Anti-vibrating cavitation performance evaluation device of engine coolant

A technology of engine coolant and evaluation device, which can be used in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., and can solve problems such as damage to dry cylinder liners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

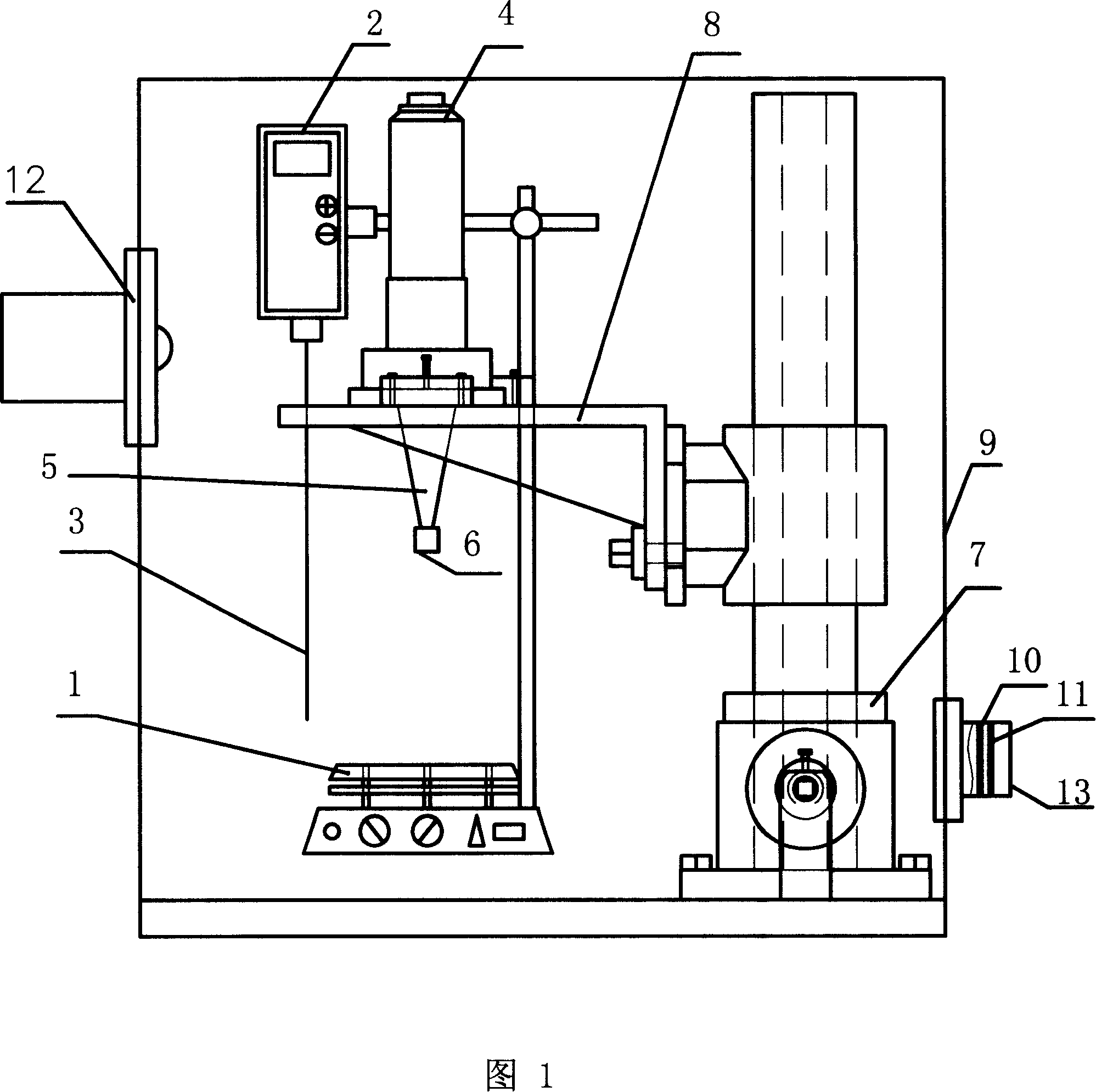

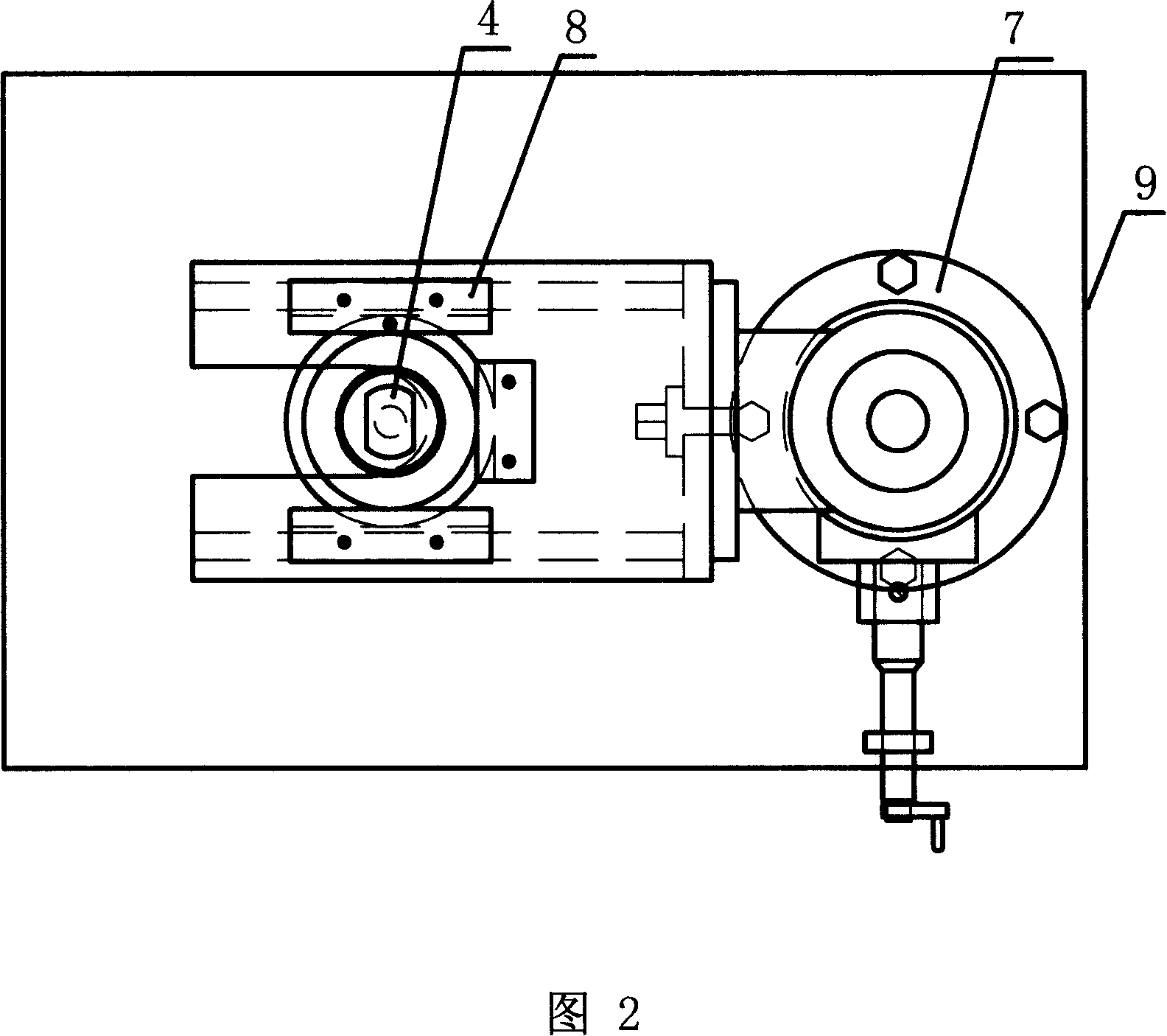

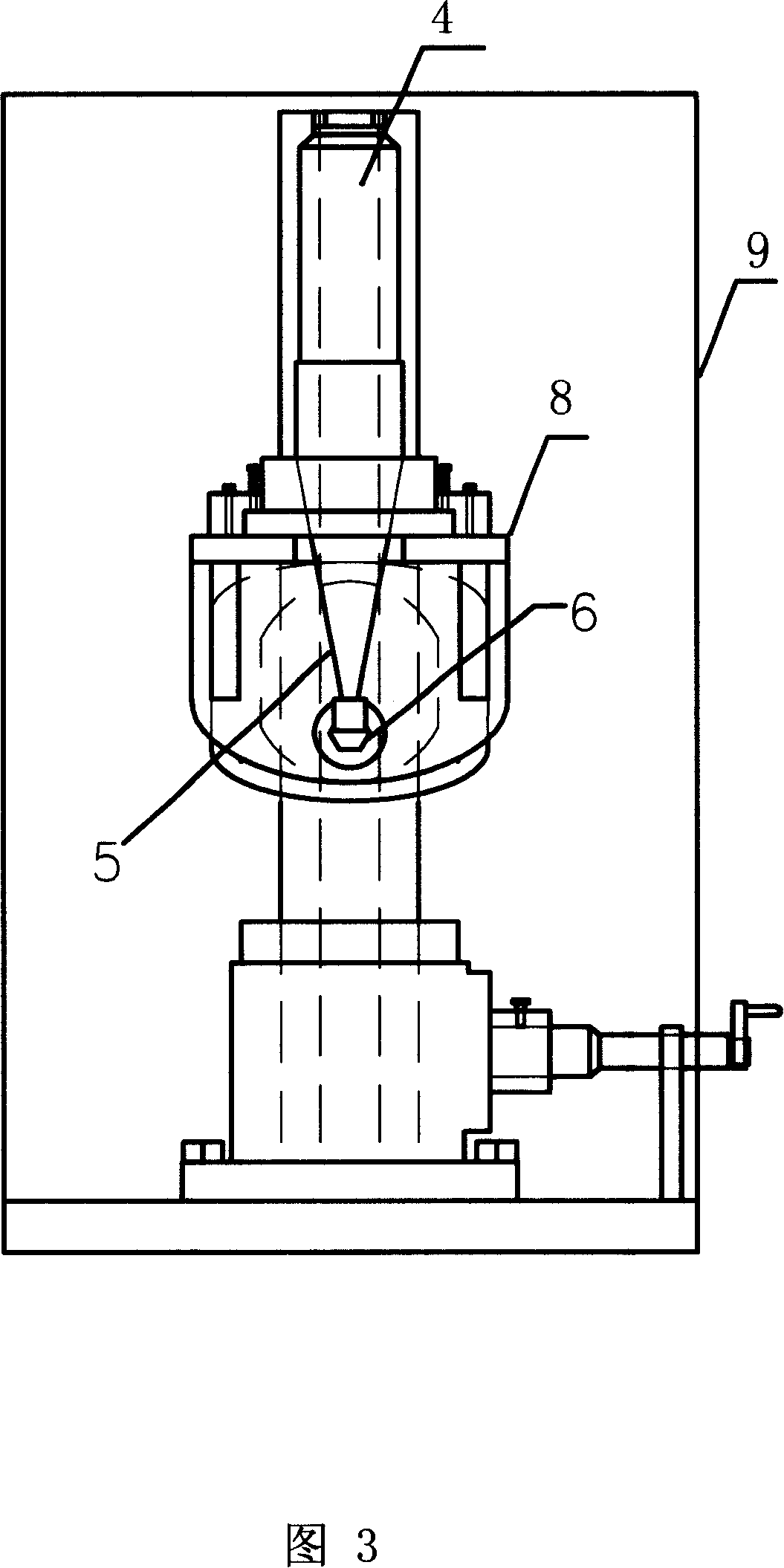

[0019] With reference to accompanying drawing 1,2 and 3, engine coolant anti-vibration cavitation performance evaluation device of the present invention comprises a tested solution heating device 1 (being an electric heating plate), and tested solution is placed on tested solution heating device 1 and carries out heating. A cavitation test device and a temperature control device 2 are placed above the test solution heating device 1 . The temperature control device 2 is integrated with the test solution heating device 1 through a fixed bracket. The temperature control device is equipped with a temperature sensor 3 , the temperature sensor 3 senses the temperature of the test solution, and transmits the temperature signal to the temperature control device 2 . The temperature control device 2 converts the temperature signal into a digital signal for processing. When the test solution was heated to 80 degrees by the test solution heating device 1, the temperature control device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com