Method and circuit for dual PWM mixed cut wave control switch part

A control circuit and control switch technology, applied in the field of control, can solve the problems of poor turn-on continuous regulation performance, large turn-on regulation dead zone, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

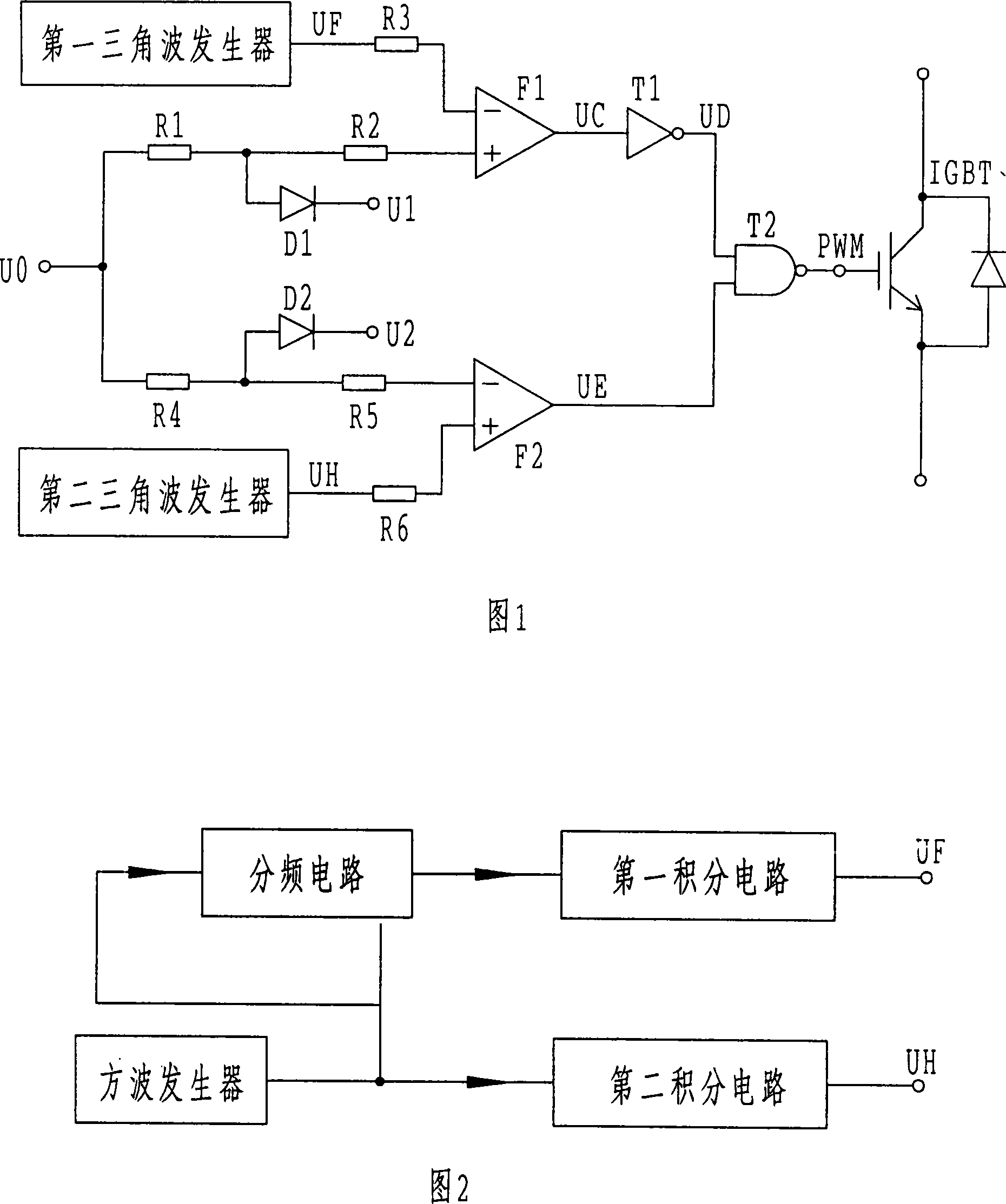

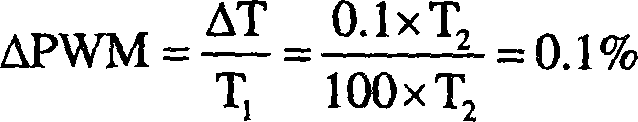

[0016] Referring to Fig. 1, the present invention adopts two main and auxiliary PWM chopper circuits to control the IGBT at the same time. In the auxiliary PWM chopper circuit, the given adjustment input U0 is sequentially connected to the positive direction of the operational amplifier F1 through the resistance R1 and the resistance R2. At the input terminal, the anode of the limiting diode D1 is connected to the series connection point of the resistor R1 and the resistor R2, and the cathode is connected to the limiting voltage U1, and the output terminal of the first triangular wave generator is connected to the reverse input terminal of the operational amplifier F1 after passing through a coupling resistor R3. The output terminal of the operational amplifier F1 is connected to an input terminal of the NAND gate T2 after passing through the NOT gate T1; in the main PWM chopper circuit, the given adjustment input value U0 is connected to the reverse input of the operational amp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com