Yarn processing system and controlled yarn tension device

A yarn brake, processing system technology, applied in the direction of transportation and packaging, textile and paper, thin material handling, etc., to achieve the effect of compact form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

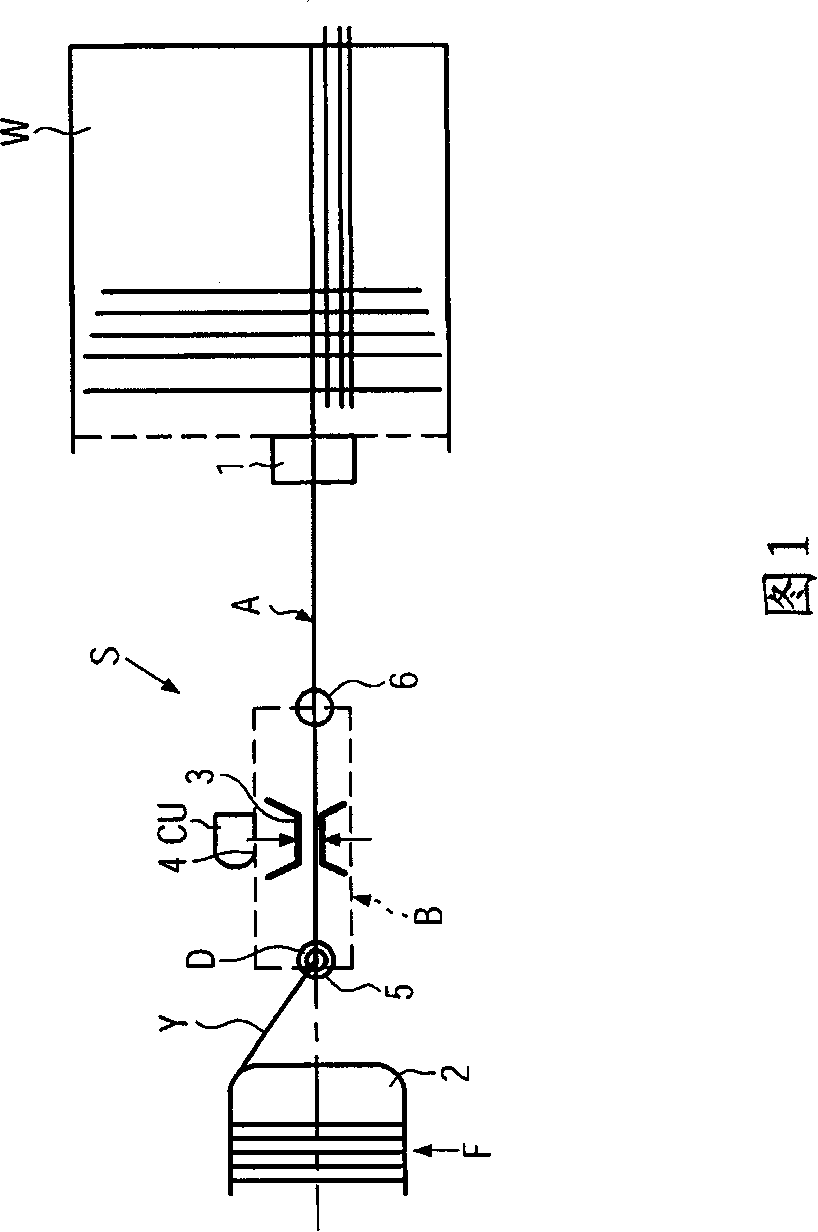

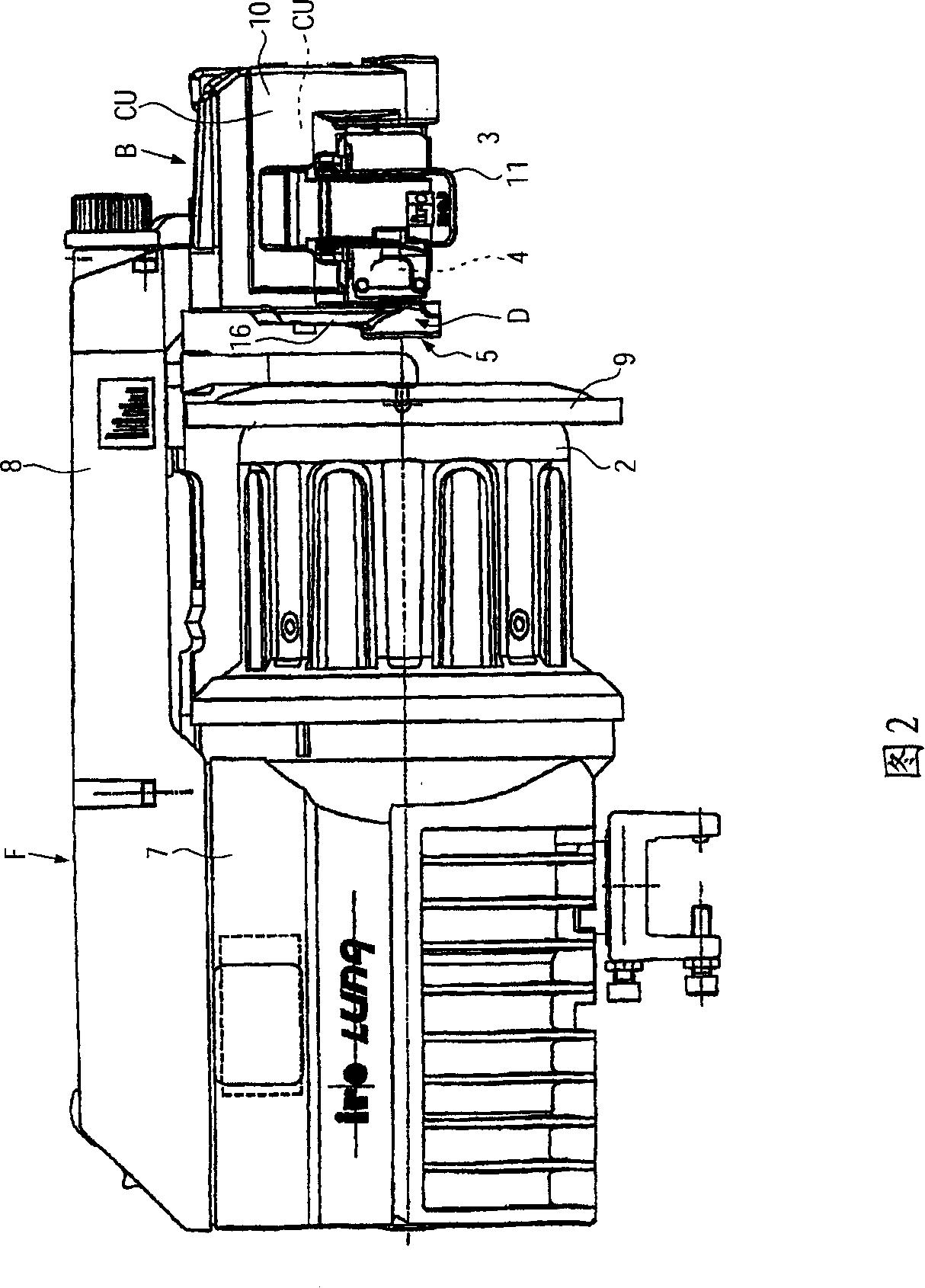

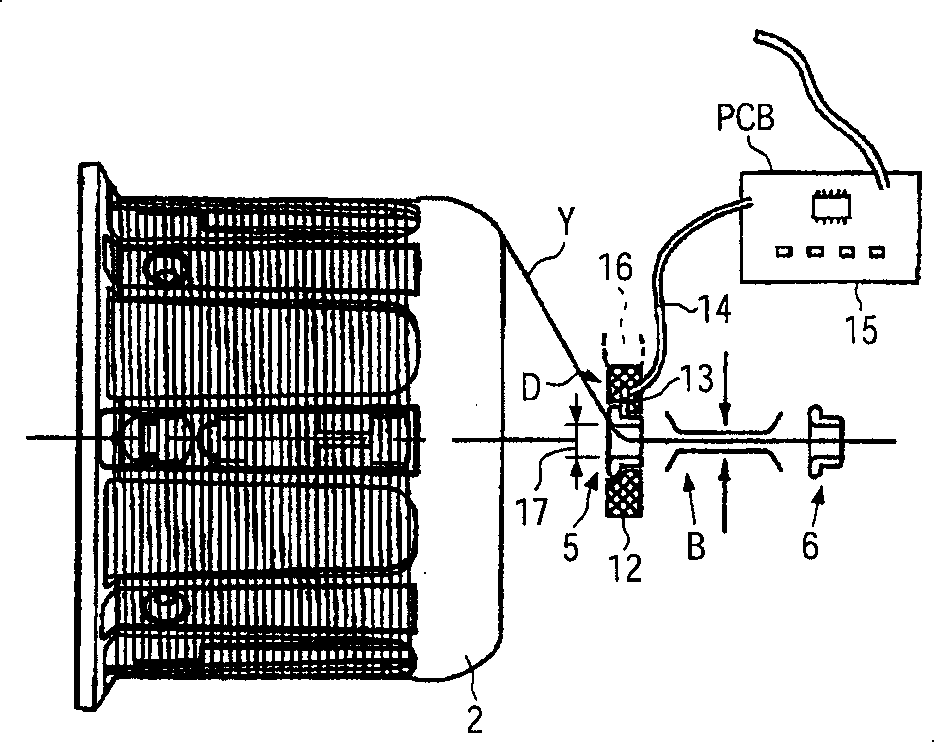

[0022] Figure 1 shows a yarn processing system S comprising a weaving machine W with at least one yarn channel A, in which a yarn feeding device F and a controllable yarn brake B are installed, which Installed downstream of the yarn path from the yarn feeding device F to the yarn feeding system 1 of the loom W. In addition, a piezoelectric weft detector D is set in the yarn path, and its function is to generate an error detection signal when the yarn feeding system 1 is interrupted or wireless, so that the yarn processing system suspends work, thereby avoiding or reducing Yarn defect. The general operating principle of the weft yarn detector D is that the error detection signal is generated by the difference between the yarn movement and the yarn stop, and the yarn must be in a moving state when the error detection signal occurs.

[0023] The loom W may be a projectile loom or a rapier loom. The yarn feeding device F is a yarn feeding device with a top unwinding device of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com