Small bead automatic coating device

An automatic and coating technology, which is applied in the direction of coating and liquid coating device on the surface, etc., can solve the problems of deep immersion of small beads in the coating liquid, failure to realize "automatic", easy to produce scars on the surface, etc., and save manpower , Improve quality stability, and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

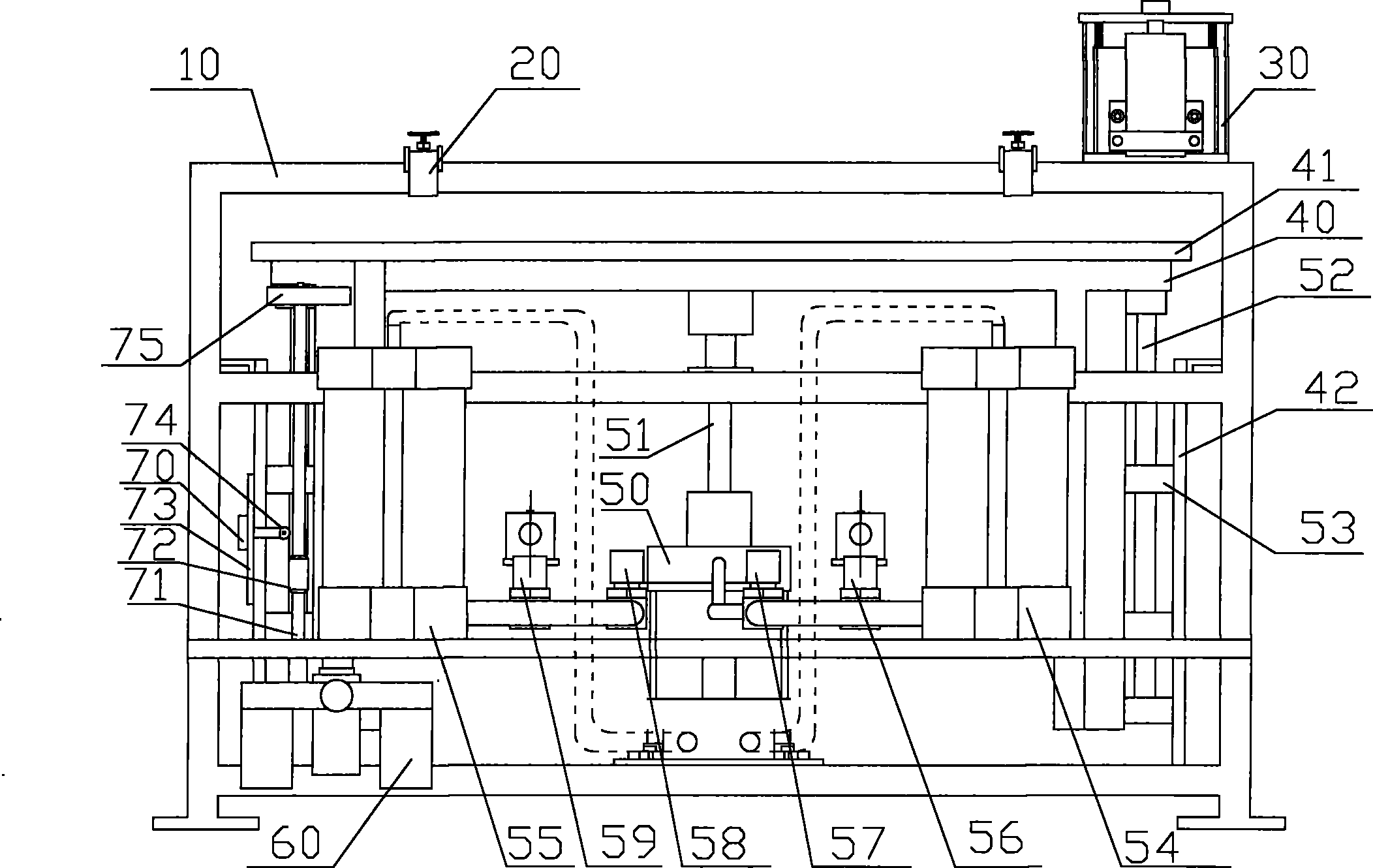

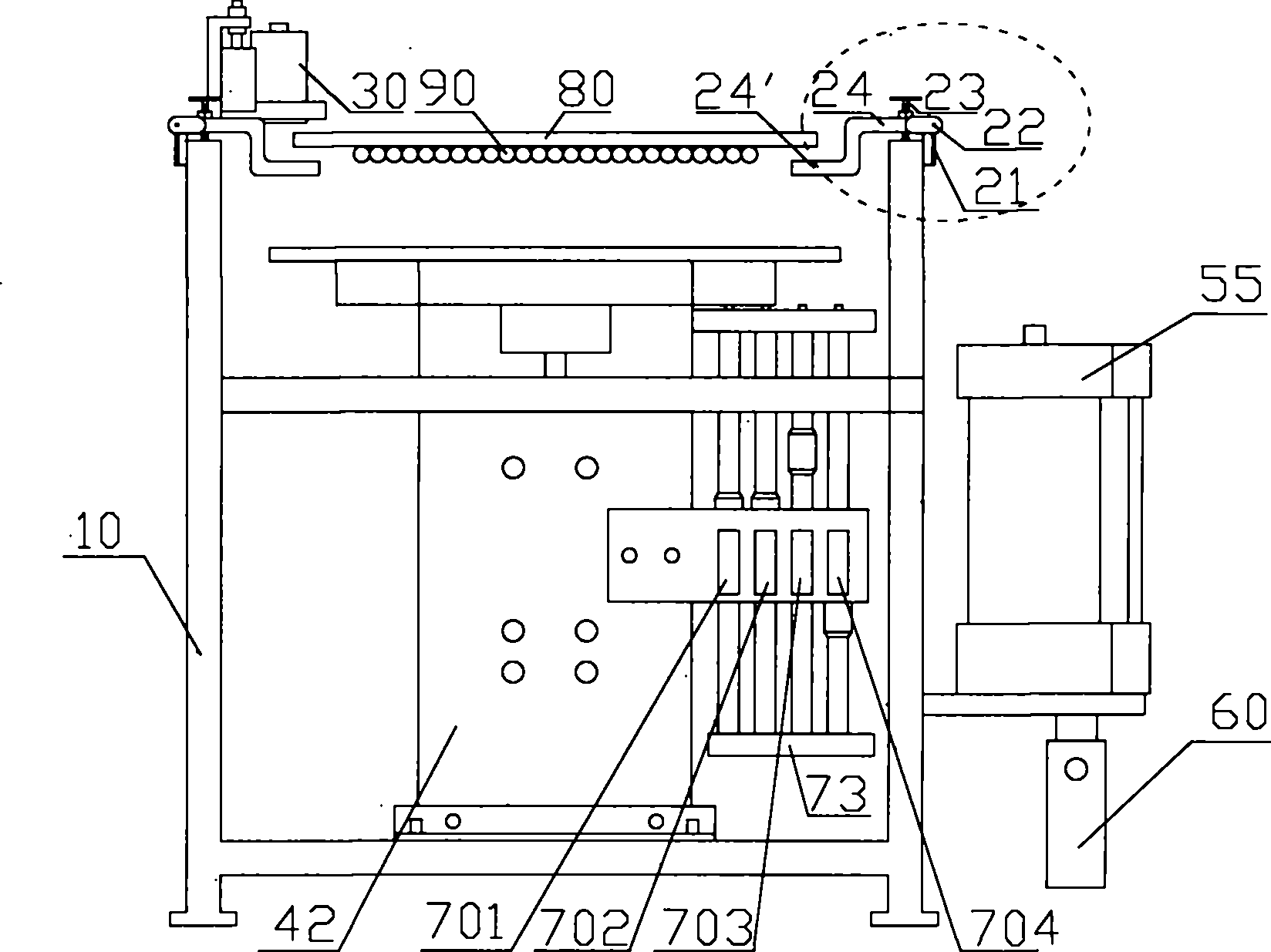

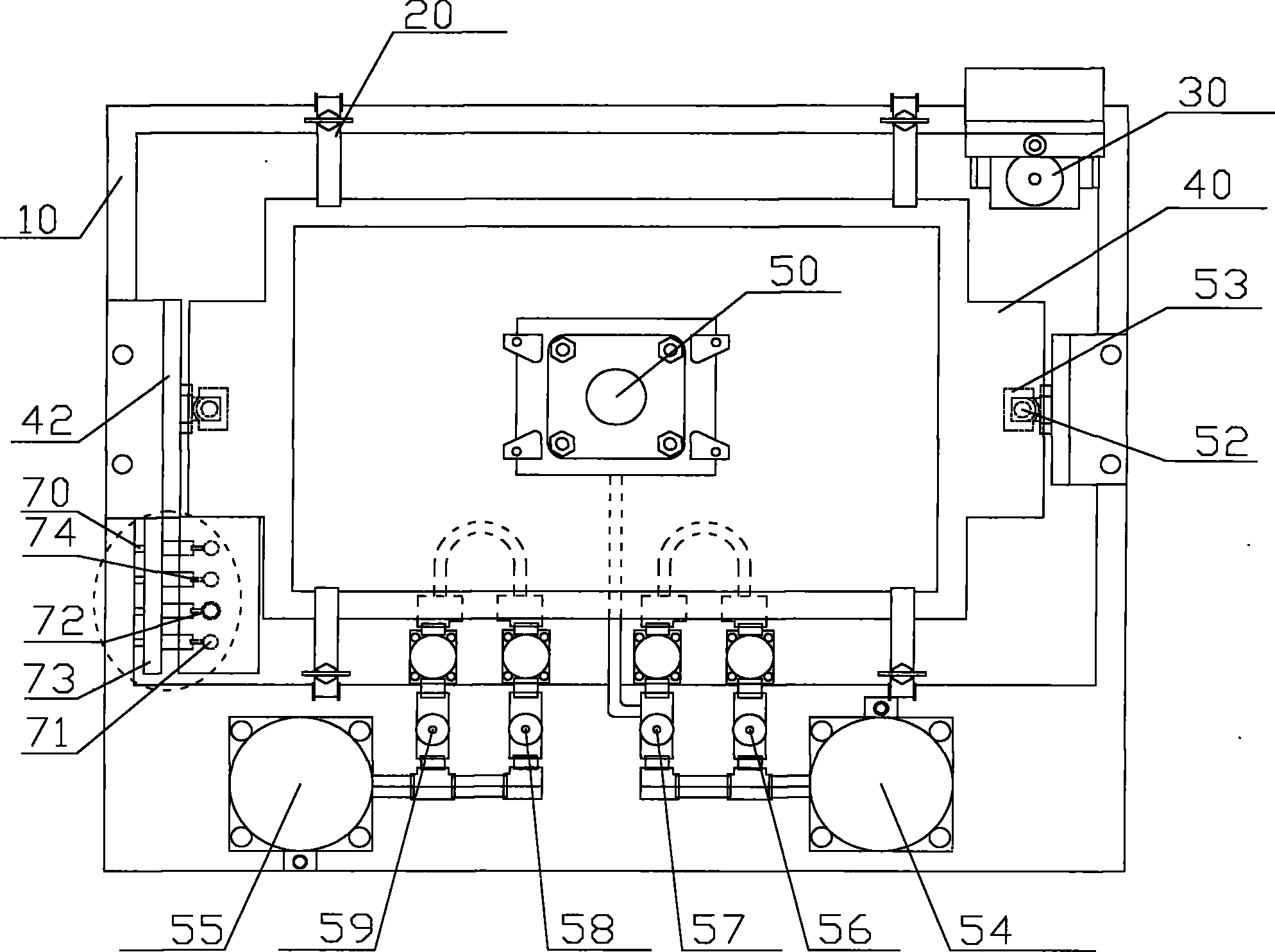

[0014] like figure 1 As shown, the present invention includes a rack 10 for installing, placing and fixing other components. The top of the rack 10 is provided with an arrangement plate level adjustment device 20, such as figure 2 and Figure 4 As shown, it includes four bracket bases 21 fixed on the outer sides of the two long sides of the rack 10 and four corresponding arrangement plate brackets 24. The upper part of the bracket bases 21 is hinged to the arrangement plate brackets 24 through pins 22. The middle part of the arrangement plate bracket 24 is provided with a threaded through hole, and the bottom surface of the matching bolt 23 is pressed on the upper surface of the frame 10; A support arm 24' is formed, and the support arm 24' is located on the inner side of the frame 10; when the bolt 23 is rotated, the arrangement plate bracket 24 rotates around the pin shaft 22, and the height and level of the support arm 24' change accordingly; When the alignment plate 80 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com