Material feeding device, recording device and liquid injecting device

A feeding device and liquid technology, applied in printing devices, thin material handling, transportation and packaging, etc., can solve problems such as cost increase, difficulty in component precision management, and long feeding roller shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0084] 6 and 7 are perspective views showing feeding devices according to other embodiments. Among them, FIG. 6 is a diagram showing no CD-R tray, and FIG. 7 is a diagram showing a CD-R tray.

[0085] As shown in FIG. 6 , the flat portion 318 of the second guide portion 111 is disposed at the same height and parallel to the upper surface of the platen 124 , and is extended further upstream in the above-mentioned embodiment. Furthermore, the retracting guide portion 117 of the second guide portion 111 is provided with a tray opening portion 319 through which the CD-R tray Q having the flat portion 318 as a lower surface can be inserted.

[0086] In addition, a discharge unit 320 for discharging paper P is provided on the front of the recording device 100 (on the front side in FIGS. 6 and 7 ). In addition, a discharge opening 321 for discharging the paper P from the inside of the recording device 100 to the outside is provided in the discharge unit 320 . For other members, sin...

other Embodiment approach

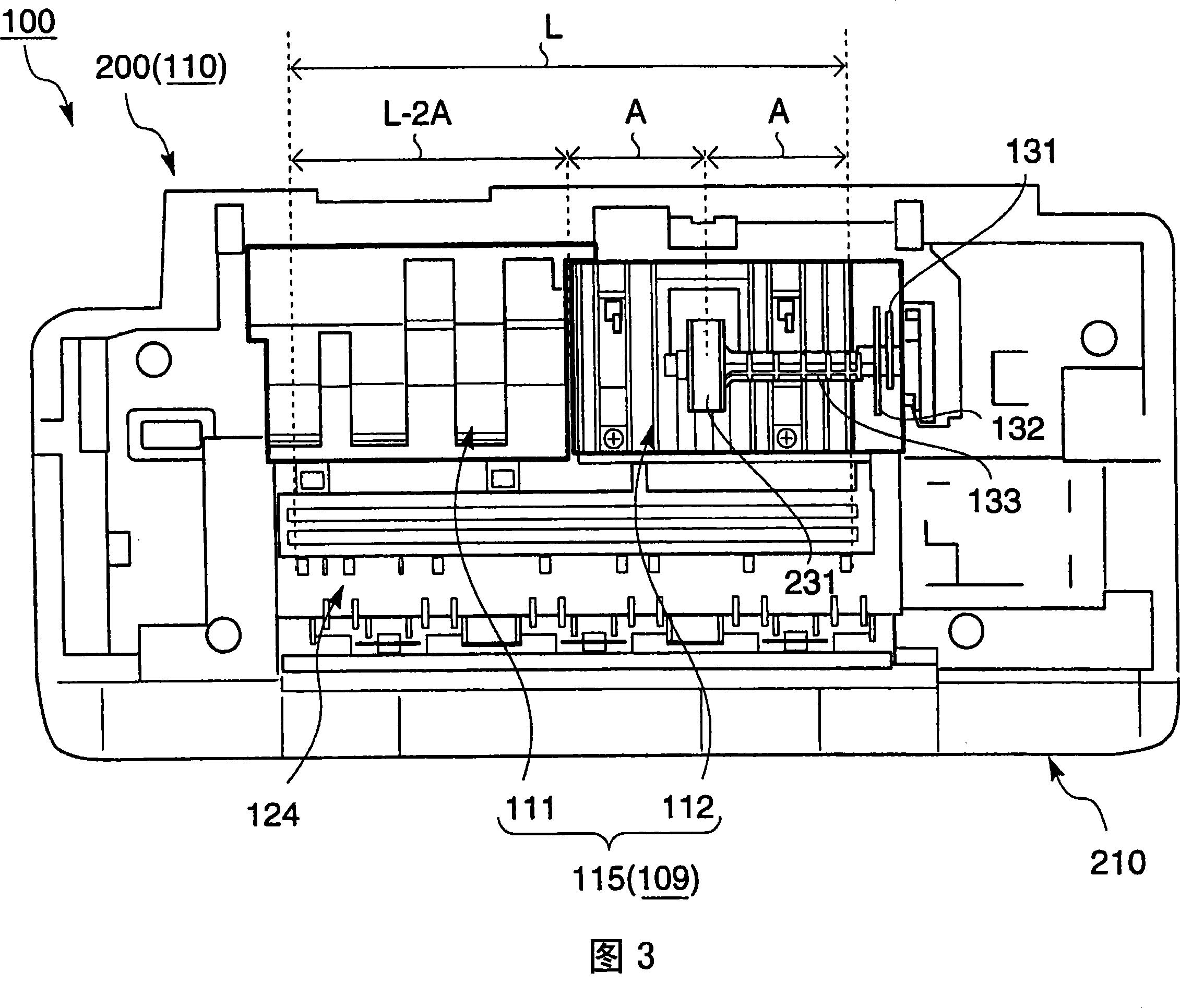

[0089] The second guide section 111 of another embodiment is characterized in that it includes a flat section 318 that not only retracts downward relative to the first guide section 112 to guide the paper P toward the conveying roller pair 240 , but also guides the sheet P as only during the main scanning. The CD-R tray Q of the second medium that performs recording within the range of the second guide section 111 in the direction X, the CD-R tray Q is set so that it is only moved in the main scanning direction of the paper guide section 115 as a medium guide section. The flat portion 318 supports and guides from below.

other Embodiment approach

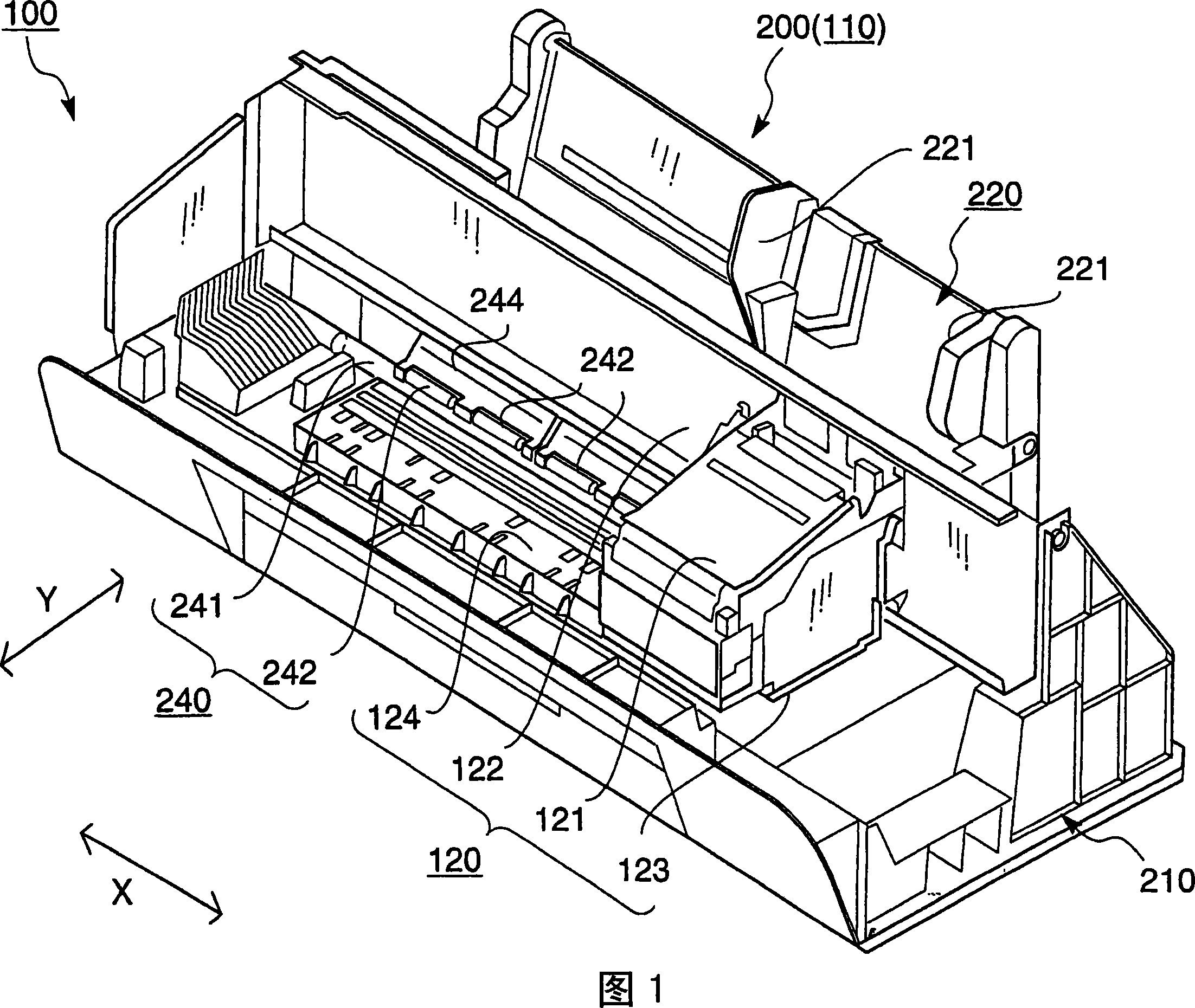

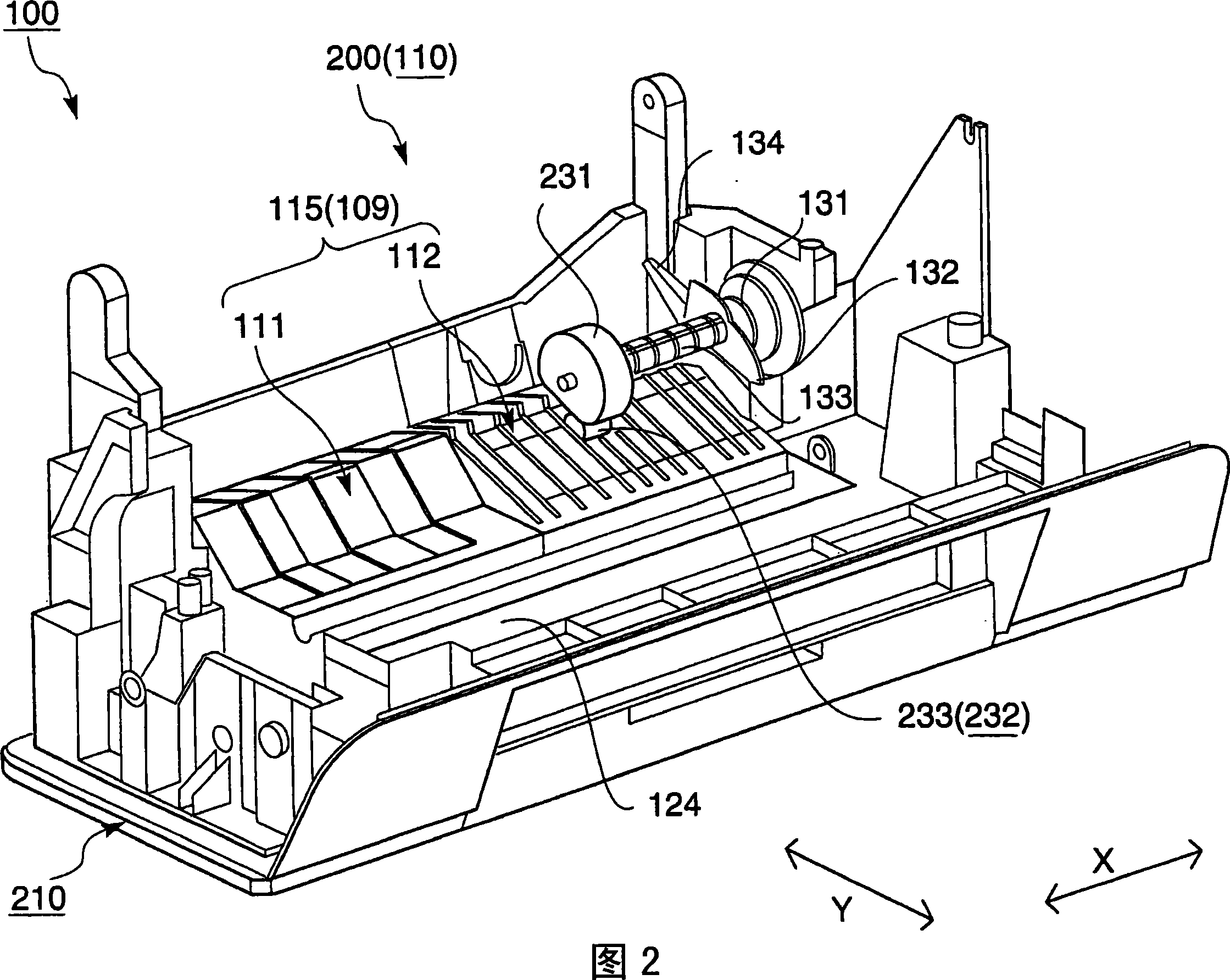

[0090] The recording device 100 of another embodiment includes: a feeding unit 110 that picks up stacked paper P and supplies it to the recording unit side; and a recording unit that ejects ink to the paper P and CD-R (Q) to perform recording. 120, characterized in that the feeding unit 110 is equipped with the above-mentioned feeding device 200.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com