Hoist-transportation machine track plain relationship and relative height difference measuring method

A technology for lifting and transporting machinery and measuring methods, which is applied in transportation and packaging, measuring devices, instruments, etc., can solve problems such as hidden dangers of measurement safety operation, and achieve the goal of reducing measurement operators, eliminating hidden dangers of safety accidents, and shortening measurement operation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

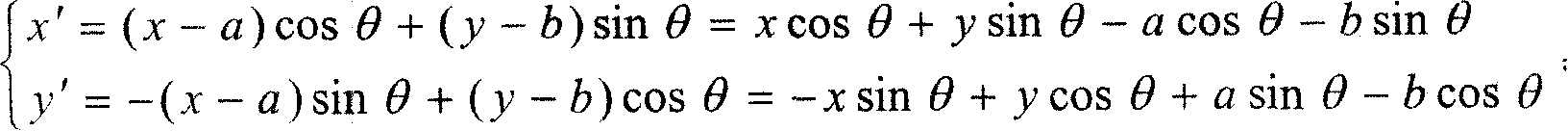

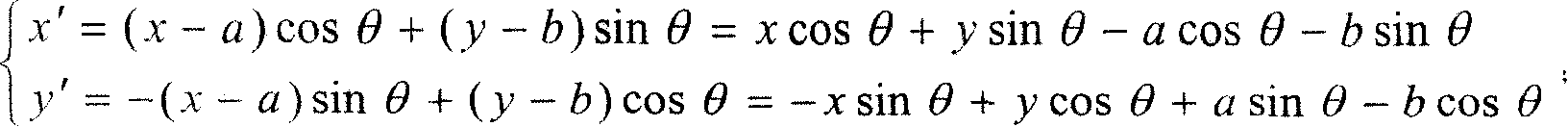

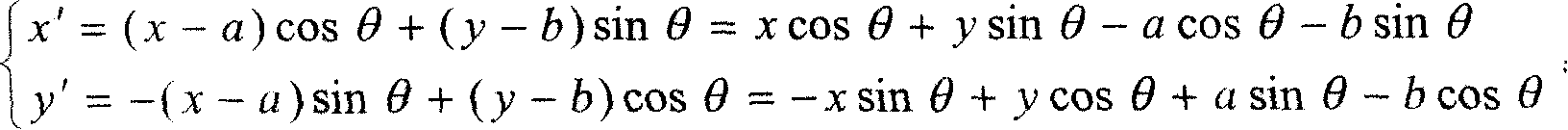

[0037] A method for measuring the plane relationship and the relative height difference between the tracks of a hoisting and transporting machine, which includes the measurement of the plane relationship and the relative height difference, and includes the following steps,

[0038] Step 1, arbitrarily set two prisms as common reference points G and H between the tracks;

[0039] Step 2, set up a total station on the head end C of a track A, and set up a measuring point prism that can move along the track on the track;

[0040] Step 3, make the measuring point prism move along the track from the head end C to the tail end E, and the total station measures and records the three-dimensional coordinates (x a 、y a ,z a ); while referring to the relative position space coordinates (Gx c 、Gy c 、Gz c ) and (Hx c 、Hy c 、Hz c );

[0041] Step 4: Set up the total station and the measuring point prism at the head end D of another track B, so that the measuring point prism moves a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com