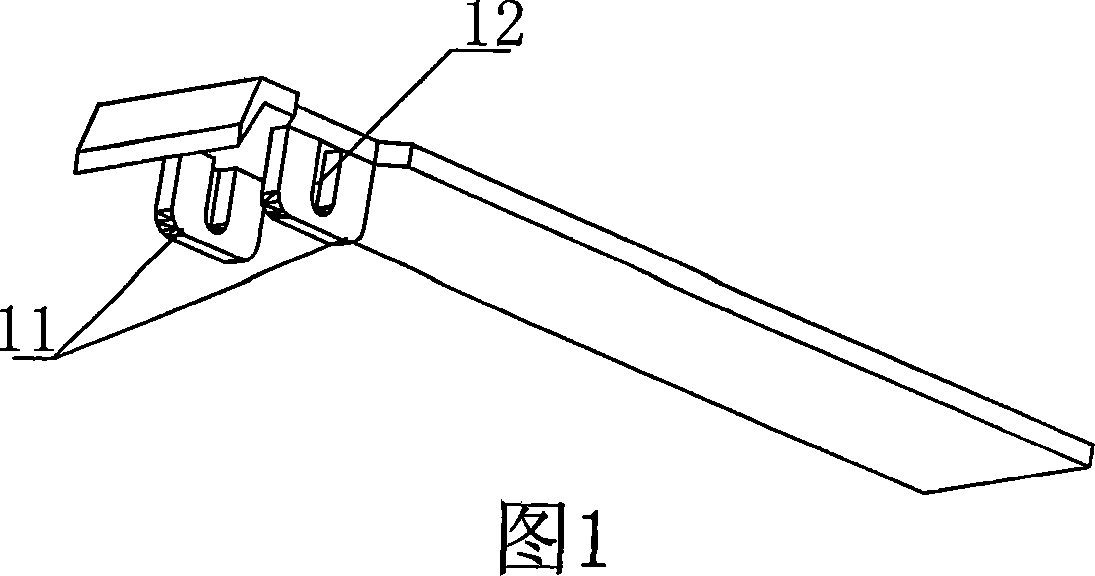

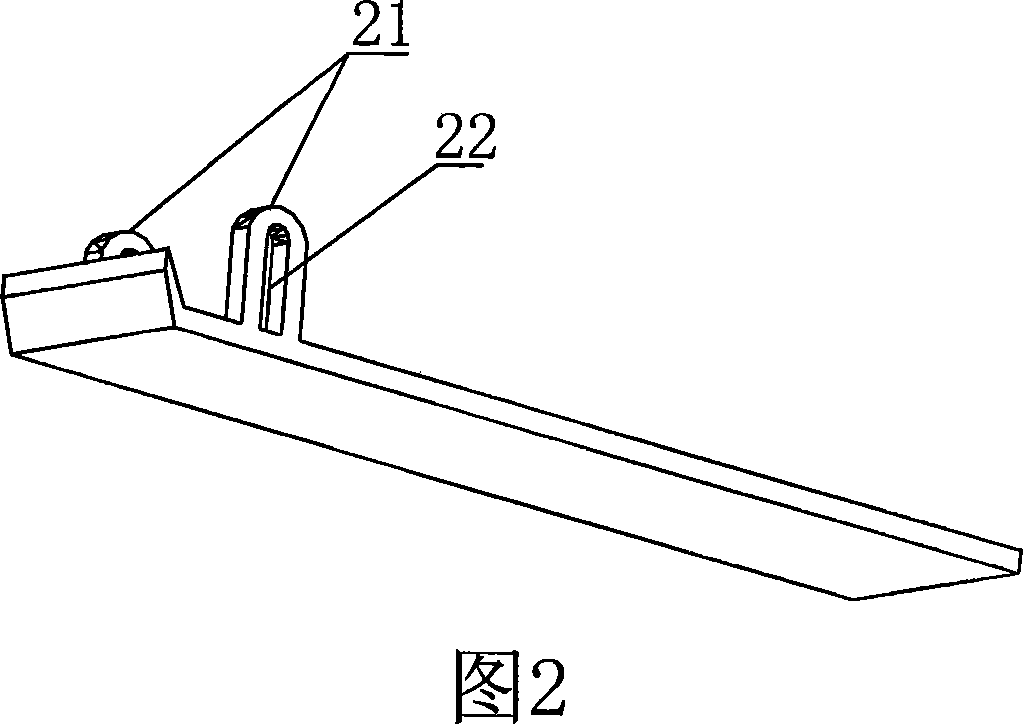

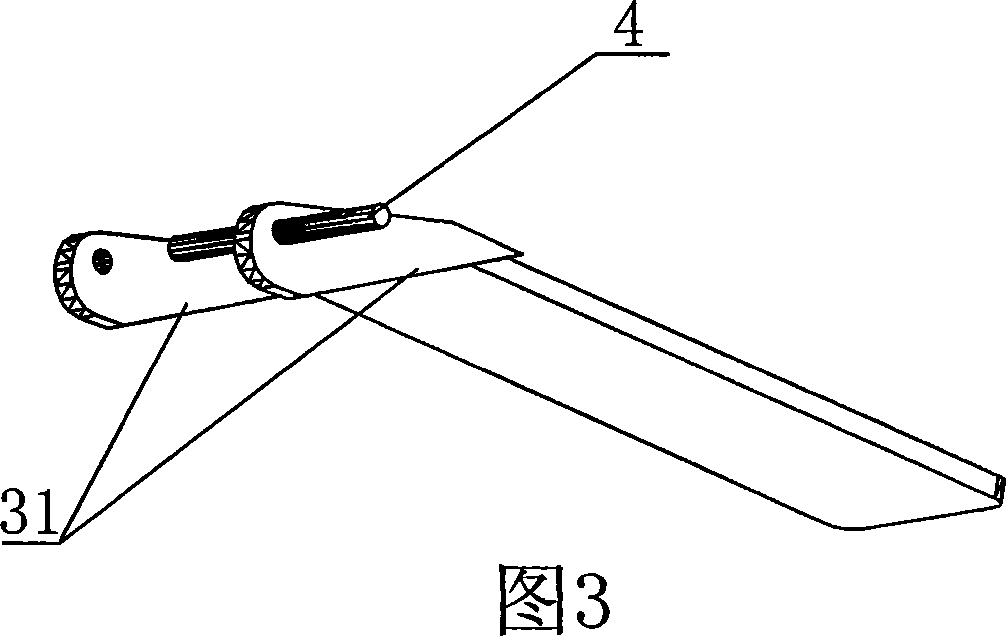

[0023] As shown in Fig. 6, Fig. 7 or Fig. 8, the present invention is a nail clipper with a pressing plate turned up and down, including an upper piece 1, a lower piece 2 and a pressing plate 3, and the tails of the upper piece 1 and the lower piece 2 are integrally formed or welded Together, the head is provided with a cutting edge, and the two sides of the head of the upper piece 1 and the lower piece 2 are respectively provided with an upper lug 11 and a lower lug 21, and a chute is arranged in the upper and lower lugs, so The intersection of the chute of the upper lug 11 and the lower lug 21 is connected by a pin 4 , the end of the pin 4 passes through the chute and extends out of the chute, and one end of the pressure plate 3 is connected with both ends of the pin 4 .

[0024] As shown in Fig. 1, Fig. 2, Fig. 4 and Fig. 5, in order to stagger the relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com