Automatic transmission with power compensation

An automatic transmission and power compensation technology, which is applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the problem of low transmission efficiency of hydraulic torque converter, complex structure of hydraulic torque converter, and automobile fuel economy. Reduce and other problems, achieve the effect of increasing the smoothness of shifting, solving the phenomenon of uneven shifting, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

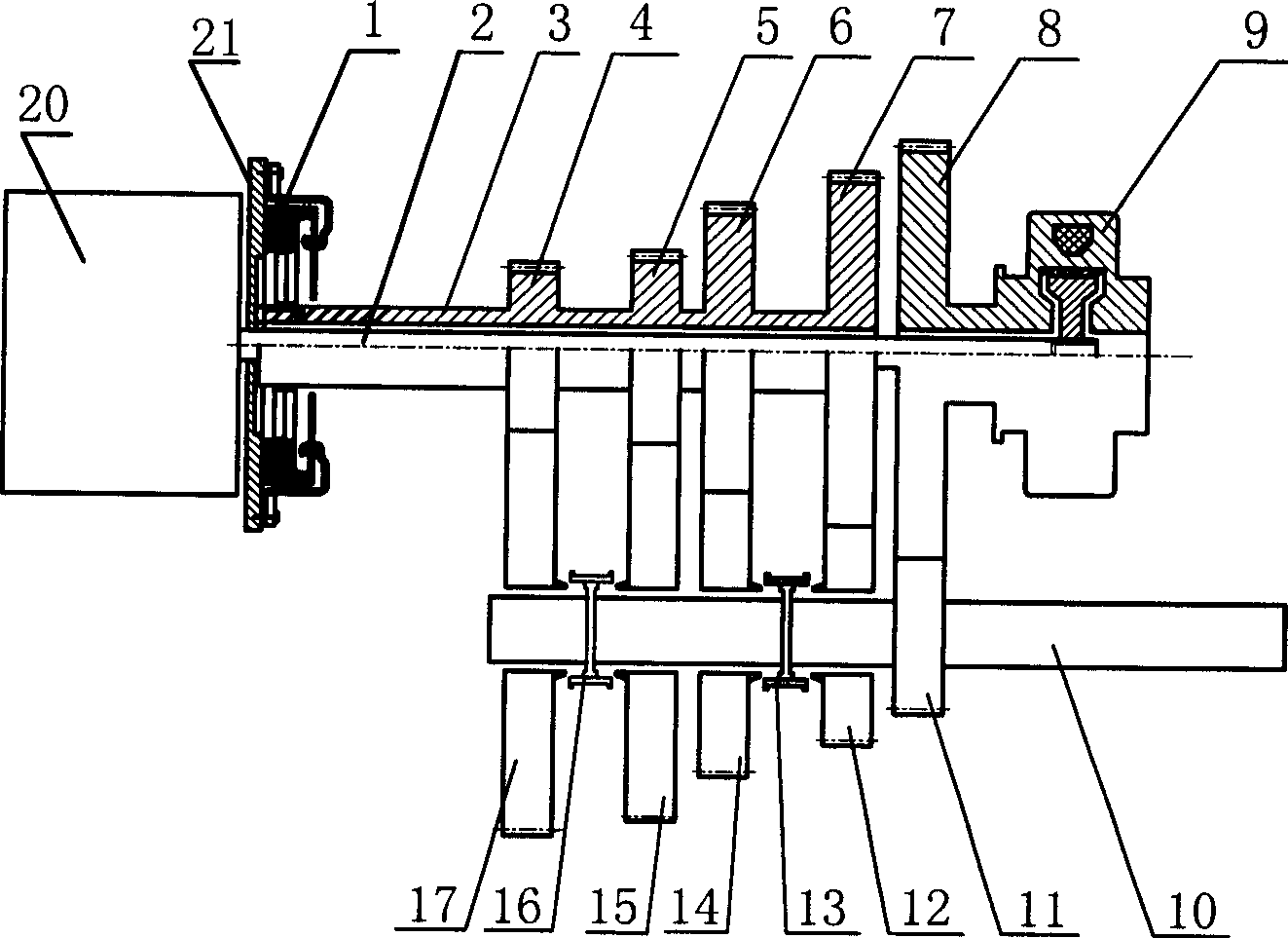

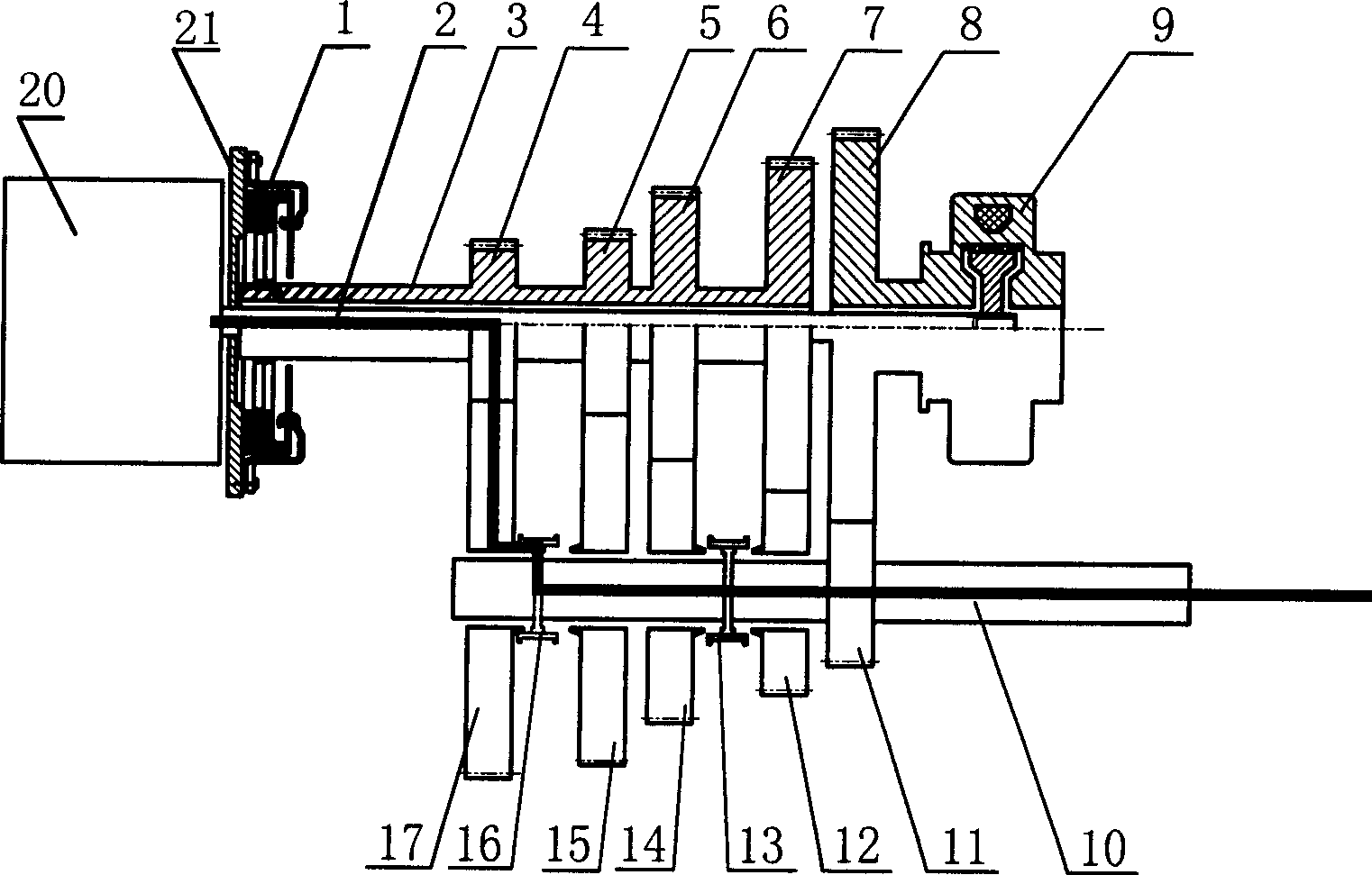

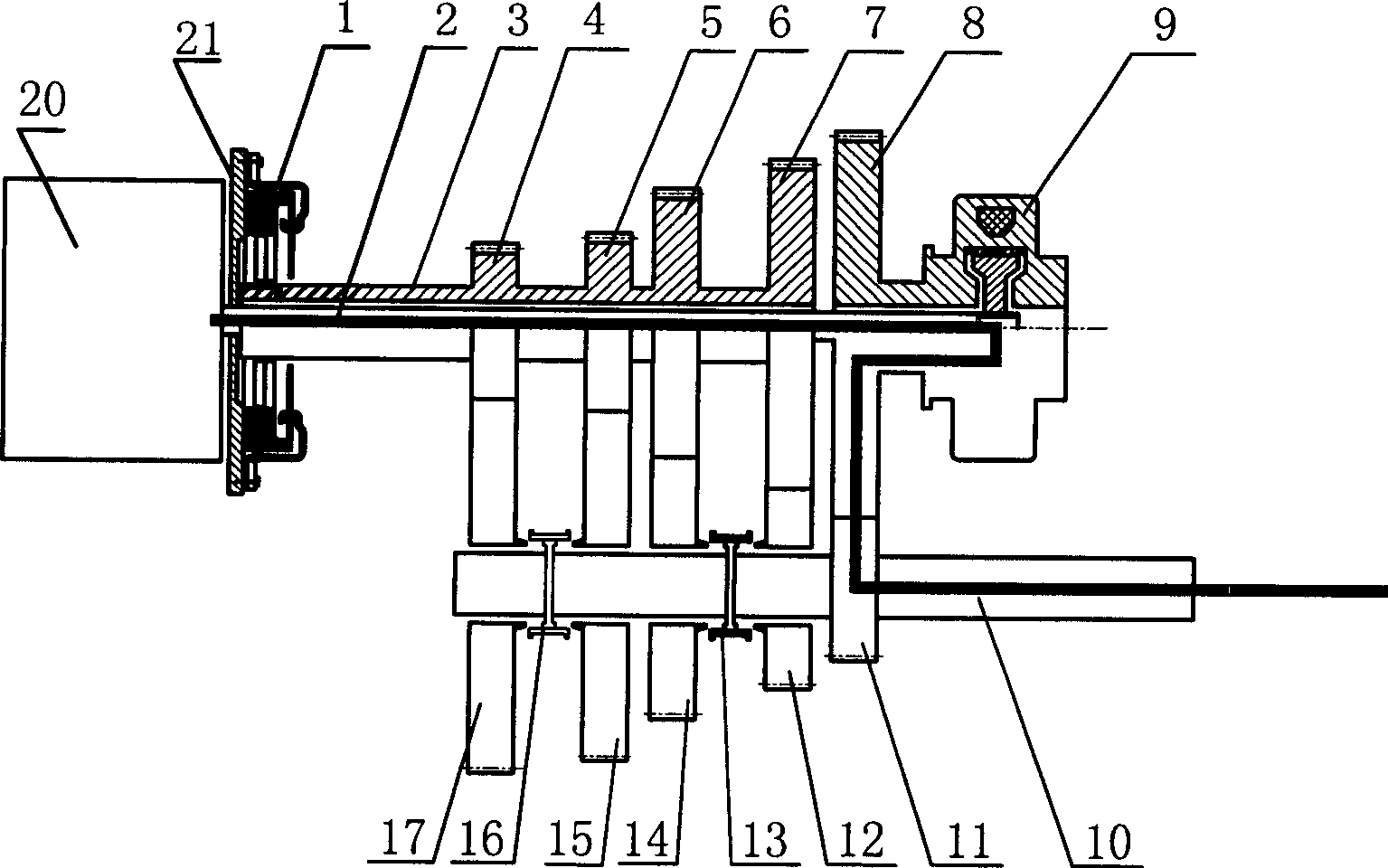

[0018] An automatic transmission with power compensation of the present invention is based on the traditional AMT gearbox, adding an auxiliary clutch 9, a vehicle speed sensor (not shown in the figure) and changing the original input shaft to be composed of a sleeve shaft 3 and a mandrel 2 Dual-shaft structure to realize uninterrupted power when shifting gears.

[0019] see figure 1 , the original input shaft has been modified into a biaxial structure consisting of a sleeve shaft 3 and a mandrel 2, wherein the sleeve shaft 3 is sleeved outside the mandrel 2, and one end of the mandrel 2 is fixedly connected with the output shaft of the original engine 20 (such as through spline fixed connection), the other end is fixedly connected with the auxiliary clutch 9, and this end is also fixedly sleeved with a high-grade gear (the fixed sleeve method is a detachable sleeve, and it can also be achieved by an integrally formed structure. The socketing of the dismounting method, such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com