Swinging washing machine

A washing machine and swing type technology, which is applied in the field of swing washing washing machines, can solve the problem that the inclination angle and level cannot be guaranteed, and achieve the effect of saving detergent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

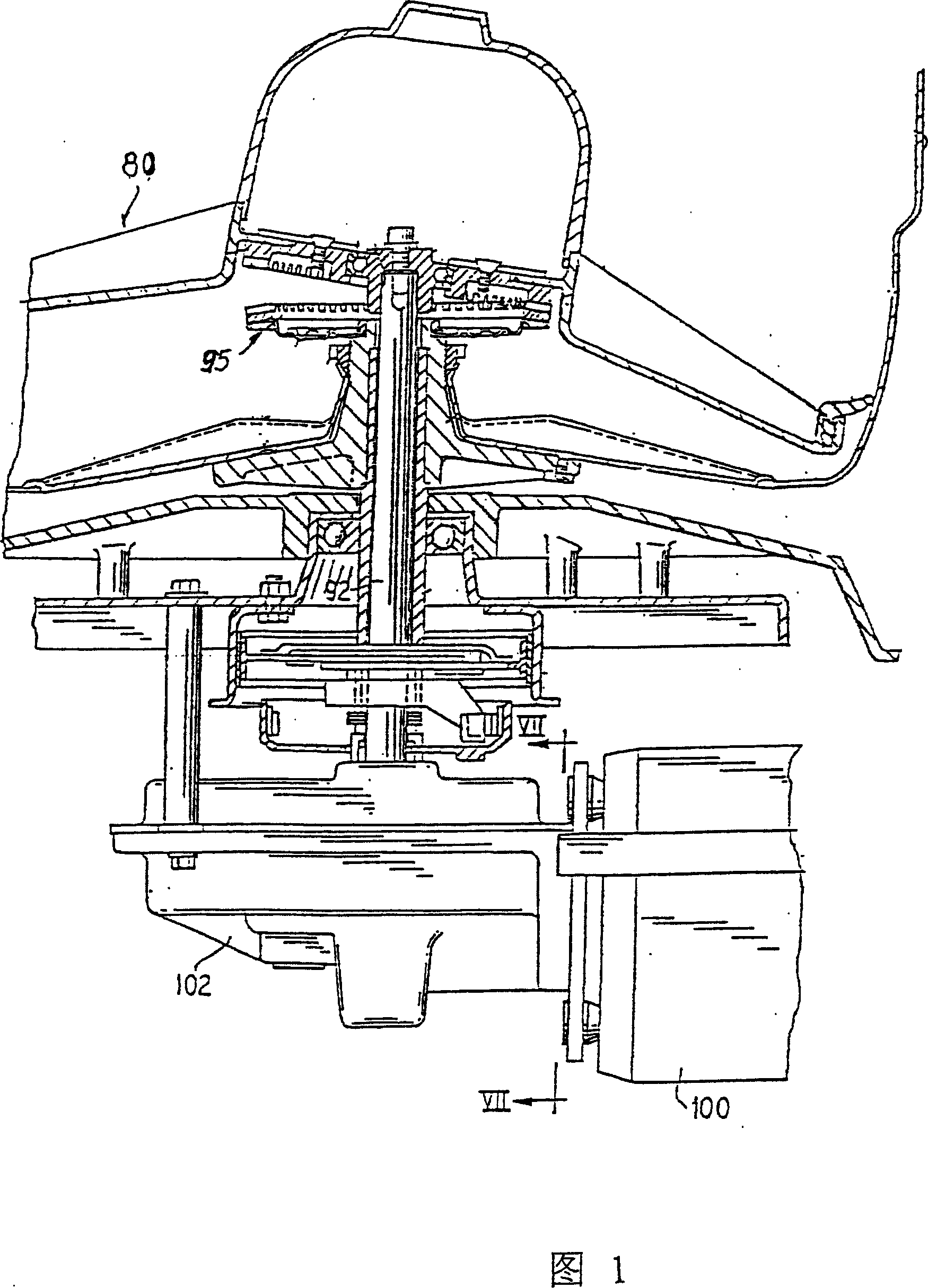

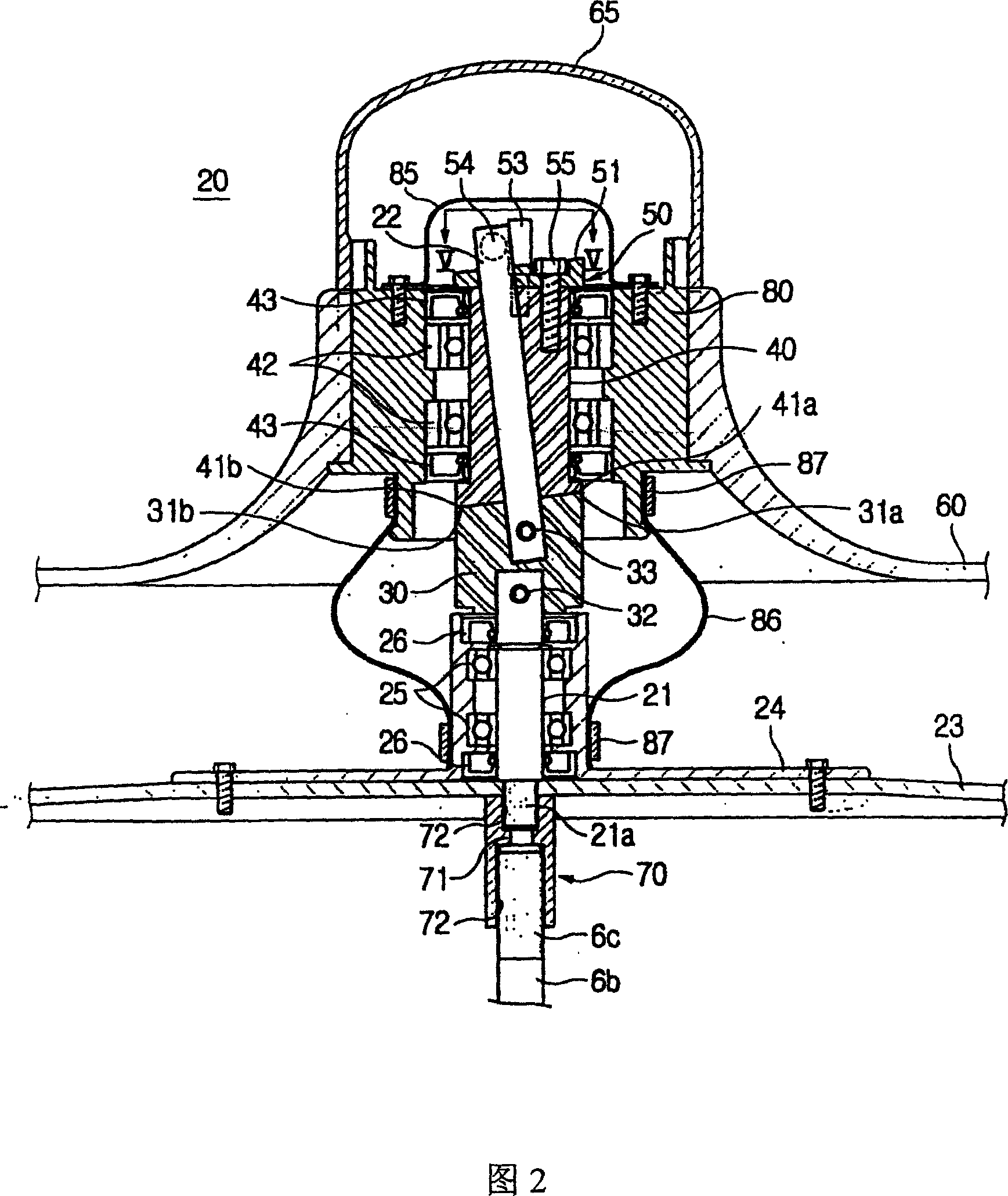

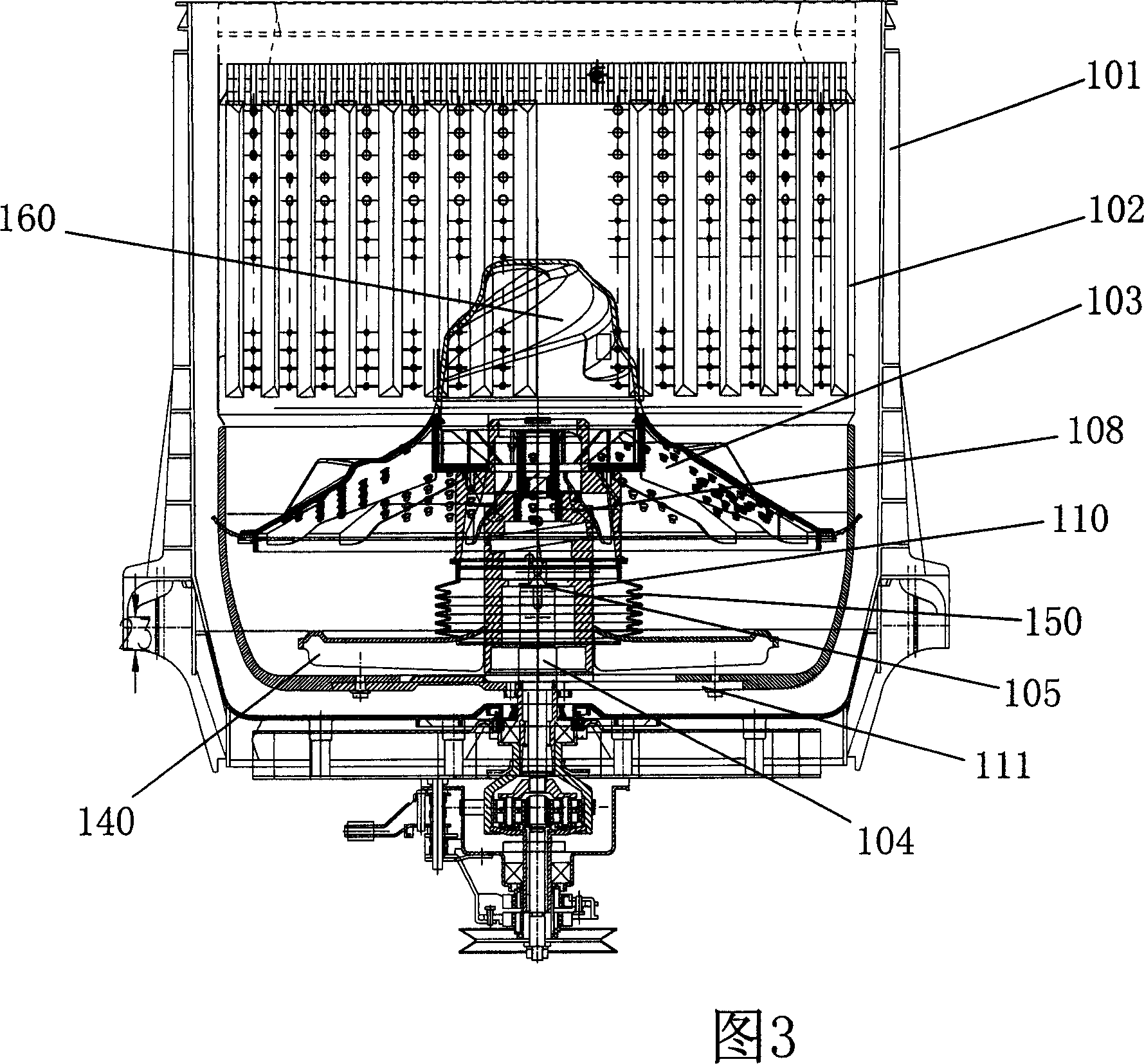

[0049] The present invention provides a pulsator swing washing machine. FIG. 3 is a structural view of the swing washing machine of the present invention, and FIG. 4 is a structural view of a swing device of the swing washing machine of the present invention. The swinging washing machine of the present invention comprises an outer tub 101, an inner tub 102, a pulsator 103, a hollow overcoat dehydration shaft 104 connected to the inner tub 102 and a pulsator shaft 105 coaxially arranged with the hollow overcoat dehydration shaft connected to the pulsator, and during the washing process, the The oscillating device of pulsator 103 swings, wherein:

[0050] As shown in Figures 3 and 4, the swing device is connected to the driving shaft 106 of the universal rotating shaft on the pulsator shaft 105, and a driving member 108 is connected to the driven shaft 107 of the universal rotating shaft through a spline or a square shaft hole. , so that the driven shaft 107 of the universal sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com