Sludge combustible gas hot blast stove ignition control system and control method

A technology of ignition control and hot blast stove, which is applied in the direction of combustion method, combustion control, combustion air/fuel supply, etc., can solve the problem of inappropriate sludge combustible gas ignition, etc., and achieve the effect of reasonable structure design and safety guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

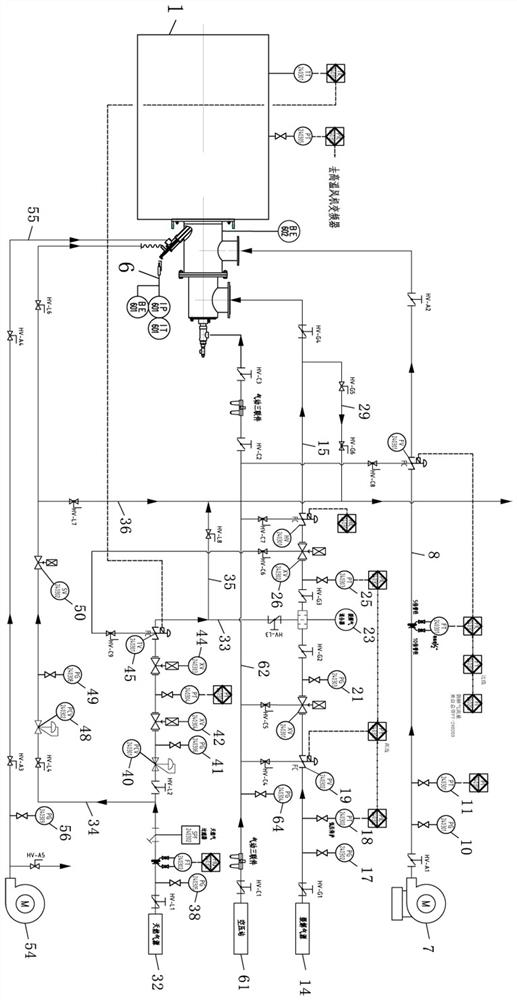

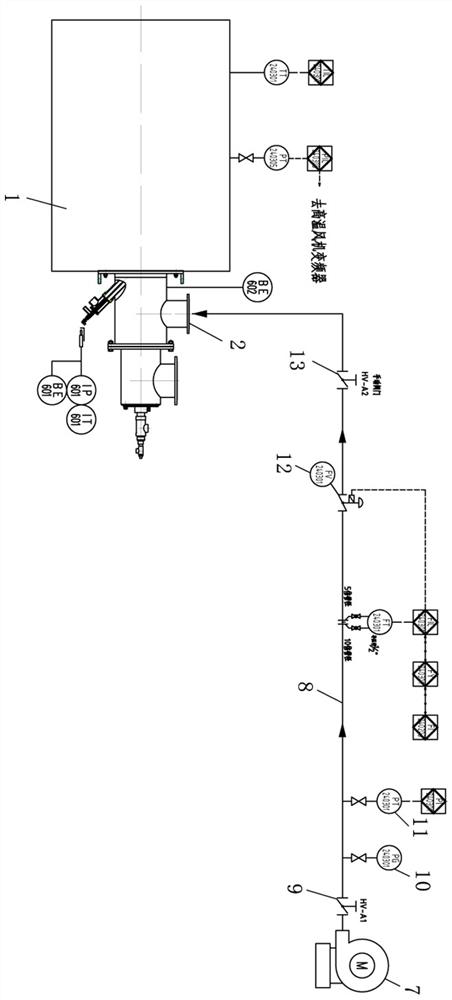

[0092] like Figure 1~Figure 7 As shown, an ignition control system for a sludge combustible gas hot blast stove includes a control cabinet and a hot blast stove connected to the control cabinet, a combustion system, a cracked gas system, a natural gas system, an ignition system, and an air compressor station system. Hot blast stove, combustion system, pyrolysis gas system, natural gas system and ignition system are controlled.

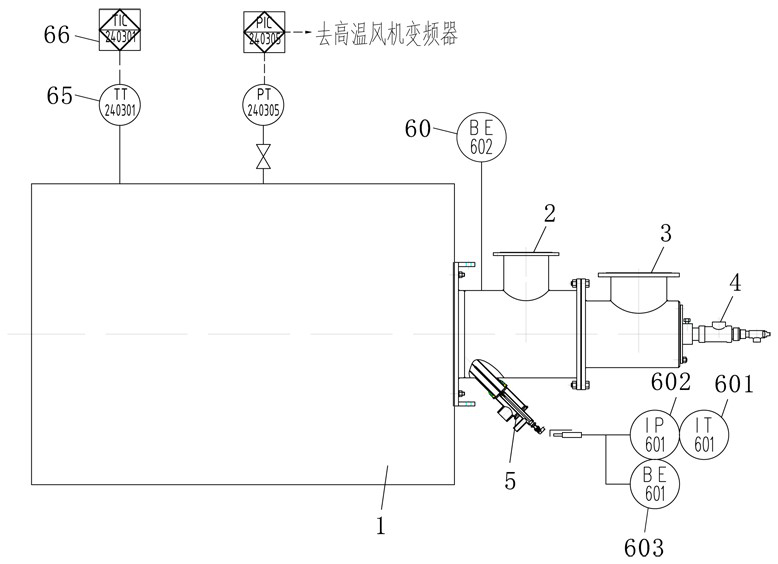

[0093] The hot blast stove includes a furnace body 1 , a combustion-supporting air inlet 2 , a pyrolysis gas inlet 3 , a compressed air inlet 4 , an igniter 5 and an ignition gun 6 .

[0094] The furnace body 1 is provided with a TT240301 thermocouple 65, which is used to detect the furnace temperature in the hot blast stove, and the detection range is 0-1300°C. The furnace body 1 is also provided with a TIC240301 temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com