Continuously casting disconnecting device

A technology of cutting device and hydraulic device, applied in the field of continuous casting cutting device, can solve the problems of uncontrollable control method, hindering continuous casting cutting function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] A preferred embodiment of the continuous casting cutting device according to the present invention will be described below with reference to the drawings.

[0045] Embodiment 1

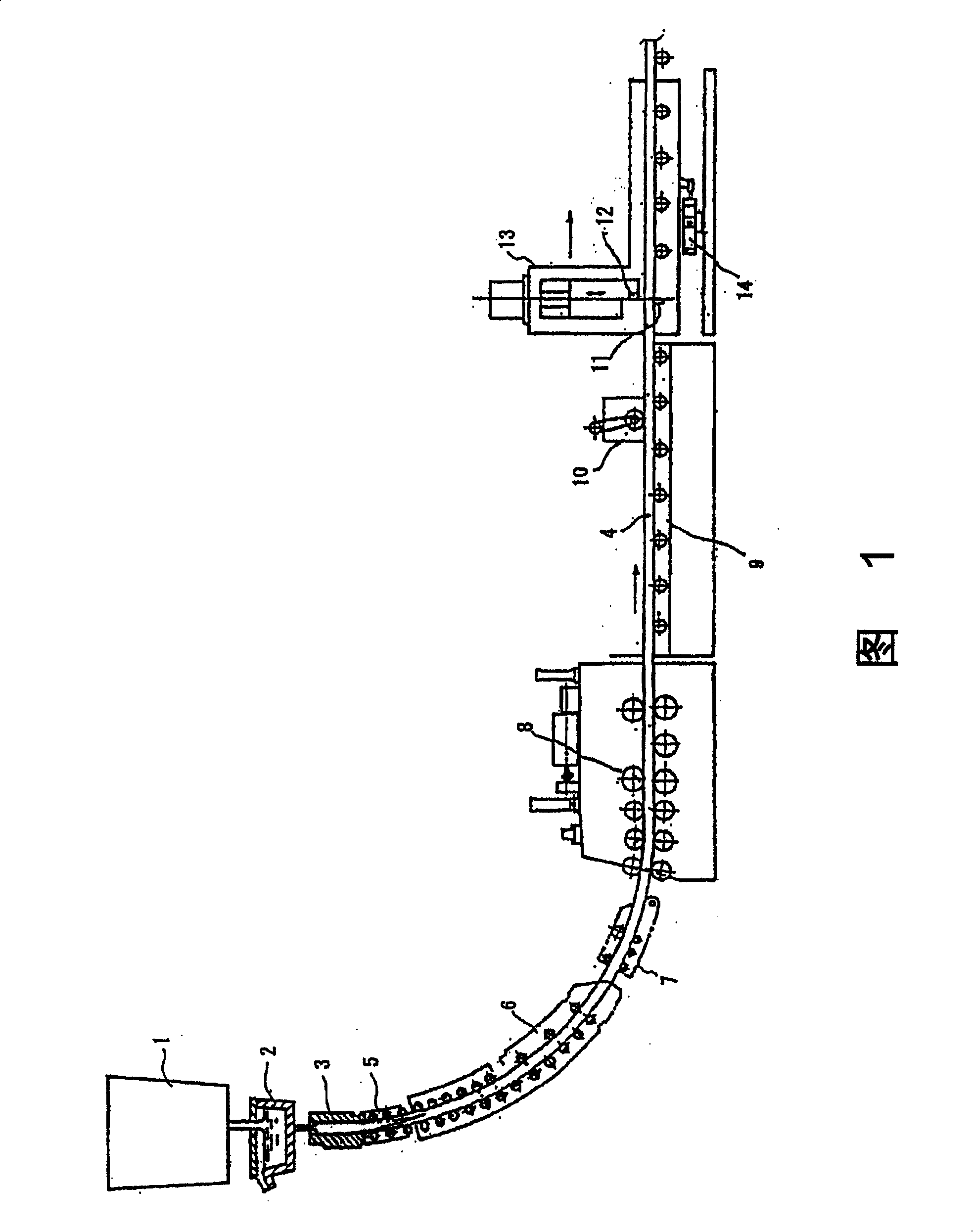

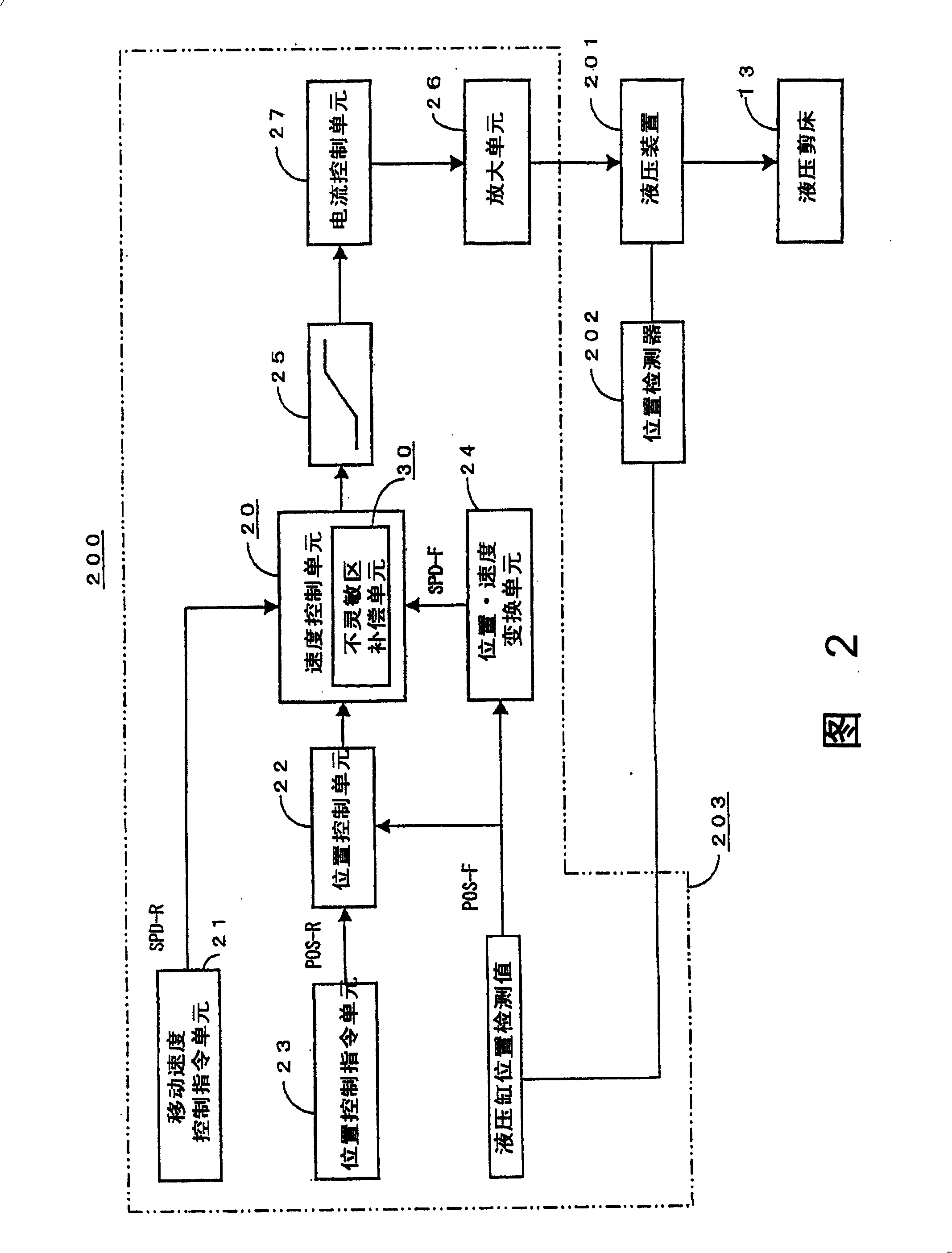

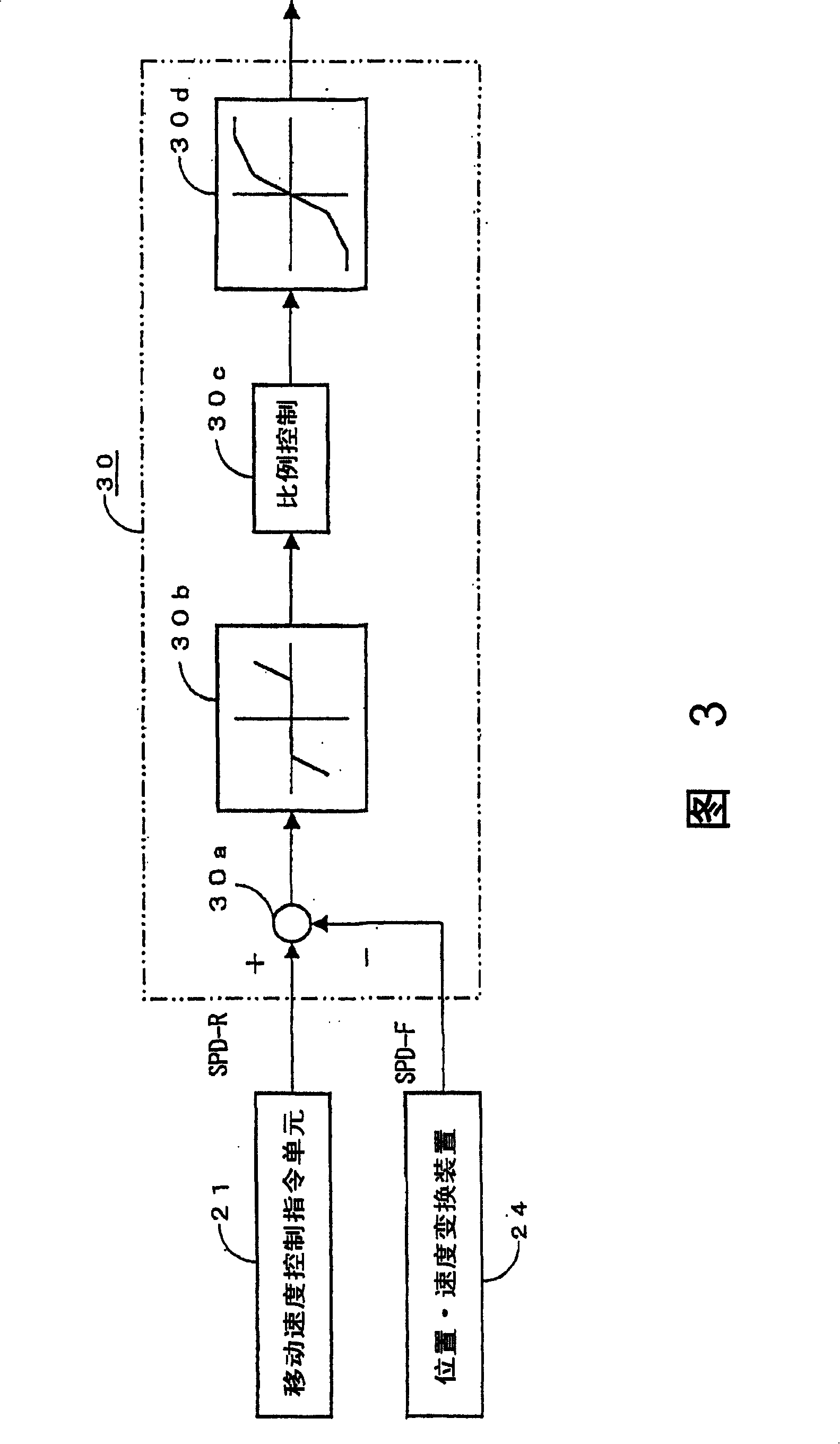

[0046] 1 to 3 are explanatory diagrams illustrating Embodiment 1 of the present invention, and FIG. 1 is an overall configuration diagram of a continuous casting apparatus employing a continuous casting and shearing apparatus related to the present invention. , FIG. 2 is a block diagram of the continuous casting cutting device, and FIG. 3 is a brief block diagram of the dead zone compensation unit included in the speed control unit of FIG. 2 .

[0047] First, an overall configuration diagram of a continuous casting machine employing a continuous casting cutting device according to the present invention will be described by citing the disclosure of the above-mentioned JP-A No. 2-295657. That is, in FIG. 1 , molten steel is placed in a ladle 1 , and molten steel is poured into each mold 3 from a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com