Installation construction method for wind generator set on the sea

A wind power generation unit and hoisting technology, which is applied to the assembly of wind power generator components, wind power motor combinations, and wind power engines, and can solve problems such as high cost, long construction period, and high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

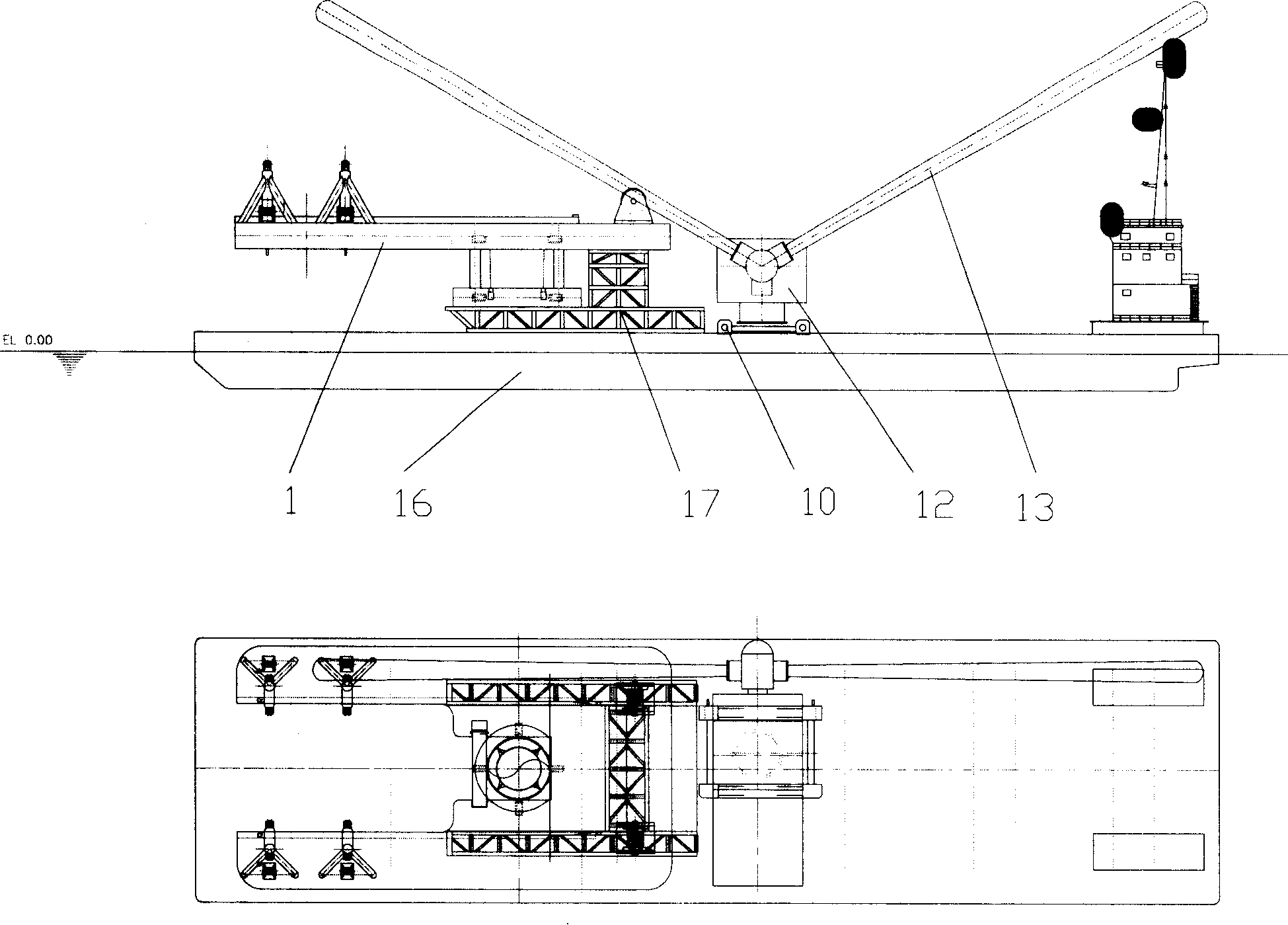

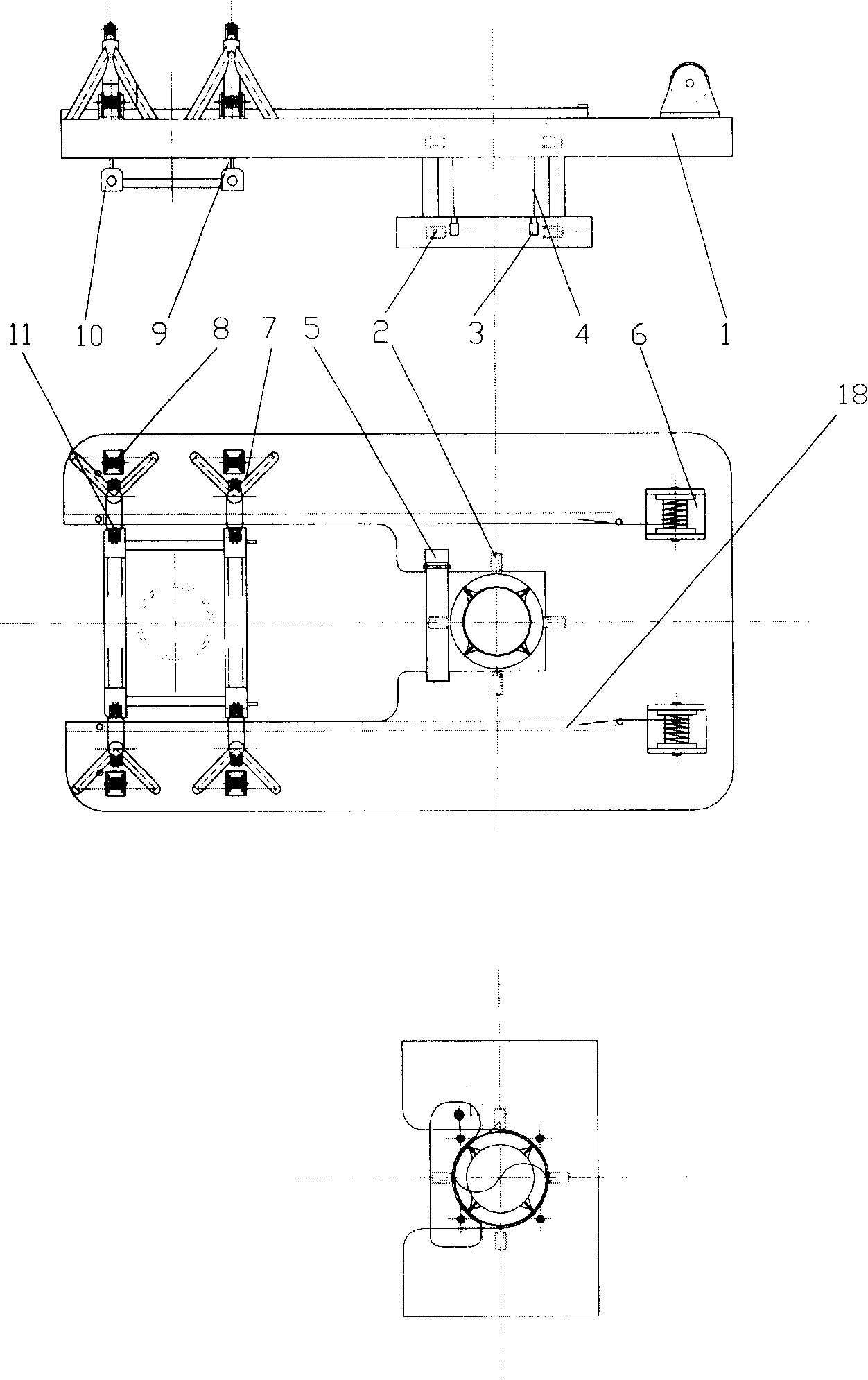

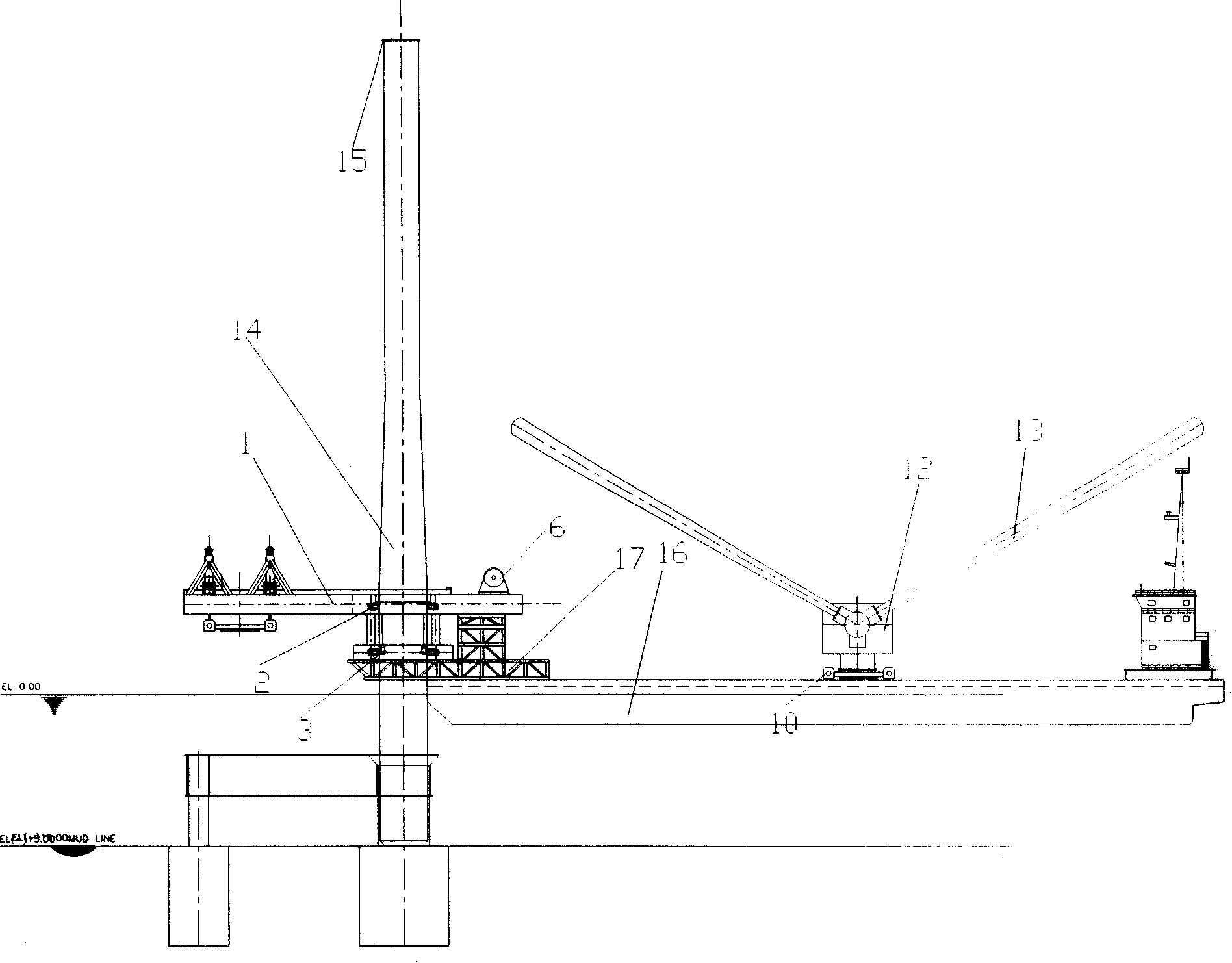

[0019] Wind turbine cabin (12) and blade (13) are hoisted on the special barge (16) and fixed at the wharf, as figure 1 . The offshore wind power generating set (12) and the jack-up wind generating set hoisting platform (1) are transported to the installed offshore wind tower body (14) by the special barge (16), and the special barge (16) will self-lift The hoisting platform (1) of the type wind power generating set is installed at the lower part of the wind tower body, and the top of the tower body is evenly distributed with four sets of hoisting points for lifting steel strands (4), and the steel strands pass through the four pulling points installed on the hoisting platform. Pull the lifting jack (3), such as image 3 . Start the hydraulically driven steel strand lifting jack (3), so that the hoisting platform (1) is lifted step by step to the top of the wind tower body, the rotating beam (5) is closed and locked, and the eight locking cylinders (2) on the hoisting platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com