Spray gun

A spray gun and paint spraying technology, applied in the direction of spraying devices, spraying devices, liquid spraying devices, etc., can solve the problems of dirty hands, reluctance to change the spraying method, etc., and achieve the effect of low complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

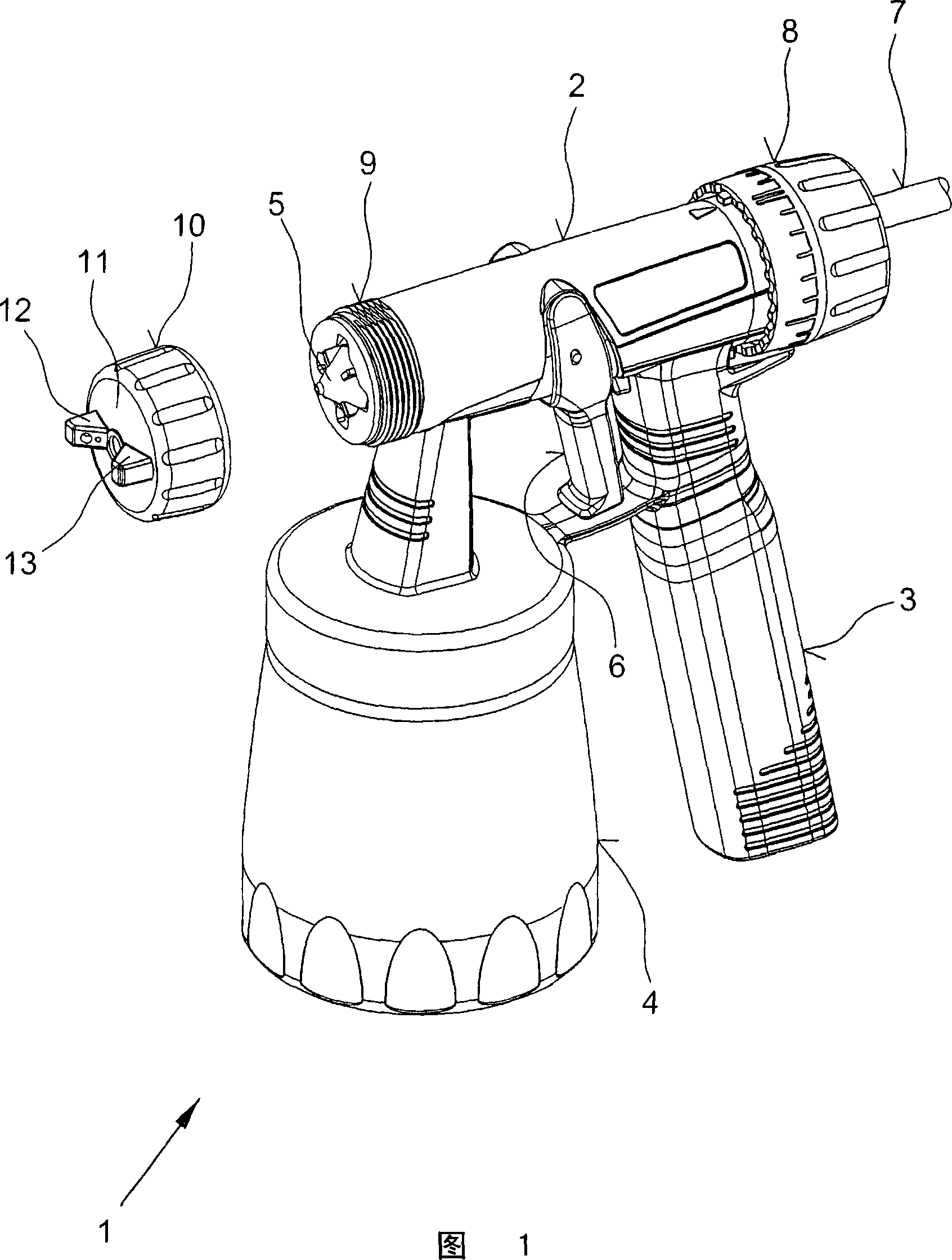

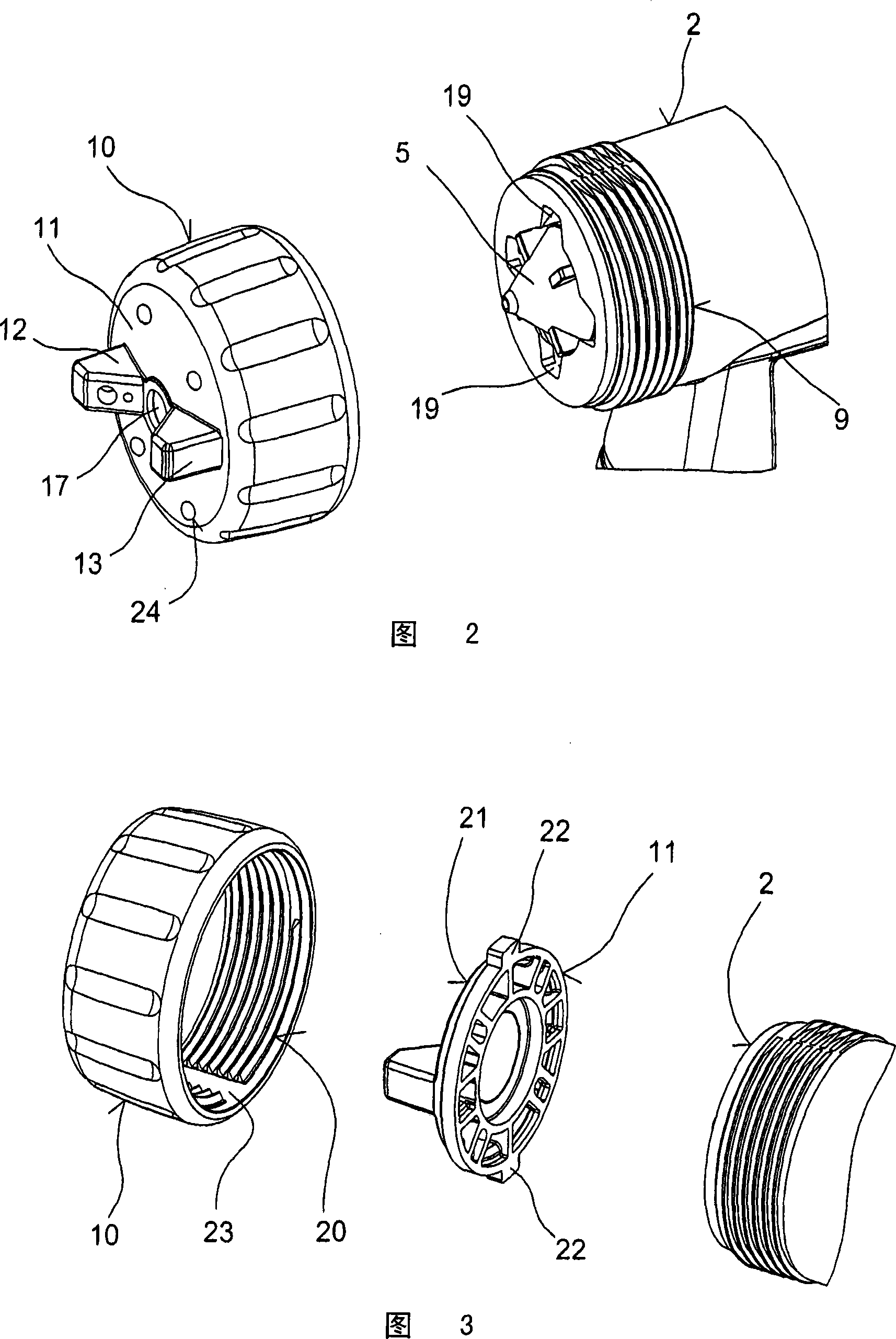

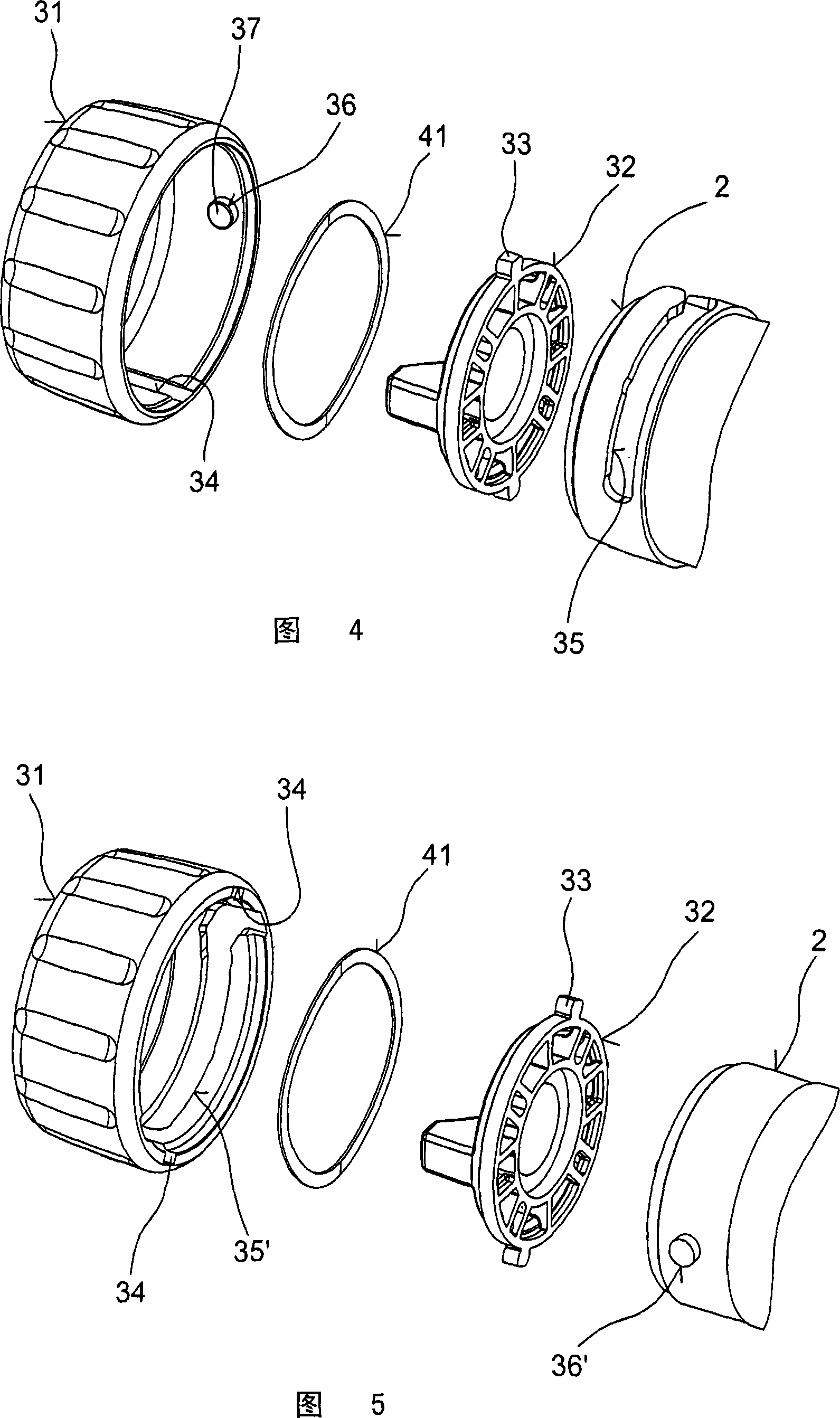

[0024] The spray gun shown in Fig. 1 numeral 1 is used for spraying paint or paint, mainly comprises the gun casing 2 that accommodates propulsion mechanism, realizes the parts of mixing and / or metering, the handle 3 that protrudes from gun casing 2, and is used for preserving Storage container 4 for the processed medium. The medium extracted from the storage container 4 is atomized by compressed air supplied through the gun housing 2 via the line 7 of the atomizing nozzle 5 . In the example shown, the atomizing nozzle 5 is held by a union nut 10 screwed onto a thread 9 machined on the gun housing 2 . The nozzle needle 16 to the atomizing nozzle 5 is controlled by the handle 6 and the amount of paint is controlled by the adjusting screw 8 .

[0025] The spray gun 1 has an air cap 11, shown in Figures 12a, 12b and 12c, by which the air cap 11 can be rotated to produce three different jets I, II and III, namely a horizontally oriented flat jet I, a round jet II and Vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com