Container shipping platform

A transport platform and container technology, applied in the field of container auxiliary transport devices, can solve the problems of inability to solve the problem of super-wide container hoisting, waste of equipment utilization, single purpose of stacking beam 4, etc., and achieve the effect of being convenient for independent transport and fork loading operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

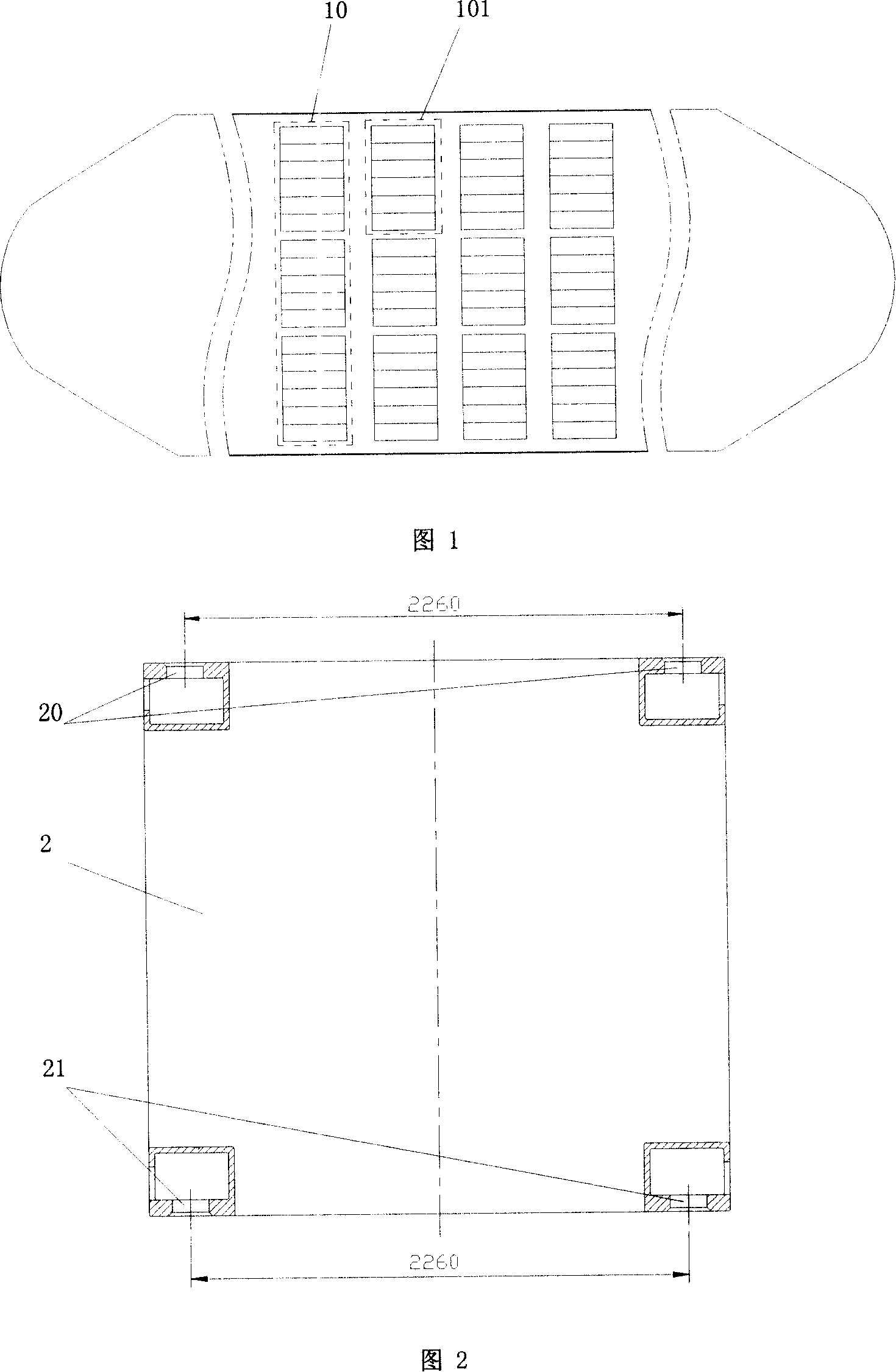

[0048] Fig. 7 and Fig. 8 show the first embodiment of the container transportation platform of the present invention. As shown in Figures 7 and 8, the container transport platform 5 (hereinafter referred to as the platform 5) includes end beams 51 arranged in parallel at both ends, an intermediate structure 50 connecting the two ends of the beams, and the lower surfaces of the two ends of the two ends of the beams 51. and the upper surface form a plane for stacking and matching with the container top corner fitting and the container bottom corner fitting respectively.

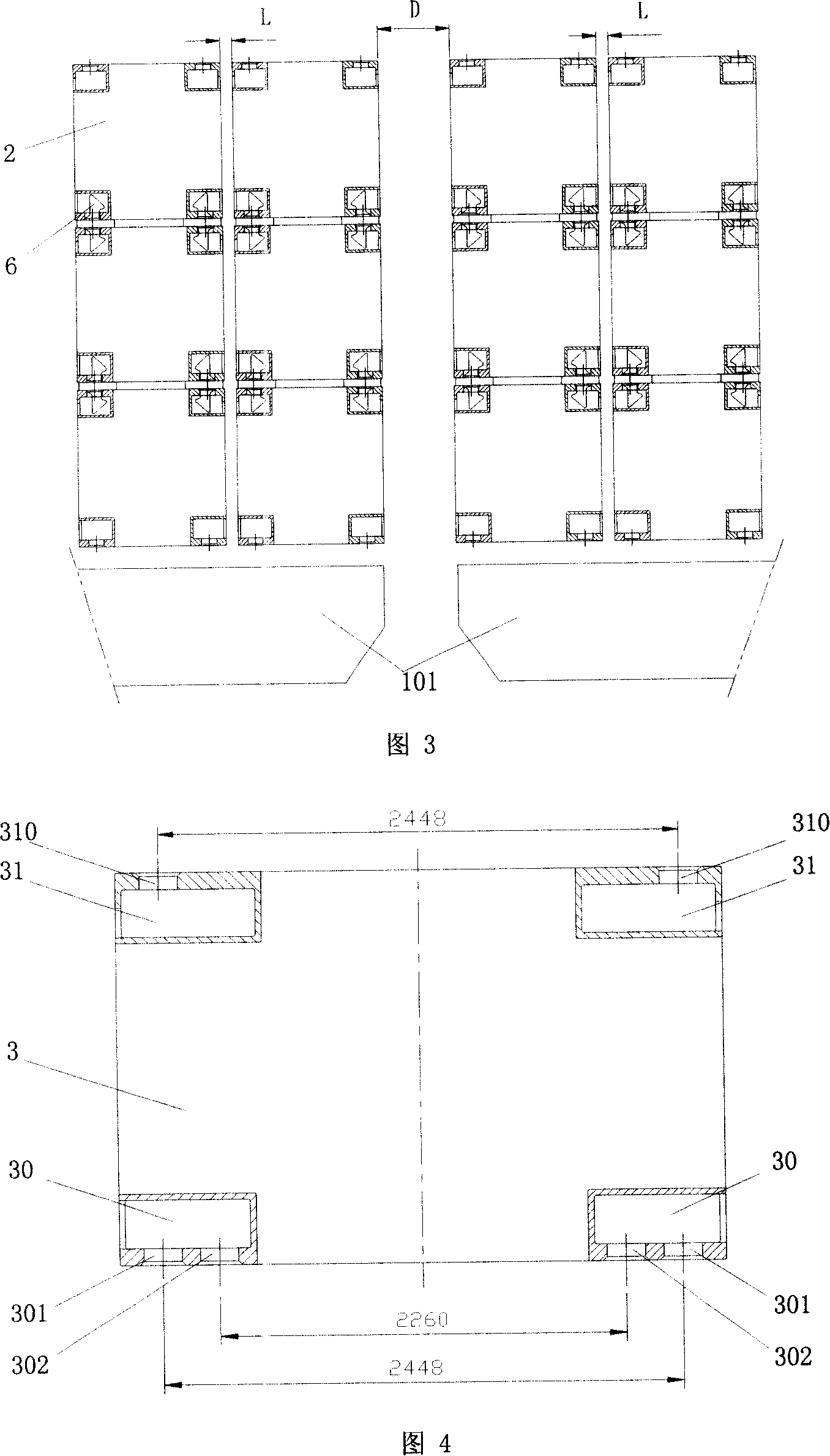

[0049] In order to avoid interference between platform 5 and containers on adjacent sides when stacking on a container ship, as shown in Figure 3, the maximum width of platform 5 is less than or equal to: standard container width+L+D=2438 mm+38 mm+365 mm= 2841 mm. In this embodiment, in order to meet the stacking, hoisting and transportation of ultra-wide boxes as shown in FIG. 4 , the width of the platform 5 ...

Embodiment 2

[0065] Fig. 16 shows the second embodiment of the container transportation platform 5 of the present invention. As shown in Figure 16, this embodiment is basically the same as Embodiment 1, the difference is that a pair of hanging holes 519 are respectively arranged on the lower surfaces of the beams 51 at both ends of the platform 5, and the hanging holes 519 are respectively symmetrical along the transverse direction of the platform 5. Set, and cooperate with the stacking holes of the top corner pieces at the 40-foot positions at both ends of the standard container, that is, the center-to-center distance of the hanging holes 519 is 2260 mm. Within the tolerance range allowed by container manufacturing, the center-to-center distance of the hanging holes 519 It can be selected between greater than or equal to 2254 mm and less than or equal to 2262 mm. The shape and size of the hanging hole 519 meet the requirements for cooperation with the container bolt lock.

[0066] In thi...

Embodiment 3

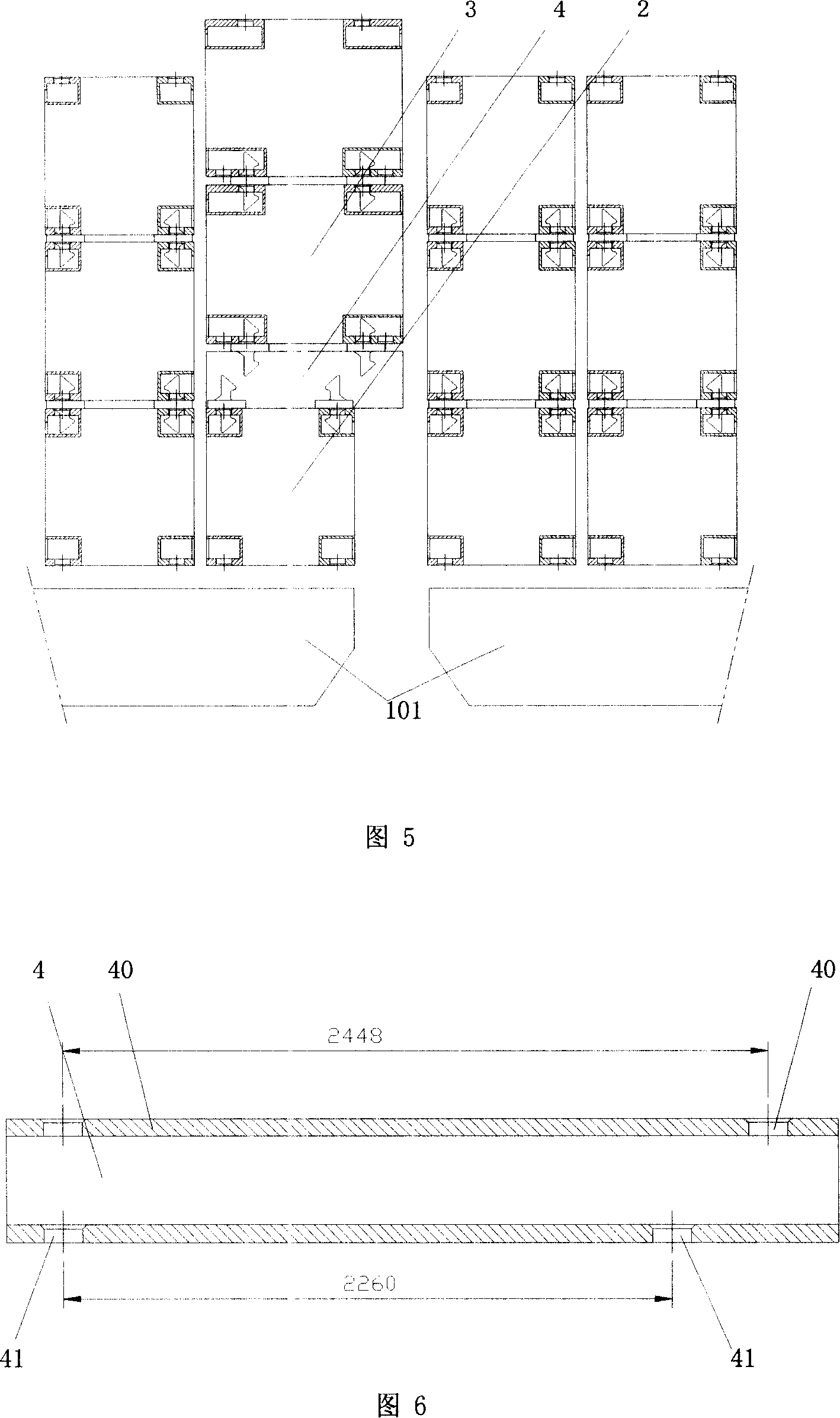

[0069] Fig. 18 shows the third embodiment of the container transport platform 5 of the present invention. The container transport platform 5 of this embodiment meets the hoisting requirements of the ultra-wide container 8 shown in Fig. 19 and the stacking requirements with the standard container 2 on a container ship.

[0070] As shown in Figure 19, the bottom corner piece 80 of the ultra-wide box 8 is only provided with a pair of stacking holes 801 with a center distance of 2448 mm, and the top corner piece 81 is provided with a pair of operation holes 810 with a center distance of 2448 mm.

[0071] As shown in Figure 18, this embodiment is basically the same as Embodiment 1, the difference is that a pair of stacking holes 518 are respectively provided on the upper surfaces of the beams at both ends of the platform 5, and the pair of stacking holes 518 are located on a pair of Outside the hoisting hole 510, it matches with the stacking hole 801 of the ultra-wide corner piece a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com