Polarizing plate sticking device

A technology of sticking device and polarizer, applied in nonlinear optics, instruments, optics, etc., can solve problems such as obstacles and shorten production time, and achieve the effect of miniaturization and simplification of composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

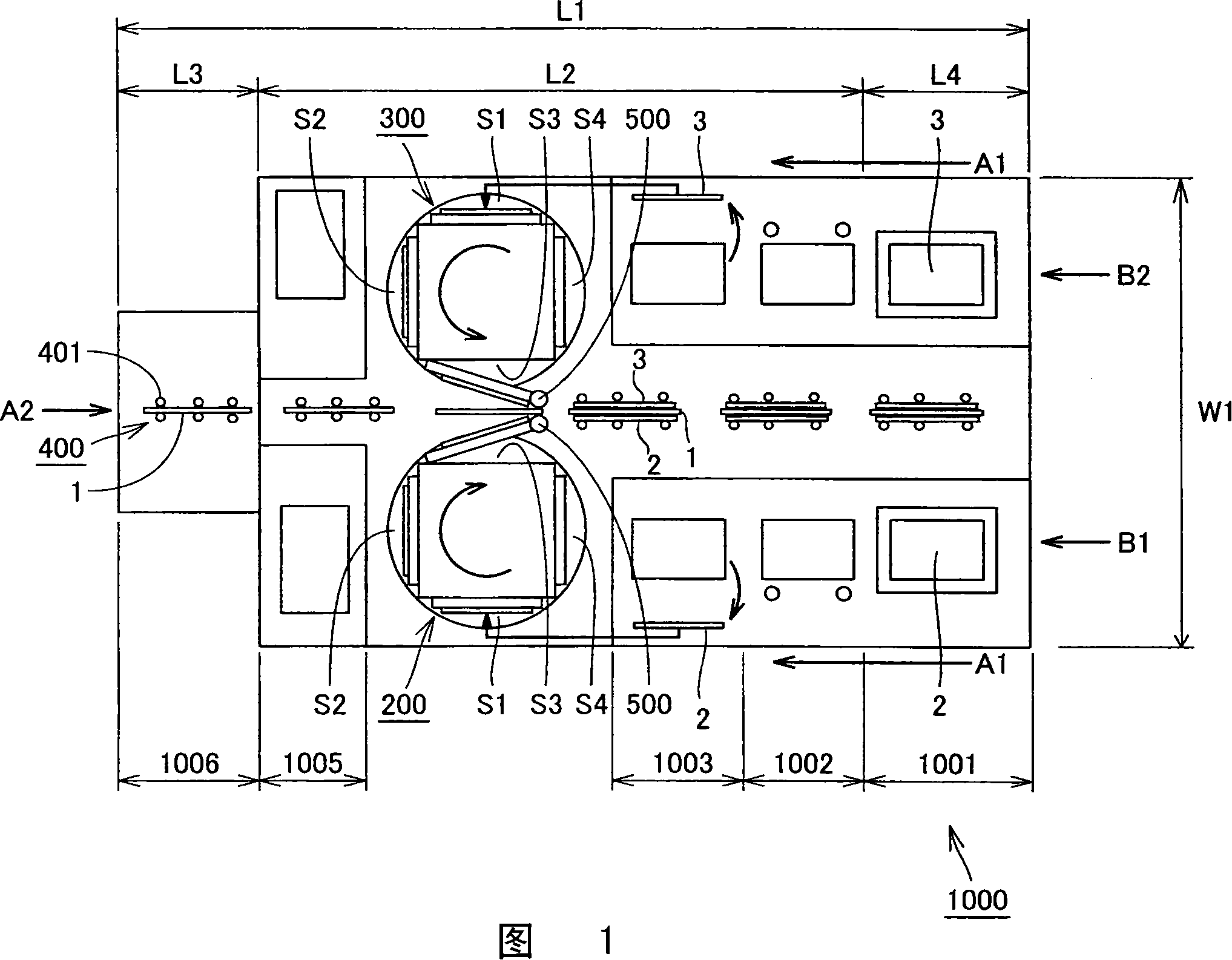

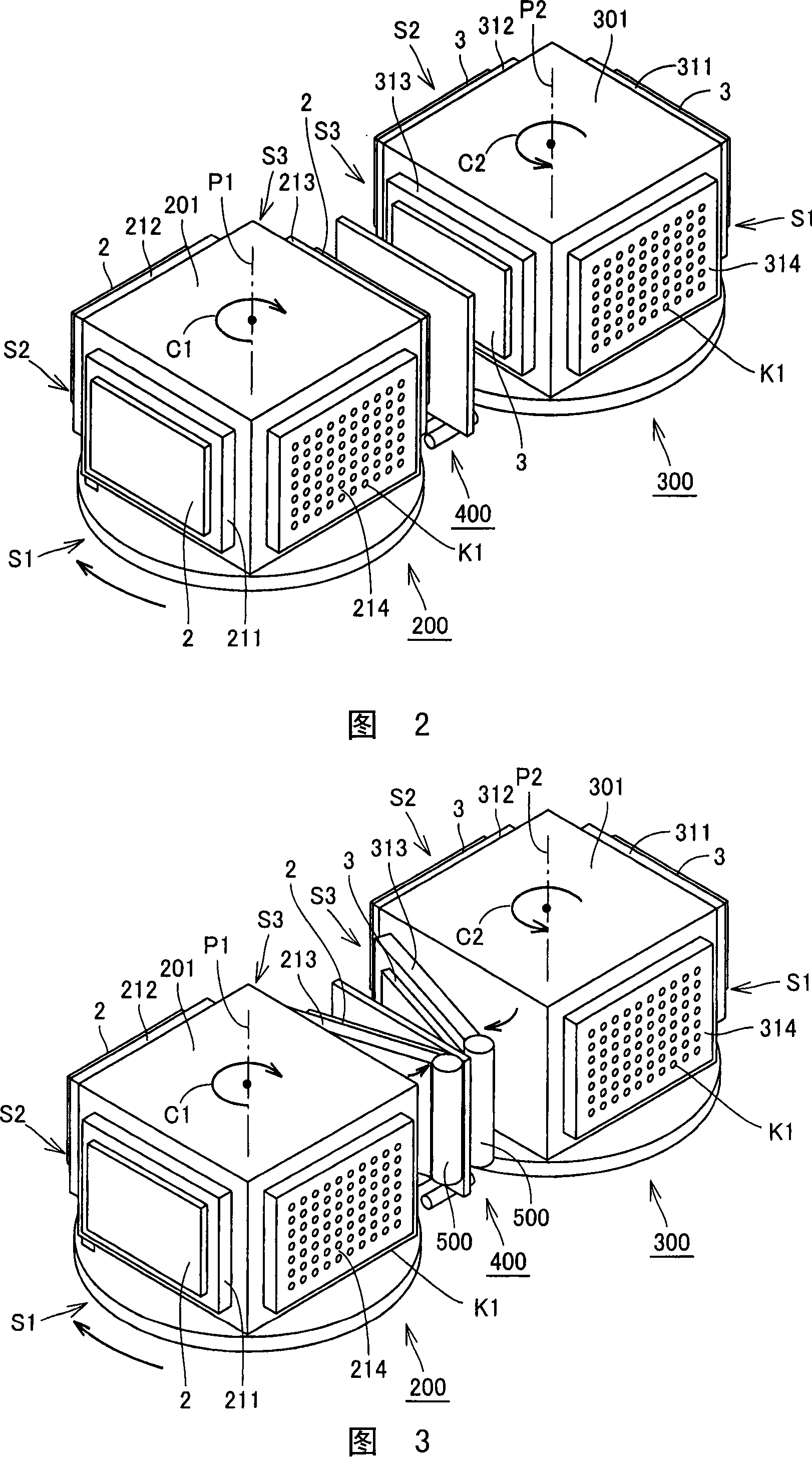

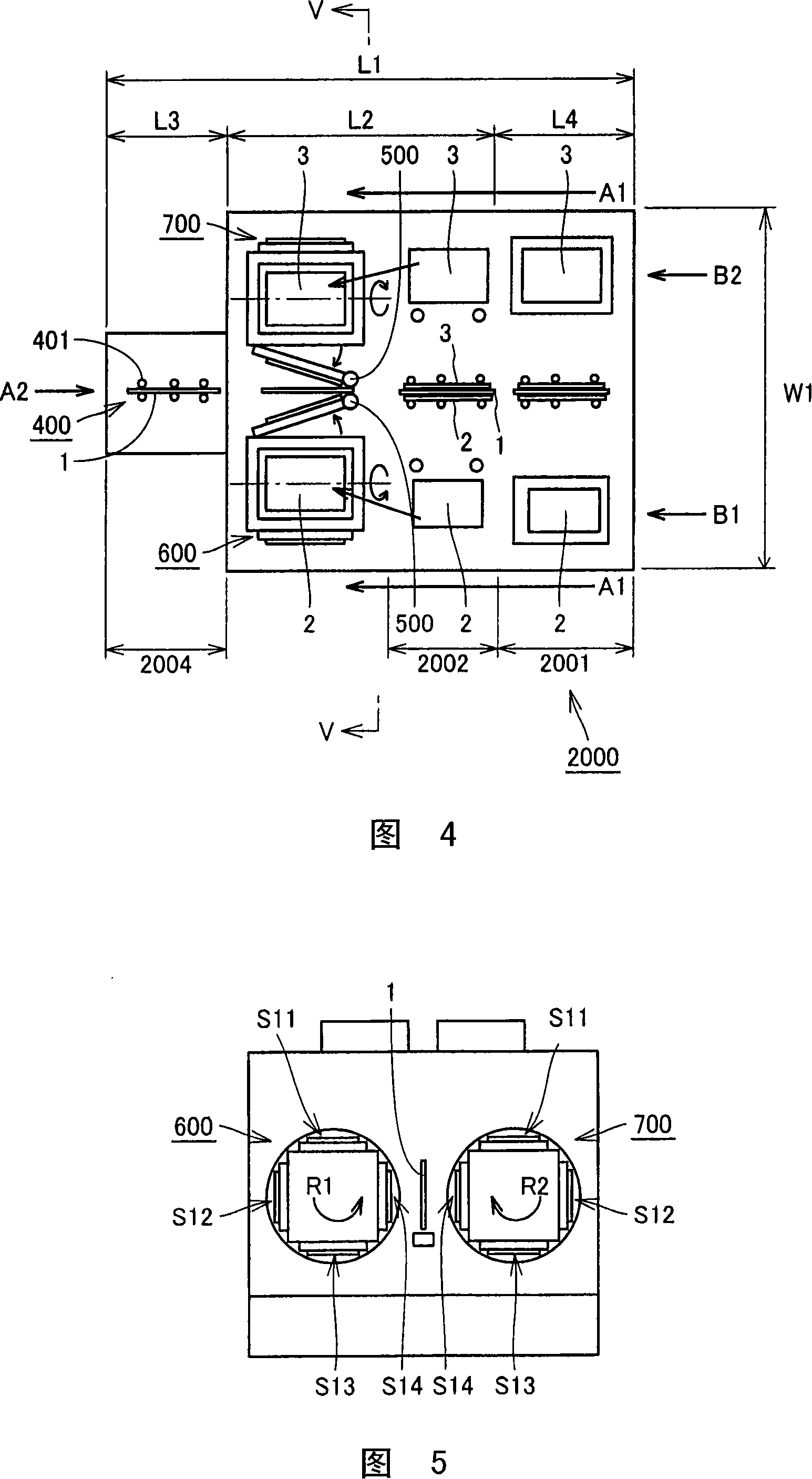

[0033]Next, a polarizer sticking device according to an embodiment of the present invention will be described with reference to the drawings. First of all, Figures 1 to 3 show the inventors of the present application on the basis of the polarizing plate sticking device disclosed in the above-mentioned prior art document 1, and through the development process of the polarizing plate sticking device of the present invention. The polarizer sticking device. Fig. 1 is a plan view showing the overall structure of a polarizer sticking device 1000 in the reference technology, and Fig. 2 is a first polarizer sticking device 200 and a second polarizer sticking device 1000 used in the reference technology The first perspective view showing the configuration of the device 300, FIG. 3 is a second perspective view showing the configurations of the first polarizing plate bonding device 200 and the second polarizing plate bonding device 300 used in the polarizing plate bonding device 1000 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com