Composition for resin

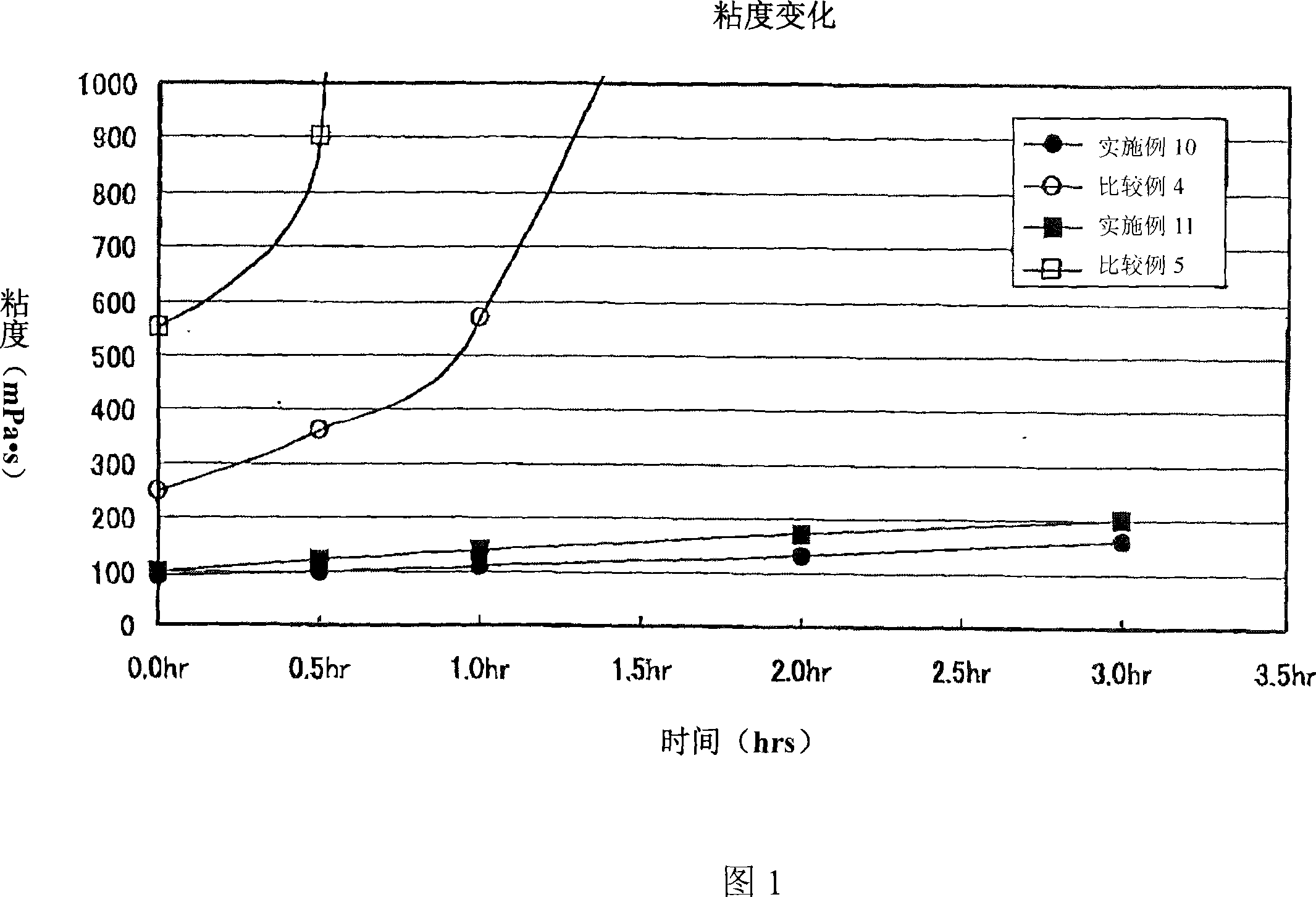

一种固化性组合物、化合物的技术,应用在仪器、眼镜/护目镜、光学等方向,能够解决组合物粘度上升、铸型聚合操作困难、粘度上升等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

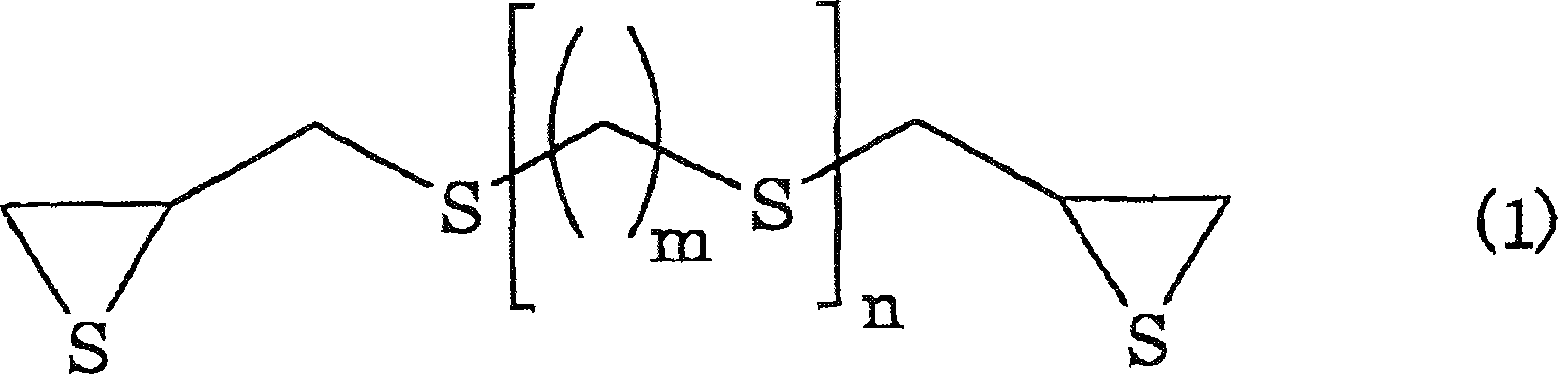

[0155] 20 parts by weight of sulfur (A1) as inorganic compound A and 80 parts by weight of bis(β-epithiopropyl)sulfide (B1) as compound B were fully mixed at 65° C. to be uniform. Then, 0.5 parts by weight of 2-mercapto-1-methylimidazole (prepolymerization catalyst) was added, and prepolymerization was performed at 60° C. for about 1 hour until the refractive index (20° C.) of the reaction system became 1.679. After cooling at 20°C, to the obtained composition were added 5 parts by weight of benzylmercaptan (C1) as compound C, 0.03 parts by weight of triethylbenzyl ammonium chloride (polymerization catalyst), and 0.2 parts by weight of The solution of di-n-butyltin dichloride (polymerization regulator), mix thoroughly and evenly. The obtained curable composition was degassed at 10 Torr and 20° C. for 10 minutes. The obtained degassing curable composition was filtered through a 0.5 μm PTFE membrane filter, and injected into a flat-plate mold having a thickness of 2.5 mm consis...

Embodiment 2-3

[0157] Example 1 was repeated except that the amount of compound C (C1) was varied. Table 1 shows the results of each evaluation.

Embodiment 4-9

[0159] Example 1 was repeated except that the species of compound C was changed. Table 1 shows the results of each evaluation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com