High-efficiency feedwater coagulating sedimentation pool

A technology for coagulation and sedimentation tank and water supply, which is used in sedimentation separation, sedimentation tank, chemical instruments and methods, etc., can solve the problems of water quality not meeting the required standards, increased treatment costs, and out of control water quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

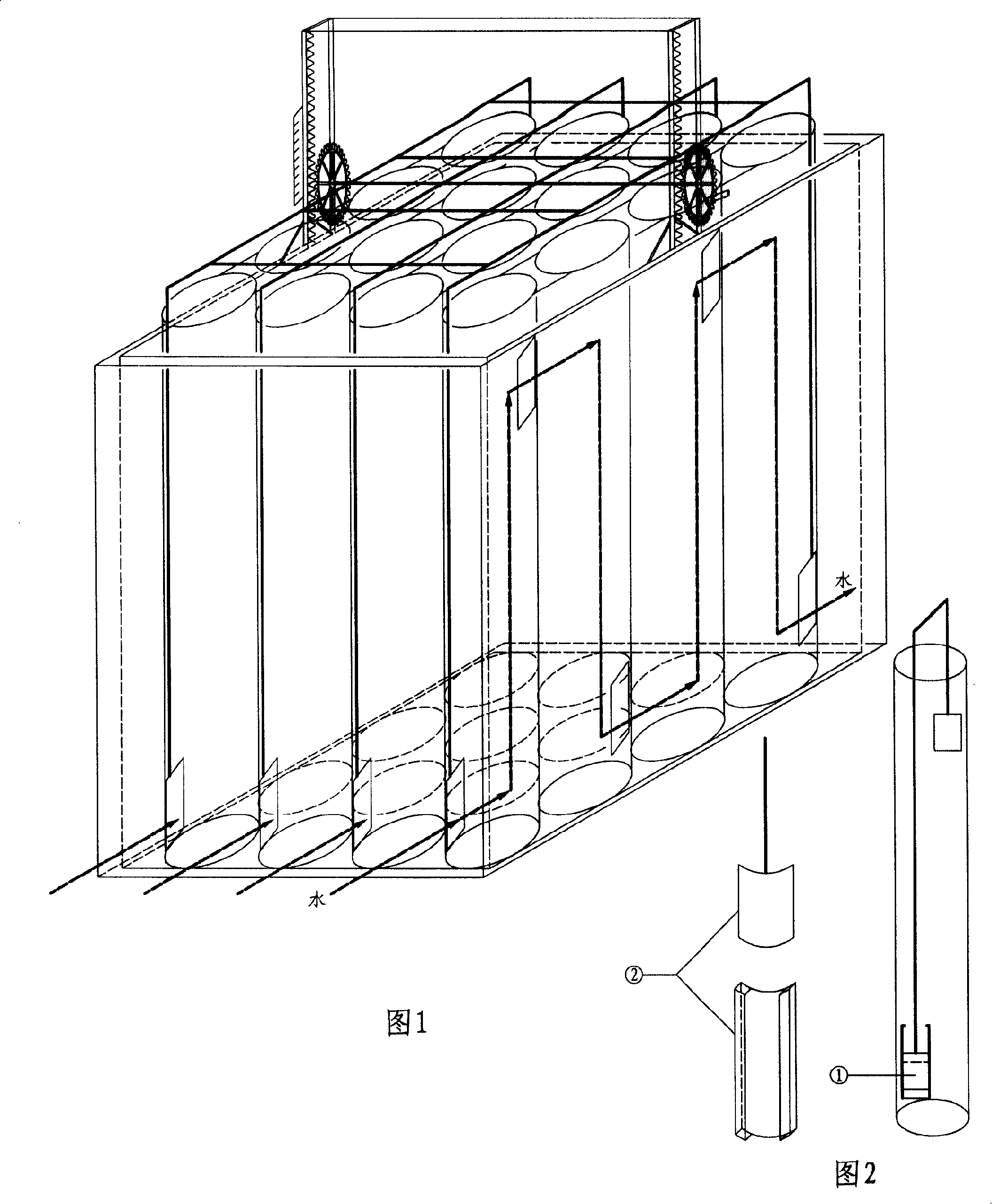

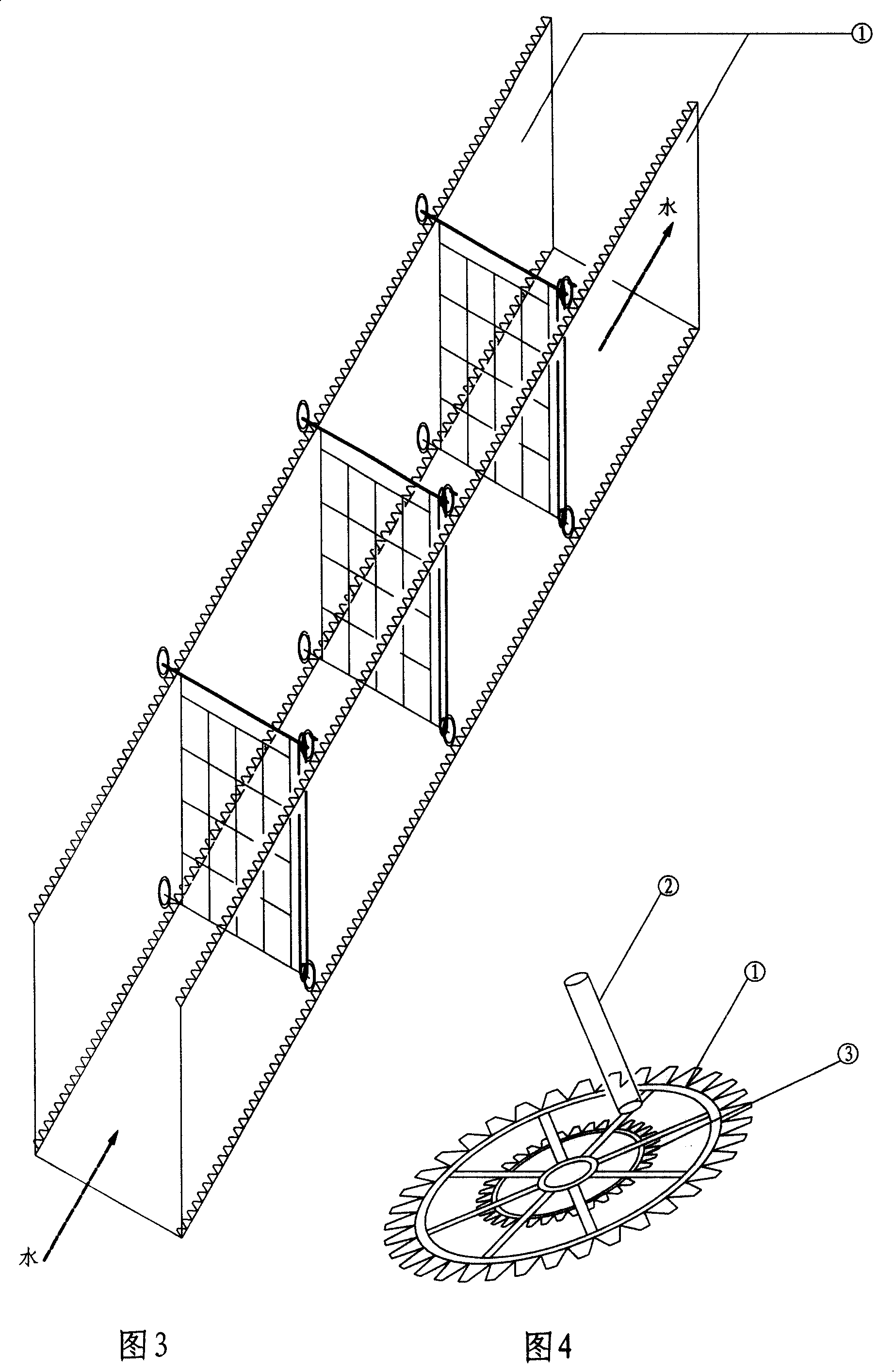

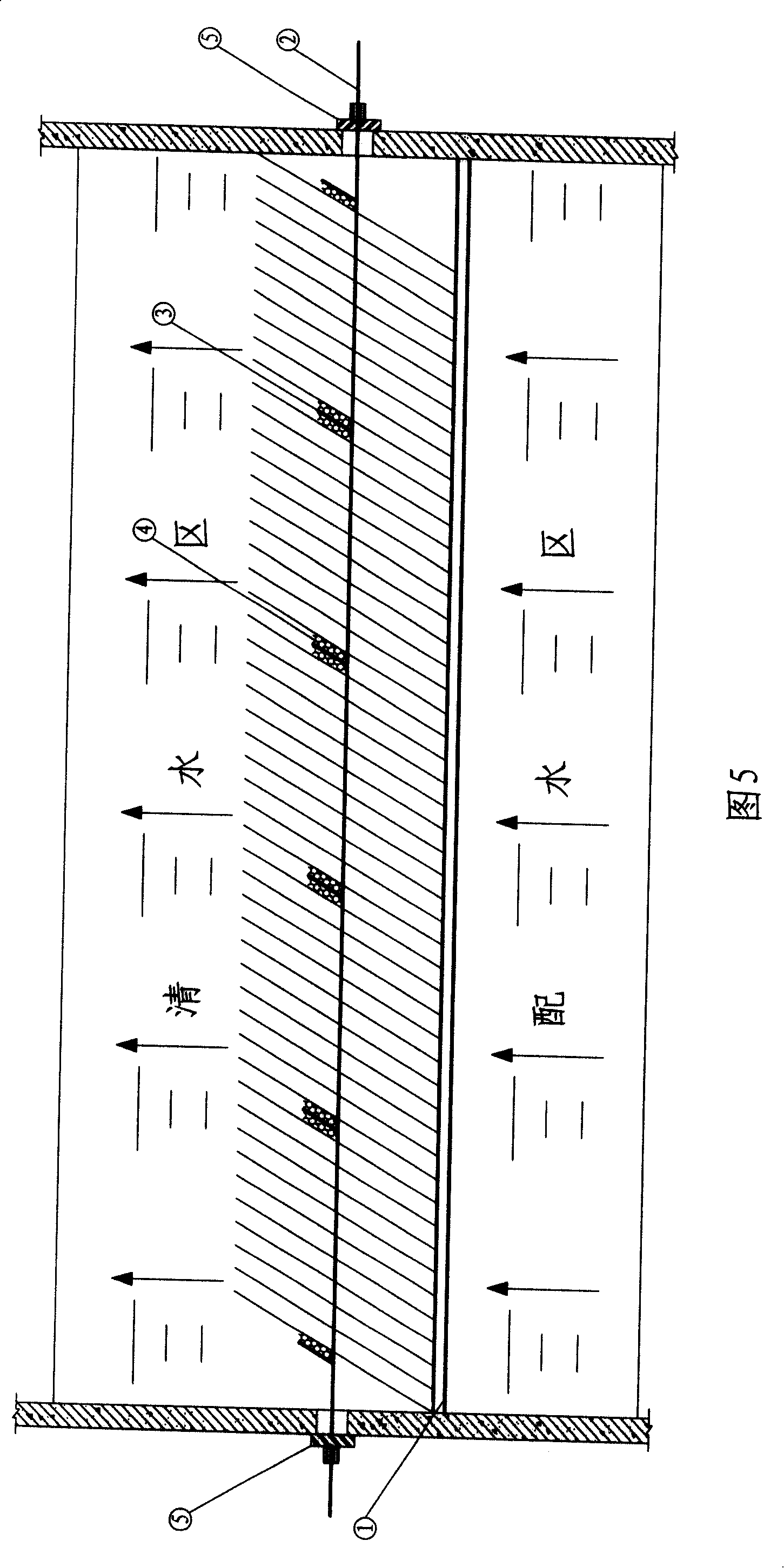

[0013] As shown in Figure 1, the volume-adjusting and speed-regulating cylinder mixing device has several monomer mixing cylinders with variable-sized water inlets and outlets connected in series, and multiple groups can be connected in series according to the amount of water to be treated. The mixing cylinders are connected in parallel to form a mixer; as shown in Figure 2, according to the size of the water intake, the single cylinder water inlet 1 and the water outlet can be used to adjust the gate device 2 to make the adjustment gate rise or fall at the same time, thereby controlling the size of the water inlet and outlet According to the amount of water inflow and the flow rate of the water body in the cylinder, the size of the water intake is controlled by the scale scale attached to the adjustment gear, so that the medicine added to the cylinder mixer can fully contact with the water entering the cylinder mixer, and the mass transfer of the water body can be improved. Ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com