Cathode active material for lithium ion secondary battery, its making method and lithium ion secondary battery including this cathode active material

A negative electrode active material, secondary battery technology, used in secondary batteries, electrode manufacturing, battery electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

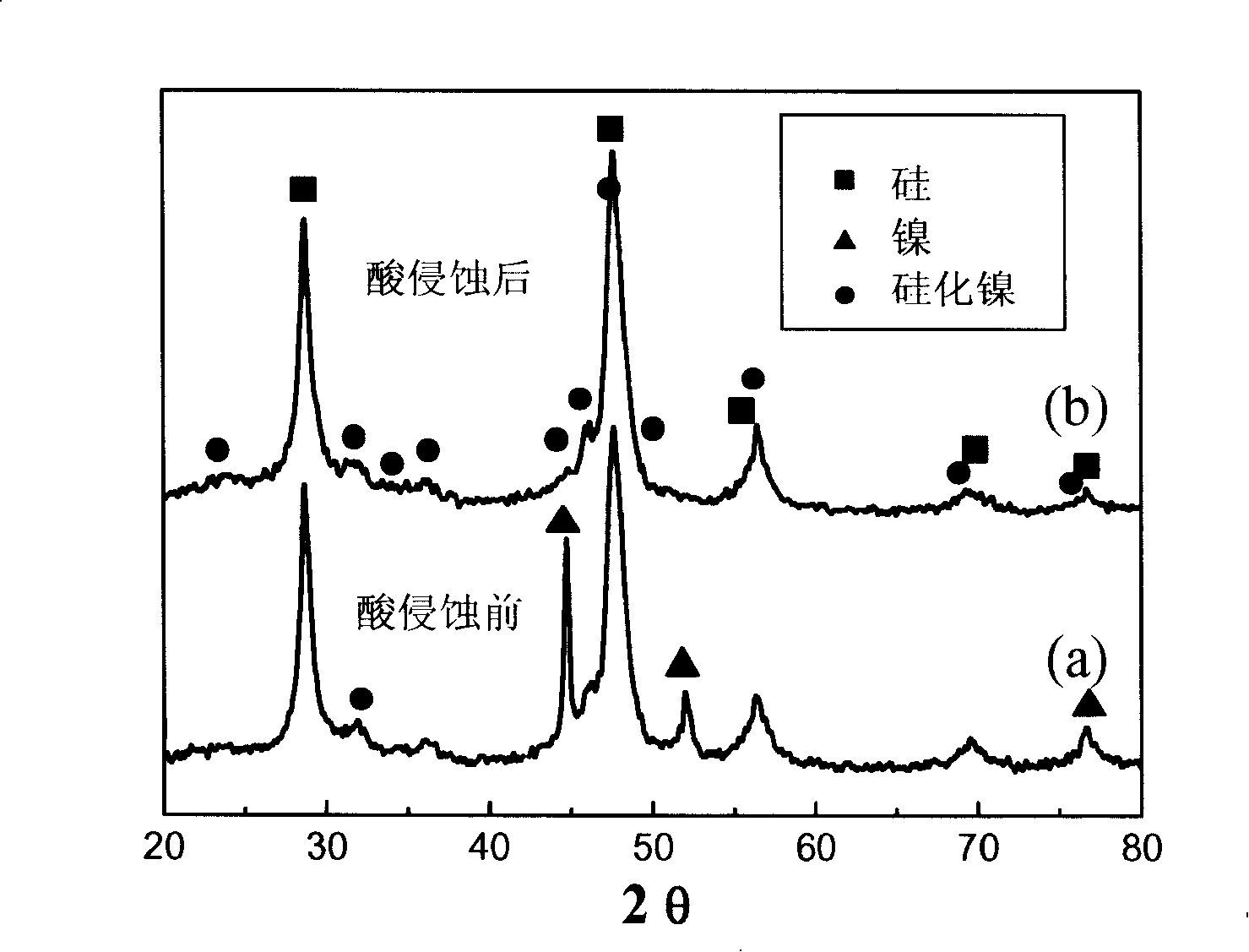

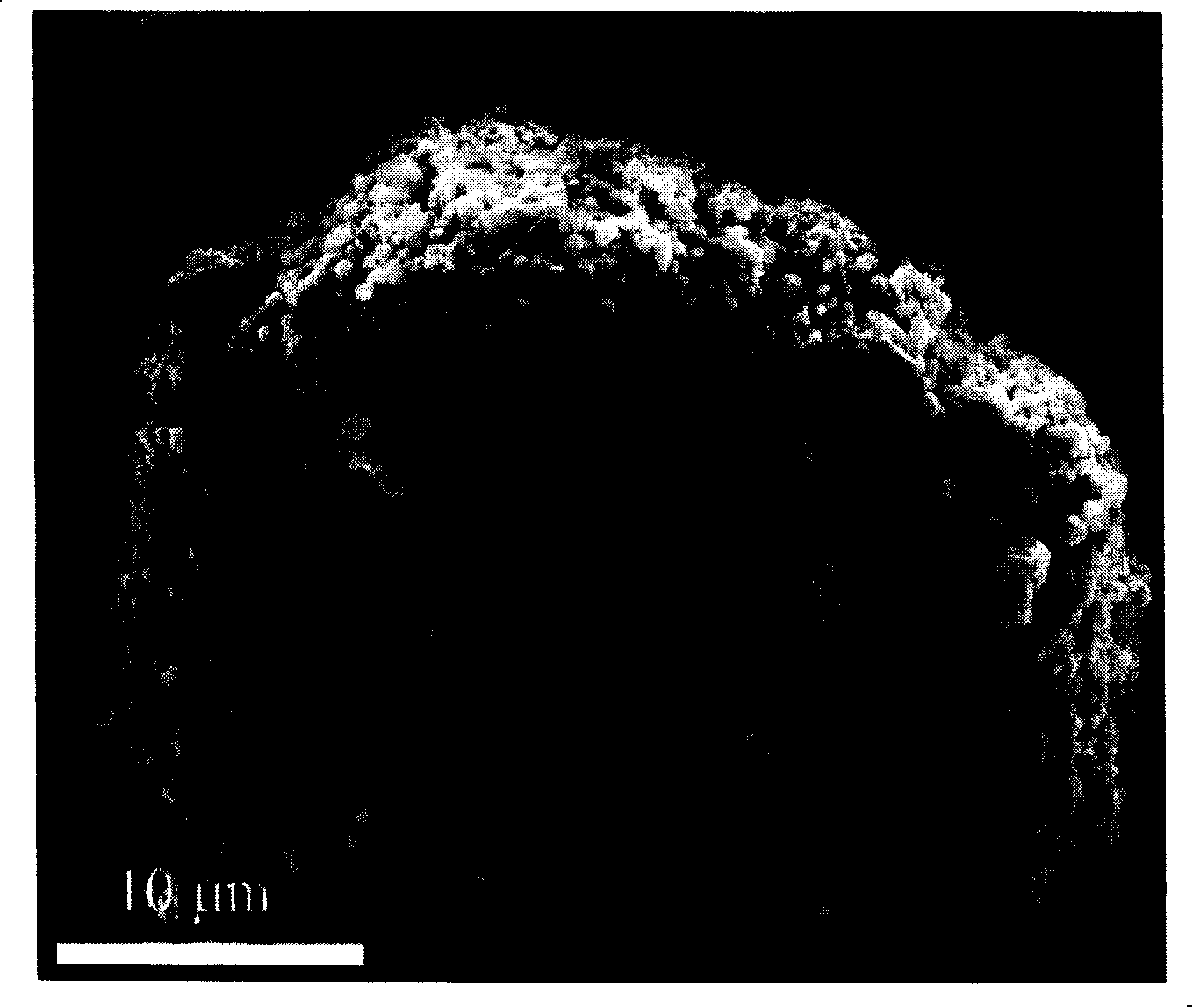

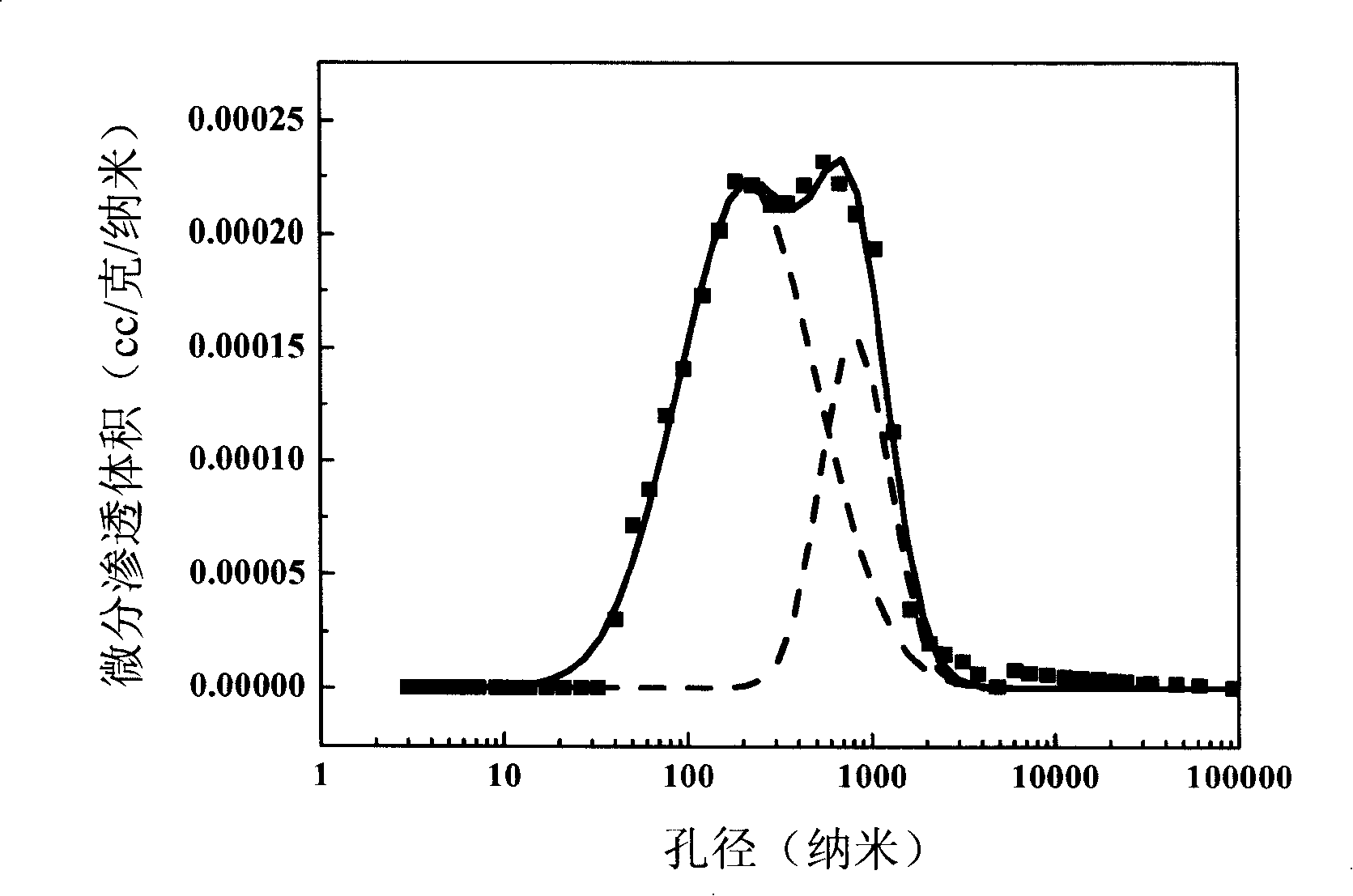

[0031] Add high-purity elemental powder silicon (99%, -325 mesh, Aldrich Company) and nickel (5 μm, CERAC Company) to mechanical alloying to synthesize alloy powder, wherein the molar ratio of silicon and nickel is 1 : 2. Mechanical alloying was carried out using a planetary mill (Pulverisette P7, Fritsch company) and stainless steel ball mill jars and balls in an argon (Ar) atmosphere, where the weight ratio of balls to powder was 14:1, and 0.5 % by weight of stearic acid [CH 3 (CH 2 ) 16 COOH] was added as a lubricant. After milling at 400 rpm for 16 hours, an intermediate product containing nickel, silicon, and nickel silicide was formed. The product obtained by milling was placed in 0.5 M nitric acid aqueous solution for 1 hour to etch away the nickel. The amount of nickel dissolved in the nitric acid aqueous solution was measured with an inductively coupled plasma (ICP) spectrometer (Optima, model 3000XL). Finally, the powder was separated from the nitric acid aqueo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap